Академический Документы

Профессиональный Документы

Культура Документы

Petroleum Products Kolkata

Загружено:

brijeshkynИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Petroleum Products Kolkata

Загружено:

brijeshkynАвторское право:

Доступные форматы

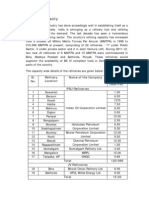

IBP Co.

Limited got merged with its parent company 'Indian Oil Corporation Limited' on 02-05-2007 under the Ministry of Petroleum & Natural Gas, Government of India. The merger ends the history of 98 year old 'IBP Co Limited', the oldest oil company in India. IBP Co. Limited was born in the then undivided British India as Indo-Burma Petroleum Company Limited a joint stock private company on 08-02-1909 at Burma, presently Myanmar. The developments that followed second world war forced the company change its head quarters to Kolkata permitting the British Government to bombard and destroy its only refinery at Rangoon. Thereafter the company joined hands with the then Indian Oil Company (Later formed as Indian Oil Corporation Limited after merger with Indian Refineries Company Limited) and carried out business in petroleum products at Mumbai and Kolkata. Though it was initially taken over by IOC in 1970, it got separated and formed as a public sector company in 1974 under the Ministry of Petroleum and Natural Gas, Government of India. By this time all the foreign private oil businesses were nationalized and made public sector companies. The Indo Burma Petroleum Company Limited changed its name to IBP Co. Limited in 1983. During 2002, it was once again acquired by the IOC and became one if its group companies. Though predominantly an oil company, IBP diversified its activities into engineering and chemicals. The venture into explosives by the chemical division was, based on a suggestion from the Govt of India when the country faced acute shortage of explosives for mining industry following an accident and strikes at the only major supplier viz IEL in India in 60s. As the country had to import huge quantities of explosives to meet consumption needs for over six months, severe difficulties were faced in storage, handling and transportation to mining areas. Finally, the Chary committee set up for the purpose strongly recommended a company to be set up in public sector for manufacture of explosives. IBP, waiting for a diversification into chemicals, readily grabbed the opportunity and commenced its business in manufacture and marketing of industrial explosives. The IBPs first packaged slurry explosive manufacturing plant was set up in Korba (then in MP now in Chattisgarh) in the year 1976 under the collaboration from Ireco Inc. USA. The unit commenced its commercial production in August 1977. Thereafter the chemical division has diversified its business into a unique technology the bulk delivered slurry explosives with the first ever plant of its kind set up in India at Kudremukh with a capacity of 5000 Tons per annum in 1980. The first ever supply of site-mixed bulk slurry explosives took place on 20-12-1980 in a blast using 63 tons of this product. Over the past 25 years, by 20th Dec 2005 it has completed supply of 64,695 MT of SMS explosives to Kudremukh Iron Ore Project. For IBP, the journey in bulk explosives commenced at Kudremukh continued a long way with new plants set up in both coal and metal mining sectors. The second plant came up at Singrauli (MP) in the year 1983 followed by Block-II Dhanbad (Jharkhand), Ramagundam (AP), Rampur Agucha (Rajasthan), Kusmunda (Chattisgarh) etc. As on date there are ten plants set up in India reaching a peak production volume of 80,000 MT of bulk explosives. In view of highly uneconomical operations, the Industrial Explosives Plant at Korba manufacturing packaged explosives was closed in the year 2008. During the year 2008, the BG-Explosives, IBP Division of IOCL entered into a five year long term agreement with Coal India Limited (CIL, the largest producer of coal in the world) for supply of bulk

explosives. On successful completion of first five year contract, process is initiated for entering in to another long term contract of five years which can be renewed further for an equal period.

Competitors[edit]

Over the years, the number of competitors in India grew from only two in the beginning to more than forty today, adversely affecting the market share in Industrial explosives of IBP from a high of around 30% down to 18%. The current installed capacity of IBP Division,IOCL is around 2.0 Lac tons. Presently, IOCL is the only central public sector company servicing the market for industrial explosives. The business group experienced very high profits in the beginning when there were only two competitors (IEL and IDL) and progressively incurred losses from the late nineties.

New technologies[edit]

The advent of modern technologies in manufacture of explosives including emulsions led IBP to radically change the original technology from Ireco Inc. and introduce new and cost effective technologies in both slurry and emulsion products. However, the original Irecos slurry technology obtained in 80s was modified through in house marketing and R&D efforts and made superior to that of emulsion technology. Keeping in view the demands for better rock breakage in very hard rock formations, currently the technology of bulk Slurry explosives is being used only at Bolani(SAIL) & Malanjkhand(HCL). The site mixed bulk delivered explosives, as the name suggests are manufactured on site in a specially designed truck (called pumptruck) by carrying non-explosive ingredients in separate chambers, mixing them in desired proportions and pumping them in liquid form directly into bore holes. The poured mixture acquires the characteristics of an explosive within few minutes of pumping. Unlike bulk emulsions, the SMS can be pumped in various densities ranging from 0.6 g/cm to as high as 1.20 g/cm and the energy can be varied to produce twenty different types of chemically balanced explosive products to exactly the suit the rock conditions and achieve techno-economic advantages for the customers. The site mixed bulk explosive system (emulsion or slurry) eliminated the need for packaging, inventory, storage and handling of various types of explosives and thus lowered direct costs to customers..

Expansion[edit]

The expansion phase of IBP Division of IOCL in the field of explosives still continues with possibilities to set up bulk emulsion plants at various mining locations across the country.

Cryogenics Division[edit]

When "Operation Flood" (a program to produce more milk in the country) was introduced in India, new technology from the Western world was adopted. One new implementation was storing bull's semen in

liquid nitrogen containers. The temperature of liquid nitrogen is minus 196 degrees Celsius. The liquid nitrogen containers are similar to thermos flasks used for storing hot water, but have advanced insulation technology to keep the liquid nitrogen cool at minus 196 degrees Celsius. For a long long time, IBP was the only company manufacturing this technology item in India. Only recently has a private player entered the market. Still, IBP is the market leader as of today (2008).

Вам также может понравиться

- Safe Use of Cryogenic MaterialsДокумент28 страницSafe Use of Cryogenic MaterialsJimmy Cuevas MonsalveОценок пока нет

- Id Number Title Year OrganizationДокумент12 страницId Number Title Year OrganizationrabeemhОценок пока нет

- Refineries in India: S. No. Name o The Company F Location o The F Refinery Capacity, MmtpaДокумент22 страницыRefineries in India: S. No. Name o The Company F Location o The F Refinery Capacity, MmtpaAmrit SarkarОценок пока нет

- SuperconductivityДокумент30 страницSuperconductivityAnna100% (1)

- N2 Operations & Calculation of N2Документ50 страницN2 Operations & Calculation of N2Anthony Lakpah88% (16)

- B2B Project On PraxairДокумент25 страницB2B Project On Praxairindsumo100% (1)

- "Accounting Method": Summited byДокумент51 страница"Accounting Method": Summited byAiswary yadavОценок пока нет

- Iocl Summer Training ReportДокумент67 страницIocl Summer Training Reportrahulmayank71% (7)

- Vocational Training Report, Indian Oil Corporation Limited, Gujarat RefineryДокумент43 страницыVocational Training Report, Indian Oil Corporation Limited, Gujarat Refineryjhashashank26883% (12)

- Barauni RefineryДокумент10 страницBarauni RefineryRajiv KalraОценок пока нет

- Hydrogen Properties PDFДокумент536 страницHydrogen Properties PDFAnonymous 3DHogIОценок пока нет

- 12th CRYOGENICS 2012 IIR International Conference Dresden GermanyДокумент477 страниц12th CRYOGENICS 2012 IIR International Conference Dresden GermanyRavi Kumar Verma100% (1)

- Cement Industry Internship ReportДокумент43 страницыCement Industry Internship ReportHaritha V H89% (9)

- Refineries in India: Prof. K. V. RaoДокумент74 страницыRefineries in India: Prof. K. V. RaoSai KiranОценок пока нет

- Cryogenic Liquid Manifolds: Applications GuideДокумент34 страницыCryogenic Liquid Manifolds: Applications GuideKadiri OlanrewajuОценок пока нет

- Coal India Company Profile and Its AnalysisДокумент14 страницCoal India Company Profile and Its AnalysisMithunОценок пока нет

- Mche - LNG PlantДокумент6 страницMche - LNG Plantchris100% (1)

- Sustainability Practices in Oil and Gas IndustryДокумент2 страницыSustainability Practices in Oil and Gas IndustryDipakОценок пока нет

- Indian RefineriesДокумент21 страницаIndian RefineriesDeep ChaudhariОценок пока нет

- A Study On Consumer Behaviour Towards Petroleum Retail Outlets in Trichy CityДокумент62 страницыA Study On Consumer Behaviour Towards Petroleum Retail Outlets in Trichy Citykeerthiananth.12388% (8)

- Industrial Fire ProofingДокумент20 страницIndustrial Fire Proofingkenoly123100% (3)

- CryogenicLiquidGuidelines PDFДокумент15 страницCryogenicLiquidGuidelines PDFMichel LopezОценок пока нет

- Storage of Cryogenic Air Gases at Users' PremisesДокумент28 страницStorage of Cryogenic Air Gases at Users' PremisesKarthick VenkateshОценок пока нет

- Gujarat NRE - AssignmentДокумент20 страницGujarat NRE - AssignmentMangesh GulkotwarОценок пока нет

- Carbon Capture, Utilization, and Storage Game Changers in Asia and the Pacific: 2022 Compendium of Technologies and EnablersОт EverandCarbon Capture, Utilization, and Storage Game Changers in Asia and the Pacific: 2022 Compendium of Technologies and EnablersОценок пока нет

- IGC Document 133 06 EДокумент30 страницIGC Document 133 06 Elutfirashid87Оценок пока нет

- Iocl ProfileДокумент20 страницIocl ProfileNupur Rajendra PanditОценок пока нет

- SAIL Refractory Company LimitedДокумент3 страницыSAIL Refractory Company LimitedSanthosh 8055Оценок пока нет

- Acl Company ProfileДокумент70 страницAcl Company Profileashishkhare2008Оценок пока нет

- A Project Report On Cil-Ipo Analysis: Central Coalfields LimitedДокумент71 страницаA Project Report On Cil-Ipo Analysis: Central Coalfields LimitedAnkita SharmaОценок пока нет

- Henry BrahmaДокумент21 страницаHenry Brahmahenry brahmaОценок пока нет

- Refinery PDFДокумент21 страницаRefinery PDFrbshah86Оценок пока нет

- Environment Management: Bokaro District Jharkhand India Soviet Steel Authority of India Limited (SAIL)Документ2 страницыEnvironment Management: Bokaro District Jharkhand India Soviet Steel Authority of India Limited (SAIL)arvidkumar87060Оценок пока нет

- Hindalco IndustriesДокумент12 страницHindalco Industriesnkumar_411861Оценок пока нет

- HR ReportДокумент46 страницHR ReportPragyan Panda50% (2)

- CIC Dire Under S 19 8a 28.11.2017Документ66 страницCIC Dire Under S 19 8a 28.11.2017J. RojalinОценок пока нет

- Heat Traced Pipeline ProjectДокумент6 страницHeat Traced Pipeline ProjectshivrinderОценок пока нет

- A Study On Bhopal Gas TragedyДокумент5 страницA Study On Bhopal Gas Tragedysksingh07Оценок пока нет

- Iocl Haldia ReportДокумент99 страницIocl Haldia ReportSnehasisDasОценок пока нет

- Ilovepdf MergedДокумент5 страницIlovepdf MergedVISHNU K RAJESH RCBSОценок пока нет

- IOCL Complete ReportДокумент43 страницыIOCL Complete ReportSanjiv KumarОценок пока нет

- Nalco Rti-Cicdireunders19 8 RevДокумент64 страницыNalco Rti-Cicdireunders19 8 RevSuneli SuhaniОценок пока нет

- Ali DaДокумент8 страницAli DaBudhaditya GoswamiОценок пока нет

- Final Project of Rayeen SteelsДокумент56 страницFinal Project of Rayeen SteelsShiva PrasannaОценок пока нет

- Internship CPCLДокумент26 страницInternship CPCLRaj Kumar Madhavaraj67% (3)

- Assignment: Macroeconomic & Business EnvironmentДокумент10 страницAssignment: Macroeconomic & Business EnvironmentHimanshu ShekharОценок пока нет

- Reliance Industrial Report)Документ48 страницReliance Industrial Report)Piyush AbhishekОценок пока нет

- Chapter - 1: LancoДокумент97 страницChapter - 1: LancotysontrivОценок пока нет

- Presentation On Training & DevelopmentДокумент66 страницPresentation On Training & DevelopmentRagini Mishra50% (2)

- Coal Sector in IndiaДокумент8 страницCoal Sector in IndiaJEFY JEAN AОценок пока нет

- L&TДокумент39 страницL&TNidhi AshokОценок пока нет

- NFL Summer Internship ReportДокумент54 страницыNFL Summer Internship ReportIsha Chhabra100% (1)

- A Report On Institutional Training Undergone at Oil and Natural Gas Corporation (Ongc)Документ55 страницA Report On Institutional Training Undergone at Oil and Natural Gas Corporation (Ongc)muthurajОценок пока нет

- Instrumentation in Crude Distillation Project DemoДокумент54 страницыInstrumentation in Crude Distillation Project DemoNiju ShamilОценок пока нет

- Iocl ReportДокумент51 страницаIocl ReportChandanKumarSinghОценок пока нет

- BusinessPlan2020 2022lasteditionДокумент91 страницаBusinessPlan2020 2022lasteditionjohnsonОценок пока нет

- Project 1Документ21 страницаProject 1Chandana BОценок пока нет

- Vision: To Be One of The Most Respected Companies in India Recognized For Challenging Conventions and Delivering On Our PromisesДокумент5 страницVision: To Be One of The Most Respected Companies in India Recognized For Challenging Conventions and Delivering On Our PromisesJasna VasОценок пока нет

- Reliance PetroleumДокумент15 страницReliance PetroleumHarsh PatelОценок пока нет

- NSUTC MDM 435 Report 1Документ50 страницNSUTC MDM 435 Report 1Shafkat SaifОценок пока нет

- Capital BudgetingДокумент67 страницCapital BudgetingBhargavi DoddaОценок пока нет

- ONGCДокумент16 страницONGCNandhini GunasekaranОценок пока нет

- Vocational Training Report Indian Oil Corporation Limited Gujarat RefineryДокумент43 страницыVocational Training Report Indian Oil Corporation Limited Gujarat RefineryVijendra KumarОценок пока нет

- A.1 Background: Saraswati Industrial Syndicate Ltd. (ISGEC Group)Документ18 страницA.1 Background: Saraswati Industrial Syndicate Ltd. (ISGEC Group)kr_gauraw1Оценок пока нет

- SOM GroupProjectДокумент19 страницSOM GroupProjectsaptarshi bhattacharjeeОценок пока нет

- Corporate DetailsДокумент90 страницCorporate Detailshinaug1996Оценок пока нет

- Preface Jindal Saw LimitedДокумент7 страницPreface Jindal Saw LimitedSuraj SinghОценок пока нет

- Hindalco Project AnkitaДокумент28 страницHindalco Project AnkitaAnkita SharmaОценок пока нет

- Circular Economy: Assessment and Case StudiesОт EverandCircular Economy: Assessment and Case StudiesОценок пока нет

- 2002, Hirano Et Al.Документ9 страниц2002, Hirano Et Al.sumitОценок пока нет

- Concept Development of A Cryogenic Tank Insulation For Reusable Launch VehicleДокумент11 страницConcept Development of A Cryogenic Tank Insulation For Reusable Launch Vehicletriwidi1768Оценок пока нет

- Cryogenic (Imperial)Документ28 страницCryogenic (Imperial)Rahul LavandОценок пока нет

- 304 For Cryogenic Taks PDFДокумент6 страниц304 For Cryogenic Taks PDFEmmanuel PonceОценок пока нет

- Artika Series: Cryogenic Submerged Pumps For Marine ApplicationsДокумент2 страницыArtika Series: Cryogenic Submerged Pumps For Marine ApplicationsCami CamilongaОценок пока нет

- Operating Instructions For The Janis Research MODEL ST-500 Supertran SystemДокумент15 страницOperating Instructions For The Janis Research MODEL ST-500 Supertran SystemshuoОценок пока нет

- Astra SealingДокумент3 страницыAstra SealingIdehen KelvinОценок пока нет

- Untuk DownloadДокумент15 страницUntuk DownloadsancesОценок пока нет

- Liquid Nitrogen Container Instruction ManualsДокумент25 страницLiquid Nitrogen Container Instruction Manualsm_najmanОценок пока нет

- F5 - Cryogenic DepressuringДокумент13 страницF5 - Cryogenic DepressuringJorge Luis HernándezОценок пока нет

- Cryogenic Tubes, Caps, and RacksДокумент4 страницыCryogenic Tubes, Caps, and Racksfathan jefriansyahОценок пока нет

- NV602 1 CH Temp PDFДокумент1 страницаNV602 1 CH Temp PDFilesh22Оценок пока нет

- Selection and RevampДокумент13 страницSelection and RevampChristianGuerreroОценок пока нет

- Full Text 01Документ51 страницаFull Text 01irinaОценок пока нет

- VDF6355 2 2 2 2 PDFДокумент2 страницыVDF6355 2 2 2 2 PDFOnur Iseri0% (1)

- Development of Cryogenic Fuel AircraftДокумент6 страницDevelopment of Cryogenic Fuel AircraftVincent S RyanОценок пока нет

- Compressed Gas Cylinders Safety ManualДокумент20 страницCompressed Gas Cylinders Safety ManualAnisa QoyumОценок пока нет