Академический Документы

Профессиональный Документы

Культура Документы

Sealpac A7

Загружено:

sealpacusaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sealpac A7

Загружено:

sealpacusaАвторское право:

Доступные форматы

Bel_Sealpac_A5_A7_A8_A10.qxd 23.05.

2007 17:22 Uhr Seite 11

fully automated tray-sealing unit SEALPAC A7 SEALPAC A7 fully automated tray-sealing unit

A7

www. casa-blanca-communication.de 2007

THE ALLROUND CLASS

F U L LY A U T O M AT E D TRAY-SEALING UNIT

A7

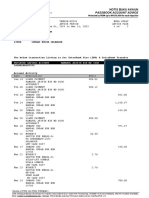

measures in mm

TECHNICAL INFORMATION

Output: up to 100 trays/minute 1)

Capacity: up to maximum 15 cycles/minute 2)

Machine weight: 1,700 kg

Air pressure: min. 6 bar

Connection values: 3 x 400/230 V+N+E

– max. 12 kW 3)

1) Machine outputs quoted refer to packaging mode vacuum/gas for food.

Outputs are generally higher for sealing applications only.

2) Capacity may vary according to tray format and other process data.

3) Connection values vary according to equipment and operation specification.

BG/GS safety tested and certified. All rights reserved for technical modifications.

For excellent service wherever you are.

Your SEALPAC partner:

S EA LPA C – your package to success.

As a high-precision manufacturer, we support our customers in

reaching their targets. We work together to create cost-effective

Ultra flexible.

and guaranteed high-quality solutions. Our flexible and dedica-

ted approach will guide you in exploring individual alternatives

Ultra durable.

to help shape your future.

SEALPAC International bv | Drielandendreef 40a | NL-3845 CA Harderwijk

Telefon: +31 (0) 341 46 20 30 | international@sealpacglobe.de | www.sealpac.eu

Bel_Sealpac_A5_A7_A8_A10.qxd 23.05.2007 17:22 Uhr Seite 13

THE ALLROUND CLASS

F U L LY A U T O M AT E D TRAY-SEALING UNIT

A7 Guaranteed clean and secure. Excellent operation guaranteed.

SIMPLE

SEALPAC A7 stands for innovative flexibility. Operation:

Use it to boost your productivity. Swivel-mounted terminal for Touchscreen panel

ergonomic and left/right-hand with 50 programmes Superior design guarantees perfection down to the very

SEALPAC-packaging systems operate successfully worldwide. This classic all-rounder provides your machine operation and packaging settings last detail. Ergonomic factors for easy handling are crucial

As a high-precession manufacturer, we share our expertise with your company opportunities and guarantees for easy use

process factors.

production. Our full product range is based on the quality standard reliable production runs. With the A7 profi-

Handling via touchscreen

“Made in Germany”. Our support is customised to meet all your tability reaches a new level.

Left/right-hand operation

needs for a specific tray-sealing system. Our solutions are tailored to

Rapid tool change system with all integrated connections

your production and profitability – that means for example lower

Digital film transport system Maximum product security via Pneumatically adjustable stoppers

maintenance costs. via Servo technology adjustable sealing pressure

In brief: state-of-art technology from an experienced manufacturer.

Today's complex production processes more than ever make flexibility

your ace card more than ever. SEALPAC A7 satisfies all needs. With

up to 100 packages per minute, depending on the application

with MAP*, it is excellent for fresh products with varying

production runs.

Our digital film transport technology in combination with Inside Cut

Transparent protective

achieves an optimal film usage on both the single- and twin-lane Tool compartment, easy cover for secure

machines. The Inside Cut system is a SEALPAC invention creating access from both sides production monitoring

cost efficient packages with a visually perfect presentational CLEAN

impact. And all of this comes with trouble-free Hygienic:

integration in existing production

lines. Food industry requires top hygiene standards for best quality.

SEALPAC maintains this quality every time via the sustained

perfection of our machines.

Compact and

systematically Wash down stainless steel frames

designed Protection standard up to IP 65

switchboard

Self draining hygienic construction

Complete sanitation without niches

Checkweighing

option before

Customised product sealing process

accessories for easy

integration

APPLICATIONS

SEALPAC MAP + SYSTEM

SECURE

Faster, fresher packaging,

Te c h n o l o g y :

with more appeal! Our mission is state-of-the-art technology and manufacturing

SEALPAC’s exclusively developed vacuum experience: SEALPAC tray sealing machines are inspirational

and gas-injection system for packaging and give eye catching innovations to the packaging market.

Fresh food requires fast and reliable processing performance. fresh food products via MAP* technology.

Secure guidance for trays in all sequential stages

The SEALPAC A7 processes all sealable materials and is especially Use the benefits with the system:

Trouble-free integration in existing production lines

suited to solutions in continually growing and dynamic markets in reduced product exposure

Interface for external communication

fresh meat and poultry, chees, fresh meat, salami and specially pre- shorter cycle times

High sealing power

pared deep-frozen and a large range of convenience foods. optimized gas figures

Proven Sealpac inside cut system

SEALPAC is the optimal packaging solution for your product. reduced gas consumption

* Modified Atmosphere Packaging

Вам также может понравиться

- Harmony Guide DatabaseДокумент7 страницHarmony Guide DatabaseAya SakamotoОценок пока нет

- Pedagogical Leadership. Baird - CoughlinДокумент5 страницPedagogical Leadership. Baird - CoughlinChyta AnindhytaОценок пока нет

- Manual Reparatie Service Expressor Siemens EQ6Документ47 страницManual Reparatie Service Expressor Siemens EQ6Constantin Popescu100% (1)

- A35D, A40D: Volvo Articulated HaulerДокумент59 страницA35D, A40D: Volvo Articulated HaulerTrọng Nghĩa Võ0% (1)

- Engine GeneralДокумент417 страницEngine GeneralAriel RamirezОценок пока нет

- 2018 Current Order GuideДокумент34 страницы2018 Current Order GuideSimon Ly0% (1)

- English Peugeot - 206 - Owners - Manual - 2002 PDFДокумент148 страницEnglish Peugeot - 206 - Owners - Manual - 2002 PDFWhiskas Thedogg100% (1)

- 6158T Steering Angle 06 13Документ24 страницы6158T Steering Angle 06 13sagarОценок пока нет

- Kalmar DRG420-1300 Reachstacker Brochure en-USДокумент17 страницKalmar DRG420-1300 Reachstacker Brochure en-USflabberОценок пока нет

- Distributor-Catalogue 2017 EN PDFДокумент284 страницыDistributor-Catalogue 2017 EN PDFbuva034Оценок пока нет

- Th545i Specification Sheet EnglishДокумент16 страницTh545i Specification Sheet EnglishVivian Lindenmeyer100% (1)

- ARBURG Packaging Technology 680582 en GBДокумент16 страницARBURG Packaging Technology 680582 en GBketan yadavОценок пока нет

- Seal ModuleДокумент4 страницыSeal ModuleDanhVôОценок пока нет

- Locking Solutions For Every Need: Abloy® Key SystemsДокумент5 страницLocking Solutions For Every Need: Abloy® Key SystemsDenis BaljakОценок пока нет

- Th545i Specification Sheet EnglishДокумент16 страницTh545i Specification Sheet EnglishTamara MonsalveОценок пока нет

- th430 Specification Sheet EnglishДокумент16 страницth430 Specification Sheet Englishnicolas100% (1)

- Ma Pseries Brochure 2019-DigitalversionДокумент6 страницMa Pseries Brochure 2019-DigitalversioneuphoryОценок пока нет

- Ishida ACP-700 Series Case Packer Brochure (6200)Документ10 страницIshida ACP-700 Series Case Packer Brochure (6200)Kundan KumarОценок пока нет

- HermannUltrasonicsDialogSpeed ControlДокумент20 страницHermannUltrasonicsDialogSpeed ControlUrielMGОценок пока нет

- GEA Marine Separator - tcm11 108810Документ16 страницGEA Marine Separator - tcm11 108810Georgiana PopaОценок пока нет

- Volvo BrochureДокумент20 страницVolvo BrochureElbert SowerwineОценок пока нет

- sx2000 - 1Документ16 страницsx2000 - 1KV SAI KIRANОценок пока нет

- A35D, A40D: Volvo Articulated HaulerДокумент59 страницA35D, A40D: Volvo Articulated HaulerTrọng Nghĩa Võ100% (1)

- A35D, A40D: Volvo Articulated HaulerДокумент59 страницA35D, A40D: Volvo Articulated HaulerTrọng Nghĩa VõОценок пока нет

- A35D, A40D: Volvo Articulated HaulerДокумент20 страницA35D, A40D: Volvo Articulated HaulerthiagofortalezaОценок пока нет

- DS-EN System: Pioneering Automatic Door Technology Since 1956 Nabco Automatic Sliding Door OperatorДокумент4 страницыDS-EN System: Pioneering Automatic Door Technology Since 1956 Nabco Automatic Sliding Door Operatordel77Оценок пока нет

- High Variety of Uses Even Under Difficult Conditions.: PK 24001 / 27001 EHДокумент16 страницHigh Variety of Uses Even Under Difficult Conditions.: PK 24001 / 27001 EHMahde KtepОценок пока нет

- Brochure Fisher Easy e Globe Valves en 4541596Документ16 страницBrochure Fisher Easy e Globe Valves en 4541596fernando geredaОценок пока нет

- 1VDD006114 Catalogue SR-SP 36kV-EN 12-2019Документ100 страниц1VDD006114 Catalogue SR-SP 36kV-EN 12-2019ArturОценок пока нет

- Agro Power: Application GuideДокумент486 страницAgro Power: Application GuideMiguel Alexis Posso ZuñigaОценок пока нет

- KMB FL Ze28 en NewДокумент8 страницKMB FL Ze28 en Newvantuan17792Оценок пока нет

- High Performance Trays PDFДокумент9 страницHigh Performance Trays PDFAlan ChewОценок пока нет

- Precisa 321lt LX Ls BrochureДокумент12 страницPrecisa 321lt LX Ls BrochurekevinОценок пока нет

- Leistungsuebersicht Platforms enДокумент26 страницLeistungsuebersicht Platforms ensmilewithbalajithОценок пока нет

- Packaging: Ready For Dynamic PerformanceДокумент19 страницPackaging: Ready For Dynamic PerformanceMuhammad DaniyalОценок пока нет

- PAMPHLET For Final Year ProjectДокумент2 страницыPAMPHLET For Final Year ProjectMuhammad Uzair KamaruddinОценок пока нет

- SY135C4Документ12 страницSY135C4Vieira InvestidorОценок пока нет

- Olex-Flexs Brochure 21092017 3 21Документ9 страницOlex-Flexs Brochure 21092017 3 21Alkris SBОценок пока нет

- Adcole Model 1100Документ5 страницAdcole Model 1100Ankush BhardwajОценок пока нет

- Wide Belt Sanding Machines SANDTEQ W 300 700 en PDFДокумент48 страницWide Belt Sanding Machines SANDTEQ W 300 700 en PDFMesara Kod KokijaОценок пока нет

- StackPack 150 TechsheetДокумент2 страницыStackPack 150 TechsheetmanishОценок пока нет

- Gmi Termination Boards 02122016Документ15 страницGmi Termination Boards 02122016steam100deg8229Оценок пока нет

- BOMAG - Brochure - BF600-700-800-3 - PRE107416 - 2103Документ32 страницыBOMAG - Brochure - BF600-700-800-3 - PRE107416 - 2103Jason TanОценок пока нет

- DAG 1000 MCT - LeafletДокумент2 страницыDAG 1000 MCT - LeafletSüleymanŞentürkОценок пока нет

- JUNE - 2002: The Indispensable Tool For Converters of Flexible PackagingДокумент6 страницJUNE - 2002: The Indispensable Tool For Converters of Flexible PackagingFelipeAndrésLondoñoGrandaОценок пока нет

- Gentex Ground CatalogДокумент43 страницыGentex Ground CatalogȘtefan Bulgaru0% (1)

- #ARaymond ProfileДокумент14 страниц#ARaymond Profilenguyenngoctuan066Оценок пока нет

- 8 - 12t XF Series IC ForkliftДокумент6 страниц8 - 12t XF Series IC ForkliftSrđan HamovićОценок пока нет

- Pre103335 2206Документ28 страницPre103335 2206Marcelo Gustavo Fuentes ValdiviaОценок пока нет

- En Prospekt SPRINTДокумент20 страницEn Prospekt SPRINThe wangОценок пока нет

- Nxt:Gran: Shredder-Feeder-Extruder CombinationДокумент18 страницNxt:Gran: Shredder-Feeder-Extruder CombinationrollandikeОценок пока нет

- Brochure Schuetz Ecobulk en PDFДокумент28 страницBrochure Schuetz Ecobulk en PDFJorge Rubén De León TristanОценок пока нет

- Innova: The Benchmark in Tool CoatingДокумент4 страницыInnova: The Benchmark in Tool Coatingjavier_mor69Оценок пока нет

- Wago-ACSPL Ship Building - Automation & ControlsДокумент24 страницыWago-ACSPL Ship Building - Automation & ControlsPAULОценок пока нет

- Insert: Get A Grip On InsertsДокумент15 страницInsert: Get A Grip On InsertsEnrique ChavezОценок пока нет

- SPMT 696691 - Cometto - Mspe - A4 - enДокумент29 страницSPMT 696691 - Cometto - Mspe - A4 - enMircea PavelОценок пока нет

- Perkin Elmer Lamda 950Документ14 страницPerkin Elmer Lamda 950lovelytitanОценок пока нет

- Brochure Concept enДокумент6 страницBrochure Concept enCarlos E AcostaОценок пока нет

- Catalogue Máy MêДокумент12 страницCatalogue Máy MêTuyen nguyen ngocОценок пока нет

- Valeoscope CV Clutch 2020Документ39 страницValeoscope CV Clutch 2020Mickael HespelОценок пока нет

- Volvo Articulated Haulers A35D A40DДокумент20 страницVolvo Articulated Haulers A35D A40DhuskerchampsОценок пока нет

- Shortform DTS0262Документ84 страницыShortform DTS0262gulatimanish1985Оценок пока нет

- ITP - Plaster WorkДокумент1 страницаITP - Plaster Workmahmoud ghanemОценок пока нет

- Three Revolutionary Architects - Boullee, Ledoux, and Lequeu PDFДокумент135 страницThree Revolutionary Architects - Boullee, Ledoux, and Lequeu PDFTran LeОценок пока нет

- Cultural Practices of India Which Is Adopted by ScienceДокумент2 страницыCultural Practices of India Which Is Adopted by ScienceLevina Mary binuОценок пока нет

- Tourism PlanningДокумент36 страницTourism PlanningAvegael Tonido Rotugal100% (1)

- RHB Islamic Bank BerhadДокумент2 страницыRHB Islamic Bank BerhadVape Hut KlangОценок пока нет

- AT ChapIДокумент48 страницAT ChapIvigneshwaranbeОценок пока нет

- Puratattva No 41Документ3 страницыPuratattva No 41ultimategoonОценок пока нет

- Excel Crash Course PDFДокумент2 страницыExcel Crash Course PDFmanoj_yadav735Оценок пока нет

- Teaching Mathematics Content Through Explicit TeachingДокумент39 страницTeaching Mathematics Content Through Explicit Teachingronna drio100% (1)

- Validación Española ADHD-RSДокумент7 страницValidación Española ADHD-RSCristina Andreu NicuesaОценок пока нет

- Apps Android StudioДокумент12 страницApps Android StudioDaniel AlcocerОценок пока нет

- Excavation Trench Permit Ex 1 F0206Документ5 страницExcavation Trench Permit Ex 1 F0206emeka2012Оценок пока нет

- Routine (27th April)Документ1 страницаRoutine (27th April)SoumitОценок пока нет

- Evolution DBQДокумент4 страницыEvolution DBQCharles JordanОценок пока нет

- Slipform Construction TechniqueДокумент6 страницSlipform Construction TechniqueDivyansh NandwaniОценок пока нет

- DLP - CO#1-for PandemicДокумент4 страницыDLP - CO#1-for PandemicEvelyn CanoneraОценок пока нет

- Changing Historical Perspectives On The Nazi DictatorshipДокумент9 страницChanging Historical Perspectives On The Nazi Dictatorshipuploadimage666Оценок пока нет

- Retirement 01Документ2 страницыRetirement 01Nonema Casera JuarezОценок пока нет

- Eurocode Conference 2023 Seters Van Eurocode 7Документ33 страницыEurocode Conference 2023 Seters Van Eurocode 7Rodolfo BlanchiettiОценок пока нет

- History Homework Help Ks3Документ8 страницHistory Homework Help Ks3afetnjvog100% (1)

- Lecture 11 - Performance AppraisalsДокумент23 страницыLecture 11 - Performance AppraisalsCard CardОценок пока нет

- Aquinas Five Ways To Prove That God Exists - The ArgumentsДокумент2 страницыAquinas Five Ways To Prove That God Exists - The ArgumentsAbhinav AnandОценок пока нет

- 05-11 Trainer Interview QuestionsДокумент8 страниц05-11 Trainer Interview QuestionsqulaityОценок пока нет

- Hayek - Planning, Science, and Freedom (1941)Документ5 страницHayek - Planning, Science, and Freedom (1941)Robert Wenzel100% (1)

- Input and Output Statements PDFДокумент11 страницInput and Output Statements PDFRajendra BuchadeОценок пока нет

- Practical Research 2.9Документ22 страницыPractical Research 2.9Michael GabertanОценок пока нет

- VPZ M BrochureДокумент2 страницыVPZ M BrochuresundyaОценок пока нет

- Using Impact IX49 and 61 With Nektar DAW Integration 1.1Документ21 страницаUsing Impact IX49 and 61 With Nektar DAW Integration 1.1Eko SeynОценок пока нет