Академический Документы

Профессиональный Документы

Культура Документы

Sieverts Apparatus and Methodology For Accurate Determination of Hydrogen Uptake by Light-Atom Hosts

Загружено:

Saumya SinhaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sieverts Apparatus and Methodology For Accurate Determination of Hydrogen Uptake by Light-Atom Hosts

Загружено:

Saumya SinhaАвторское право:

Доступные форматы

Journal of Alloys and Compounds 446447 (2007) 692697

Sieverts apparatus and methodology for accurate determination of hydrogen uptake by light-atom hosts

T.P. Blach, E.MacA. Gray

Nanoscale Science and Technology Centre, Grifth University, Brisbane 4111, Australia Received 27 September 2006; received in revised form 5 December 2006; accepted 18 December 2006 Available online 21 December 2006

Abstract Accurate determination of the quantity of hydrogen absorbed by a potential hydrogen storage material is crucial to progress in the eld. The most common techniques for measuring hydrogen uptake from the gas phase by a solid host, the Sieverts technique and gravimetry, both become susceptible to systematic errors as the density of the host material decreases. We focus here on the Sieverts technique, which in a poorly designed apparatus may produce errors 100% in the quantity of absorbed hydrogen owing to a realistic 25% error in the density of a light-atom sample. Using hydrogen absorption isotherms measured for low-density materials, including carbon nanotubes, potassium-intercalated graphite and lithium nitride, we show that designing the Sieverts apparatus with carefully chosen volumes greatly lessens the impact of uncertainty in the sample density. Rules-of-thumb for the volumes in the apparatus and the volume occupied by the sample itself, and a gure of merit for the sensitivity of the system to changes in the hydrogen content of the sample, are introduced. 2007 Elsevier B.V. All rights reserved.

Keywords: Hydrogen absorbing materials; Nitride materials

1. Introduction Reliable measurement of hydrogen uptake in the laboratory is a vital prerequisite to the real-world application of new hydrogen storage materials, especially to verify claims in the literature and to facilitate meaningful comparisons between sample preparation routes. Interest in high-capacity solid-state hydrogen storage hosts with non-metallic character, based on light elements, especially Li, B, C, N, Mg and Al, is rising rapidly in the pursuit of the US Department of Energy mass density criteria (6 wt.% by 2010; 9 wt.% by 2015) [1]. These materials have much lower densities than classic metal-H systems such as LaNi5 -H2 . We show here that this fact has ramications for the accurate determination of the mass density of absorbed or adsorbed hydrogen. The most common techniques for measuring hydrogen uptake by a solid host are the Sieverts (manometric) technique and gravimetry, with the focus of this work being on the former technique owing to its practicability and very widespread

Corresponding author. Tel.: +61 7 3735 7240; fax: +61 7 3735 7656. E-mail address: E.Gray@grifth.edu.au (E.MacA. Gray).

use. The Sieverts technique is cheap, robust, portable, simple and, when practised with reasonable care, universally accepted as accurate. In the Sieverts technique, a calibrated reference volume is lled with gas to a measured pressure and then opened to the sample chamber, the gas uptake by the sample being calculated from the change in the gas pressure in the system. Hydrogen uptake is represented here by the hydrogen-to-host atomic ratio, H/X, by analogy with the hydrogen-to-metal ratio for a metal, H/M. The authors became aware [2] of problems with the credibility of measurements of hydrogen uptake by low-density hosts using the Sieverts technique, in which a modest uncertainty in the density of the sample was observed to lead to an amplied uncertainty in the hydrogen concentration in the host. Whereas the need to measure temperature and pressure accurately is obvious and widely accepted, the problem of accounting for the sample volume turns out to be more subtle and potentially much more detrimental to the measurement of H/X. The Sieverts technique is sensitive to the density of the sample because the volume occupied by the sample must be subtracted from the volume of the empty sample cell in order to calculate H/X. The difculty then arises of dening and accurately measuring the volume occupied by a low-density sample with

0925-8388/$ see front matter 2007 Elsevier B.V. All rights reserved. doi:10.1016/j.jallcom.2006.12.061

T.P. Blach, E.MacA. Gray / Journal of Alloys and Compounds 446447 (2007) 692697

693

an effective dimensionality between 2 and 3 owing to its pore structure or a high surface-to-volume ratio. In an extreme case, such as carbon nanofoam [3], it may be practically impossible to dene the material density. Furthermore, the X-ray density of a new starting material may not be known until a structure determination has been done, a problem compounded by any change in the sample density owing to hydrogen uptake. The sample volume problem has been pointed out before [4] in the context of high-pressure measurements, but we show here that the problem also occurs at pressures of a few bar. We note that the alternative gravimetric technique, in which the change in the weight of the sample owing to gas uptake is measured, is likewise sensitive to the sample volume through buoyancy forces on the components of the system immersed in the gas. As the buoyancy force on a system component is the weight of the gas displaced by it, the volume of the sample and hence its density enter the calculation, with the density of the sample becoming more important as it decreases. This paper reports our ndings from experiments and simulations in which real experimental data taken with the Sieverts technique were re-analysed assuming that the density of the sample varied in a range of 25% about its nominal value. The aim was to construct some design rules which would minimise the sensitivity of the calculated value of H/X to uncertainty in the sample density, while maintaining acceptable sensitivity to changes in the hydrogen content of the sample. 2. Sieverts technique for measuring hydrogen uptake Fig. 1 shows a generic Sieverts hydrogenator on which the following analysis is based. The analysis applies in principle to any gas. The measurement of hydrogen uptake is made stepwise. Suppose that, at the end of the k 1th step, a pressure psys of hydrogen is present throughout the hydrogenator, which we refer to as the system pressure. The gas in the reference volume is at temperature Tref and the gas in the sample cell is at Tcell . The connecting valve, S, is closed to isolate the sample cell, which has an empty volume Vcell . A new pressure pref at temperature Tref is established in the reference volume, Vref . S

is then opened and a new value psys is measured, along with new values of Tref and Tcell . The number of moles of hydrogen atoms absorbed (we will simply say absorbed to mean absorbed or adsorbed) or desorbed by the sample in the kth step, nk H , is then calculated from the change in the pressure measured when S is opened: nk H =2 pk pk sys ref Vref k k k k )RT k k Z(pref , Tref )RTref Z(psys , Tref ref pk sys

k k Z(pk sys , Tcell )RTcell

1 pk sys 1 k 1 k 1 Z (p k sys , Tcell )RTcell

Vcell

mX (nk H) k X (nH )

(1)

where Z is the compressibility of a real gas, dened by modifying the ideal gas law such that pV/nRT = Z rather than one. The total change in the hydrogen content of the sample after N steps is nN H =

N k=1

nk H.

Eq. (1) simply accounts for all the gas in the system and has been written so as to expose the dependence of the calculation on the volume of sample present in the cell, VX = mX /X . Note that the mass of the sample, mX , and its density, X , depend in general on its hydrogen content. As the measurement relies on changes in the pressure in the system owing to absorption or desorption of hydrogen by the sample, a gure of merit which relates to the system resolution and accuracy is a helpful design parameter. Consider the evolution of the pressure in the hydrogenator during the kth step, and momentarily omit the index k for convenience. Once the connecting valve S has been opened and the ideally instantaneous change in pressure owing to the larger volume sampled by the pressure transducer has occurred, the system is isochoral (constant volume) and the number of moles of hydrogen contained as gas and in the sample is constant: 2 psys R Vj + nH = constant, Z(p, Tj )Tj (2)

where the sum runs over all the volumes in the hydrogenator, Vref and Vcell in the simplest case under consideration. The change in the hydrogen content of the sample is therefore reected in a change in the system pressure which is given, according to Eq. (2), by nH = 2 psys R Vj . Z(psys , Tj )Tj

Fig. 1. Minimal Sieverts apparatus for determining the uptake of gas atoms or molecules by the sample contained in a cell with empty volume Vcell , based on the initial pressure of gas in Vref and a further measurement of pressure after the valve S has been opened.

Using the denition of H/X, the isochoral constraint may then be expressed in terms of the time evolution of the system pressure as the hydrogen is absorbed or desorbed during the kth step according to the kinetics of the sample:

k pk sys (t ) = psys (0) sk

H X

694

T.P. Blach, E.MacA. Gray / Journal of Alloys and Compounds 446447 (2007) 692697

where psys (0) is the system pressure immediately after the valve S has been opened, before any change in nH has occurred, and sk is the slope of the isochore for the kth step: sk = nX R 2

j k k Vj /Z(pk sys , Tj )Tj

sk indicates the sensitivity of the system to changes in H/X, as measured by changes in the system pressure, and so helps to quantify the performance of the hydrogenator. To arrive at a gure of merit for the hydrogenator we compare sk to the performance of the pressure transducer, P in Fig. 1. If the full-scale range of the pressure transducer is F and its relative accuracy is , the useable resolution of the transducer is p = F. The performance of the hydrogenator will improve as F decreases relative to the change in pressure ( psys ) accompanying a change in hydrogen content of the sample, and also as decreases. Therefore, we propose a gure of merit: sk (3) = . p with 100 being a suitable rule of thumb for obtaining data of high quality in our experience, in the absence of errors in the volumes or sample density. 3. Effect of uncertain sample density The premise of the Sieverts technique is that accurate values for all the parameters in Eq. (1) are known at the end of the kth step, most fundamentally the volumes that comprise the system. Eq. (1) shows that uncertain knowledge of the sample volume (via its mass and density) and cell volume affect the calculation as if an error had occurred in the calibration of the hydrogenator. If expansion accompanies absorption by the sample, the sample volume cannot be assumed to be constant. This effect needs then to be allowed for by calculation, which might not be feasible, or, preferably, by designing out the sensitivity to it. Partially differentiating Eq. (1) with respect to density shows that (a) the effect of a change in density on the calculated hydrogen uptake depends on 2 , conrming the increased sensitivity to low but uncertain sample densities, and (b) the dependence on the actual instantaneous conditions of p, V and Z is complicated and not amenable to analytic analysis. Simulation was therefore employed to explore the consequences of inaccurately known sample density and, for comparison, compressibility and volumes (see Section 4). Experimental isotherms measured on several sets of Sieverts apparatus were re-analysed with Eq. (1) using a range of assumptions for the density of the sample. The most signicant differences between the various experimental setups were in the ratio of the reference volume, Vref , to the empty volume of the sample cell, Vcell , and in the fraction of the cell volume actually occupied by sample. Fig. 2 shows an isotherm measured for a sample of potassiumintercalated graphite with nominal density 2.0 g/cc. Varying the assumed density by 25% produced alarming changes 100% in the apparent quantity of adsorbed hydrogen. Given the difculty in dening the meaning of density for this low-dimensional

Fig. 2. Effect of a 25% change in sample density on the apparent hydrogen uptake of C24 K at room temperature, measured in a system of insufcient volume relative to the volume of sample.

system, the measurements are rendered meaningless. While high pressures were applied, the error in the apparent quantity of absorbed hydrogen was already extreme at a few tens of bar hydrogen pressure. Fig. 3 shows an isotherm measured for a sample of multiwalled carbon nanotubes with nominal density 1.5 g/cc in a second Sieverts apparatus. The apparent quantity of absorbed hydrogen owing to a 25% variation in assumed sample density is moderate at 10%. Fig. 4 shows an isotherm measured with a third Sieverts apparatus for a sample of lithium nitride at 285 C with nominal density 1.294 g/cc, calculated from the lattice parameters at room temperature [5]. In this case the amount of apparent hydrogen absorption changes by only 0.1% in response to a change in the assumed density of to a change in the assumed density of 25%, despite having the lowest sample density of those studied. Fig. 5 shows an isotherm for the LaNi5 -H2 system and reinforces the occurrence of the problem only among samples of low

Fig. 3. Effect of a 25% change in sample density on the apparent hydrogen uptake of a sample of carbon nanotubes at room temperature, measured in a system which is fairly large compared to the volume of sample.

T.P. Blach, E.MacA. Gray / Journal of Alloys and Compounds 446447 (2007) 692697

695

Table 1 Comparison of the sensitivity of the calculated hydrogen-to-host atomic ratio to a change in the assumed density of the sample, for three examples of lowdensity materials studied with sets of Sieverts apparatus with varying ratios of the system, cell and sample volumes Vsys /Vcell Vsys /Vsam Vcell /Vsam Sensitivity to density Refers to gure 6.2 47.8 7.7 High 100 approx. 2 10.3 273.7 26.7 Moderate 150 approx. 3 2.1 2978 1393 Low 85 approx. 4

is the gure of merit for the usable sensitivity of the Sieverts apparatus dened in Eq. (3).

Fig. 4. Effect of a 25% change in sample density on the apparent hydrogen uptake of a sample of Li3 N at 285 C, measured in a system which is very large compared to the volume of sample and has comparable reference and empty-cell volumes, Vref and Vcell in Eq. (1).

Fig. 5. Absorption isotherm of a relatively dense sample, LaNi5 . Note the insensitivity of the result to variations in the sample density, even though the ratio of the system volume to the cell volume is about the same as in Fig. 2.

density. Here the ratio of system to cell volume is similar to the worst case shown in Fig. 2, but the sample density is higher and the volume occupied by the sample is relatively smaller, leading to an acceptable error 0.2% in the quantity of H absorbed when the 24% expansion of the hydride relative to the metal is ignored altogether. 4. Discussion Ones rst intuition that insensitivity to the sample density will be conferred by making the sample cell volume a small fraction of the system volume is wrong. Table 1 summarises the ndings of the simulation experiment. Just shrinking the cell volume does not achieve the desired outcome. Likewise, a small sample in a cell which is itself a small fraction of the total system volume is not completely effective (Fig. 3). The best outcome was obtained with comparable reference and cell volumes and a sample which occupied a small fraction of the

system volume (Fig. 4). This may be rationalised as follows. The vulnerability of the Sieverts technique is that it relies on calculating the quantity of hydrogen exchanged with the sample in the kth step by the subtraction of two relatively large numbers, which are the amounts of hydrogen in the system before and after the kth step. If the cell volume is very small, the system pressure, pk sys in Eq. (1), will not be much different from the pressure in the reference volume, pk ref , that initiated it. If Vref is fairly large, the rst term in Eq. (1) will then be of moderate magnitude. However, the change in system pressure between the kth and (k + l)th steps may be large if the isotherm contains a small number of points, and this difference amplies the volume term containing the difference between the empty-cell and the sample volumes, making it also of moderate magnitude. Thus there is the potential for a large effect on the calculated quantity of hydrogen exchanged with the sample owing to an error in the volume occupied by the sample, implicating the sample density. The approach of making both Vref and Vcell large compared to the notional volume of sample needs to be balanced against the gure of merit for the system (Eq. (3)), which will degrade as the system volume becomes too large unless a pressure transducer of increased accuracy is employed. Considering Fig. 4, we note that the total quantity of absorbed H is larger than expected from the limiting Li3 NH4 stoichiometry by some 2.5%. The limitation on the accuracy of this measurement is most likely the marginal sensitivity of the system ( < 100), which exposes the results to systematic errors in the pressure readings. It is not possible to precisely dene the optimum ratio of volumes because of the complicated dependence of the systematic error in H/X caused by a density error on p, T and Z: there is no single setup that is optimum for all conditions of pressure and temperature, but it is certainly possible to greatly lessen the sensitivity of the results to uncertain sample density by following the rules-ofthumb proposed here. A common approach to the problem of dening the volume of the sample is to measure the effective volume of the loaded sample cell with an inert gas. The validity of this procedure is undoubted where the sample has a three-dimensional morphology and its density does not change owing to hydrogen absorption. Particularly in the case of the latter reality, however, the problem of uncertain density is still present and the system should be designed to minimise its effect. Furthermore, even He

696

T.P. Blach, E.MacA. Gray / Journal of Alloys and Compounds 446447 (2007) 692697

Fig. 6. Effect of a 1% change in compressibility on the isotherm in Fig. 2. The spread of values is indicated by the dashed lines. Note the insensitivity to compressibility and, therefore temperature and pressure accuracy, relative to sample density.

Fig. 7. Effect of a 1% change in sample cell volume on the isotherm in Fig. 4, illustrating the necessity to accurately calibrate Vcell with respect to Vref .

is reported to adsorb onto activated carbon and zeolites [6] and onto single-walled carbon nanotubes [7] at 300 C, raising serious doubts about the accuracy of this approach unless great care is taken with the determination of the so-called helium density of the sample. Comparing Figs. 2 and 5 (roughly equivalent setups) exposes the aw in a popular method of checking the performance of a Sieverts system, that of rst measuring LaNi5 as a de-facto standard. As its density is high, an accurate determination of hydrogen content may well be made on LaNi5 , but this does not guarantee a good result with samples of low density. Recent papers [7,8] advocate a modied Sieverts technique based on the pressure difference between identical reference and sample arms. In our view this approach, while achieving high sensitivity, is still vulnerable to systematic errors caused by uncertain sample density, as the results were shown to depend strongly on calibration of the effective volume of the loaded sample cell. The verication of performance made using LaNi5 in Ref. [8] is therefore not conclusive, for the reason given above. Lastly, we compare the effect of uncertainty in the sample density to the effect of uncertainties in the measured or calculated parameters p, T and Z and in the relative volumes of the sample cell (Vcell ) and the reference volume (Vref ). As Eq. (1) depends on the rst power of p, T and Z, uncertainties in their values affect the calculation in essentially the same way. Fig. 6 shows the effect on the isotherm in Fig. 2 of a 1% change in all the values of Z in Eq. (1), representing a realistic systematic error in the compressibility. Z was calculated using a modied van der Waals equation [9] which was solved numerically [10] with accuracy better than 0.1% in the range of our data. As the effect of uncertain Z is very small compared to the effect of the 25% assumed uncertainty in sample density, this comparison demonstrates that the density problem is very signicant compared to the likely uncertainties in p, T and Z, which should all be kept small compared to 1% by design anyway to ensure high-quality results. Regarding the effect of an inaccurate volume calibration [4], inspection of Eq. (1) shows that the change in H/X in every step depends on the absolute

reference volume in the same linear way. As the calibration of absolute volumes is easy to perform to an accuracy better than 1%, this is a minor effect compared to the density problem in a poorly designed system. In contrast, Eq. (1) also shows that the results have the same sensitivity to the empty-cell volume, Vcell , as to the volume occupied by the sample. While increasing Vcell to be comparable to Vref mitigates the sample density problem, it consequently becomes important to carefully calibrate Vcell against Vref to maintain accuracy. Fig. 7 shows the effect on the isotherm in Fig. 4 of a 1% error in Vcell with Vref held constant. The ratio Vcell //Vref must therefore be determined as accurately as the uncertainties in p, T and Z allow. 5. Conclusions By simulating the effect of unknown or wrong density for samples of low density in several sets of Sieverts apparatus, we have developed rules-of-thumb for designing a system which limit the effect of the density uncertainty on the calculated quantity of hydrogen in the sample. These rules are (i) ensure that the reference volume and the empty-cell volume are (a) both large compared to the volume notionally occupied by the sample, by a factor of at least 100 in each case, and (b) ideally about equal; (ii) ensure a gure of merit for the hydrogenator (Eq. (3)) of at least 100. Demonstrating accurate results with a relatively dense standard sample such as LaNi5 does not guarantee accuracy with low-density samples. In a poorly designed system the density problem may be much more signicant than feasible errors in system variables or volume calibrations. System variables (p, T, Z) should be determined with accuracy signicantly better than 0.1%. The ratio of the sample cell volume to the reference volume should be calibrated to better than 0.1%. Acknowledgement The authors thank E.A. Burt for the data on which Figs. 4 and 7 are based.

T.P. Blach, E.MacA. Gray / Journal of Alloys and Compounds 446447 (2007) 692697

697

References

[1] Hydrogen Storage Technologies Roadmap. URL: http://wwwl.eere.energy. gov/vehiclesandfuels/pdfs/program/hydrogen storage roadmap.pdf Department of Energy, Washington, 2005. [2] C.E. Buckley, D.A. Sheppard. Private communication. [3] A.V. Rode, S.T. Hyde, E.G. Gamaly, R.G. Elliman, D.R. McKenzie, S. Bulcock, Appl. Phys. A. 69 (1999) S755S758. [4] O. Beeri, D. Cohen, Z. Gavra, J.R. Johnson, M.H. Mintz, J. Alloys Compd. 267 (1998) 113120.

[5] A. Rabenau, H. Schulz, J. Less-Common Met. 50 (1976) 155159. [6] P. Malbrunot, D. Vidal, J. Vermesse, R. Chahine, T.K. Bose, Langmuir 13 (1997) 539544. [7] M.K. Haas, J.M. Zielinski, G. Dantsin, C.G. Coe, G.P. Pez, A.C. Cooper, J. Mater. Res. 20 (2005) 32143223. [8] J.M. Blackman, J.W. Patrick, C.E. Snape, Carbon 44 (2006) 918927. [9] H. Hemmes, A. Driessen, R. Griessen, J. Phys. C: Solid State Phys. 19 (1988) 35713585. [10] K.G. McLennan, E.MacA. Gray, Meas. Sci. Technol. 15 (2004) 211 215.

Вам также может понравиться

- Tight Rock Permeability Measurement by Pressure Pulse Decay and ModelingДокумент12 страницTight Rock Permeability Measurement by Pressure Pulse Decay and ModelingRosa K Chang HОценок пока нет

- Scaling of turbulence transition threshold in a pipe follows an inverse Reynolds number relationshipДокумент5 страницScaling of turbulence transition threshold in a pipe follows an inverse Reynolds number relationshiprpulkstensОценок пока нет

- 1990 Sca Conference Paper Number 9013Документ57 страниц1990 Sca Conference Paper Number 9013Munif ThalibОценок пока нет

- A Micro-Convection Model For Thermal Conductivity of NanofluidsДокумент7 страницA Micro-Convection Model For Thermal Conductivity of NanofluidsratchagarajaОценок пока нет

- SPE 92196 Experimental Study of Effective Diffusion in Porous MediaДокумент7 страницSPE 92196 Experimental Study of Effective Diffusion in Porous MediamsmsoftОценок пока нет

- Estimation of Pure Component Properties. Part 4 - Estimation of The Saturated Liquid Viscosity of Non-Electrolyte Organic Compounds Via Group Contributions and Group InteractionsДокумент23 страницыEstimation of Pure Component Properties. Part 4 - Estimation of The Saturated Liquid Viscosity of Non-Electrolyte Organic Compounds Via Group Contributions and Group InteractionscymyОценок пока нет

- ILASS-16 Karathanassis Et Al Camera-ReadyДокумент10 страницILASS-16 Karathanassis Et Al Camera-ReadyBRICKTOP000Оценок пока нет

- Low Mach Number ApproximationДокумент42 страницыLow Mach Number ApproximationDiana MitroiОценок пока нет

- A Simplified Model For Real Gas Expansion Between Two Reservoirs Connected by A Thin TubeДокумент14 страницA Simplified Model For Real Gas Expansion Between Two Reservoirs Connected by A Thin TubeSatyanarayan SahooОценок пока нет

- 5.2. Dilatometric Methods: 5.2.1. Fluid Confinement DilatometryДокумент4 страницы5.2. Dilatometric Methods: 5.2.1. Fluid Confinement Dilatometrysonia161990Оценок пока нет

- Spe 89866-Cap Pressure in TgsДокумент11 страницSpe 89866-Cap Pressure in TgsKald FahmeОценок пока нет

- Oxygen Transfer Model Development Based On Activated Sludge and Clean WaterДокумент9 страницOxygen Transfer Model Development Based On Activated Sludge and Clean WaterSol AngelОценок пока нет

- Smoothing of Slug Tests For Laboratory Scale Aquifer Assessment-A Comparison Among Different Porous MediaДокумент18 страницSmoothing of Slug Tests For Laboratory Scale Aquifer Assessment-A Comparison Among Different Porous MediaMaria Fernanda Rivera VelasquezОценок пока нет

- Capillary Super Critical FluidДокумент8 страницCapillary Super Critical FluidCarlos Alberto Rueda SanabriaОценок пока нет

- Rock Permeability ExperimentДокумент12 страницRock Permeability ExperimentSaroo BastkyОценок пока нет

- Numerical Investigation of Thermal Processes in Shell and Tube Heat ExchangerДокумент10 страницNumerical Investigation of Thermal Processes in Shell and Tube Heat Exchangermladen018Оценок пока нет

- Ju Li Et Al - Theoretical Evaluation of Hydrogen Storage Capacity in Pure Carbon NanostructuresДокумент10 страницJu Li Et Al - Theoretical Evaluation of Hydrogen Storage Capacity in Pure Carbon NanostructuresKiomaxОценок пока нет

- ILAR HydrodynamicsДокумент16 страницILAR HydrodynamicsFritz FestejoОценок пока нет

- Experimental and Theoretical Study of Dryout in Annular Ow in Small Diameter ChannelsДокумент20 страницExperimental and Theoretical Study of Dryout in Annular Ow in Small Diameter ChannelsHavocFireОценок пока нет

- Spe 116575 Ms P Tim WhiitleДокумент9 страницSpe 116575 Ms P Tim WhiitleglsancorОценок пока нет

- Experimental investigation of microchannel flow with internal pressure measurementsДокумент16 страницExperimental investigation of microchannel flow with internal pressure measurementsAnonymous cnX4B1NavIОценок пока нет

- Apparatus For The Laboratory Study of Gas Absorption in Packed TowersДокумент3 страницыApparatus For The Laboratory Study of Gas Absorption in Packed TowersHanaОценок пока нет

- Inducing Pulses in Trickle-Bed Reactors by Cycling Liquid FeedДокумент10 страницInducing Pulses in Trickle-Bed Reactors by Cycling Liquid FeedOlla YoLaОценок пока нет

- Buoyancy Driven Mixing Studies of Natural Circulation Flows at The Rocom Facility Using The Ansys CFX CodeДокумент8 страницBuoyancy Driven Mixing Studies of Natural Circulation Flows at The Rocom Facility Using The Ansys CFX CodeSajjad AhmedОценок пока нет

- International Journal of Heat and Mass Transfer: Shou-Shing Hsieh, Chih-Yi LinДокумент11 страницInternational Journal of Heat and Mass Transfer: Shou-Shing Hsieh, Chih-Yi LinPankaj SinghОценок пока нет

- CFD Analysis of Feedwater Flow in The HPLWR Pressure Vessel: Helena - Foulonk@iket - Fzk.deДокумент4 страницыCFD Analysis of Feedwater Flow in The HPLWR Pressure Vessel: Helena - Foulonk@iket - Fzk.deSlim KanounОценок пока нет

- On The Modelling of Bubble Plumes in A Liquid PoolДокумент25 страницOn The Modelling of Bubble Plumes in A Liquid PoolStephany CamacaroОценок пока нет

- The Summary of "Critical Heat Flux of Water at Subatmospheric Pressures in Microchannels" ArticleДокумент3 страницыThe Summary of "Critical Heat Flux of Water at Subatmospheric Pressures in Microchannels" ArticleAgustinah Rizky AmaliaОценок пока нет

- G. Benedek, P. Nieto and J.P. Toennies - The Geyser Effect in The Expansion of Solid Helium Into VacuumДокумент13 страницG. Benedek, P. Nieto and J.P. Toennies - The Geyser Effect in The Expansion of Solid Helium Into VacuumJuaxmawОценок пока нет

- The Influence of Knudsen Number On The Hydrodynamic Development Length Within Parallel Plate Micro-ChannelsДокумент10 страницThe Influence of Knudsen Number On The Hydrodynamic Development Length Within Parallel Plate Micro-ChannelsChong Jen HawОценок пока нет

- Gravity-Current Transport in Building FiresДокумент7 страницGravity-Current Transport in Building Firesreader1900Оценок пока нет

- Adsorption Equilibrium of Water On Silica GelДокумент4 страницыAdsorption Equilibrium of Water On Silica GelHamza MoussaОценок пока нет

- Grav JournaДокумент11 страницGrav Journawafiyyah fadillahОценок пока нет

- Simulation Study of Mass Transfer Coefficient in Slurry Bubble Column Reactor Using Neural NetworkДокумент11 страницSimulation Study of Mass Transfer Coefficient in Slurry Bubble Column Reactor Using Neural NetworkEmad ElsaidОценок пока нет

- Cryo 1Документ6 страницCryo 1gdoninaОценок пока нет

- Kvamme 1995Документ6 страницKvamme 1995Jagho PraisakaОценок пока нет

- Experimental Study of Pressure Gradients Occurring During Continuous TwoДокумент2 страницыExperimental Study of Pressure Gradients Occurring During Continuous TwoAbdulrahman NasirudeenОценок пока нет

- Mousa 2015Документ16 страницMousa 2015Mohammed YahyaОценок пока нет

- Testing of Small Differential Pressure Cone Meters On Wet Gas - Brazil (Rio)Документ11 страницTesting of Small Differential Pressure Cone Meters On Wet Gas - Brazil (Rio)Philip A Lawrence C.Eng. F. Inst M.C.Оценок пока нет

- By K.L. Ancell, H.S. Price, and W.K. Ford, INTERCOMP Resource Development and Engineering, Inc., Members SPF-AIMEДокумент8 страницBy K.L. Ancell, H.S. Price, and W.K. Ford, INTERCOMP Resource Development and Engineering, Inc., Members SPF-AIMEعبدالغفار بيزانОценок пока нет

- Fluent Help Evaporation TutorialДокумент5 страницFluent Help Evaporation TutorialsidyantОценок пока нет

- Mulero Parra 08 1Документ16 страницMulero Parra 08 1Mustapha MaaroufОценок пока нет

- A Case of Negative Apparent Activation Energy Due To Pore Diffusion EffectsДокумент3 страницыA Case of Negative Apparent Activation Energy Due To Pore Diffusion EffectsBamrung SungnoenОценок пока нет

- Rock Permeability: Reservoir Rock Properties LabДокумент12 страницRock Permeability: Reservoir Rock Properties LabhashoОценок пока нет

- Refrigerant in Capillary Tube PDFДокумент6 страницRefrigerant in Capillary Tube PDFMayank Kumar100% (2)

- Relationship Between Capillary Pressure and Resistivity IndexДокумент12 страницRelationship Between Capillary Pressure and Resistivity IndexRosa K Chang HОценок пока нет

- Articol 23-24Документ9 страницArticol 23-24Antonia LorenaОценок пока нет

- Seyoum-Tanyimboh2017 Article IntegrationOfHydraulicAndWaterДокумент19 страницSeyoum-Tanyimboh2017 Article IntegrationOfHydraulicAndWaterFarzana Rahman ZuthiОценок пока нет

- The Limits of Navier-Stokes Theory and Kinetic Extensions For Describing Small-Scale Gaseous HydrodynamicsДокумент19 страницThe Limits of Navier-Stokes Theory and Kinetic Extensions For Describing Small-Scale Gaseous HydrodynamicsPrabal NegiОценок пока нет

- Thermal Science and Engineering Progress: Satyajit Kumar Shukla, A.M. Naveen Samad, Sumana GhoshДокумент7 страницThermal Science and Engineering Progress: Satyajit Kumar Shukla, A.M. Naveen Samad, Sumana GhoshSaif EvonyОценок пока нет

- Algorithms 13 00053 v2 PDFДокумент22 страницыAlgorithms 13 00053 v2 PDFJohn DoeОценок пока нет

- Equation-Based Rigorous Modelling of The NO Absorption Process: Model Development and Process OptimizationДокумент6 страницEquation-Based Rigorous Modelling of The NO Absorption Process: Model Development and Process OptimizationAlberto TousОценок пока нет

- Wetted WallДокумент20 страницWetted WallMuhammad AhsanОценок пока нет

- Infer Poiseuille's Law Through Simple Lab ExperimentsДокумент7 страницInfer Poiseuille's Law Through Simple Lab ExperimentsArjun SinghОценок пока нет

- Residence Time Distribution Modeling for Tubular ReactorsДокумент6 страницResidence Time Distribution Modeling for Tubular ReactorsAfrillia FahrinaОценок пока нет

- A New Determination of The Structure of Water at 25°CДокумент14 страницA New Determination of The Structure of Water at 25°CAnonymous sAJECXОценок пока нет

- Santra 2008Документ10 страницSantra 2008hassanОценок пока нет

- A New Approach To Derive Relative Permeability Data While Measuring Resistivity IndexДокумент12 страницA New Approach To Derive Relative Permeability Data While Measuring Resistivity IndexRosa K Chang HОценок пока нет

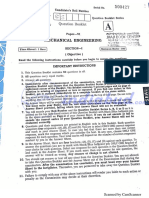

- ME Paper 6 Section 1 PDFДокумент7 страницME Paper 6 Section 1 PDFSaumya SinhaОценок пока нет

- Automobile Pdf1Документ31 страницаAutomobile Pdf1srinivasnaikОценок пока нет

- Introduction to Vehicle Transmission ComponentsДокумент21 страницаIntroduction to Vehicle Transmission ComponentsManohara ErlaОценок пока нет

- Checking Atrocities Against DalitsДокумент2 страницыChecking Atrocities Against DalitsSaumya SinhaОценок пока нет

- What Caused The Crisis in West AsiaДокумент2 страницыWhat Caused The Crisis in West AsiaSaumya SinhaОценок пока нет

- Epicyclic Gear Train Apparatus PDFДокумент1 страницаEpicyclic Gear Train Apparatus PDFSaumya SinhaОценок пока нет

- Advertisement 43 2016 PDFДокумент7 страницAdvertisement 43 2016 PDFSaumya SinhaОценок пока нет

- China Commissions Dam On BrahmaputrДокумент1 страницаChina Commissions Dam On BrahmaputrSaumya SinhaОценок пока нет

- Me MCQДокумент13 страницMe MCQSaumya SinhaОценок пока нет

- Indian Concern Over A US-Pak Nuclear DealДокумент1 страницаIndian Concern Over A US-Pak Nuclear DealSaumya SinhaОценок пока нет

- Uniform Civil Code Whats The AgendaДокумент1 страницаUniform Civil Code Whats The AgendaSaumya SinhaОценок пока нет

- 91.the Big Picture India-Africa Forum Summit What Is The Agenda PDFДокумент1 страница91.the Big Picture India-Africa Forum Summit What Is The Agenda PDFSaumya SinhaОценок пока нет

- Is It Time To Dump Sedition LawДокумент2 страницыIs It Time To Dump Sedition LawSaumya SinhaОценок пока нет

- China Ends One Child Policy Time To Dump Malthusian TheoryДокумент2 страницыChina Ends One Child Policy Time To Dump Malthusian TheorySaumya SinhaОценок пока нет

- India-Africa Forum Summit What Is The AgendaДокумент1 страницаIndia-Africa Forum Summit What Is The AgendaSaumya SinhaОценок пока нет

- 28th July MCQДокумент5 страниц28th July MCQSaumya SinhaОценок пока нет

- Ease of Doing Business What Has ChangedДокумент2 страницыEase of Doing Business What Has ChangedSaumya SinhaОценок пока нет

- China Ends One Child Policy Time To Dump Malthusian TheoryДокумент2 страницыChina Ends One Child Policy Time To Dump Malthusian TheorySaumya SinhaОценок пока нет

- 26th July 2016 MCQДокумент6 страниц26th July 2016 MCQSaumya SinhaОценок пока нет

- India-Nepal Acrimony IncreasesДокумент2 страницыIndia-Nepal Acrimony IncreasesSaumya SinhaОценок пока нет

- Options For Government On Economic Amp Policy ReformsДокумент1 страницаOptions For Government On Economic Amp Policy ReformsSaumya SinhaОценок пока нет

- US-China Face-Off in South China SeaДокумент2 страницыUS-China Face-Off in South China SeaSaumya SinhaОценок пока нет

- 24th July MCQДокумент5 страниц24th July MCQSaumya SinhaОценок пока нет

- 27th July 2016 MCQДокумент5 страниц27th July 2016 MCQSaumya SinhaОценок пока нет

- Current Affairs Pocket PDF - July 2016 by AffairsCloudДокумент39 страницCurrent Affairs Pocket PDF - July 2016 by AffairsCloudPriyatam BolisettyОценок пока нет

- 30th July MCQДокумент5 страниц30th July MCQSaumya SinhaОценок пока нет

- Current Affairs July 25 2016: Narsingh Yadav Banned from Rio OlympicsДокумент5 страницCurrent Affairs July 25 2016: Narsingh Yadav Banned from Rio OlympicsSaumya SinhaОценок пока нет

- 7.MCQ 31st July 2016Документ5 страниц7.MCQ 31st July 2016Saumya SinhaОценок пока нет

- 29th July MCQДокумент5 страниц29th July MCQSaumya SinhaОценок пока нет

- MCQ August 2016Документ39 страницMCQ August 2016Saumya SinhaОценок пока нет

- Chapter 6 Designing Global Supply Chain NetworksДокумент22 страницыChapter 6 Designing Global Supply Chain NetworksRashadafaneh100% (1)

- Cost Plus Pricing Strategy in Construction IndustryДокумент2 страницыCost Plus Pricing Strategy in Construction IndustryCarlose GonsalvesОценок пока нет

- Part 4C (Quantitative Methods For Decision Analysis) 354Документ102 страницыPart 4C (Quantitative Methods For Decision Analysis) 354Noel Cainglet0% (1)

- EA-4-16 G-2003. EA Guidelines On The Expression of Uncertainty in Quantitative TestingДокумент28 страницEA-4-16 G-2003. EA Guidelines On The Expression of Uncertainty in Quantitative Testingcolve87Оценок пока нет

- Din 211 Risk Management and Insurance 2019 NotesДокумент99 страницDin 211 Risk Management and Insurance 2019 NotesNancyОценок пока нет

- Water 12 01493 v2Документ12 страницWater 12 01493 v2Bjorn FejerОценок пока нет

- Tolerance CalibrationДокумент29 страницTolerance CalibrationSunil GurubaxaniОценок пока нет

- Monographie BIPM-5 Tables Vol2 PDFДокумент307 страницMonographie BIPM-5 Tables Vol2 PDFMadalina-Elena CostacheОценок пока нет

- E1781-98 Secondary Calibration of AE SensorsДокумент7 страницE1781-98 Secondary Calibration of AE SensorssanthakumarОценок пока нет

- The Influence of E-Commerce Live Streaming On Lifestyle Fit Uncertainty and Online Purchase Intention of Experience ProductsДокумент10 страницThe Influence of E-Commerce Live Streaming On Lifestyle Fit Uncertainty and Online Purchase Intention of Experience Productsying xieОценок пока нет

- Theory of Uncertainty of Measurement PDFДокумент14 страницTheory of Uncertainty of Measurement PDFLong Nguyễn VănОценок пока нет

- 1st Year Physics According To COVID-19 Syllabus PDFДокумент334 страницы1st Year Physics According To COVID-19 Syllabus PDFMohsin HayatОценок пока нет

- 2009 - Mil HDBK 1823a PDFДокумент171 страница2009 - Mil HDBK 1823a PDFEidertxuОценок пока нет

- [Studies in Fuzziness and Soft Computing 340] Jagdeep Kaur, Amit Kumar (Auth.) - An Introduction to Fuzzy Linear Programming Problems_ Theory, Methods and Applications (2016, Springer International Publishing)Документ132 страницы[Studies in Fuzziness and Soft Computing 340] Jagdeep Kaur, Amit Kumar (Auth.) - An Introduction to Fuzzy Linear Programming Problems_ Theory, Methods and Applications (2016, Springer International Publishing)Carlos VelasquezОценок пока нет

- How To Quantify ErrorДокумент10 страницHow To Quantify ErrorTunica Prince100% (1)

- IPC2022-87108 Advances in Using Probability of Exceedance Methods For Defining Remediation Options FinalДокумент10 страницIPC2022-87108 Advances in Using Probability of Exceedance Methods For Defining Remediation Options FinalOswaldo MontenegroОценок пока нет

- Measuring Asymmetry with MomentsДокумент12 страницMeasuring Asymmetry with MomentsPedro Tavares MurakameОценок пока нет

- BLDG3012 - Week 1 PDFДокумент32 страницыBLDG3012 - Week 1 PDFQingyang PanОценок пока нет

- PMG Note Chapter 2Документ9 страницPMG Note Chapter 2Nur Alisa FatinОценок пока нет

- Evaluating The Uncertainty of Polynomial Regression Models Using ExcelДокумент18 страницEvaluating The Uncertainty of Polynomial Regression Models Using ExcelSatria WijayaОценок пока нет

- Otc 21575Документ7 страницOtc 21575Mintu ChoudhuryОценок пока нет

- Notes On Medical StatisticsДокумент10 страницNotes On Medical StatisticsCalvin Yeow-kuan ChongОценок пока нет

- Artha Eco Magazine 2020Документ135 страницArtha Eco Magazine 2020tanvi murumkarОценок пока нет

- CHAPTER 1 Risk and Related Topics NewДокумент10 страницCHAPTER 1 Risk and Related Topics NewbikilahussenОценок пока нет

- Wgiiar5 Partb FinalДокумент696 страницWgiiar5 Partb FinalluzОценок пока нет

- Page No 16-17 of PMF 5.0 User GuideДокумент2 страницыPage No 16-17 of PMF 5.0 User GuideSingh RanjitОценок пока нет

- EMD Report PDFДокумент32 страницыEMD Report PDFVelmurugan KОценок пока нет

- APMP - Pr-K3.a Technical ProtocolДокумент23 страницыAPMP - Pr-K3.a Technical ProtocolAdindra Vickar EgaОценок пока нет

- Sharing Realities 04 Reasonable ChoicesДокумент17 страницSharing Realities 04 Reasonable ChoicesRichard OstrofskyОценок пока нет

- Writing Lab ReportsДокумент31 страницаWriting Lab ReportschaciОценок пока нет

![[Studies in Fuzziness and Soft Computing 340] Jagdeep Kaur, Amit Kumar (Auth.) - An Introduction to Fuzzy Linear Programming Problems_ Theory, Methods and Applications (2016, Springer International Publishing)](https://imgv2-2-f.scribdassets.com/img/document/452938159/149x198/4d9ede7a15/1600771084?v=1)