Академический Документы

Профессиональный Документы

Культура Документы

Lab Manual Rear Axle

Загружено:

Ankit G SinghИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lab Manual Rear Axle

Загружено:

Ankit G SinghАвторское право:

Доступные форматы

AIM- Study ,dismantling and assembly of rear axle .

INTRODUCTION- For many years the most popular drive axle assembly was mounted at

the rear of the car . Hence the axle engaged to the side gears in the differential ,drive and rear wheels . each axle is contained in and protected by a rear axle housing. The gear lubricant flows down the long prevent leakage .the axles are supported at one end in the carrier . at the wheel end they are supported by a rear axle bearing placed between the axle and the housing . The wheel supports the weight of the automobile through the axle and bearing to the housing. The rear axle bearing may be sealed ,or it may be lubricated by the oil in the rear axle housing . The axle usually drives the rear wheel through a flange and stud arrangement .The studs on the flange mount to wheel with lug nuts. On another arrangement , the axle has a key or splines that engage a hub to which the wheel is mounted .

TYPES OF REAR AXLE There are three types of rear axle as followed1. LIVE AXLE- It supports part of the weight of the vehicle and drives the wheels connected to the half shafts or axle shafts . 2. DEAD AXLE- A dead axle or non drive axle carries part of the weight ,but does not drive the wheels . 3. INDEPENDENT REAR SUSPENSION TYPE In this type the differential is bolted to the chasis and does not with the suspension .

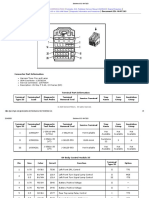

Dismantling Of Rear Axle- According to this first of all

1. Remove six cap screws holding axle housing to transaxle housing, and remove axle assembly. 2. Clean axle housing and transverse mating surfaces. 3. Repeat for other side if necessary. Installation is done in the reverse order of removal. 4. Remove large snap ring from groove of axle housing. 5. Use a press to remove axle shaft from axle housing. 6. Remove remaining snap ring to remove axle shaft components. 7. Inspect axle shaft and housing for wear or damage Replace parts as necessary. 8. Inspect bearing for smooth rotation. Replace if necessary.

NOTE: Ball bearing is not pressed into housing. When placed

in axle housing it may be loose. A clearance up to 0.38 mm (0.015 in.) is normal.

Assembly of Rear Axle- according to this as follows1. Install bearing, seal and snap ring into axle housing. Put spring-side of seal into housing first. 2. Apply petroleum jelly to lips of seal and inner diameter of sleeve. 3. Install snap ring, washer and sleeve on axle shaft. Use a piece of pipe with a minimum inside diameter of 31 mm (1- 3/16 in.) to push sleeve and washer tight against shoulder of shaft. 4. Install axle shaft assembly into axle housing using a press. Press shaft only until a rapid increase in pressure is noticed. 5. Install washer and snap ring on axle shaft.

6. Use a piece of pipe (D) with a minimum inside diameter of 31 mm (1-3/16 in.), maximum outer diameter of 43 mm (1-11/16 in.) and approximately 330 mm (13 in.) long to install snap ring.

Important-Avoid damage! Do not use excessive force to

install axle shaft. Axle housing may be cracked or damaged if too much force is used.

Вам также может понравиться

- N54 Engine Mechanical PDFДокумент17 страницN54 Engine Mechanical PDFRolando Bass Werner100% (1)

- Unitech MIS DataДокумент1 475 страницUnitech MIS DataAkash Gola50% (2)

- Strut and Spring Assembly Disassembly and Assembly PDFДокумент2 страницыStrut and Spring Assembly Disassembly and Assembly PDFMichael HernandezОценок пока нет

- Design of Jigs Fixtures and Press Tools PDFДокумент4 страницыDesign of Jigs Fixtures and Press Tools PDFniharika kadiriОценок пока нет

- WWW - Incar.tw-Kobelco Ck2500 2 Cke2500 2 Crawler Crane Service Shop Repair ManualДокумент5 страницWWW - Incar.tw-Kobelco Ck2500 2 Cke2500 2 Crawler Crane Service Shop Repair Manuallechinh100% (1)

- Body Control Module X5Документ3 страницыBody Control Module X5Men PanhaОценок пока нет

- Cera Hyperplast XR-W40Документ2 страницыCera Hyperplast XR-W40Arun ChaitanyaОценок пока нет

- Alluminio TeoriaДокумент91 страницаAlluminio TeoriaxypangioОценок пока нет

- Pfs PPT 3Документ16 страницPfs PPT 3api-3037204070% (1)

- Ceramic WasteДокумент18 страницCeramic WasteJagdish Prasad MandawraОценок пока нет

- Study On Ready Mix ConcreteДокумент6 страницStudy On Ready Mix ConcreteHafiz FizuОценок пока нет

- AamerДокумент19 страницAamerKlien Parker100% (1)

- Development of Resin Coated Sand: Ravi AutosДокумент5 страницDevelopment of Resin Coated Sand: Ravi AutosInsan KamilОценок пока нет

- K.K.I.W.E.E.R Department of Mechanical Engineering, Nashik 1Документ18 страницK.K.I.W.E.E.R Department of Mechanical Engineering, Nashik 1kshitijОценок пока нет

- Casting: Shival Dubey Assistant Professor Mechanical EngineeringДокумент31 страницаCasting: Shival Dubey Assistant Professor Mechanical EngineeringChirag TaterОценок пока нет

- Sprayed ConcreteДокумент27 страницSprayed ConcreteSharanu PujariОценок пока нет

- Flooring PresentationДокумент30 страницFlooring PresentationNevin PudukadОценок пока нет

- Extrusion Design GuideДокумент12 страницExtrusion Design GuideL.A. AlumíniosОценок пока нет

- Oxalicacidmanufacturing 201231154014Документ18 страницOxalicacidmanufacturing 201231154014Mg H100% (1)

- Faults in Grinding WheelДокумент2 страницыFaults in Grinding WheelVaibhav Vithoba NaikОценок пока нет

- 3 - Foundry&Casting - Shop 1Документ9 страниц3 - Foundry&Casting - Shop 1Mansi NegiОценок пока нет

- Grouts Standards and TestingДокумент12 страницGrouts Standards and TestingmithileshОценок пока нет

- Prefab 2marksДокумент16 страницPrefab 2marksSulthan SuperTrampОценок пока нет

- Design of RivetsДокумент20 страницDesign of RivetsRavishanker BaligaОценок пока нет

- Rose Rosa Deco Tile CatalogueДокумент22 страницыRose Rosa Deco Tile Cataloguegoji0% (1)

- Module 2Документ54 страницыModule 2akash kumarОценок пока нет

- Aerated Concrete Production Using Various Raw MaterialsДокумент5 страницAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- CON2910 Project B Basic Wood Joinery NotesДокумент8 страницCON2910 Project B Basic Wood Joinery NotesEd PawliwОценок пока нет

- For Wood Cutter MachineДокумент19 страницFor Wood Cutter MachineRahul Rajput100% (1)

- Good Practices in Civil WorksДокумент33 страницыGood Practices in Civil Worksமாறன் செங்கேணிОценок пока нет

- Pointing Building Construction Finishing @KivipPdfДокумент18 страницPointing Building Construction Finishing @KivipPdfbirukОценок пока нет

- Surface EngineeringДокумент43 страницыSurface Engineering10rajОценок пока нет

- Prefaricated Structures Unit IIДокумент55 страницPrefaricated Structures Unit IIvgshankar26Оценок пока нет

- Roof TileДокумент10 страницRoof TileAshutosh PrateekОценок пока нет

- Block Egg LayingДокумент17 страницBlock Egg LayingDebasishSwainОценок пока нет

- Batching, Mixing, Placing and Compaction of ConcreteДокумент7 страницBatching, Mixing, Placing and Compaction of ConcreteRommel Villaroman EstevesОценок пока нет

- Glass: Submitted By: Manav Batch 19 Submitted To: Soniya TiwariДокумент35 страницGlass: Submitted By: Manav Batch 19 Submitted To: Soniya TiwarimanavОценок пока нет

- Different Types of Compaction EquipmentsДокумент11 страницDifferent Types of Compaction EquipmentsNinad Kshirsagar100% (1)

- Creo Tool Design: PrerequisitesДокумент23 страницыCreo Tool Design: PrerequisitesLucianОценок пока нет

- Project Report On Composite Sleepers (17102023) - Maam CorrectionДокумент44 страницыProject Report On Composite Sleepers (17102023) - Maam Correctionsmitirupa.pradhanfmeОценок пока нет

- Mineral Casting As Material For Machine Base Frames of Precision MachinesДокумент4 страницыMineral Casting As Material For Machine Base Frames of Precision MachinesrahulkumbharkarОценок пока нет

- General Tyre and Rubber CompanyДокумент44 страницыGeneral Tyre and Rubber Companyrashid100% (1)

- Paints Final Assignment 6th NovДокумент8 страницPaints Final Assignment 6th NovGlobal PMCОценок пока нет

- Identify The Available Construction Materials in The Laboratory On The Basis of Their SourceДокумент32 страницыIdentify The Available Construction Materials in The Laboratory On The Basis of Their SourceR 34 Arya RoyОценок пока нет

- Types of Blocks: S. S. KambleДокумент13 страницTypes of Blocks: S. S. KambleSushant WaghmareОценок пока нет

- Experimental Study On Bamboo Reinforced BeamДокумент32 страницыExperimental Study On Bamboo Reinforced BeamPraveen RajОценок пока нет

- Flat Slab - Types of Flat Slab Design and Its AdvantagesДокумент7 страницFlat Slab - Types of Flat Slab Design and Its AdvantagesnandanaОценок пока нет

- Submission: X' S2 of S2Документ1 страницаSubmission: X' S2 of S2Varalika SahuОценок пока нет

- Pfs PPT 2Документ27 страницPfs PPT 2api-303720407Оценок пока нет

- RCC Chaukath Making MachineДокумент9 страницRCC Chaukath Making MachineShibinMohammedIqbalОценок пока нет

- AbrasivesДокумент86 страницAbrasivesHuron Industrial SupplyОценок пока нет

- Is 3115 - 1992 (Lime Based Blocks)Документ8 страницIs 3115 - 1992 (Lime Based Blocks)satnam1979Оценок пока нет

- Precast Concrete Slab: Here Starts The Lesson!Документ55 страницPrecast Concrete Slab: Here Starts The Lesson!Kimberly LoОценок пока нет

- Brick BondДокумент29 страницBrick BondArchana AcchuОценок пока нет

- Catalogue Shotcrete MachineДокумент6 страницCatalogue Shotcrete MachineSushmit SharmaОценок пока нет

- Pattern MaterialsДокумент16 страницPattern MaterialsMani Kandan100% (1)

- Concrete Masonry ReportДокумент21 страницаConcrete Masonry ReportPrincess Earl Dianne LaderaОценок пока нет

- Tips & More: For Economical DesignДокумент4 страницыTips & More: For Economical DesignLuis Horacio Martínez MartínezОценок пока нет

- Partition - Metal StudДокумент27 страницPartition - Metal StudJaiОценок пока нет

- Lecture-1 Introdution To Machine DrawingДокумент23 страницыLecture-1 Introdution To Machine DrawingGurpreet MeeluОценок пока нет

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionОт Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotОценок пока нет

- 80-96 F150 2 1/2" Lift Kit InstructionsДокумент4 страницы80-96 F150 2 1/2" Lift Kit Instructionsisaacllugo1Оценок пока нет

- Change Procedure of Hub BearingsДокумент4 страницыChange Procedure of Hub BearingsRadu DumbravaОценок пока нет

- Jaypee Greater Noida ComplaintsДокумент4 страницыJaypee Greater Noida ComplaintsAnkit G SinghОценок пока нет

- Guest ListДокумент8 страницGuest ListAnkit G SinghОценок пока нет

- 505, Hemkunt Chambers, 89 Nehru Place, New Delhi - 110 019: Developers Township Property Owners Welfare Society ® (Dtpows)Документ3 страницы505, Hemkunt Chambers, 89 Nehru Place, New Delhi - 110 019: Developers Township Property Owners Welfare Society ® (Dtpows)Ankit G SinghОценок пока нет

- 29d95MTT 305Документ1 страница29d95MTT 305Ankit G SinghОценок пока нет

- Rent Date Tick Electricity Date Tick January February March April May June July August September October November DecemberДокумент4 страницыRent Date Tick Electricity Date Tick January February March April May June July August September October November DecemberAnkit G SinghОценок пока нет

- German NotesДокумент22 страницыGerman NotesAnkit G SinghОценок пока нет

- Market ResearchДокумент9 страницMarket ResearchAnkit G SinghОценок пока нет

- Auto Manual 2011 LJIETДокумент33 страницыAuto Manual 2011 LJIETAnkit G SinghОценок пока нет

- 57e0dinternship Not Submitted 20052013Документ10 страниц57e0dinternship Not Submitted 20052013Ankit G SinghОценок пока нет

- "Solar Cooker": Uttar Pradesh Technical University, Lucknow (India)Документ67 страниц"Solar Cooker": Uttar Pradesh Technical University, Lucknow (India)Ankit G SinghОценок пока нет

- Parts Manual Takeuchi TB290Документ389 страницParts Manual Takeuchi TB290Aleksandar RadovićОценок пока нет

- 03 Intermodal Routing Canada-Mexico PDFДокумент15 страниц03 Intermodal Routing Canada-Mexico PDFiruiz85Оценок пока нет

- E-Class Specifications: E 320 Sedan E 320 Wagon E 500 Sedan E 500 4 Wagon E 55 Amg Sport SedanДокумент29 страницE-Class Specifications: E 320 Sedan E 320 Wagon E 500 Sedan E 500 4 Wagon E 55 Amg Sport SedanSalmaanHajeeSheriffОценок пока нет

- CSCP Pretest Questions For Quick Review (APICS)Документ11 страницCSCP Pretest Questions For Quick Review (APICS)sasharma82Оценок пока нет

- Assignment Society (T)Документ5 страницAssignment Society (T)Noor FatihahОценок пока нет

- 18MRH-X242A Axle Service ManualДокумент60 страниц18MRH-X242A Axle Service Manualheiner duran100% (1)

- Lamborghini Murcielago SV LP 670 4 Spare Parts 2010Документ20 страницLamborghini Murcielago SV LP 670 4 Spare Parts 2010christina100% (38)

- Aircraft Landing Gear System: Presented By: Rishikesh K. Singh Roll No. 134103054 Guided by Dr. Ujjwal Kumar SahaДокумент39 страницAircraft Landing Gear System: Presented By: Rishikesh K. Singh Roll No. 134103054 Guided by Dr. Ujjwal Kumar SahaindahОценок пока нет

- Bishnupriya Manipuri Online Digest June 2012 IssueДокумент50 страницBishnupriya Manipuri Online Digest June 2012 Issuebishnupriyamanipuri.blogspot.comОценок пока нет

- Ch-5 GSKДокумент13 страницCh-5 GSKDeepu RaiОценок пока нет

- TRIP Moving South Carolina Forward Report September 2021Документ21 страницаTRIP Moving South Carolina Forward Report September 2021WMBF NewsОценок пока нет

- Glossary of Ocean Cargo Insurance TermsДокумент57 страницGlossary of Ocean Cargo Insurance TermsDimitrios PhilippopoulosОценок пока нет

- Item Master Form: Tab/Side Buttons Field Group Field TypeДокумент32 страницыItem Master Form: Tab/Side Buttons Field Group Field TypeniravmodyОценок пока нет

- W211 E 500 Oil ChangeДокумент3 страницыW211 E 500 Oil Changeniladam2002Оценок пока нет

- YDIP - Yearly Safety Drills Plan-Table A3-Edition 2 Rev 1Документ3 страницыYDIP - Yearly Safety Drills Plan-Table A3-Edition 2 Rev 1im túОценок пока нет

- 10 Design Loads On Bridges - Highway & Rail Bridge - Miscellaneous LoadsДокумент3 страницы10 Design Loads On Bridges - Highway & Rail Bridge - Miscellaneous LoadsfaridullahОценок пока нет

- Lecture 3 Mechanistic-Empirical Pavement Desing Flex and RigidДокумент56 страницLecture 3 Mechanistic-Empirical Pavement Desing Flex and RigidThe HackerОценок пока нет

- 120 SXJ Operation - 3121809 - 05-30-02 - CE - EnglishДокумент80 страниц120 SXJ Operation - 3121809 - 05-30-02 - CE - EnglishrajОценок пока нет

- 1DX 28199 20 PDFДокумент100 страниц1DX 28199 20 PDFMihai LucianОценок пока нет

- STRAIL Installation Instructions 03Документ7 страницSTRAIL Installation Instructions 03Link LinkadoОценок пока нет

- Aero BertaReportДокумент6 страницAero BertaReportaklracingОценок пока нет

- Leaflet C-HR 2022Документ4 страницыLeaflet C-HR 2022Obito UchihaОценок пока нет

- Ticket Enquiry: Onward Journey Ticket DetailsДокумент2 страницыTicket Enquiry: Onward Journey Ticket DetailsRohit VermaОценок пока нет

- 1 s2.0 S2468013315300127 MainДокумент10 страниц1 s2.0 S2468013315300127 Maintomo1973Оценок пока нет

- M 3 Toll Rates Lahore Abdul Hakeem KM 228 2Документ7 страницM 3 Toll Rates Lahore Abdul Hakeem KM 228 2kaleem ullah janОценок пока нет

- Mahesh X 21 - Georgia Tour 07 Nights - AmendedДокумент7 страницMahesh X 21 - Georgia Tour 07 Nights - AmendedPriya SubuОценок пока нет