Академический Документы

Профессиональный Документы

Культура Документы

WPS - Smaw - 2

Загружено:

Harkesh RajputОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

WPS - Smaw - 2

Загружено:

Harkesh RajputАвторское право:

Доступные форматы

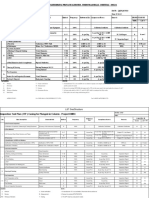

MANUFACTURER'S NAME &

QUALITY ASSURANCE PLAN

ADDRESS: M/S. ENCON, FARIDABAD

Sl. No.

COMPONENT

P.O. NO. ITEMS : TUNDISH PREHEATING STATION TUNDISH DRYING STATION SEN PREHEATING OVEN CHARACTERSTICS TYPE/METHOD EXTEN REFERENCE TO BE CHECKED CATEGOR OF CHECK T OF DOCUMENT CHECK Y

QAP NO. REV. PAGE I OF 3

NAME OF CLIENT : DANIELI INDIA LIMITED PROJECT : JINDAL STEEL & BSRM JOB POSITION AGENCY P W V REMARKS

ACCEPTANCE NORMS

FORMAT OF RECORD

RAW MATERIAL BOUGHT OUT ITEMS FOR PACKAGE UNITS. PHYSICAL & MAJOR 1 PLATE, ANGLE, CHANNEL, BEAM CHEMICAL PROPERTIES

MILL TC

APPROVED MANUFACTURIN 100% G DRG. DATA SHEET/ DAN STD.

APPROVED MANUFACTURER'S MANUFACTURING TC DRG. DATA SHEET/ DAN STD. MANUFACTURER'S TC

UT REPORT FOR 16 MM 1 & ABOBE THK TO BE SUBMITTED

2 ROUND BAR

PHYSICAL & CHEMICAL PROPERTIES

MAJOR MILL TC 100% DO DO

UT REPORT FOR 50 MM 1 & ABOBE DIAMETER TO BE SUBMITTED

3 PIPE (CU, CS & SS 4 ELECTRICALS & INSTRUMENTS

PHYSICAL & CHEMICAL PROPERTIES MANUFACTURER'S TC

MAJOR MILL TC MAJOR PERFORMANCE CERTIFICATION 100% DO DO

MANUFACTURER'S TC MANUFACTURER'S TC MANUFACTURER'S TC MANUFACTURER'S TC MANUFACTURER'S TC MANUFACTURER'S TC MANUFACTURER'S TC MANUFACTURER'S TC

100% 100%

DO DO DO DO DO DO DO

DO DO DO DO DO DO DO

2 2 2 2 2 2 2

1 1 1 1 1 1 1

5 THERMOCOUPLE MANUFACTURER'S TC MANUFACTURER'S 6 VALVES TC MANUFACTURER'S 7 HOSE TC 8 PLUMMER BLOCK MANUFACTURER'S WITH BEARING TC 9 AIR/GAS/RATIO REGULATOR 10 PR. GUAGE

MAJOR MAJOR MAJOR MAJOR MATERIAL & PR. TEST MATERIAL & PR. TEST MATERIAL

100% 100% 100%

MANUFACTURER'S MAJOR TC MANUFACTURER'S MAJOR TC

PERFORMANCE REPORT CALIBRATION CERTIFICATE

100% 100%

PREPARED BY:

LEGENDS:

P-PERFORM, W-WITNESS, V-VERIFICATION

APPROVED BY :

1- TPIA/DIL/CUSTOMER/CONSULTANT, 2-MANUFACTURER

MANUFACTURER'S NAME &

QUALITY ASSURANCE PLAN

P.O. NO. ITEMS : TUNDISH PREHEATING STATION TUNDISH DRYING STATION SEN PREHEATING OVEN TYPE/METHOD OF CHECK EXTEN T OF CHECK REFERENCE DOCUMENT ACCEPTANCE NORMS

ADDRESS: M/S. ENCON, FARIDABAD

QAP NO. REV. PAGE 2 OF 3

Sl. No.

NAME OF CLIENT : DANIELI INDIA LIMITED PROJECT : JINDAL STEEL & BSRM JOB POSITION AGENCY REMARKS P W V

COMPONENT

CHARACTERSTICS CATEGOR TO BE CHECKED Y

FORMAT OF RECORD

RAW MATERIAL BOUGHT OUT ITEMS FOR PACKAGE UNITS. MANUFACTURER'S MAJOR 11 HYDRAULIC CYLINDER TC

MATERIAL, PR. TEST & B/O DETAILS ROUTINE TEST CERTIFICATE VISUAL DIMENSION & SIMULATION MATERIAL & PERFORMANCE TEST REPORT MATERIAL & PERFORMANCE TEST REPORT MATERIAL & PHYSICAL PROPERTIES CERTIFICATION MEASUREMENT

APPROVED MANUFACTURIN 100% G DRG. DATA SHEET/ DAN STD. 100% DO

APPROVED MANUFACTURER'S MANUFACTURING TC DRG. DATA SHEET/ DAN STD. DO MANUFACTURER'S TC MANUFACTURER'S TC MANUFACTURER'S TC MANUFACTURER'S TC

12 POWER PACK

MANUFACTURER'S TC

MAJOR

13 CONTROL PANEL MANUFACTURER'S TC 14 BURNER MANUFACTURER'S TC MANUFACTURER'S TC

MAJOR

100%

DO

DO

MAJOR

100%

DO

DO

15 BLOWER

MAJOR

100%

DO

DO

16 REFRACTORY & INSULATION

MANUFACTURER'S TC

MAJOR

100%

DO

DO

MANUFACTURER'S TC

IN-PROCESS INSPECTION OF PACKAGE UNITS MAJOR 16 STRUCTURAL STEEL & PIPING WPS, PQR, WPQ 17 STRUCTURAL STEEL & PIPING WELDING 18 ELECTRICAL PANEL MAJOR NDT MEGGER TEST, HV TEST MAJOR

ASME SEC-IX DAN STD CLASS-B 100%

ASME SEC-IX DAN STD CLASS-B

MANUFACTURER'S RECORD INSPECTION REPORT

2 2 2

1 1 1

MEASUREMENT

NOT LESS THAN INSPECTION REPORT IM ohm

PREPARED BY:

LEGENDS:

P-PERFORM, W-WITNESS, V-VERIFICATION

APPROVED BY :

1- TPIA/DIL/CUSTOMER/CONSULTANT, 2-MANUFACTURER

MANUFACTURER'S NAME &

QUALITY ASSURANCE PLAN

ADDRESS: M/S. ENCON, FARIDABAD

QAP NO. REV. PAGE 3 OF 3

Sl. No.

COMPONENT

CHARACTERSTICS CATEGOR TO BE CHECKED Y

TYPE/METHOD OF CHECK

EXTEN T OF CHECK

REFERENCE DOCUMENT

ACCEPTANCE NORMS

FORMAT OF RECORD

NAME OF CLIENT : DANIELI INDIA LIMITED PROJECT : JINDAL STEEL & BSRM JOB POSITION AGENCY REMARKS P W V 2 1 1 CALIBRATION CERTIFICATES OF MEASURING INSTRUMENTS ARE TO BE SUBMITTED

FINAL INSPECTION OF PACKAGE UNITS MAJOR 19 COMPLETE UNIT VISUAL, IN ASSEMBLED DIMENSIONAL, CONDITION WITH FUNCTIONAL ONBOARD TEST/ RUN TEST PIPING, (ONEUMATIC ONBOARD MOVEMENT ELECTRICALS & CHECK, COLD INTERCONNECTI TEST FOR NGS ELECTRICAL CIRCUIT, BURNER. IGNITION & REGULATION. (WITH FULL AUTOMATIC SCOPE OF TEMPERATURE SUPPLY) CONTROL IN PRESET MODE FUNCTIONAL DYNAMICS FUNCTIONAL & SAFETY INTERLOCKS) 20 ASSEMBLED UNIT MAJOR

MEASUREMENT

100% APPROVED GA DRG. DATA SHEET

APPROVED GA DRG. DATA SHEET

INSPECTION REPORT

SURFACE PREPARATION & PAINTING

DFT, ADHESSION, SHADE, VERIFICATION

100% AS PER CONTRACT AS PER CONTRACT

INSPECTION

1 1

PREPARED BY:

LEGENDS:

P-PERFORM, W-WITNESS, V-VERIFICATION

APPROVED BY :

1- TPIA/DIL/CUSTOMER/CONSULTANT, 2-MANUFACTURER

PROCEDURE QUALIFICATION RECORDS (PQR) Construction Code : (ASME Sec IX) Company Name : M/s. Encon Thermal Engineers, Palwal PQR No: ETE/PQR/004 Date : 12/09/2013 Rev. No. WPS No: ETE/WPS/004, Date : 12/09/2013 Welding Process(es)/Type: Joints (QW-402 : Groove Design of Test Coupon:

Page 1 of 2

Rev. Date: SMAW /Manual

BASE METALS (QW-403) Material specification : IS:2062 to IS:2062 Type or Grade Gr. B TO Gr. B P-No: to P-No. : Thickness of Test Coupon : 12 mm Diameter of Test Coupon: Other:. FILLER METALS (QW-404) Buttweld SFA No. : AWS CLASS: F. No.: A. No.: Size of Filler Metals Deposited Weld Metal Thickness Range

POSITIONS (QW-405) 5.1 E-7018 4 1 2.50 / 3.15

POST WELD HEAT TREATMENT (QW407) Temperature Range :... Time range:. Other GAS(QW-408 Gases Mixture Shielding .. .. Trailing None None Backing None None Fillet

ELECTRICAL CHARACTERISTICS (QW-409)

Flow rate .. None None

Current : (AC or DC): DC Polarity : (SP or RP): RP Amps. See table Volts: See table Tungsten Electrode Size and Type: NA

Other :

12mm

TECHNIQUE (QW-410) Travel speed: Refer Table

String or Weave Bead: -Root stringe,sub runs weave Bead -Max. 3 times of rod dia.

Positions of groove: 3G Welding Progression: Uphill Other PREHEAT (QW-406) Preheat Temperature, Minimum: N.A Inter pass Temperature, Maximum : 250 to 300 C Other : Filler Metal Weld Process Layer(s) F-No. A-No. SFA No. AWS No. Root 1st & 2nd Layer 3rd + n Layer Back side 1st Layer SMAW SMAW SMAW SMAW 1 1 1 1 5.1 5.1 5.1 5.1 E-7018 E-7018 E-7018 E-7018

Oscillation: Side to Side Multiple or Single Pass (per side) : Multiple Multiple or Single Electrodes : Single Method of back Gouging: Grinding Peening : NA Other : Trav. Speed Size Type Other Amp. Volt. Range Range 6-8 in./Min. 2.5mm Solid 80/100A 20/32V 3.15mm 3.15mm 3.15mm Solid Solid Solid 90/120A 90/120A 90/120A 20/35V 20/35V 20/35V 6-8 in./Min. 6-8 in./Min. 6-8 in./Min.

Page 2 of 2 PQR No: ETE/PQR/004 Date : 12/09/2013 Rev No: Rev. Date:

Tensile Test (QW - 150)

Test Report No: STH/2013/TC/I-006-2, Dt. 10/09/2013

Specimen No. UTS-1 UTS-2

Width 24.8 25.7

Thickness 12.2 mm 12.2 mm

Area 302.56 313.54

Ultimate Total Load (Kgf) 13700 14700

Ultimate Unit Stress-kg/mm2 45.28 46.88

Type of Failure and Location Broken from Parent Metal Broken from Parent Metal

Guided -Bend Test (QW-160) Specimen No. RB-1 RB-2 FB-1 FB-2 Type and Figure No. ROOT BEND TEST AT 180 DEG. ROOT BEND TEST AT 180 DEG. FACE BEND TEST AT 180 DEG. FACE BEND TEST AT 180 DEG. Toughness Tests (QW-170)

Test Report N0: STH/2013/TC/I-006-2, Dt. 10/09/2013 Result SATISFACTORY SATISFACTORY SATISFACTORY SATISFACTORY Test Report No:

Specimen Notch No. Location

Specimen Size

Test Temperature N.A.

Impact Value Impact Value % Shear Mills

Drop Weight Break (Y/N)

Comments: NDE Result : NA Result: NA Fillet Weld Tests (QW-180):-Result ----Macro - Results: NA Other Tests Visual Inspection Appearance : SATISFACTORY N.A. Test Report No.: Test Report No:--

Penetration in to Parent Metal:-----

Other Tests (Micro/Micro/Hardness)

Welder Name & Welder ID Number: Mr. Sanjay Singh - W6 Tests Conducted by: SARRC Test House, Faridabad. We certify that the statements in this record are correct and that the test welds/coupons were prepared, welded, and tested in accordance with the requirements of Section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Prepared By: M/s. ENCON Thermal Engineers (P) Ltd., Palwal

WELDING PROCEDURE SPECIFICATION (WPS) Construction Code : (ASME Sec IX)

Company : M/s. ENCON Thermal Engineers (P) Ltd., Faridabad WPS No: ETE/WPS/004 Supporting PQR No: ETE/PQR/006 Welding Process(es)/Type : SMAW JOINTS (QW-402) Jooint Design ( Manufacturing Drawing) BUTT WELD SINGLE V GROOVE Date : 06/08/2013 Date : 12/09/2013 PREHEAT (QW-406) Preheat temperature, Minimum: N. A. Rev No. 00 Page 1 of 1

Inter pass Temperature : 250 to 300 C

Backing: - No Backing Material(Type) : N/A BASE METALS(QW-403) P-No. 8 Group No. 1 To P-No. 8 Group No. 1 Or Spec.Type & Grade to spec: Type & Grade : A240 Gr. 304 to A240 Gr. 304 Thickness Range: Base metal 4 to 10 mm plate Fillet All Pipe Dia. (mm); Max Thick per pass(mm) Other: FILLER METALS (QW-404) Butt Weld Fillet F. No: 5 A. No: 8 SFA No: 5.4 AWS CLASS: E-308 (L) -16 Size of filler Metals 2.50 & 3.15 Deposited Weld Metal Thickness Range: 5 mm Thickness Range(Groove) Upto 10 mm Thickness Range(filler) All Electrode Flux(Class) N.A. Flux Trade Name Consumable Insert other; POSITIONS(QW-405) Positions of groove: 1G Welding Progression: Uphill Position(s) of Fillet :All Weld Layers(s) Root 1st Layer 2nd + n Layer Process SMAW SMAW SMAW F-No. A-No. 8 8 8

N.A. N.A. N.A.

Preheat maintenance: N. A. POST WELD HEAT TREATMENT (QW407) Temprature Range: N. A. Time Range: N. A. GAS(QW-408) Gases Mixture Flow rate . Shielding None None Trailing None Backing None None None ELECTRICAL CHARACTERISTCS(QW-409): Current :(AC or DC): DC Polarity:(SP or RP): RP Metal Transfer Mode for GMAW/FCAW:-N.A. Tungsten Electrode Size and Type : None Electrode Wire Feed Speed Range: N. A. TECHNIQUE(QW-410)

String or Weave Bead: -Root stringe,sub runs weave Bead -Max. 3 times of rod dia.

Filler Metal SFA NO. 5.1 5.1 5.1 AWS NO. E-308(L)- 16 E-308(L)- 16 E-308(L)- 16

Orifice or Gas Cup Size: N. A. Initial & interpass: Cleaning(Brushing, Grinding etc.): Brushing and Grinding Method of Back Gouging: Grinding Oscillation: Side to Side Contact Tube to Work Distance: N. A. Multiple or Single Pass(per side): Multiple Layer Multiple or Single Electrodes: Single Teravel Speed (range): See Table Trav. Speed Size Type Other Amp. Volt Range Range 40-50 2.5mm Solid 60/80A 17/18V mm/Min. 40-50 3.15mm Solid 60/110A 18/25V mm/Min. 40-50 3.15mm Solid 60/110A 18/25V mm/Min.

Prepared By: M/s. ENCON Thermal Engineers (P) Ltd., Faridabad.

Вам также может понравиться

- WPS For Structure Mild Steel Fillet WeldДокумент2 страницыWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- BK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldДокумент2 страницыBK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldHarkesh RajputОценок пока нет

- Larsen & Toubro underground piping inspection planДокумент4 страницыLarsen & Toubro underground piping inspection planBhavani PrasadОценок пока нет

- PQR-WPS-WPQR XXX Rev 0Документ6 страницPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Schneider LV Switchboard Inspection GuideДокумент59 страницSchneider LV Switchboard Inspection GuideAlp Arslan Ok100% (1)

- Quality Assurance PlanДокумент3 страницыQuality Assurance PlanVicky Gautam100% (1)

- Weld Joint 1Документ81 страницаWeld Joint 1rajibali27100% (1)

- PQR Is7307Документ1 страницаPQR Is7307Tridib Dey100% (1)

- ITP For Steel Structure1Документ3 страницыITP For Steel Structure1吴兴泊Оценок пока нет

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingДокумент3 страницыDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyОценок пока нет

- Inspection and Test Plan: ITP NO: 7979-ITP-ME-031-1 Title: Bolt Tightening WorksДокумент9 страницInspection and Test Plan: ITP NO: 7979-ITP-ME-031-1 Title: Bolt Tightening WorksDelta akathehuskyОценок пока нет

- Steel TankДокумент4 страницыSteel TankRanu JanuarОценок пока нет

- Welding Procedure Specification For Storage Tank & Piping SystemДокумент3 страницыWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadОценок пока нет

- ITP For Pipeline Construction Table 1Документ3 страницыITP For Pipeline Construction Table 1wahyu100% (2)

- Rotating Itp 1Документ4 страницыRotating Itp 1abdul aziz100% (1)

- Itp PipingДокумент4 страницыItp PipingkennethОценок пока нет

- QUALITY ASSURANCE PROTOCOLДокумент2 страницыQUALITY ASSURANCE PROTOCOLShah Newaz KabirОценок пока нет

- WPS Pipe 08'' SHD 40 SMAW REV02Документ2 страницыWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejОценок пока нет

- SteelKote EP ZN HS: High-Build Zinc-Rich Epoxy PrimerДокумент3 страницыSteelKote EP ZN HS: High-Build Zinc-Rich Epoxy Primerprasanth cp100% (1)

- Welding Proposed Pwps For Our Jubail WorkДокумент2 страницыWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- VGS 8.1.2 Rev.20 - UTДокумент29 страницVGS 8.1.2 Rev.20 - UTPaul-Petrus MogosОценок пока нет

- Replace No.3 API Oil Separator Project: Daily Fitup ReportДокумент20 страницReplace No.3 API Oil Separator Project: Daily Fitup Reportsajay2010Оценок пока нет

- Inspection Test Plan Fuel Gas Conditioning SkidДокумент19 страницInspection Test Plan Fuel Gas Conditioning SkidDin AizuОценок пока нет

- WPS Resrvoire Sous Pression Smaw SawДокумент6 страницWPS Resrvoire Sous Pression Smaw SawDanem HalasОценок пока нет

- NRP QapДокумент10 страницNRP QapKevin Mathew100% (1)

- Wps PQR Spec IndexДокумент1 страницаWps PQR Spec IndexTridib DeyОценок пока нет

- DiodeДокумент22 страницыDiodeSaurabh Mittal100% (1)

- Proposed WPSДокумент2 страницыProposed WPSChisom Ikengwu100% (2)

- Sample API 1104 WpsДокумент1 страницаSample API 1104 Wpsippon_osoto100% (1)

- Design of A Fluidized Drum GranulatorДокумент6 страницDesign of A Fluidized Drum GranulatorditchcheОценок пока нет

- Grounding and JumperingДокумент16 страницGrounding and Jumperingferreiramarco56Оценок пока нет

- Guess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerДокумент31 страницаGuess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerAlam Shamsher0% (1)

- WPQ Template (Asme Ix) No LogoДокумент4 страницыWPQ Template (Asme Ix) No LogorcpretoriusОценок пока нет

- PQR 014 (Qualified Sa 106 GR BДокумент5 страницPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Itp For InsulationДокумент14 страницItp For InsulationHytham El-NoubyОценок пока нет

- Material Inspection Report: Project Name Date InspДокумент22 страницыMaterial Inspection Report: Project Name Date InspRafiqKuОценок пока нет

- 24.tank Oil Chalk TestДокумент3 страницы24.tank Oil Chalk TestShubham ShuklaОценок пока нет

- L&T GeoStructure casing inspection planДокумент2 страницыL&T GeoStructure casing inspection plansanil50% (2)

- Fit Up & Weld VisualДокумент2 страницыFit Up & Weld VisualBhanu Pratap ChoudhuryОценок пока нет

- How Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?Документ6 страницHow Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?joseОценок пока нет

- F07-Visual Inspection Report NEWДокумент1 страницаF07-Visual Inspection Report NEWmohd as shahiddin jafriОценок пока нет

- Pipeline Tow MethodДокумент25 страницPipeline Tow MethodctrlaltdestroyОценок пока нет

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Документ2 страницыLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidОценок пока нет

- WPS For A333 AДокумент1 страницаWPS For A333 ARamzi BEN AHMED100% (1)

- Welding Map: PROJECT: Repair of Damaged Pipelines & Process Lines - MARETAP - EZZAOUIA FIELDДокумент1 страницаWelding Map: PROJECT: Repair of Damaged Pipelines & Process Lines - MARETAP - EZZAOUIA FIELDMajdi Jerbi100% (1)

- WPQ-1083 3G PDFДокумент2 страницыWPQ-1083 3G PDFduendex360100% (1)

- Qualified Welder List Valid Until - 03-12-2019Документ2 страницыQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- Wps Gmaw SawДокумент2 страницыWps Gmaw Sawupedro26Оценок пока нет

- Ut Format Report For Ut Libra (Naidu)Документ4 страницыUt Format Report For Ut Libra (Naidu)vsnaiduqcОценок пока нет

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Документ2 страницыWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangОценок пока нет

- Wps For Smaw06-001 (Pipe 6g CS)Документ10 страницWps For Smaw06-001 (Pipe 6g CS)walitedisonОценок пока нет

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationДокумент2 страницыASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaОценок пока нет

- Wps Mig PDF FreeДокумент3 страницыWps Mig PDF Freehanz bermejoОценок пока нет

- QC FORMДокумент3 страницыQC FORMRicardo LourençoОценок пока нет

- ARCC Hydrotest Packages Summary ReportДокумент4 страницыARCC Hydrotest Packages Summary ReportSiddiqui Abdul KhaliqОценок пока нет

- INSPECTION REPORT TITLEДокумент7 страницINSPECTION REPORT TITLEABEC Trombay siteОценок пока нет

- Welding Procedure Specification (WPS) : N.A N.AДокумент1 страницаWelding Procedure Specification (WPS) : N.A N.AMajdi JerbiОценок пока нет

- WOPQ Form English1Документ2 страницыWOPQ Form English1oaperuchenaОценок пока нет

- Sample WPS 1Документ13 страницSample WPS 1waqas pirachaОценок пока нет

- Cold Tap Coating Report 2Документ1 страницаCold Tap Coating Report 2Jamal BakhtОценок пока нет

- Inspection Report - ValvesДокумент2 страницыInspection Report - ValvesJaspal KaurОценок пока нет

- 1.13 Inspection & Test PlansДокумент1 страница1.13 Inspection & Test Plansabimanyubawono100% (2)

- NDT Request (Template)Документ4 страницыNDT Request (Template)Bethel NdifonОценок пока нет

- 2.8.2. Indicative QAP - ColumnsДокумент12 страниц2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- N0200003 - NEW-F201-0 - Inspection & Test PlanДокумент3 страницыN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliОценок пока нет

- Painting & Inspection FormatДокумент1 страницаPainting & Inspection FormatABEC Trombay siteОценок пока нет

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryДокумент1 страницаMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalОценок пока нет

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Документ1 страницаQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Оценок пока нет

- Piping Daily Fit Up Quality Control and Inspection Report FormДокумент4 страницыPiping Daily Fit Up Quality Control and Inspection Report FormnguyenquanghiepОценок пока нет

- Ayari Maher: Qualified Welder I.D.CardДокумент10 страницAyari Maher: Qualified Welder I.D.CardZouhair BenmabroukОценок пока нет

- Wps Pip Gtaw - ArabianДокумент1 страницаWps Pip Gtaw - ArabianIshack MohammedОценок пока нет

- Dimen - Report of ElbowДокумент1 страницаDimen - Report of ElbowHarkesh RajputОценок пока нет

- Fabrication and Manwork ProfileДокумент12 страницFabrication and Manwork ProfileHarkesh RajputОценок пока нет

- Spartech Cutter Price ListДокумент1 страницаSpartech Cutter Price ListHarkesh RajputОценок пока нет

- Company Profile - Naman EngineersДокумент8 страницCompany Profile - Naman EngineersHarkesh RajputОценок пока нет

- Lithika - 001Документ1 страницаLithika - 001Harkesh RajputОценок пока нет

- HESPLДокумент6 страницHESPLHarkesh RajputОценок пока нет

- Pca Act 1960Документ27 страницPca Act 1960Harkesh RajputОценок пока нет

- Company ProfileДокумент8 страницCompany ProfileHarkesh RajputОценок пока нет

- Ea80 Series PDFДокумент82 страницыEa80 Series PDFAnca MunteanuОценок пока нет

- Dimensions of Physical Quantities DensityДокумент100 страницDimensions of Physical Quantities DensityGerman Rincon UrregoОценок пока нет

- Seminar ReportДокумент30 страницSeminar Reportshashank_gowda_7Оценок пока нет

- Carimin Acacia Stability-Onhire Loading JerunДокумент6 страницCarimin Acacia Stability-Onhire Loading Jerunh2sbnj86b4Оценок пока нет

- Operator Interface Hmi Touch Screen Cmore - 10Документ54 страницыOperator Interface Hmi Touch Screen Cmore - 10QuantumAutomation100% (1)

- Smart Access 1105Документ12 страницSmart Access 1105Gerson Freire De Amorim FilhoОценок пока нет

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Документ3 страницыLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifОценок пока нет

- 5TH Week EnergyДокумент6 страниц5TH Week EnergyMira VeranoОценок пока нет

- CED 426 Quiz # 2 SolutionsДокумент26 страницCED 426 Quiz # 2 SolutionsMary Joanne AninonОценок пока нет

- 06 HVAC Plumbing PDFДокумент727 страниц06 HVAC Plumbing PDFTamОценок пока нет

- NUSTian Final July SeptДокумент36 страницNUSTian Final July SeptAdeel KhanОценок пока нет

- Sinusverteiler Multivalent SolutionsДокумент13 страницSinusverteiler Multivalent SolutionsIon ZabetОценок пока нет

- Magnum 3904 DatasheetДокумент3 страницыMagnum 3904 DatasheetbobОценок пока нет

- Communication System (LC-ECE204G) LAB ManualДокумент54 страницыCommunication System (LC-ECE204G) LAB ManualBindia HandaОценок пока нет

- Assign4 RANSДокумент2 страницыAssign4 RANSankitsaneetОценок пока нет

- Lab5 AnswerSheetДокумент3 страницыLab5 AnswerSheetnislam57Оценок пока нет

- XZX ZX ZXДокумент4 страницыXZX ZX ZXWong VoonyeeОценок пока нет

- Classification of FluidДокумент29 страницClassification of FluidAbdur RehmanОценок пока нет

- PDVSA Engineering Design Manual Volume 9–I Process AnalyzersДокумент25 страницPDVSA Engineering Design Manual Volume 9–I Process AnalyzersAlberto Enrique De Santa Anna CampderáОценок пока нет

- Simucube 2 Quick Release GuideДокумент7 страницSimucube 2 Quick Release Guideemyrs12Оценок пока нет

- Establishing OPC UA Connectivity With Rockwell Automation® Integrated ArchitectureДокумент3 страницыEstablishing OPC UA Connectivity With Rockwell Automation® Integrated ArchitecturehuiyitОценок пока нет