Академический Документы

Профессиональный Документы

Культура Документы

Cibc

Загружено:

kokiskoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cibc

Загружено:

kokiskoАвторское право:

Доступные форматы

Cutting it A Bit Closer

By R. G. Sparber

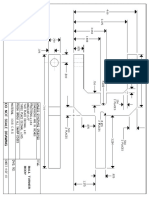

Copyleft protects this document.1 Recently I needed to cut a cylinder longitudinally along its diameter on my horizontal/vertical bandsaw. The cut was not critical but I did want it to look good. I was off by maybe 0.02 which was serviceable but certainly not pleasing to the eye. That got me thinking, how can I better align my blade for a closer cut. Here is how I did it.

To hold the work piece I used a drill press vise from Harbor Freight. One side has been raised up about so when the bandsaw blade is down on the vise ways, it is in full contact. This is a very handy trick that I picked up on some gifted Japanese craftsmans web site. My cylinder was 1 in diameter so I want the center of my blade to be from the fixed jaw. Typically, I do this by eye but it is hard to see in there so my results are not that great.

You are free to copy and distribute this document but not change it. March 24, 2012 Page 1 of 5

R. G. Sparber

I started by clamping two pieces of round stock in the vise. The bar was necessary to prevent the right bar from falling in the gap between vise ways and fixed jaw.

R. G. Sparber

March 24, 2012

Page 2 of 5

I then placed the assembly in my horizontal/vertical bandsaw vise so it could still slide side to side. With the saw off, I lowered the blade into the gap between rods. With a little wiggling, I could feel it drop in. Next I raised and lowered the blade into this gap. I could hear a faint twang as the blade was deflected by one of the rods. I slightly moved the inner vise, and continued to raise and lower the blade until there was no sound. Then the saws vise was tightened. This procedure should put the center of the blade very close to from the fixed jaws face.

R. G. Sparber

March 24, 2012

Page 3 of 5

To test my alignment, I put a block of aluminum in the vise and made a cut about 0.1 deep. I then remove the test block and measured the distance from the face that contacted the fixed jaw to the nearest edge of the saw kerf. It was 0.475. I then used a pin gage to measure the saw kerf which came out to 0.040. And lastly, I measured the diameter of each rod used during the alignment. They came out to 0.497. The distance from the face of the block that contacted the fixed jaw to the center . line of the kerf was 0.475 + = 0.495. That compares almost too well with the diameter of the rod at 0.497. Now, I know this is not a proof, but it does demonstrate that I can set the inner vise a lot better with this procedure than by eye.

R. G. Sparber

March 24, 2012

Page 4 of 5

I welcome your comments and questions. Rick Sparber Rgsparber@aol.com Rick.Sparber.org

R. G. Sparber

March 24, 2012

Page 5 of 5

Вам также может понравиться

- Chainmail Made Easy: 8 Wicked Weaves with 8 Practical Projects: Chainmail Made Easy, #2От EverandChainmail Made Easy: 8 Wicked Weaves with 8 Practical Projects: Chainmail Made Easy, #2Рейтинг: 4.5 из 5 звезд4.5/5 (11)

- How To Fix The Wobbling Table Saw ArborДокумент5 страницHow To Fix The Wobbling Table Saw ArborSonia CireaşăОценок пока нет

- Turning A Precision WasherДокумент7 страницTurning A Precision WasherkokiskoОценок пока нет

- Height of Lathe Cutter V1Документ4 страницыHeight of Lathe Cutter V1kokiskoОценок пока нет

- Toolpost Attachment For A High Speed Rotary ToolДокумент32 страницыToolpost Attachment For A High Speed Rotary Toolkokisko100% (1)

- Lathebasics 4-5Документ3 страницыLathebasics 4-5Mike Forbes100% (2)

- Simple Knife With Simple ToolsДокумент26 страницSimple Knife With Simple ToolsElias MuñozОценок пока нет

- Carving An Ash Flat BowДокумент15 страницCarving An Ash Flat Bowanon_3839218100% (1)

- 1911 Frontstrap CheckeringДокумент11 страниц1911 Frontstrap CheckeringMark AllenОценок пока нет

- 50 Cal PlansДокумент24 страницы50 Cal PlansClint Muldoon100% (10)

- Making a Bent Dublin PipeДокумент15 страницMaking a Bent Dublin PipeMiguel Mendoza100% (1)

- Engraver Tool To MakeДокумент15 страницEngraver Tool To MakeDave Bass100% (6)

- Balancing Surfer Man 1Документ10 страницBalancing Surfer Man 1api-698537315Оценок пока нет

- How To CutДокумент23 страницыHow To CutAnxi NurhudaОценок пока нет

- Easy Resawing: The Fence. The FenceДокумент2 страницыEasy Resawing: The Fence. The FenceBilAndersenОценок пока нет

- Строгание грифа 2Документ20 страницСтрогание грифа 2священник Евгений КукушкинОценок пока нет

- How To Make A Slipjoint Pocket Knife: by Chris CrawfordДокумент35 страницHow To Make A Slipjoint Pocket Knife: by Chris CrawfordArif Baskoro AdiwimartaОценок пока нет

- Dovetail Guide User ManualДокумент9 страницDovetail Guide User ManualAnonymous 9zL9MblM3HОценок пока нет

- Bolt Action 9Документ10 страницBolt Action 9spartywrx100% (1)

- How to cut key ways using a ShaperДокумент26 страницHow to cut key ways using a ShaperAhmad Abdullahi TijjaniОценок пока нет

- Making A Mallet - Preparing The BlockheadДокумент9 страницMaking A Mallet - Preparing The BlockheadKoki MostafaОценок пока нет

- Woodgears CAДокумент8 страницWoodgears CAWalter RamirezОценок пока нет

- Absolute Cheapskate Way To Start Making KnivesДокумент18 страницAbsolute Cheapskate Way To Start Making KnivesvetsinОценок пока нет

- Mould MaintenanceДокумент8 страницMould Maintenance631052Оценок пока нет

- Wire WorkДокумент72 страницыWire WorkRene Irrma100% (1)

- Wigjig Video 4 On Making A Bead Dangle by Selecting HereДокумент24 страницыWigjig Video 4 On Making A Bead Dangle by Selecting HereRene Irrma100% (1)

- Paul Rodgers - How To Make A ReamerДокумент4 страницыPaul Rodgers - How To Make A Reamerpepito2002cu100% (1)

- Art of Slow Dovetailing Through DovetailsДокумент7 страницArt of Slow Dovetailing Through DovetailsleeroyhaspoonОценок пока нет

- A Reed Making Process For The Great Highland BagpipeДокумент11 страницA Reed Making Process For The Great Highland BagpipekriktsemajОценок пока нет

- Bolt Action 6Документ10 страницBolt Action 6spartywrxОценок пока нет

- Scythe Peening ManualДокумент16 страницScythe Peening ManualBotan Anderson100% (1)

- Gavel Turning: Woodturning Project Tutorials by Larry HancockДокумент21 страницаGavel Turning: Woodturning Project Tutorials by Larry HancockJaime MontielОценок пока нет

- Screen Printing Press PDFДокумент8 страницScreen Printing Press PDFIndra KusumaОценок пока нет

- Woodworking - Home Made Table Saw Box Joint JigДокумент5 страницWoodworking - Home Made Table Saw Box Joint Jigleehoin100% (2)

- Knife Grinding Jig: DIY Project Guide for Sharpening BladesДокумент13 страницKnife Grinding Jig: DIY Project Guide for Sharpening BladesZarcano FariasОценок пока нет

- Knife Grinding JigДокумент13 страницKnife Grinding JigZarcano FariasОценок пока нет

- AR15 Forging ReceiverДокумент105 страницAR15 Forging ReceiverNO2NWO100% (10)

- Fish Mouth Jig For The LatheДокумент5 страницFish Mouth Jig For The Latheradio-chaserОценок пока нет

- Compass Rose Hand Router FinalДокумент10 страницCompass Rose Hand Router FinalJohnОценок пока нет

- Pen Turning OverviewДокумент3 страницыPen Turning Overviewscooby dooОценок пока нет

- Sweeping Grind TipsДокумент3 страницыSweeping Grind TipskayraОценок пока нет

- Tute 001 Cage PendantДокумент10 страницTute 001 Cage PendantAnonymous uSezVd1L100% (2)

- Wooden Box Project: by Jashan SidhuДокумент20 страницWooden Box Project: by Jashan Sidhuapi-719798768Оценок пока нет

- The Essential Steps to Building a Liner-Lock Folder KnifeДокумент61 страницаThe Essential Steps to Building a Liner-Lock Folder KnifeChris ParsonОценок пока нет

- Absolute Cheapskate Way to Start Making Knives on a BudgetДокумент17 страницAbsolute Cheapskate Way to Start Making Knives on a Budgetalquimico8Оценок пока нет

- How To Make A Ring With Bezel SettingДокумент5 страницHow To Make A Ring With Bezel Settingmobsivac100% (3)

- Knife Making Process Photo GuideДокумент18 страницKnife Making Process Photo GuidePinjaman Peribadi67% (3)

- Shop Made Saw ViseДокумент2 страницыShop Made Saw VisesergiaocunhaОценок пока нет

- A 45° Jaw Set For A Horizontal/Vertical Bandsaw, Version 4: by R.G. Sparber Copyleft Protects This ArticleДокумент9 страницA 45° Jaw Set For A Horizontal/Vertical Bandsaw, Version 4: by R.G. Sparber Copyleft Protects This ArticlekokiskoОценок пока нет

- Making A Wooden Clockworks 2Документ8 страницMaking A Wooden Clockworks 2MiguelDelBarrioIglesisasОценок пока нет

- Consejos de La Sierra de Mesa ByrnesДокумент7 страницConsejos de La Sierra de Mesa ByrnesraidblackОценок пока нет

- Knife SharpeningДокумент19 страницKnife Sharpeninggbrn100% (1)

- Scrapwood Frame Saw: InstructablesДокумент12 страницScrapwood Frame Saw: InstructablesJasmine VaaltynОценок пока нет

- Sig Mosquito Dis-Assemble and Re-AssembleДокумент28 страницSig Mosquito Dis-Assemble and Re-Assemblercol8314100% (1)

- Great Book of Woodworking Tips: Over 650 Ingenious Workshop Tips, Techniques, and Secrets from the Experts at American WoodworkerОт EverandGreat Book of Woodworking Tips: Over 650 Ingenious Workshop Tips, Techniques, and Secrets from the Experts at American WoodworkerРейтинг: 4.5 из 5 звезд4.5/5 (7)

- Boxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopОт EverandBoxes to Build: Sturdy & Stylish Projects to Organize Your Home & ShopОценок пока нет

- Wire-Wrapped & Beaded JewelryОт EverandWire-Wrapped & Beaded JewelryJ. Devlin BarrickРейтинг: 2 из 5 звезд2/5 (1)

- A Method of Dividing The Circumference of A CircleДокумент3 страницыA Method of Dividing The Circumference of A CirclekokiskoОценок пока нет

- Ball Turner Prints PDFДокумент10 страницBall Turner Prints PDFkokiskoОценок пока нет

- Anti-Gravity PropulsionДокумент16 страницAnti-Gravity PropulsionTony FreelandОценок пока нет

- Assessing Potential Propulsion Breakthroughs: Marc G. MillisДокумент21 страницаAssessing Potential Propulsion Breakthroughs: Marc G. MillisnenucarqОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 1769 Compound Rest AssyДокумент1 страница1769 Compound Rest AssykokiskoОценок пока нет

- Quantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadaДокумент32 страницыQuantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadakokiskoОценок пока нет

- Ball Turner PrintsДокумент10 страницBall Turner PrintskokiskoОценок пока нет

- SMD Electrolysis PDFДокумент1 страницаSMD Electrolysis PDFkokiskoОценок пока нет

- Quantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadaДокумент32 страницыQuantum Wave of Life Evolution: Written by DR Kiril Chukanov, June 2009, Calgary, CanadakokiskoОценок пока нет

- UFOДокумент2 страницыUFOkokiskoОценок пока нет

- Anti-Gravity PropulsionДокумент16 страницAnti-Gravity PropulsionTony FreelandОценок пока нет

- WO9010337 Magnetic MotorДокумент23 страницыWO9010337 Magnetic MotorAndras KondratОценок пока нет

- Mysteries of The Unknown - The UFO PhenomenonДокумент162 страницыMysteries of The Unknown - The UFO Phenomenonanaximandre06100% (3)

- RB 7x12 Minilathe BedwaysДокумент2 страницыRB 7x12 Minilathe BedwayskokiskoОценок пока нет

- GAA Bortone June02Документ2 страницыGAA Bortone June02kokiskoОценок пока нет

- Spindle, 7x10, 12 Mini LatheДокумент1 страницаSpindle, 7x10, 12 Mini LatheramaaramaaОценок пока нет

- Evading Thermal Imaging and Radar Detection-1Документ8 страницEvading Thermal Imaging and Radar Detection-1kokiskoОценок пока нет

- Ralph Patterson Speed Reducer 2Документ27 страницRalph Patterson Speed Reducer 2kokiskoОценок пока нет

- Drive TroubleshootingДокумент9 страницDrive TroubleshootingkokiskoОценок пока нет

- Change Gears Charts For Metric Threading On The 7x MiniДокумент2 страницыChange Gears Charts For Metric Threading On The 7x MinikokiskoОценок пока нет

- Ralph Patterson Tailstock Camlock 2Документ13 страницRalph Patterson Tailstock Camlock 2supremesportsОценок пока нет

- Metal Drilling Speed ChartДокумент3 страницыMetal Drilling Speed ChartkokiskoОценок пока нет

- Cross slide nut modification for Grizzly 7x12/24 latheДокумент3 страницыCross slide nut modification for Grizzly 7x12/24 lathekokiskoОценок пока нет

- Rollies Dads MethodДокумент4 страницыRollies Dads Methodctin12Оценок пока нет

- Perreault, Bruce A. U.S. Patent Application Filed May 04, 2007Документ9 страницPerreault, Bruce A. U.S. Patent Application Filed May 04, 2007kokiskoОценок пока нет

- Morse Taper Dimensions and Drill Chuck ArborsДокумент4 страницыMorse Taper Dimensions and Drill Chuck ArborskokiskoОценок пока нет

- r8 5c Collet DimensionsДокумент2 страницыr8 5c Collet DimensionskokiskoОценок пока нет

- How To Make Economical BateryДокумент85 страницHow To Make Economical BaterykokiskoОценок пока нет

- Ball Turning Toolpost - Complete PDFДокумент5 страницBall Turning Toolpost - Complete PDFRamanujam O SОценок пока нет