Академический Документы

Профессиональный Документы

Культура Документы

Johnson Controls

Загружено:

CallGR0 оценок0% нашли этот документ полезным (0 голосов)

49 просмотров0 страницASHRAE Handbook (2008): "a Heat Pump extracts heat from a source and transfers it to a sink at a higher temperature" YORK heat pumps are designed to chill water and provide a percentage of heat as warm water Typically 95-105 o F (35-40. O C) Control: Compressor capacity is controlled by Leaving Chilled Water set point.

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документASHRAE Handbook (2008): "a Heat Pump extracts heat from a source and transfers it to a sink at a higher temperature" YORK heat pumps are designed to chill water and provide a percentage of heat as warm water Typically 95-105 o F (35-40. O C) Control: Compressor capacity is controlled by Leaving Chilled Water set point.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

49 просмотров0 страницJohnson Controls

Загружено:

CallGRASHRAE Handbook (2008): "a Heat Pump extracts heat from a source and transfers it to a sink at a higher temperature" YORK heat pumps are designed to chill water and provide a percentage of heat as warm water Typically 95-105 o F (35-40. O C) Control: Compressor capacity is controlled by Leaving Chilled Water set point.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 0

Hot Water Solutions

Hot Water Solutions by J ohnson Controls by J ohnson Controls

Agenda Agenda

Heat Pump Solutions

What is a heat pump?

Control & Sizing

Application Benefits

Heat Recovery Solutions

What is heat recovery?

Control & Sizing

Application Benefits

Application Considerations

J CI Chiller Solutions

End Note

2

Options for improving building efficiency Options for improving building efficiency

3

Heat Pump

Specifically designed to provide

100% of heat as hot water

Typically 120-180

o

F (49-82

o

C)

Control:

Compressor capacity is controlled by Leaving

Condenser Water set point

Intent:

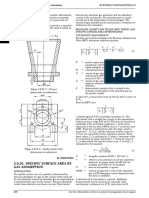

Compound Centrifugal

(CYK) Chiller

600-2800 Tons

(2115-9850 kW)

Heat Recovery

Double Bundle YORK

Heat Recovery Chiller

250-2800 Tons

(880-9850 kW)

Designed to chill water and provide a

percentage of heat as warm water

Typically 95-105

o

F (35-40.5

o

C)

Control:

Compressor capacity is controlled by Leaving

Chilled Water set point

Intent:

4

Heat Pump Systems

What is a Heat Pump? What is a Heat Pump?

5

ASHRAE Handbook (2008):

A Heat Pump extracts heat from a source and transfers it to a sink

at a higher temperature

In engineering, however, the term Heat Pump is generally

reserved for equipment that heats for beneficial purposes, rather

than that which removes heat for cooling only

System Designs:

Air-Source Ground-Source Water-Source

YORK Affinity Series

YORK Geysir Series

YORK Screw Chiller (YS)

What is a Heat Pump? What is a Heat Pump? Chiller Vapor Chiller Vapor- -Compression Cycle Compression Cycle

6

Motor

Motor

I nput w or k

Chi l l er :

Usef ul w or k

44F 95F

(6.7C)

(35C)

Evaporator

Evaporator

Heat Pump

Condenser

Heat Pump

Condenser

Comp

Comp

What is a Heat Pump? What is a Heat Pump? Refrigerant P Refrigerant P- -H Diagram H Diagram

7

P

r

e

s

s

u

r

e

Energy / Enthalpy

L

i

q

u

i

d

L

i

n

e

V

a

p

o

r

L

i

n

e

Evaporator

Input

Cooling

Heat Rejected

1.25 X

Evaporator Heat

110F(43.3C)

96F

(35.6C)

8

Typical Arrangement: Side-car

130F

Hot water loop

Chilled water loop

150F

42F

Heat

Pump

Heat

Pump

58F 42F

50F

150F

Boiler

Boiler

(54.4C)

(65.6C)

(65.6C)

(14.4C)

(5.6C)

(10C) (5.6C)

Heat Pump Control & Sizing Heat Pump Control & Sizing

CH1

CH1

CH2

CH2

CH3

CH3

CH

n

CH

n

Heat Pump Benefits Heat Pump Benefits

Compliance with Industry Standards & Programs

LEED

ASHRAE 90.1 (simultaneous heating & cooling)

9

Why use heat pumps?

Social / Environmental Advantages

CO

2

reductions

Reduced water consumption

Economic Advantages

Operational savings

Lets take a closer look at each benefit

Heat Pump Benefits Heat Pump Benefits

10

Economic Advantages

Operational Savings

Economic Advantages

Operational Savings

1 uni t

0.35 uni t

Heating COP =1.35 / 0.35 =3.8

Combined COP =2.35 / 0.35 =6.7

Comp

I nput w or k

Usef ul c ool i ng

1.35 uni t

Usef ul Heat i ng

Cooling COP =1.00 / 0.35 =2.9

150F

42F

(65.6C)

(5.6C)

Motor

Motor

Evaporator

Evaporator

Heat Pump

Condenser

Heat Pump

Condenser

Comp

Comp

Cost to produce 10,000 kcal

Natural Gas Water Heater

10,000 kcal / 90% efficiency / 8,500 kcal/SCM x Rs.20/SCM = Rs.26.14

Fuel Oil Water Heater

10,000 kcal / 90% efficiency / 9,000 kcal/ltr x Rs.35/ltr = Rs.43.20

Electric Water Heater

10,000 kcal / 95% efficiency / 860 kcal/hr/kW x Rs.6.00/kW.hr = Rs.73.44

Heat Pump

10,000 kcal / 380% efficiency / 860 kcal/hr/kW x Rs.6.00/kW.hr = Rs.18.35

10,000 kcal / 670% efficiency / 860 kcal/hr/kW x Rs.6.00/kW.hr = Rs.10.41

COP

h

= 3.8 (no cooling credit)

COP

c+h

= 6.7 (with cooling credit)

Electric Rs.6.00/kW.hr

Gas Rs.20/SCM

Heat Pump Benefits Heat Pump Benefits

12

Social / Environmental Advantages

CO

2

reductions

Reduced water consumption

Social / Environmental Advantages

CO

2

reductions

Reduced water consumption

Natural Gas Boiler

(85% efficient)

Heat Pump

A 600 Ton Heat Pump, at a 65% average load, would offset approximately 55,000

MMBTU and would save 1467 Tons of CO

2

annuall y compared to a natural gas boiler.

This is equivalent of removing 244 cars from the road!

13.0 lbs of CO

2

per

100,000 BTU

7.7 lbs of CO

2

per

100,000 BTU

Heat Pump Benefits Heat Pump Benefits

13

How much water do we save by not sending it

to the cooling tower?

Assuming:

Cooling tower consumption per evaporation rate of 1% & blow-down of 0.3% (4 cycles of concentration)

3 gpm/ton (0.054 L/s) condenser water flow

Ex: 600 Ton (2110 kW) Heat Pump, with a 65% utilization factor:

Water savings would be 22,500 gallons (85,171 L) per DAY!

Social / Environmental Advantages

CO

2

reductions

Reduced water consumption

Social / Environmental Advantages

CO

2

reductions

Reduced water consumption

14

Heat Recovery Systems

What is Heat Recovery? What is Heat Recovery?

15

ASHRAE Handbook (2008):

In many large buildings, internal heat gains require year-round chiller

operation. The chiller condenser water heat is often wasted through a

cooling tower

[Heat recovery] uses otherwise wasted heat to provide heat at the

higher temperatures required for space heating, reheat, and domestic

water heating

YORK Double Bundle Heat

Recovery Chiller

Water-Source

System Designs:

Air-Source

Outside

Air

Supply

Air

Exhaust

Air

Return

Air

What is Heat Recovery? What is Heat Recovery?

Compressor Motor

Evaporator

Condenser

Expansion Device

Cooling Tower

Adding

Energy

(Electricity)

Heat Recovery

105 F

(40.5 C)

95 F

(35 C)

54 F

(12.2 C)

44 F

(6.7 C)

105 F

(40.5 C)

95 F

(35 C)

16

What is Heat Recovery? What is Heat Recovery?

17

The cooling load controls the system and the Hot Water

temperature is variable.

Heat

Recovery

Water Tank

Pre-heat

domestic water

storage tank

Supplemental heating (boiler) may

be needed to achieve full heat

load

Supplemental heating (boiler) may

be needed to achieve full heat

load

YORK Double Bundle

Heat Recovery Chiller

18

YORK YORK Heat Pump Heat Pump Solutions Solutions

YS Sc r ew Heat Pump

Evap Tons 100-330 Tons

(350-1160 kW)

Max leaving hot water =140

o

F (60

o

C)

Max Lift =100

o

F (37.8

o

C)

Max heat per unit =5,300 MBH

(1,560 kW)

Simultaneous heating & cooling

Single screw compressor package

Experience

Innovati on

Sustai nable

Soluti ons

Customer

Commitment

19

YORK YORK Heat Recovery Heat Recovery Solutions Solutions

YK Cent r i f ugal Heat Rec over y

Max leaving hot water =110

o

F (43.3

o

C)

Max Lift =65

o

F (18.3

o

C)

Max heat per unit =40,000 MBH

(11,725 kW)

Simultaneously Cooling & Heating

Single centrifugal compressor

package

Experience

Innovati on

Sustai nable

Soluti ons

Customer

Commitment

Evap Tons 280-2800 Tons

(985-9850 kW)

20

Reduce your energy costs today!

With our extensive track record of success, J ohnson Controls is well matched

to meet your hot water needs by delivering flexible, innovative, and sustainable

equipment for efficient and long lasting operation.

Вам также может понравиться

- DocumentДокумент1 страницаDocumentCallGRОценок пока нет

- WWW Hvac Okstate EduДокумент15 страницWWW Hvac Okstate EduCallGRОценок пока нет

- 2115 2588 1 PBДокумент14 страниц2115 2588 1 PBCallGRОценок пока нет

- Fisher Control Valve Sourcebook - Power and Severe ServiceДокумент220 страницFisher Control Valve Sourcebook - Power and Severe Servicemtrj59Оценок пока нет

- Fisher Control Valve Sourcebook - Power and Severe ServiceДокумент220 страницFisher Control Valve Sourcebook - Power and Severe Servicemtrj59Оценок пока нет

- Parkinson's Law Quantified: Three Investigations On Bureaucratic InefficiencyДокумент14 страницParkinson's Law Quantified: Three Investigations On Bureaucratic InefficiencyCallGRОценок пока нет

- Air-to-Water Heat Pump (50Hz, R410A) 5BPM0-01C (Replace:5BPM0-01B)Документ73 страницыAir-to-Water Heat Pump (50Hz, R410A) 5BPM0-01C (Replace:5BPM0-01B)CallGRОценок пока нет

- Readme FreeVersionДокумент4 страницыReadme FreeVersionCallGRОценок пока нет

- Grundfos PumpsДокумент120 страницGrundfos PumpsNaser TahaОценок пока нет

- Analysis and Design of A Surge TankДокумент7 страницAnalysis and Design of A Surge TankUchirai Dede100% (3)

- Guide to Earthing Systems in Electrical NetworksДокумент113 страницGuide to Earthing Systems in Electrical NetworksRameez ZafarОценок пока нет

- 2 Plug Fans - GRДокумент2 страницы2 Plug Fans - GRCallGRОценок пока нет

- AAM Applications Chassis Suspension 4 Steering SystemДокумент15 страницAAM Applications Chassis Suspension 4 Steering SystemrajdrklОценок пока нет

- Test 1Документ2 страницыTest 1CallGRОценок пока нет

- ch09Документ14 страницch09CallGRОценок пока нет

- Pefy P Vms e Pefy P VMR e Databook1 1Документ76 страницPefy P Vms e Pefy P VMR e Databook1 1CallGRОценок пока нет

- Steering Systems: 4.1 Axle-Beam Steering SystemДокумент12 страницSteering Systems: 4.1 Axle-Beam Steering SystemCallGRОценок пока нет

- 17 Drainage and Irrigation DesignДокумент36 страниц17 Drainage and Irrigation DesignCallGRОценок пока нет

- Caja V V Manual EngineeringДокумент18 страницCaja V V Manual EngineeringCallGRОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Chimney & Venting Sizing HandbookДокумент50 страницChimney & Venting Sizing HandbookCallGRОценок пока нет

- ISOVERДокумент35 страницISOVERMadhu RaghuОценок пока нет

- Designing Smoke Control Systems in Car Parks According to QCDD 7.2Документ87 страницDesigning Smoke Control Systems in Car Parks According to QCDD 7.2Chidi Henry100% (1)

- 05-1 en Frese Optima Aug 10Документ12 страниц05-1 en Frese Optima Aug 10CallGRОценок пока нет

- Pffy p20 40vkm e SM (Oc404reva)Документ32 страницыPffy p20 40vkm e SM (Oc404reva)CallGRОценок пока нет

- Jetfoil - Tunnel FansДокумент16 страницJetfoil - Tunnel FansCallGRОценок пока нет

- Heat Pumps Water WaterДокумент105 страницHeat Pumps Water Wateratisz333Оценок пока нет

- Air Flow Air Friction BrochureДокумент4 страницыAir Flow Air Friction BrochureCallGRОценок пока нет

- 64904Документ49 страниц64904CallGRОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Experiment ChemДокумент45 страницExperiment Chemstanleylee100% (3)

- 1 s2.0 S0360319922001793 MainДокумент17 страниц1 s2.0 S0360319922001793 MainAbhi KrishОценок пока нет

- Nondestructive Natural Gas Hydrate Recovery Driven by Air and Carbon DioxideДокумент8 страницNondestructive Natural Gas Hydrate Recovery Driven by Air and Carbon DioxideFomalhaut AdityaОценок пока нет

- Volumetric Gas Adsorption Technique - Magnesium Stearate - EP6.0 - 01 - 231Документ4 страницыVolumetric Gas Adsorption Technique - Magnesium Stearate - EP6.0 - 01 - 231Debahis BoseОценок пока нет

- P Bahadur Modified ResumeДокумент3 страницыP Bahadur Modified ResumePrashant BahadurОценок пока нет

- Fuel Cell Lab ReportДокумент6 страницFuel Cell Lab ReportSumeet RanuОценок пока нет

- Multi-Phase Flow Measurment by Orifice MeterДокумент8 страницMulti-Phase Flow Measurment by Orifice MeterAbdeldjalil AchourОценок пока нет

- Class 11 Annual ExamДокумент9 страницClass 11 Annual ExamAshraf KhanОценок пока нет

- L4-Superconductivity Lecture NotesДокумент34 страницыL4-Superconductivity Lecture NoteswellplacedcommaОценок пока нет

- 1st Law of Thermo WorksheetДокумент2 страницы1st Law of Thermo WorksheetAngelica Calamba CalicaОценок пока нет

- Core 1: EnergyДокумент13 страницCore 1: EnergyJuliana ShahatitОценок пока нет

- Simulation and Optimization of Hydrogen Production From Autothermal Reforming of Ethane For Fuel Cell ApplicationsДокумент91 страницаSimulation and Optimization of Hydrogen Production From Autothermal Reforming of Ethane For Fuel Cell ApplicationsainmnrhОценок пока нет

- Thermal Efficiency of Steam TurbinesДокумент26 страницThermal Efficiency of Steam TurbinesBoshra NouriОценок пока нет

- Fundamentals of Thermodynamics Fundamentals of ThermodynamicsДокумент32 страницыFundamentals of Thermodynamics Fundamentals of ThermodynamicsYep IdidthisОценок пока нет

- ReviewДокумент50 страницReviewSipps311Оценок пока нет

- Engineering Chemistry Unit III(A) - Definition and Types of LubricantsДокумент25 страницEngineering Chemistry Unit III(A) - Definition and Types of Lubricantssri aknth100% (1)

- A Fast and Efficient Approach To Prepare Starch Nanocrystals FromДокумент7 страницA Fast and Efficient Approach To Prepare Starch Nanocrystals FromLina Maria RodriguezОценок пока нет

- Colligative Properties of SolutionsДокумент11 страницColligative Properties of SolutionsNelsonMoseM100% (1)

- Heat and Mass Transfer in Impingement DryingДокумент31 страницаHeat and Mass Transfer in Impingement DryingEKKACHAI PRABNAKORNОценок пока нет

- Peka F5 Experiment 1.2Документ3 страницыPeka F5 Experiment 1.2han13f0% (1)

- Assignment 2Документ1 страницаAssignment 2Ankit OlaОценок пока нет

- Characteristic Reactions of Organic HalidesДокумент6 страницCharacteristic Reactions of Organic HalidesJules Patrick JacobОценок пока нет

- Instrumental Methods of Analysis TechniquesДокумент2 страницыInstrumental Methods of Analysis TechniquesUadОценок пока нет

- Materials and Manufacturing ProcessesДокумент6 страницMaterials and Manufacturing ProcessesNaresh Kumar ReddyОценок пока нет

- COL - L 60 (8x30) Liquid Phase Bituminous Coal Base CarbonДокумент1 страницаCOL - L 60 (8x30) Liquid Phase Bituminous Coal Base CarbonHenry SalasОценок пока нет

- Test For Anions (Chemistry)Документ22 страницыTest For Anions (Chemistry)abby jacksonОценок пока нет

- Cambridge International Advanced Subsidiary and Advanced LevelДокумент12 страницCambridge International Advanced Subsidiary and Advanced LevelRahi FurqanОценок пока нет

- Extraction of Safrole From Essential OilsДокумент81 страницаExtraction of Safrole From Essential OilsMehdi MsmОценок пока нет

- Talk 5-3-1 CST Euc 2012Документ175 страницTalk 5-3-1 CST Euc 2012Anonymous 3GE9cFCОценок пока нет

- Data Sheets - UpdatedДокумент267 страницData Sheets - Updateddurgesh82338114100% (1)