Академический Документы

Профессиональный Документы

Культура Документы

GOR and Separator Fluid Composition Had Negligible

Загружено:

Zulfina RiantiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GOR and Separator Fluid Composition Had Negligible

Загружено:

Zulfina RiantiАвторское право:

Доступные форматы

Abstract Volatile Oil reservoir are sometimes evaluated as gas and condensate systems when pressure in the well

neighborhood reaches values fairly below saturation pressure. This pressure drop is common in almost all reservoirs at late depletion stages or from the beginning in tight formations. When this situation occurs, it does not matter how carefully the sample is taken, it always leads to non-representative PVT analysis. Based on a real case study on a tight formation, sampled at the beginning of production history, a dynamic data integration between petrophysical and thermodynamic information was conducted in order to understand overall reservoir behavior. As part of this integration, a compositional material balance was developed in order to describe the reservoir performance against pressure. A sensitivity case to relative permeability curves was run with the material balance. The fairly good matching of the material balance model with the production test allowed us to determine the most probable reservoir fluid composition. It was also noted that the relationship between GOR and separator fluid composition had negligible dependence on relative permeabilities. The evaluation of PVT properties of reservoir fluid becomes a fundamental step during the initial reservoir characterization stage. Initial forecasts are made based on usually few and often uncertain data, by means of simple calculation tools like material balance and correlations. Because of its influence in the calculations, and mainly on the economics of a project, the

type of fluid and its behavior constitutes one of the most important overall information. The determination of reservoir fluid type (Black Oil, Volatile Oil, Gas, etc) seems to be a simple task after initial production data are collected (Stock Tank Oil Gravity, GOR, etc.). General thumb rules have been developed to accomplish this job 1-2, but they require to have representative samples. In this way, the same causes that affect sample representativity, can affect correct reservoir fluid type identification. Among the most common causes of non-representative sampling, the following can be mentioned: 1. Low permeability or formation damage that generates significant pressure drop during production tests. 2. Non-stabilized production tests. This situation is common in off shore wells where test duration should be minimized due to the high costs involved. 3. Commingled production from more than one formation with different fluids. The present paper is based on a real case study where it was difficult to establish the type of fluid, based on the available information. Moreover lab tests, conducted on the samples, indicated their lack of representativity. Using the general characteristics of the real case, an illustrating example is presented herein. Available Information The following information, which was used as basic data in our example, contains the general characteristics of the real case: Reservoir. A tight formation field with just one well completed in one productive layer. The initial pressure, which corresponds with the hydrostatic one, is around 6.000 psia and the average formation temperature, extrapolated from the value recorded during logging, is about 248 F. Production Test. A less than 24 hours draw-down test was conducted on the well. Although results did not show signs of stabilization during the last test hour, the test was stopped because the results obtained during it, discouraged further investigation at the test costs. Flowing pressure was around 2.500 psia, generating gas and oil to flow in the well neighborhood. Sampling. In a separator at last test hour conditions. The compositions of gas and liquid from the separator samplediscouraged further investigation at the test costs. Flowing

pressure was around 2.500 psia, generating gas and oil to flow in the well neighborhood. As during the test, GORs between 6.737 scf/bbl and 16.843 scf/bbl where observed, these recombinations seemed to be out of the logical range suggested by the well test. On this point, it should be noted that as no pseudo-steady state could be reached, and there are important volumes of flowing gas and liquid in the neighborhood of the well perforations, the production of gas and oil is strongly influenced by the relative permeability curves of the system. With all of this incompatible and apparently useless information, the reservoir engineer is confronted with the need to solve the following dilemmas: 1. Decide what type of fluid is present in the reservoir knowing that : 1.1. The production GOR indicates a gas and condensate field. 1.2. The physical aspect of the surface sample (colour, viscosity, etc.) suggests a Volatile Oil system. 1.3. The well test and logs run do not allow to discriminate if there was, originally, two possible flowing phases in the system (sample contamination) or not. 2. Recommend future actions based on fluid type selection. 3. Generate representative and adequate thermodynamic information for reservoir engineering tools such as Numerical Simulation, Material Balance and Volumetric Analysis. In this paper a practical working methodology is presented in order to reasonably reconstruct the reservoir fluid characteristics for a correct reservoir modeling. Working Methodology The proposed methodology includes a qualitative stage followed by a quantitative stage. The fundamental decisions are made in the first stage. Qualitative Stage. In this part all the basic assumptions are set and general guidelines for the study are proposed. For the analyzed case, the following assumptions were made: The original fluid, in the perforated interval, is present in only one phase. As there would be infinite solutions (saturation values and relative permeabilities) for the case where two mobile phases were present in the perforated interval, this situation was excluded. All the remaining available information was used as basic evidence to support this idea.

All the values recorded and reported during the field and lab tests were assumed to be valid. The authors consider a popular bad practice to neglect some part of the information on the solely basis that it presents an apparent inconsistency with the rest of the data. Prior to its rejection, the origin of this inconsistency should be carefully analyzed. Once all the assumptions were made, the type of fluid present in the reservoir was analyzed. Assuming a gas and condensate system is present in the reservoir, on the surface sampling, a higher GOR value that the one measured should have been recorded. This should occur because gas has a greater mobility than liquid and, once liberated, it moves easier to the wellbore than the oil in the reservoir giving, as a result, a higher production GOR. As a result, the liquid acumulation in the wellbore neighborhood should give a production GOR above 28.072 scf/bbl, value measured in the lab tests. A Volatile Oil system should be compatible with the information measured during the production test. The case where two mobile phases originally exists at the perforations has been previously discarded because there is no available information that points towards this situation. On the other hand, if this condition is presented in real life, the problem turns out into an inverse problem. In addition, the inverse problem encountered during dynamic data integration are ill-posed by essence, that is the solutions of such problems can have existence, uniqueness or stability difficulties.3 Quantitative Stage. Once accepted the presence of a Volatile Oil fluid as the most probable situation, it is necessary to determine its composition and thermodynamic behavior. It is important to clarify that the lab recombination at a GOR of 3.930 scf/bbl is not representative of the reservoir fluid because the formulation of the problem indicates that if the test GOR was higher than its Volatile Oil lab GOR it indicates that there should have been an independent supply of free gas coming from the wellbore neighborhood. This free gas has a different composition from the total gas liberated from the original oil, so the gas at the separator has an altered composition. In order to obtain a representative composition and its thermodynamic behavior, the following task were performed: 1. A thermodynamic model was adjusted in order to adequately describe the lab test corresponding to the Volatile Oil system. The adjusted thermodynamic

parameters were the ones used in the subsequent compositional simulation stages. 2. Separator gas and liquid was numerically recombined based on the production test GOR. 3. Due to the presence of a gas cap in nearby areas, an originally saturated fluid was assumed. So using the,adjusted parameters from the first step, thermodynamic equilibrium, at a saturation pressure equal to the static pressure, was obtained. 4. Once equilibrium was reached, the remaining free gas was liberated 5. The liquid phase left was used to simulate the Volatile Oil behavior at reservoir conditions. Simulation was performed by using the liquid phase left as entry stream of a compositional material balance (CMB), trying to obtain, as the simulation output, a similar production (GOR and composition) as the one recorded during well test. The CMB used in this study is based on reference 4 and calculates the produced stream through the following scheme: The volume of each phase is determined through thermodynamic equilibrium at each stage of depletion. Gas and oil production is calculated using relative mobility of each phase, based on relative permeability curve, phase viscosity and average saturation. Result Analysis Applying the previous mentioned steps 1 through 4, on the available information, the reservoir fluid composition presented at Table 2 was obtained. The thermodynamic simulation of this fluid indicates that the representative flash GOR of the original fluid at test separator conditions should be 2526 scf/bbl. This value is clearly different from the GOR measured at test conditions. To obtain gas and liquid production from the material balance at different average reservoir pressures, a relative permeability curve was needed as input. The employed curve was considered as base curve and is presented in Table 3 and Figure 1. As part of the scope of the study, sensitivity to the quality and quantity of produced fluids was also tested. This analysis was achieved by changing the shape and extreme points of the relative permeability curve. In this way, an alternative relative permeability curve, which results significatively different from the base curve, was utilized.. The alternative curve is presented as Table 4 and Figure 2. A notable alteration on the relative permeability curve, for

a given GOR, produces important changes in the average reservoir pressure at sampling time, but only generates a small variation in the composition of the production streams. This behavior is presented in Tables 5, 6 and in Figure 3. The small difference in compositions among the production streams presented in Table 6 indicates some kind of independence between composition and porous media. On the other hand, if production composition, given a GOR value, was dependent of the relative permeability curves, the system should have multiple solutions. For this dependent situation, the representative pseudo relative permeability of the system is needed to know in order to univocally establish the original fluid composition. Also in this particular case, it is very important to have reliable measured test in order to conduct a posterior history matching using a CMB or numerical simulation. The results of the study allowed us to conclude with a high degree of confidence that the reservoir fluid composition found with this methodology is adequate. Conclusions 1. A valid working methodology to dynamically integrate the reservoir model with the available information of nonrepresentative Volatile Oil samples is presented. 2. Producing GOR in a Volatile Oil system could be misleading, especially at flowing pressures below saturation pressure. The representative GOR of the system, as is the case of the example presented herein, can be very different from the sampling value registered. 3. Lab test over nonrepresentative samples can be reevaluated, once the cause of non-representativity has been established. The results obtained on the case presented are of extreme importance for the reservoir characterization of a Volatile Oil reservoir. 4. For the present work, once the production GOR is fixed and using a CMB, a small dependence between the effluent composition and the relative permeability curve was observed. This point is of extreme importance to sustain the conclusions herein presented. The small influence of the relative permeability curves over the effluent composition for a given GOR, allow to postpone a detailed evaluation of the porous media. Nomenclature GOR = Gas Oil Ratio, L3/L3, scf/bbl References 1. Moses, P.L.: Engineering Applications of Phase Behavior of Crude Oil and Condensate System, JPT (July 1986) 715.

2. Mc Cain Jr., W.D.: Reservoir-Fluid Property Correlations State of the Art, SPERE (May 1991) 266. 3. Hadamard, J.: Lecons sur la Propagation des Ondes et les Equations de lHydrodynamique, Chelsea Publication Co., New York (1949) 4. Reudelhuber, F.O. and Hinds, R. F.: A Compositional Material Balance Method for Prediction of Recovery from Volatile Oil Depletion Drive Reservoirs, Trans. AIME (1957), 210, 19. SI Metric Conversion Factors F (F-32)/1.8 = C scf/bbl x 1.781 130 E -01 = m3/m3 psi x 6.894 575 E+00 = kPa Volatile Oil p-T Diagram

z From: Properties of Petroleum Fluids

z Schematic p-T Diagram: Volatile Oil Fluid is typically dark brown, orange or green.

McCain (1990).

o<45o API, 2000 < (GOR)i < 3300 scf/STB, Boi > 2.0 RB/STB, 12.5 < C7+ < 20 %.

Вам также может понравиться

- Confined Fluid Phase Behavior and CO2 Sequestration in Shale ReservoirsОт EverandConfined Fluid Phase Behavior and CO2 Sequestration in Shale ReservoirsОценок пока нет

- Regional Government of KurdistanДокумент16 страницRegional Government of KurdistanMohammed MohammedОценок пока нет

- FP-Lect9 - Fluid StudyДокумент40 страницFP-Lect9 - Fluid StudymoazОценок пока нет

- Examination Cover Sheet: (Do Not Alter This Form)Документ4 страницыExamination Cover Sheet: (Do Not Alter This Form)Victor IkeОценок пока нет

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringОт EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringОценок пока нет

- Scal For Gas Reservoirs: A Contribution For Better ExperimentsДокумент13 страницScal For Gas Reservoirs: A Contribution For Better ExperimentsMustapha Bouregaa100% (1)

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОт EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОценок пока нет

- Mini-Frac Analysis For Unconventional Reservoirs Using Fast Welltest 16-Aug-2013 0Документ44 страницыMini-Frac Analysis For Unconventional Reservoirs Using Fast Welltest 16-Aug-2013 0Anonymous U7yp0xОценок пока нет

- Dissolved Gas Concentration in Water: Computation as Functions of Temperature, Salinity and PressureОт EverandDissolved Gas Concentration in Water: Computation as Functions of Temperature, Salinity and PressureОценок пока нет

- Permeability NMRДокумент5 страницPermeability NMRFarid Hendra Pradana100% (1)

- Module 6 Capillary Pressure PDFДокумент42 страницыModule 6 Capillary Pressure PDFMusic Resources100% (1)

- QAДокумент34 страницыQAAAADSFDVSDVОценок пока нет

- Interfacial Tension of (Brines + CO 2)Документ11 страницInterfacial Tension of (Brines + CO 2)Julian De BedoutОценок пока нет

- PVT Analysis Principles and ApplicationДокумент2 страницыPVT Analysis Principles and ApplicationMukhtarov PgОценок пока нет

- REN5415 - Y19 - Lec13, 14 &15Документ87 страницREN5415 - Y19 - Lec13, 14 &15Abdulla MohammadОценок пока нет

- Example #7-Pumping Oil Well (Example7.csv)Документ5 страницExample #7-Pumping Oil Well (Example7.csv)Anonymous OtSaas5VОценок пока нет

- Anderson, W. G. - Wettability Literature SurveyДокумент97 страницAnderson, W. G. - Wettability Literature SurveyMARCO100% (1)

- Advances in CMOST AI Development: Chaodong YangДокумент32 страницыAdvances in CMOST AI Development: Chaodong Yanglvt2906100% (1)

- Relative Permeability PDFДокумент12 страницRelative Permeability PDFsawanОценок пока нет

- 12injection Well TestingДокумент12 страниц12injection Well TestingtauseefaroseОценок пока нет

- Saturation and Capillary Pressure in Reservoir RocksДокумент30 страницSaturation and Capillary Pressure in Reservoir Rocksmhdstat100% (1)

- Identification of Pitfalls in PVT Gas Condensate Modeling Using Modified Black-Oil FormulationsДокумент13 страницIdentification of Pitfalls in PVT Gas Condensate Modeling Using Modified Black-Oil FormulationsChávez Ibarra Sergio Kevin100% (1)

- Hydrocarbon Phase BehaviourДокумент75 страницHydrocarbon Phase BehaviourB. JOSEPH KWAMEОценок пока нет

- Properties of Natural GasДокумент5 страницProperties of Natural GasDaniel WigginsОценок пока нет

- Prof. Dr. Eng: - Ahmed El-Gibaly: Suez Canal University Faculty of Pet. & Min. Eng. Petroleum Engineering DeptДокумент22 страницыProf. Dr. Eng: - Ahmed El-Gibaly: Suez Canal University Faculty of Pet. & Min. Eng. Petroleum Engineering Deptcmrig74Оценок пока нет

- Fundamentals of WettabilityДокумент19 страницFundamentals of WettabilityJosé Juan Montejo100% (1)

- Abdullwahid Ahmed EXPДокумент14 страницAbdullwahid Ahmed EXPAbdullwahid AhmedОценок пока нет

- Part 8 - Type Curve AnalysisДокумент37 страницPart 8 - Type Curve AnalysisChai CwsОценок пока нет

- Van Everdingen Hurst AquifersДокумент21 страницаVan Everdingen Hurst Aquifers13670319100% (1)

- Pressure Transient Testing of Gas WellsДокумент8 страницPressure Transient Testing of Gas WellsLuis Alfredo Romero AguileraОценок пока нет

- Fundamental of Well Inflow Performance Relationships (IPR) and Deliverability AnalysisДокумент64 страницыFundamental of Well Inflow Performance Relationships (IPR) and Deliverability Analysisroohullah100% (1)

- 2020 CMOST Presentation Conventional Tight OnlineДокумент51 страница2020 CMOST Presentation Conventional Tight OnlineJulian GonzalezОценок пока нет

- Chapter 3 - Single Phase Fluid FlowДокумент128 страницChapter 3 - Single Phase Fluid FlowZulfikri ZulkifliОценок пока нет

- Peterhead - 11.097 Well Completion Concept Select ReportДокумент148 страницPeterhead - 11.097 Well Completion Concept Select ReportF SedighiОценок пока нет

- Wu Gas Flow in Porous Media With Klinkenberg EffectsДокумент21 страницаWu Gas Flow in Porous Media With Klinkenberg Effectssahand_neko64Оценок пока нет

- Oil Formation Volume Factor - An Overview - ScienceDirect Topics PDFДокумент27 страницOil Formation Volume Factor - An Overview - ScienceDirect Topics PDFVinod KumarОценок пока нет

- Method Computes PVT Properties For Gas CondensateДокумент5 страницMethod Computes PVT Properties For Gas CondensateSergio FloresОценок пока нет

- Water Injection Efficiency AnalysisДокумент12 страницWater Injection Efficiency Analysissaimanoj kumar naikОценок пока нет

- Multiphase Flow Correlation ReportДокумент10 страницMultiphase Flow Correlation ReportGarion CharlesОценок пока нет

- Introduction To CMG Reservoir SimulatorДокумент22 страницыIntroduction To CMG Reservoir SimulatormehdiОценок пока нет

- Reservoir Performance and PredictionДокумент33 страницыReservoir Performance and PredictionBishal SarkarОценок пока нет

- CO Storage Resources Management System: (Approved July 2017)Документ45 страницCO Storage Resources Management System: (Approved July 2017)Yamal E Askoul T100% (1)

- SC RE Chap6 LiquidsДокумент54 страницыSC RE Chap6 LiquidsweldsvОценок пока нет

- Introduction To Well Testing AnalysisДокумент236 страницIntroduction To Well Testing AnalysisGustavo TeixeiraОценок пока нет

- PET 504 Advanced Well Test Analysis: Spring 2015, ITUДокумент72 страницыPET 504 Advanced Well Test Analysis: Spring 2015, ITUEmre CengizОценок пока нет

- Jhon Lee Gas ReservesДокумент26 страницJhon Lee Gas ReservesMitsúMilagrosToroSayasОценок пока нет

- The Five Reservoir FluidsДокумент18 страницThe Five Reservoir FluidsFanny BalamОценок пока нет

- Seminar-Water ConingДокумент22 страницыSeminar-Water Coningcrown212100% (3)

- MBAL CompleteДокумент565 страницMBAL Completeeechzaan1233475100% (1)

- 5 34-10-17 PVT Analysis of Bottom Hole SampleДокумент21 страница5 34-10-17 PVT Analysis of Bottom Hole SampleswpuxiaofanОценок пока нет

- PVTДокумент3 страницыPVTsaeedОценок пока нет

- Brine Displacement by CO 2, Energy Extraction Rates, and Lifespan of AДокумент13 страницBrine Displacement by CO 2, Energy Extraction Rates, and Lifespan of AJulian De BedoutОценок пока нет

- SC RE Chap4 - Phase BehaviourДокумент68 страницSC RE Chap4 - Phase BehaviourweldsvОценок пока нет

- Volumetric Reserves EstimatesДокумент34 страницыVolumetric Reserves EstimatesmhmdsaalemОценок пока нет

- Day 2 - Part 2: Equation of State ModelsДокумент42 страницыDay 2 - Part 2: Equation of State Modelsfoxnew11Оценок пока нет

- Reservoir Lab Manual 2016-17Документ37 страницReservoir Lab Manual 2016-17Amit Verma100% (1)

- Classification of Hydrocarbon Reservoir: Chapter OneДокумент19 страницClassification of Hydrocarbon Reservoir: Chapter OneWanambwa SilagiОценок пока нет

- Hydrate Phase Diagrams For Methane + Ethane + Propane MixturesДокумент13 страницHydrate Phase Diagrams For Methane + Ethane + Propane MixturesHuancong HuangОценок пока нет

- Importance of Porosity - Permeability Relationship in Sandstone Petrophysical PropertiesДокумент61 страницаImportance of Porosity - Permeability Relationship in Sandstone Petrophysical PropertiesjrtnОценок пока нет

- Rsi r2 Super Rsi FaqДокумент14 страницRsi r2 Super Rsi FaqChandrasekar Chandramohan100% (1)

- Misc 8DNL 8MPL 8MPN B PDFДокумент41 страницаMisc 8DNL 8MPL 8MPN B PDFVesica PiscesОценок пока нет

- Community Profile and Baseline DataДокумент7 страницCommunity Profile and Baseline DataEJ RaveloОценок пока нет

- 2010 - Howaldt y Schwarz - Social Innovation-Concepts, Research Fields and International - LibroДокумент82 страницы2010 - Howaldt y Schwarz - Social Innovation-Concepts, Research Fields and International - Librovallejo13Оценок пока нет

- 06 SAP PM Level 1 Role Matrix Template SampleДокумент5 страниц06 SAP PM Level 1 Role Matrix Template SampleRiteshSinhmar100% (1)

- Abnt NBR 16868 1 Alvenaria Estrutural ProjetoДокумент77 страницAbnt NBR 16868 1 Alvenaria Estrutural ProjetoGIOVANNI BRUNO COELHO DE PAULAОценок пока нет

- ISO Position ToleranceДокумент15 страницISO Position ToleranceНиколай КалугинОценок пока нет

- Management PriniciplesДокумент87 страницManagement Priniciplesbusyboy_spОценок пока нет

- The Essence of Technology Is by No Means Anything TechnologicalДокумент22 страницыThe Essence of Technology Is by No Means Anything TechnologicalJerstine Airah SumadsadОценок пока нет

- Government Hazi Muhammad Mohsin College Chattogram: Admission FormДокумент1 страницаGovernment Hazi Muhammad Mohsin College Chattogram: Admission FormThe Helper SoulОценок пока нет

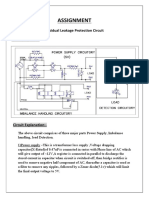

- Assignment: Residual Leakage Protection Circuit Circuit DiagramДокумент2 страницыAssignment: Residual Leakage Protection Circuit Circuit DiagramShivam ShrivastavaОценок пока нет

- Rankine-Froude Model: Blade Element Momentum Theory Is A Theory That Combines BothДокумент111 страницRankine-Froude Model: Blade Element Momentum Theory Is A Theory That Combines BothphysicsОценок пока нет

- SAMPLE MCQuestions ByTopicsДокумент45 страницSAMPLE MCQuestions ByTopicsVeeru ManikantaОценок пока нет

- .CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADOДокумент782 страницы.CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADOMarcelo JesusОценок пока нет

- CHAPTER 2 Part2 csc159Документ26 страницCHAPTER 2 Part2 csc159Wan Syazwan ImanОценок пока нет

- Sprinkler Sizing en v1Документ12 страницSprinkler Sizing en v1CristianDumitru0% (1)

- Radio Ac DecayДокумент34 страницыRadio Ac DecayQassem MohaidatОценок пока нет

- Electronic Diversity Visa ProgrambДокумент1 страницаElectronic Diversity Visa Programbsamkimari5Оценок пока нет

- Atoma Amd Mol&Us CCTK) : 2Nd ErmДокумент4 страницыAtoma Amd Mol&Us CCTK) : 2Nd ErmjanviОценок пока нет

- For Accuracy and Safety: Globally ApprovedДокумент4 страницыFor Accuracy and Safety: Globally ApprovedPedro LopesОценок пока нет

- IJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyДокумент12 страницIJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyImpact JournalsОценок пока нет

- VOTOL EMController Manual V2.0Документ18 страницVOTOL EMController Manual V2.0Nandi F. ReyhanОценок пока нет

- Project Name: Repair of Afam Vi Boiler (HRSG) Evaporator TubesДокумент12 страницProject Name: Repair of Afam Vi Boiler (HRSG) Evaporator TubesLeann WeaverОценок пока нет

- Intelligent Status Monitoring System For Port Machinery: RMGC/RTGCДокумент2 страницыIntelligent Status Monitoring System For Port Machinery: RMGC/RTGCfatsahОценок пока нет

- Sheet-Metal Forming Processes: Group 9 PresentationДокумент90 страницSheet-Metal Forming Processes: Group 9 PresentationjssrikantamurthyОценок пока нет

- Ce-Series - TK60981-ML-18 IM - Rev - 0 - 05-13Документ96 страницCe-Series - TK60981-ML-18 IM - Rev - 0 - 05-13VERDADE MUNDIAL GUERRAОценок пока нет

- 28 TerminalsДокумент42 страницы28 TerminalsAlin FazacasОценок пока нет

- Installation Instructions INI Luma Gen2Документ21 страницаInstallation Instructions INI Luma Gen2John Kim CarandangОценок пока нет

- Abilash - Subramanian CV - 003 PDFДокумент4 страницыAbilash - Subramanian CV - 003 PDFAbilash SubramanianОценок пока нет

- Sully: The Untold Story Behind the Miracle on the HudsonОт EverandSully: The Untold Story Behind the Miracle on the HudsonРейтинг: 4 из 5 звезд4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldОт EverandThe Fabric of Civilization: How Textiles Made the WorldРейтинг: 4.5 из 5 звезд4.5/5 (58)

- Hero Found: The Greatest POW Escape of the Vietnam WarОт EverandHero Found: The Greatest POW Escape of the Vietnam WarРейтинг: 4 из 5 звезд4/5 (19)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaОт EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaОценок пока нет

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОт EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОценок пока нет

- A Place of My Own: The Architecture of DaydreamsОт EverandA Place of My Own: The Architecture of DaydreamsРейтинг: 4 из 5 звезд4/5 (242)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestОт EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestРейтинг: 4 из 5 звезд4/5 (28)

- Reality+: Virtual Worlds and the Problems of PhilosophyОт EverandReality+: Virtual Worlds and the Problems of PhilosophyРейтинг: 4 из 5 звезд4/5 (24)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980От Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Рейтинг: 4 из 5 звезд4/5 (21)

- Pale Blue Dot: A Vision of the Human Future in SpaceОт EverandPale Blue Dot: A Vision of the Human Future in SpaceРейтинг: 4.5 из 5 звезд4.5/5 (588)

- The End of Craving: Recovering the Lost Wisdom of Eating WellОт EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellРейтинг: 4.5 из 5 звезд4.5/5 (80)

- Packing for Mars: The Curious Science of Life in the VoidОт EverandPacking for Mars: The Curious Science of Life in the VoidРейтинг: 4 из 5 звезд4/5 (1395)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationОт EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationРейтинг: 4.5 из 5 звезд4.5/5 (46)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerОт EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerРейтинг: 4.5 из 5 звезд4.5/5 (122)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureОт EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureРейтинг: 5 из 5 звезд5/5 (125)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyОт EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyОценок пока нет

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОт EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОценок пока нет

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerОт EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerРейтинг: 4.5 из 5 звезд4.5/5 (54)

- The Weather Machine: A Journey Inside the ForecastОт EverandThe Weather Machine: A Journey Inside the ForecastРейтинг: 3.5 из 5 звезд3.5/5 (31)