Академический Документы

Профессиональный Документы

Культура Документы

How To Implement Leak

Загружено:

jaimeОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

How To Implement Leak

Загружено:

jaimeАвторское право:

Доступные форматы

How to implement leak detection techniques in compressed air

Regularly checking for and repairing leaks in compressed air systems will save your organisation money and cut its carbon emissions.

Compressed air is probably the most expensive energy source on your site. Of the total energy supplied to a compressor, as little as 8% to 10% may be converted into useful energy. The average leak rate in the UK is estimated to be between 20% and 50%,which represents a major cost to businesses, as well as unnecessary carbon emissions.

The business case

Using a contractor to carry out a survey on your site costs around 500 a day. The leak survey shown in Figure 1 took half a day to complete. Ultrasonic detectors cost between 750 and 5,000, depending on their sophistication. Hire costs again vary, depending on the complexity of the machine, but shouldnt be more than 150 per week. Table 1 gives an indication of just how expensive leaks can be depending on their size. The real cost to your business, though, also depends on energy prices and your operating hours. Introducing a programme of detecting and repairing leaks will save you money and though costs vary should pay for itself within a year.

Table 1 Annual cost of air leaks Hole diameter (mm) Air leakage at 7bar (g) litre/s 0.20 1.8 7.1 28 cfm1 0.42 3.8 15 59 0.06 0.54 2.1 8.4 Power to air leaks2 (kW) Cost of leak3 ( year) 48 hours /week 10 95 365 1460 120 hours/ week 26 234 920 3650

0.50 1.5 3.0 6.0

1 Cubic feet per minute 2 Based on 300W/l 3 based on 7 .3p/kWh

How to implement leak detection techniques in compressed air

The technology

Most industrial maintenance staff will have the ability to detect and repair leaks, but you can also choose to use specialist contractors. The three methods outlined beloware the main ways to detect leaks. Listening for a hissing sound The simplest method. This is really only possible when production processes have stopped or in quieter areas. It doesnt give a detailed picture of how big the leaks are, but will indicate where they are. Using soap solution Apply a soap solution to joints. The more bubbles, the larger the leak. Again, you wont get a detailed picture, but you will see where the leaks are and which ones are the worst. This can be very time consuming and messy but can be useful to pinpoint multiple small leaks in a specific area.

Ultrasonic detection You can use this method at any time, even with production processes running. Not only is it the quickest method, it gives an indication of how bad each leak is so that you can work out what the leak is costing you and prioritise repairs. Figure 1 shows the sort of results you can get from an ultrasonic survey. Ultrasonic detectors arent difficult to use, but you need to decide whether to; Use a contractor to carry out the survey. Hire a detector to carry out the survey yourself. Or buy a detector and its software. All three approaches can be used with any compressed air system from small garages to major chemical plants. Your choice of detection method will depend on the size and complexity of the site you need to check. Small systems wont usually need an ultrasonic survey, but large ones will be able to justify the costs.

Figure 1 Example results from an ultrasonic survey

How to implement leak detection techniques in compressed air

Specification checklist

Table 2 takes you through the stages of deciding how to detect leaks and then how to start the process. Table 2 Specification Checklist

Consideration/Action Will you use in-house staff or a contractor to carry out the leak detection? Are there times when production is stopped? If production dosent stop, use ultrasonics or the soap solution method. If youve decided on in-house staff, hire or buy an ultrasonic detector.

Comment Do you have the resources in-house? If so, you can choose any of the three methods. Whether to hire or buy depends on the size of the site and how often you expect to use the detector.

Commissioning checklist

If you decide not to use a contractor, you do need to allow time to train in-house staff and to carry out some basic preparation: Have a drawing of the compressed air distribution system available. Have tags available to identify any leaks you find. Carry out the survey. Mark the leak location on the drawings. Place a tag on each leak to identify it. Calculate the energy and cost losses from the leaks.

If sections of pipework are valved off, there will be no pressure in the line and leaks will not show up. Out-of-date drawings of the air distribution system may not include all parts of the system. Guards or covers may need to be removed to access the leak. It should also be remembered that over time new leaks develop and small ones worsen. Leak surveys should be repeated regularly to maintain low leakage levels.

Finding a supplier

You may already know of a good contractor. If not, the British Compressed Air Society may be able to help. They give technical advice and have a list of companies that offer inspection and maintenance services. You can contact the British Compressed Air Society by phoning 020 7935 2464 or learn more about their services by visiting their website, www.bcas.org.uk

Common problems

Detecting leaks is easier if the production plant is closed down, but there are still some problems you may have to deal with; Other noises, such as steam leaks, can give false results in ultrasonic surveys. Soap solution isnt always an accurate indicator, as the solution can be blown off a large leak. Multiple leaks on a system can make it difficult to identify the largest one. Leaks at high level may be hard to detect without access equipment.

Legal information

Вам также может понравиться

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentОт EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentРейтинг: 4.5 из 5 звезд4.5/5 (3)

- 10 Tips To Optimize Dust Collection System PerformanceДокумент9 страниц10 Tips To Optimize Dust Collection System PerformancePunto MühendislikОценок пока нет

- 10 Rules For Condition Monitoring.Документ8 страниц10 Rules For Condition Monitoring.Zegera MgendiОценок пока нет

- Some Fiber Optic Measurement ProceduresДокумент6 страницSome Fiber Optic Measurement ProceduresAmir SalahОценок пока нет

- Flir Gas Detection GuidebookДокумент40 страницFlir Gas Detection Guidebookkcharles2003Оценок пока нет

- Leak Detection Methods: A Comparative Study of Technologies and Techniques Short VersionДокумент24 страницыLeak Detection Methods: A Comparative Study of Technologies and Techniques Short VersionHappy202180% (5)

- E-Book - Leak Testing in The Automotive IndustryДокумент51 страницаE-Book - Leak Testing in The Automotive IndustryKrishna Mohan T.RОценок пока нет

- Compressed Air Audit - Plant Services 2Документ11 страницCompressed Air Audit - Plant Services 2Swapnil PatadeОценок пока нет

- Cut The Cost and Raise The Reliability of Your InstrumentationДокумент5 страницCut The Cost and Raise The Reliability of Your InstrumentationJulie MerrillОценок пока нет

- Safety 3Документ8 страницSafety 3AsanTubigKoОценок пока нет

- Compressed Gas Leak Detection ServicesДокумент4 страницыCompressed Gas Leak Detection Serviceskeerthisai23Оценок пока нет

- Methods of Refrigerant Leak DetectionДокумент7 страницMethods of Refrigerant Leak DetectionVivek TyagiОценок пока нет

- Varian Leak Detection BrochureДокумент42 страницыVarian Leak Detection BrochureKarthikeyan SankarrajanОценок пока нет

- Events Oilgas 20090914 Picard1Документ18 страницEvents Oilgas 20090914 Picard1sadiqОценок пока нет

- Flow Meter Selection-Craig MarshallДокумент33 страницыFlow Meter Selection-Craig MarshallAlvaro Andres Blanco GomezОценок пока нет

- MaintenanceДокумент10 страницMaintenanceShivaji ThubeОценок пока нет

- GN1 - Good Practice A4 DONEДокумент10 страницGN1 - Good Practice A4 DONEchris655Оценок пока нет

- Bought Cheap, Often Turns Out Expensive. It May Sound Obvious, But They're Words To Live byДокумент3 страницыBought Cheap, Often Turns Out Expensive. It May Sound Obvious, But They're Words To Live byaseОценок пока нет

- SF6 Meas Tech.Документ6 страницSF6 Meas Tech.sameerОценок пока нет

- 230926-A Sensor-Contamination r1p00Документ4 страницы230926-A Sensor-Contamination r1p0027z65mhf9kОценок пока нет

- How To Determine Calibration Frequency For Pipettes in The LabДокумент4 страницыHow To Determine Calibration Frequency For Pipettes in The LabVer Bautista100% (1)

- Meter Selection Guides: Flowmeter Characteristics Comparison SheetДокумент12 страницMeter Selection Guides: Flowmeter Characteristics Comparison SheetBhumik DadhaniaОценок пока нет

- Pipeline Leak Detection TechniquesДокумент10 страницPipeline Leak Detection TechniquesMohamed Alaa100% (1)

- Predictive MaintenanceДокумент17 страницPredictive Maintenancejimmy_d_nasutionОценок пока нет

- GE Paper On Transformer MonitoringДокумент8 страницGE Paper On Transformer MonitoringUmer AdnanОценок пока нет

- Guide To Good Leak TestingДокумент10 страницGuide To Good Leak Testingchristodoulos charalambousОценок пока нет

- Unit One This or That 1Документ9 страницUnit One This or That 1sushantОценок пока нет

- Filtration BasicsДокумент6 страницFiltration Basicsaushad3mОценок пока нет

- LL Dimgatestat PDFДокумент12 страницLL Dimgatestat PDFsalasineОценок пока нет

- Procedure Natural Gas Piping Purging HazardsДокумент4 страницыProcedure Natural Gas Piping Purging HazardsEko KurniawanОценок пока нет

- Lecture - Composition AnalyzersДокумент58 страницLecture - Composition AnalyzersAnonymous b9fcR5Оценок пока нет

- Leak Detection A4 2013Документ17 страницLeak Detection A4 2013Sharon LambertОценок пока нет

- Madule 5Документ17 страницMadule 5Aditya ranjan BubunОценок пока нет

- Derouging & Passivation Webinar - Q&A PDFДокумент4 страницыDerouging & Passivation Webinar - Q&A PDFDheeraj Chowdary DhanekulaОценок пока нет

- Mtro (Fifth Unit)Документ17 страницMtro (Fifth Unit)Selva GanapathyОценок пока нет

- Leak Testing Basic Principles - Background Information of Leaks and Leak Testing From TQCДокумент3 страницыLeak Testing Basic Principles - Background Information of Leaks and Leak Testing From TQCMirza Safeer Ahmad100% (1)

- Filter ManualДокумент53 страницыFilter ManualHazem DiabОценок пока нет

- Vacuum AuditsДокумент8 страницVacuum AuditsBapu612345Оценок пока нет

- XGF GB Feasibility of Vacuum Distillation SystemsДокумент3 страницыXGF GB Feasibility of Vacuum Distillation SystemsTIPAZOОценок пока нет

- Air Gauging BaiscsДокумент36 страницAir Gauging BaiscsAnil MoreОценок пока нет

- Gas SamplingДокумент8 страницGas Samplingmagobo220772100% (1)

- 2K24 - Mrep - Gas Leakage Detection SytsemДокумент23 страницы2K24 - Mrep - Gas Leakage Detection SytsemRaju'K HalgyeОценок пока нет

- Eurovent-4 10Документ32 страницыEurovent-4 10MichaelОценок пока нет

- GC Supelco Troubleshooting 2Документ24 страницыGC Supelco Troubleshooting 2pagumilanoОценок пока нет

- Contol Ebook PDFДокумент71 страницаContol Ebook PDFbab_ooОценок пока нет

- What SF6 Gas TestingДокумент4 страницыWhat SF6 Gas TestingAnonymous V1oLCBОценок пока нет

- Air Compressor Energy Savings:: Finding The Low-Hanging FruitДокумент4 страницыAir Compressor Energy Savings:: Finding The Low-Hanging FruitgurkanarifОценок пока нет

- Improve Refinery Production and Efficiency With Asset MonitoringДокумент11 страницImprove Refinery Production and Efficiency With Asset MonitoringVishwarajОценок пока нет

- 2008CoxPaper - The Benefits of Online DGA Tap Changer MonitoringДокумент6 страниц2008CoxPaper - The Benefits of Online DGA Tap Changer Monitoringlbk50Оценок пока нет

- Leak Survey HandbookДокумент11 страницLeak Survey HandbookebbasinghОценок пока нет

- CalibrationДокумент13 страницCalibrationAmanjit SinghОценок пока нет

- 28-114 UVAS Application Guide PIBДокумент8 страниц28-114 UVAS Application Guide PIBprannoyОценок пока нет

- Robert Lacoste's The Darker Side: Practical Applications for Electronic Design Concepts from Circuit CellarОт EverandRobert Lacoste's The Darker Side: Practical Applications for Electronic Design Concepts from Circuit CellarОценок пока нет

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AОт EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AОценок пока нет

- Aeration Control System Design: A Practical Guide to Energy and Process OptimizationОт EverandAeration Control System Design: A Practical Guide to Energy and Process OptimizationОценок пока нет

- Facility Maintenance Series: Types of Maintenance ProgramsОт EverandFacility Maintenance Series: Types of Maintenance ProgramsРейтинг: 5 из 5 звезд5/5 (1)

- Dimensional Analysis: Practical Guides in Chemical EngineeringОт EverandDimensional Analysis: Practical Guides in Chemical EngineeringОценок пока нет

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsОт EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsРейтинг: 3.5 из 5 звезд3.5/5 (14)

- The First-Time Homeowner's Survival Guide: A Crash Course in Dealing with Repairs, Renovations, Property Tax Issues, and Other Potential DisastersОт EverandThe First-Time Homeowner's Survival Guide: A Crash Course in Dealing with Repairs, Renovations, Property Tax Issues, and Other Potential DisastersРейтинг: 2.5 из 5 звезд2.5/5 (3)

- Alhijama Book PDFДокумент16 страницAlhijama Book PDFSyah MieОценок пока нет

- Graficas de Semana 43 Cumplimiento MPДокумент7 страницGraficas de Semana 43 Cumplimiento MPjaimeОценок пока нет

- Co2 PDFДокумент24 страницыCo2 PDFjaimeОценок пока нет

- Co2 R D I H L CO2 Report and Status in The PlantДокумент21 страницаCo2 R D I H L CO2 Report and Status in The PlantjaimeОценок пока нет

- Work Order - ReportДокумент1 страницаWork Order - ReportjaimeОценок пока нет

- 2009 11 17 Arduino Basics PDFДокумент36 страниц2009 11 17 Arduino Basics PDFgpt1708Оценок пока нет

- Alhijama Book PDFДокумент16 страницAlhijama Book PDFSyah MieОценок пока нет

- Co2 R D I H L CO2 Report and Status in The PlantДокумент21 страницаCo2 R D I H L CO2 Report and Status in The PlantjaimeОценок пока нет

- Compressed Air Energy Savings ProjectsДокумент64 страницыCompressed Air Energy Savings ProjectsjaimeОценок пока нет

- Compressed AIR: Energy Efficiency Reference GuideДокумент0 страницCompressed AIR: Energy Efficiency Reference GuidejaimeОценок пока нет

- Leak Detection MethodsДокумент24 страницыLeak Detection MethodsjaimeОценок пока нет

- Compressed Air Fact Sheet CTДокумент6 страницCompressed Air Fact Sheet CTjaimeОценок пока нет

- Compressed Air GuidelinesДокумент19 страницCompressed Air GuidelinesJhansi RaniОценок пока нет

- Annual Cost of Air LeaksДокумент2 страницыAnnual Cost of Air LeaksjaimeОценок пока нет

- How To Check For LeaksДокумент1 страницаHow To Check For LeaksjaimeОценок пока нет

- Compressed Air 2Документ32 страницыCompressed Air 2jaime100% (1)

- 25 Things You Should Do With LeaksДокумент2 страницы25 Things You Should Do With LeaksjaimeОценок пока нет

- Hydronic Hose Leak CheckДокумент1 страницаHydronic Hose Leak CheckjaimeОценок пока нет

- Conserve Water Outside The HomeДокумент1 страницаConserve Water Outside The HomejaimeОценок пока нет

- A Step by Step Guide ToДокумент4 страницыA Step by Step Guide TojaimeОценок пока нет

- Hydronic Hose Leak CheckДокумент1 страницаHydronic Hose Leak CheckjaimeОценок пока нет

- Home Pressure TestДокумент11 страницHome Pressure TestjaimeОценок пока нет

- How To Detect Gas LeakДокумент4 страницыHow To Detect Gas LeakjaimeОценок пока нет

- Fixing Compressed Air LeaksДокумент2 страницыFixing Compressed Air LeaksjaimeОценок пока нет

- Vacuum LeaksДокумент4 страницыVacuum LeaksPaula Cathrine FloresОценок пока нет

- Us DoeДокумент2 страницыUs DoeFelipe CarvalhoОценок пока нет

- Do e Reparando VazamentosДокумент7 страницDo e Reparando VazamentosLSAQUINOОценок пока нет

- Fix A Leak Week Family Fact SheetДокумент2 страницыFix A Leak Week Family Fact SheetjaimeОценок пока нет

- Conserve Water Outside The HomeДокумент1 страницаConserve Water Outside The HomejaimeОценок пока нет

- Dir SHP2004Документ71 страницаDir SHP2004Deepak AroraОценок пока нет

- Aurora Pump School 101Документ87 страницAurora Pump School 101metropumpsОценок пока нет

- ISWA6 7-000-2 WtE State of The Art Report 2012 Revised November 2013 PDFДокумент210 страницISWA6 7-000-2 WtE State of The Art Report 2012 Revised November 2013 PDFCesar LopezОценок пока нет

- 13.LESER India Catalogue Type 526 IC API Series PDFДокумент12 страниц13.LESER India Catalogue Type 526 IC API Series PDFsatheeshОценок пока нет

- Wellington Middle East UnrestДокумент5 страницWellington Middle East UnrestmariovassarОценок пока нет

- Electrical VivaДокумент5 страницElectrical VivaHari KrishnanОценок пока нет

- 8 - Chitapon - TR Winding Buckling - Paper PDFДокумент5 страниц8 - Chitapon - TR Winding Buckling - Paper PDFbcqbaoОценок пока нет

- 405 488 1 PB PDFДокумент6 страниц405 488 1 PB PDFhadisetiawanОценок пока нет

- Well Site Supervisor or Well Site ForemanДокумент3 страницыWell Site Supervisor or Well Site Foremanapi-77401757Оценок пока нет

- Preparing For The FutureДокумент5 страницPreparing For The FutureRaghu RamanОценок пока нет

- Proposal On Role of Micro Hydro-Power Development in NepalДокумент34 страницыProposal On Role of Micro Hydro-Power Development in NepalAakar ArrjyalОценок пока нет

- ACCR Case Studies Presentation 1-22-13Документ59 страницACCR Case Studies Presentation 1-22-13deepu_erОценок пока нет

- MDKA - 2022 09 05 - JPM Conference PDFДокумент40 страницMDKA - 2022 09 05 - JPM Conference PDFJovi TobingОценок пока нет

- BP090&120 50 HZ TechДокумент24 страницыBP090&120 50 HZ Techmauricio.vidalyork6735Оценок пока нет

- Chapter No.5 Reactor DesignДокумент8 страницChapter No.5 Reactor DesignmichsantosОценок пока нет

- Sacrificial AnodesДокумент4 страницыSacrificial AnodesCK ZeeKei100% (1)

- Company ProfileДокумент8 страницCompany ProfileArun GuptaОценок пока нет

- Pipe Hydrotest ProcedureДокумент3 страницыPipe Hydrotest ProcedurejacquesmayolОценок пока нет

- Previews - ASHRAE 100Документ18 страницPreviews - ASHRAE 100souhaОценок пока нет

- 24 GB - 12 - STD - LOTO - 024 Logout and TagoutДокумент11 страниц24 GB - 12 - STD - LOTO - 024 Logout and TagoutBudi susenoОценок пока нет

- Transformer Manual: Instructions ForДокумент56 страницTransformer Manual: Instructions Fordeepak2628100% (7)

- Battery Catalogue 2014Документ84 страницыBattery Catalogue 2014Chiranjivi Kuthumi100% (1)

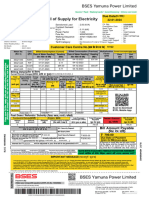

- Connected Load Charge PDFДокумент3 страницыConnected Load Charge PDFckwei0910Оценок пока нет

- SFFECO Profile - PreQualification - 2019 PDFДокумент240 страницSFFECO Profile - PreQualification - 2019 PDFMohammed SbeitanОценок пока нет

- 30 Advanced English Verbs: Vocabulary & Pronunciation Lesson & QuizДокумент4 страницы30 Advanced English Verbs: Vocabulary & Pronunciation Lesson & QuizHamza AfzalОценок пока нет

- Bill of Supply For Electricity: BSES Yamuna Power LimitedДокумент2 страницыBill of Supply For Electricity: BSES Yamuna Power LimitedvoiceofindiapressОценок пока нет

- Housing AffordabilityДокумент13 страницHousing Affordabilityjeanette narioОценок пока нет

- 824 DQ IQ OQ PQ Protocol Mowden Rev 0Документ31 страница824 DQ IQ OQ PQ Protocol Mowden Rev 0Manolo Moreno100% (3)

- Submersbile PumpДокумент8 страницSubmersbile PumpIslam FawzyОценок пока нет