Академический Документы

Профессиональный Документы

Культура Документы

189 010 - en 15.710057 V3.0

Загружено:

balzac191Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

189 010 - en 15.710057 V3.0

Загружено:

balzac191Авторское право:

Доступные форматы

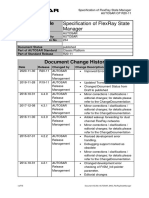

U 189-010 en

Vacuum Change-over Device U 189-010 Technical Information

15.710057-V3.0

U 189-010 en

Imprint

Vacuum Change-over U 189-010 Technical Information Version 3.0 Publisher: ALLDOS Eichler GmbH Reetzstrae 85 76327 Pfinztal (Sllingen) Postfach 1160 76317 Pfinztal Tel. +49 72 40 61-0 / Fax. +49 72 40 61-211 Mail: alldos.de@alldos.com Internet: www.alldos.com 2007 by ALLDOS Eichler GmbH Subject to change.

V3.0

U 189-010 en

Installation Data

NOTE Please fill in this form following commissioning. It will help you and your GRUNDFOS Alldos servicing partner to adjust the device during subsequent corrections.

Owner: GRUNDFOS Alldos customer No.: Contract No.: Order No. of device: Serial number of device: Put into service on: Location of device:

Used for:

Installation Diagram

15.710057-V3.0

U 189-010 en

CONTENT 1

1.1 1.2

PAGE 5

5 5

Of General Interest

General Notice Safety Instructions

2 3

3.1

Construction and Function Technical Data

Electrical Data of Remote Indicator

6 6

6

4 5

5.1 5.2 5.3 5.4

Installation Commissioning

Leak Test of the Vacuum Side Leak Test of the Pressure Side First Commissioning Checking the Change - Over Function

6 8

8 8 8 8

6 7

Fault Correction Spare Parts Set

9 9

V3.0

U 189-010 en

1

1.1

Of General Interest

General Notice

1.2

Safety Instructions

The safety instructions WARNING, CAUTION and NOTE employed in this technical manual have the following meaning:

This Technical Information contains instructions for the installation, commissioning as well as attendance and maintenance of the vacuum change - over device described in this manual. For reasons of clarity, however, this document neither takes into consideration complete details concerning each variant nor every conceivable case of installation and operation. If you require further information or any problems arise which are not reflected in detail in this manual, contact ALLDOS directly for the information needed. Furthermore we want to point out that the warranty in accordance with our general terms of sale and delivery shall only be valid, if the installation is implemented exclusively by an authorized and suitably qualified personnel. The safety instructions and recommendations given in this technical information have strictly to be observed.

WARNING

This heading is used, if inexact observance or non-observance of operating instructions, work instructions, the stipulated sequence of work and suchlike can result in injuries, accidents or death. This heading is used, if inexact observance or non-observance of operating instructions, work instructions, the stipulated sequence of work and suchlike can result in damage to the device. This heading is used, if the user attention is to be drawn to an exceptional feature.

CAUTION

NOTE

15.710057-V3.0

U 189-010 en

Construction and Function

Installation

The vacuum change - over device U 189-010 ensures a continuous gas supply for gas dosing systems by changing the gas supply over in time from the empty supply battery to a stand - by battery. The vacuum change - over device is operable without auxiliary power. From which battery the gas is supplied, is indicated visually, but as an option the change - over position can also be remote indicated via 2 reed contacts. As soon as the vacuum rises to a value of about 3 - 4 m WS / 78" - 118" WC, which can be caused by an empty or closed supply battery, the change - over function is triggered. The change - over device can be used in connection with the chlorine dosing units C 105 and V 107 or V 115.

Connect the vacuum change - over device at the inlet side to two vacuum regulators and at the outlet side to the chlorine gas dosing unit. The inlet connections for the vacuum regulators are marked with the inscriptions IN I and IN II, the connection for the chlorine dosing unit with OUT. The vacuum lines between the vacuum regulators and the change - over device should be kept as short as possible and should not exceed a maximum length of 6 m. Thus a minimum pressure loss can be ensured. A precondition for trouble - free functioning of the vacuum change - over device is the tightness of all lines and connections. see 5.1 / 5.2 Leak test

NOTE

If the chlorine gas dosing units V 107 and V 115 are retrofitted with the change - over device, a compensation for the main regulator has to be provided.

The vacuum change - over device should be installed as depicted in figure 1 on the following page.

Technical Data

Cl2, SO2 10 kg/h Cl2, SO2 500 PPD Cl2, SO2 50 g/h Cl2, SO2 2.5 PPD Cl2, SO2 PE - tube 8 x 11 for max. 4 kg/h Cl2, SO2 PE - tube 10 x 14 for max. 10 kg/h Cl2, SO2 PVC - pipe DN 10 for max. 10 kg/h Cl2, SO2 PE - tube 1/2" od. 3/8" NPT threaded up to 200 PPD (USA) PE - tube 3/8" od. 3/8" NPT threaded up to 500 PPD (USA)

Medium Maximum flow rate Minimum flow rate

Optional connections

Materials Weight

PVC / Viton / FEP / glass silver / Hastelloy C about 2 kg

3.1

Electrical Data

for option with 2 reed contacts for remote indication

Supply voltage Power consumption Wattage

max. 75 V DC / 50 V AC 1A max. 50 W

V3.0

U 189-010 en

Figure 1 Functional scheme and connection chart of a chlorine gas dosing system with vacuum change - over device 189-010

1 2 3 4 5 6 7 8

Gasdetect Adsoroption filter Vacuum regulator with liquid trap Vacuum change - over device Chlorine drum Chlorine drum support Chlorine gas dosing unit Injector

15.710057-V3.0

U 189-010 en

Commissioning

5.3

First Commissioning

After having completed the installation continue ommissioning the change - over device.

After the leak test has been terminated successfully, the vacuum change - over device can be commissioned. 1 Entirely open the connecting valves of the drums or cylinders. Start the injector. Thereafter chlorine gas is dosed. The position of the indicator pin of the change - over device signals from which battery the chlorine gas is supplied.

WARNING

The device must be commissioned only by qualified personnel strictly complying with the instructions for handling the hazardous substance chlorine. The qualified staff must wear protective clothing and gas mask when doing the work described in the following. Prior to the initial starting all parts carrying chlorine gas have to be checked for leaks.

NOTE

5.4

1

Checking the Change - Over Function

Open all cylinders or drums and start the injector. Close the supply battery that is in operation. The change - over device switches the gas supply over to the stand - by battery after a short period of time (that depends on the dosing quantity and the length of the line). Then check, if the changing over from the stand - by battery to the former supply battery functions, as well. Open again all cylinders or drums. The vacuum change - over device is now ready for operation.

5.1

1 2

Leak Test of the Vacuum Side

Close the connecting valves of the drums or cylinders.

2 3

Start the injector. Thereupon the vacuum lines are evacuated and in this operating state the change - over device switches uncontrollably. After about 10 minutes (depending on the length of the vacuum lines and on the setting of the adjusting valve) the rotameter must not indicate a flow. If the rotameter yet indicates a flow, the complete dosing system must be checked for possible leaks. 4

Warning

As precondition for the leak test the chlorine gas dosing unit must be evacuated and free of chlorine gas and the injector be in operation.

To check the single components of the dosing system, disconnect the vacuum lines between the vacuum regulators and the rotameter one after the other and close them tight with the finger. If the rotameter stops indicating a flow after having disconnected one of the vacuum lines, the leaks has to be at the disconnected component.

5.2

1 2

Leak Test of the Pressure Side

Stop the injector. Open the connecting valves of the drums or cylinders by about one revolution. Check the connecting parts and inlet valves of the vacuum regulators for leaks by means of ammonia. Leaks are localized by passing the bottle with ammonia close by the relevant parts and squeezing a little bit of ammonia gas out of the bottle. If there is chlorine gas escaping anywhere, white vapour develops.

WARNING

Even the slightest detected leaks have to be removed immediately.

V3.0

U 189-010 en

Fault Correction

The numbers in brackets occurring in the following refer to the items of the enclosed sectional drawings 15.189-200 and 12.4188-300.

FAULT

No changing over

CAUSE

The gas dosing system is leaky, so that the vacuum required for the change - over function cannot be generated.

DISCERNIBLE FROM

The rotameter indicates a flow, although the supply battery (cylinder, drum) is empty or closed.

CORRECTION

Check the dosing system for leaks. For this purpose disconnect the vacuum lines between the rotameter and the vacuum regulators one after the other, close them with the finger and observe the rotameter. See sections 5.1 and 5.2 Leak test. Arrange a compensation for the main regulator.

The change - over device is coupled with a chlorine gas dosing unit V 107 or V 115, without having provided a compensation for the main regulator. The diaphragm (2) or o - ring (3) in the change - over device are leaky. The vacuum regulator lets through only an insufficient amount of chlorine or the vacuum line is too long (this fault occurs mainly with a high flow rate). It can also be the case that a chlorine cylinder is frozen up. Using the change - over device in connection with the vacuum regulator C 105-230 (all vacuum system) the flow rate of each regulator can exceed 600 g/ h or 30 PPD.

The vacuum of 2 - 3 m WS / 52" - 78" WC required for the change - over function is not attained (measure the vacuum between change - over device and regulator with a vacuum meter). The rotameter indicates a flow, although the supply battery (cylinder, drum) is empty or closed. Measure the vacuum after the outlet of the change over device with a vacuum meter. The vacuum must amount to less than 2 m WS / 52" WC.

Replace the defective parts.

The change - over device switches to the stand - by battery despite filled cylinder or drum and opened connecting valve.

Clean the vacuum regulator and restart it or lay a vacuum line with a larger cross section.

Measure the vacuum after the outlet of the change over device with a vacuum meter. The vacuum has to be less than 2 m WS / 52" WC. Adjust a smaller flow rate, so that the value of the operating vacuum falls below that of the vacuum required for the change - over function.

Add a further vacuum regulator with chlorine cylinder to the supply battery, if the maximum flow rate is required.

Spare Parts Set

There is a spare parts set, order no. 553-1024 available for the vacuum change - over device U 189-010. It comprises the o - rings (1 / 3 / 4 / 5 / 7 / 8 / 9), the diaphragm (2) as well as the pressure spring (6). If other than the indicated parts are defective, return the change - over device to the works for repair or replacement.

15.710057-V3.0

10

51.3 51.25 7 51.8 26

21.6

21.6

149.2 (57/8)

connection PVC pipe DN15

54 (21/8)

21.6

73 (3)

connection PVC pipe DN10

4 (5/32)

21.6 51.14

gas outlet

51.13

100 (4)

Signal transmitter for remote indication see drawing no. 12.4188-310

connection 10 x 14 gas inlet II

95.25 (33/4)

gas inlet I

gree

67 (25/8)

n

bro

139 (51/2)

connection PE 12 x 16

sealed with Teflon strip

6.5 (1/4)

white wn

29.5

length 3 m

type plate

220.5 (811/16) 240.5 (915/32)

connection USA 1/2"

spare parts set: 553-1024

U 189-010 en

V3.0

15.189-200

U 189-010 en

15.710057-V3.0

length 3 m

bro

gree

white

wn

switch direct voltage max. 1,0 A contact load max. 50 W switch direct voltage 75V switch alternating voltage 50 AC

Signal transmitter for remote indication

12.4188-310

11

U 189-010 en

12

V3.0

Вам также может понравиться

- Air Blower ManualДокумент16 страницAir Blower ManualshaiknayeemabbasОценок пока нет

- Operating Manual: Altronic Gas Control Valve, 690210Документ12 страницOperating Manual: Altronic Gas Control Valve, 690210Esau Jose PabloОценок пока нет

- Altronic EPC 110-120 Operating Manual (FORM EPC-110/120 OM)Документ55 страницAltronic EPC 110-120 Operating Manual (FORM EPC-110/120 OM)francis_mouille_iiОценок пока нет

- Ldu 11 Eun 7696 en 25042005Документ16 страницLdu 11 Eun 7696 en 25042005Thiago FernandesОценок пока нет

- Ejector Cloro17Документ14 страницEjector Cloro17Robinson SanchezОценок пока нет

- SG Actuator Gas Over OilДокумент4 страницыSG Actuator Gas Over Oiltoader56Оценок пока нет

- Instruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaДокумент14 страницInstruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaAlexandre EmmerickОценок пока нет

- XB 13 InstallДокумент8 страницXB 13 InstalljbozakОценок пока нет

- Re 07700Документ2 страницыRe 07700Ahmed Abd ElhakeemОценок пока нет

- Manual Alimentador Piab PDFДокумент28 страницManual Alimentador Piab PDFsol soto100% (1)

- Instalación y Mantenimiento de Válvulas RotativasДокумент4 страницыInstalación y Mantenimiento de Válvulas RotativasGustavo León CarreraОценок пока нет

- 52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFДокумент7 страниц52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFysr3eeОценок пока нет

- Epc100E OM 5 06 FullДокумент73 страницыEpc100E OM 5 06 Fulljim_kellyОценок пока нет

- Orbinox VG08 Knife Gate ValveДокумент8 страницOrbinox VG08 Knife Gate ValveYorkistОценок пока нет

- Tourniquet User Manual 2012 PDFДокумент10 страницTourniquet User Manual 2012 PDFphuongo2Оценок пока нет

- 3-5400 SERIES Safety Relief Valves: Instruction ManualДокумент16 страниц3-5400 SERIES Safety Relief Valves: Instruction ManualPrashant ChauhanОценок пока нет

- FlowCon EVC Instr USДокумент4 страницыFlowCon EVC Instr USb82monicaОценок пока нет

- Donaldson Process Chiller Manual MiniДокумент31 страницаDonaldson Process Chiller Manual MiniTasos Mythbuster50% (6)

- Fluids Entry HBV Cetop 7 & 8 Series 101109Документ12 страницFluids Entry HBV Cetop 7 & 8 Series 101109Enhtuwshin BarkhasbadiОценок пока нет

- HD 102 Alarm Valve Model AДокумент9 страницHD 102 Alarm Valve Model AjabbanОценок пока нет

- SL700 ManualДокумент62 страницыSL700 Manualkrzys10Оценок пока нет

- TC02 DigitalДокумент17 страницTC02 DigitalNebojsa CekicОценок пока нет

- RTHC Svn02c enДокумент16 страницRTHC Svn02c enRicardo100% (1)

- 122 6006Документ14 страниц122 6006Paulo Jurandir Santos PereiraОценок пока нет

- 'TTA IOM R22 Jan10Документ28 страниц'TTA IOM R22 Jan10Luong DaoОценок пока нет

- HL2-90 Compressor Instr ManualДокумент12 страницHL2-90 Compressor Instr ManualCosmin Iulian100% (3)

- Go Range: Gas-Over-Oil Scotch Yoke ActuatorsДокумент13 страницGo Range: Gas-Over-Oil Scotch Yoke ActuatorsLuan HuynhОценок пока нет

- Water Cooled Fcu Piping DetailsДокумент14 страницWater Cooled Fcu Piping Detailsfernandoreyes893Оценок пока нет

- s2k ManualДокумент4 страницыs2k Manualspartako84Оценок пока нет

- Altronic GSVДокумент8 страницAltronic GSVhamadaОценок пока нет

- Medaes Agss CatalogДокумент3 страницыMedaes Agss CatalogzampacaanasОценок пока нет

- PS-203 Rev B LO Range ManualДокумент16 страницPS-203 Rev B LO Range ManualRussbelth OrtegaОценок пока нет

- Lessons Learned-FINAL-NEW PDFДокумент8 страницLessons Learned-FINAL-NEW PDFImtinan MohsinОценок пока нет

- PFS Mcquay Manual 01 PDFДокумент30 страницPFS Mcquay Manual 01 PDFevrimk75% (4)

- Reliableb1acc 1Документ6 страницReliableb1acc 1salajeanuОценок пока нет

- User's Manual: Oil Content Meter Model GQS-206Документ19 страницUser's Manual: Oil Content Meter Model GQS-206Bhayu alfianОценок пока нет

- ECC Manual-Turbine Fow MeterДокумент22 страницыECC Manual-Turbine Fow MeterOctavio ParedesОценок пока нет

- V776-561-004S Air Dryer CheckДокумент4 страницыV776-561-004S Air Dryer CheckWilson BuenoОценок пока нет

- Operating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasДокумент20 страницOperating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasCarlos RondonОценок пока нет

- Es-Of1465tm 1665TMДокумент3 страницыEs-Of1465tm 1665TMWattsОценок пока нет

- Sf6 Circuit Breakers Catalog 1Документ8 страницSf6 Circuit Breakers Catalog 1Leonardo HernandesОценок пока нет

- Compresor SullairДокумент86 страницCompresor Sullairseze71100% (1)

- VC Series: Installation Instruction - EinbauanleitungДокумент12 страницVC Series: Installation Instruction - EinbauanleitungIon VasileОценок пока нет

- Belajar Shutdown ValveДокумент12 страницBelajar Shutdown ValveRiky SusantoОценок пока нет

- Installation / Operation / Maintenance Instructions Magnetic Level GaugeДокумент6 страницInstallation / Operation / Maintenance Instructions Magnetic Level GaugeHumayun NawazОценок пока нет

- FlowCon EVC Instruction 05.2010Документ4 страницыFlowCon EVC Instruction 05.2010Jeff Anderson CollinsОценок пока нет

- General Instructions For Safe Operation of High Pressure CompressorsДокумент6 страницGeneral Instructions For Safe Operation of High Pressure CompressorsTansu MavunacıОценок пока нет

- 38hds Installation ManualДокумент8 страниц38hds Installation Manualdelmar02Оценок пока нет

- Indoor RMU ManualДокумент20 страницIndoor RMU Manualhardeepsingh_08Оценок пока нет

- AIB - GVS - 20 Bomba de VacioДокумент11 страницAIB - GVS - 20 Bomba de VacioRico GonzalezОценок пока нет

- Document PotterДокумент28 страницDocument PotterSuciu MariusОценок пока нет

- 1063 Forged Brass Spring Check ValveДокумент5 страниц1063 Forged Brass Spring Check ValveSyed FazluОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsОт EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsОценок пока нет

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryОт EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryОценок пока нет

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- CL17 Chlorine - AnalyzerДокумент56 страницCL17 Chlorine - Analyzerbalzac191Оценок пока нет

- CL17 Chlorine - AnalyzerДокумент56 страницCL17 Chlorine - Analyzerbalzac191Оценок пока нет

- General CatalogueДокумент72 страницыGeneral Cataloguebalzac191Оценок пока нет

- Acessórios Cloro Gás - VaccupermДокумент28 страницAcessórios Cloro Gás - Vaccupermbalzac1910% (1)

- MA OPTIFLUX2000 en 120328 4000839502 R02Документ44 страницыMA OPTIFLUX2000 en 120328 4000839502 R02balzac191Оценок пока нет

- 180-2 en 15.710050-V1.0Документ24 страницы180-2 en 15.710050-V1.0balzac191Оценок пока нет

- AUTOSAR SWS FlexRayStateManagerДокумент73 страницыAUTOSAR SWS FlexRayStateManagerStefan RuscanuОценок пока нет

- Aspire Es1-432 - Quanta ZQF - Da0zqfmb6f0Документ32 страницыAspire Es1-432 - Quanta ZQF - Da0zqfmb6f0Nico Saibort JuniorОценок пока нет

- 121 3 1000125009Документ9 страниц121 3 1000125009Rehana AzeemОценок пока нет

- Commissioning CANopen Device CMMPДокумент23 страницыCommissioning CANopen Device CMMPninja dragonОценок пока нет

- Is.1795.1982 Pillar TapДокумент20 страницIs.1795.1982 Pillar Tapkishor150688Оценок пока нет

- C091 (J) Aisg C091 (K) 3MДокумент2 страницыC091 (J) Aisg C091 (K) 3MАлександрОценок пока нет

- Base Compensation - PeoplesoftДокумент270 страницBase Compensation - PeoplesoftkumarnujОценок пока нет

- ISO 9001 - HutchinsonДокумент2 страницыISO 9001 - HutchinsonUğurОценок пока нет

- The Comprehensive Solution For Capacitor Bank ProtectionДокумент8 страницThe Comprehensive Solution For Capacitor Bank Protectionwindreader1Оценок пока нет

- SPДокумент12 страницSProdrigo100% (1)

- LTE PP SlidesДокумент13 страницLTE PP SlidesAnonymous VHXJw23L2l50% (2)

- Lesson 3 Information LiteracyДокумент26 страницLesson 3 Information LiteracyTrisha Mae DeveraОценок пока нет

- Catalogue - LS-Titan Position SwitchesДокумент33 страницыCatalogue - LS-Titan Position SwitchesRicardo CalmonОценок пока нет

- Choosing An FM Operating ModelДокумент5 страницChoosing An FM Operating ModelKeith SpencerОценок пока нет

- Configuring SLD Security RolesДокумент3 страницыConfiguring SLD Security Roleshaja5419Оценок пока нет

- SIS - Safety Instrumented Systems - A Practical View - Part 1Документ58 страницSIS - Safety Instrumented Systems - A Practical View - Part 1mgkvprОценок пока нет

- Printers Repair PDFДокумент6 страницPrinters Repair PDFRaboni Claudemir75% (4)

- 16' X 22' Ball Mill Installation ManualДокумент54 страницы16' X 22' Ball Mill Installation Manualpataza011100% (3)

- IATF 16949 2016 Transition Overview October 2016 UpdateДокумент3 страницыIATF 16949 2016 Transition Overview October 2016 UpdateVaspeoОценок пока нет

- HCPL 314JДокумент14 страницHCPL 314JonafetsОценок пока нет

- FactoryTalk Batch - User Guide PDFДокумент820 страницFactoryTalk Batch - User Guide PDFVÕ QUỐC HIỆUОценок пока нет

- BS 476-1 1953Документ27 страницBS 476-1 1953iask5275Оценок пока нет

- Ch19 Modern Auditing 8e Boynton 2006 Completing The Audit Post Audit ResponsibilitiesДокумент22 страницыCh19 Modern Auditing 8e Boynton 2006 Completing The Audit Post Audit Responsibilitiesrifqoh100% (2)

- 3GPP TS 22.011Документ28 страниц3GPP TS 22.011Dhendhi Buchi ReddyОценок пока нет

- Segmentation, Targeting and PositioningДокумент18 страницSegmentation, Targeting and PositioningHussain AhmedОценок пока нет

- Business Administration: Master of ScienceДокумент4 страницыBusiness Administration: Master of ScienceBianca SăvulescuОценок пока нет

- Y Motor Planet GearДокумент4 страницыY Motor Planet GearFabian FragosoОценок пока нет

- LEEA ACADEMY Course Study Materials - MCE - V1.0 Mar 2020-MergedДокумент189 страницLEEA ACADEMY Course Study Materials - MCE - V1.0 Mar 2020-MergedRana DanishОценок пока нет

- Flowserve Valdisk TX3Документ8 страницFlowserve Valdisk TX3RodrigoAndrés Cepeda PérezОценок пока нет

- LTE RAN Parameters - Ericsson-NSNДокумент178 страницLTE RAN Parameters - Ericsson-NSNRahul Gupta33% (3)