Академический Документы

Профессиональный Документы

Культура Документы

Mix Design Formula & Formet 857

Загружено:

Bilal Ahmed BarbhuiyaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mix Design Formula & Formet 857

Загружено:

Bilal Ahmed BarbhuiyaАвторское право:

Доступные форматы

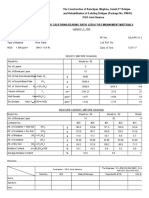

GOVT. OF ASSAM ROAD RESEARCH LABORATORY PWD (R&B) AMBARI FATASIL GUWAHATI-25 NO. RRL/BII/81/pt-II/3052 DT.

17/10/02 To Sri Bhagya Kalita, Class 1 A Redg. Contractor, Piyali Phukan Road, Rehabari, Guwahati-8 Sub: IRQ from K.M. 180/0 to 185/0 (5 km) of NH-37 under Guwahati NH Division. (Job No. 037-AS-2001-02-857) Ref: No. BK/RRL/2002/ dt. 19-08-02

With reference to the above cited subject, Please find herewith the laboratory testing results of Job mix formula for (i) 50mm thick BM (ii) 25mm thick SDBC and also testing results of coarse aggregate for your information and necessary action. Two copies of laboratory testing bill (original and duplicate) are enclosed herewith for doing needful. Yours faithfully

Research Officer Road Research Laboratory PWD (R&B) Ambari, Guwahati-25 Memo No. 636.38 DT. 22/10/2002 Copy to: 1. The Executive Engineer, PWD, Guwahati NH Division, for information & necessary action 2. The Asstt. Executive Engineer, PWD, Guwahati NH Sub Division, for information & necessary action. 3. -------

Research Officer Road Research Laboratory PWD (R&B) Ambari, Guwahati-25

JOB MIX FORMULA Sub: Ref: IRQ from K.M. 180/0 to 185/0 (5 km) of NH-37 under dt. 19-08-02

Guwahati NH Division. (Job No. 037-AS-2001-02-857) No. BK/RRL/2002/

Following materials were supplied by Sri Bhagya Kalita, Class 1 A Redg. Contractor, Piyali Phukan Road, Rehabari, Guwahati-8 for performing Job mix formula for (i) 50 mm thick BM (ii) 25mm thick SDBC and also testing results of Coarse Aggregate. 1. Sample No. 1 = 26.5mm down chips 2. Sample No. 2 3. Sample No. 3 4. Sample No. 4 5. Sample No. 5 6. Bitumen 80/100 For 50 mm thick BM: For 50 mm thick BM all the above five samples were utilized for grading of materials and are shown below: Sample No 1 IS Sieve Percentage Designation Passing 26.5 mm 100 19.0 mm 73.029 13.2 mm 16.178 4.75 mm 1.247 2.36 mm 0.30 mm 0.075 mm Sample No 2 IS Sieve Percentage Designation Passing 26.5 mm 100 19.0 mm 98.952 13.2 mm 37.952 4.75 mm 3.190 2.36 mm 0.30 mm 0.075 mm Sample No 3 IS Sieve Percentage Designation Passing 26.5 mm 19.0 mm 13.2 mm 4.75 mm 2.36 mm 0.30 mm 0.075 mm = = = = 20.0mm down chips 11.2mm down chips 5.6mm down chips Crusher Dust

Sample No 4 IS Sieve Percentage Designation Passing 26.5 mm 19.0 mm 13.2 mm 4.75 mm 2.36 mm 0.30 mm 0.075 mm

Sample No 5 IS Sieve Percentage Designation Passing 26.5 mm 19.0 mm 13.2 mm 4.75 mm 2.36 mm 0.30 mm 0.075 mm

Aggregate were blended in the ratio (By weight of dry aggregate) as shown below: 1 : 2 : 3 : 4 : 5 = 25 : 25 : 20 : 20 : 10 So actual grading is achieved after blending the sample in above proportions are shown below: IS Sieve Designation 26.5 mm 22.4 mm 11.2 mm 5.6 mm 2.8 mm 90.0 Mic. Percentage Passing 100 82.590 57.960 27.792 14.505 2.182 Percentage by weight Passing the IS Sieve 100 75 100 50 85 20 40 5 20 05

PHYSICAL PROPERTIES OF AGGREGATE : 1. Specific Gravity: 1) Sample No. 1 2) Sample No. 2 3) Sample No. 3 4) Sample No. 4 5) Sample No. 5 2. Impact Value in percentage 2. Abrasion Value in P.C. 1) Sample No. 1 2) Sample No. 2 1) Sample No. 1 2) Sample No. 2 = 2.621 = 2.620 = 2.623 = 2.620 = 2.601 = 27.01 = 27.11 = 29.00 = 29.16

4. Bulk Density in Kg/m3

1) Sample No. 1 2) Sample No. 2 3) Sample No. 3 4) Sample No. 4 5) Sample No. 5

= 1540 = 1503 = 1491 = 1489 = 1671 = 18.24 = 21.09 = 23.19 = NIL = NIL = 0.343 = 0.763 = 0.457 = 0.422 = 0.603 = 92 = 46 = Greater then 75

5. Flakiness index in percentage

1) Sample No. 1 2) Sample No. 2 3) Sample No. 3

6. Stripping value in percentage 7. Water Absorption in P.C.

1) Sample No. 1 2) Sample No. 2 1) Sample No. 1 2) Sample No. 2 3) Sample No. 3 4) Sample No. 4 5) Sample No. 5

PHYSICAL PROPERTIES OF BITUMEN 1) Penetration Test (100 gms. 25OC, 5 Sec. 1/100 cm) 2) Softening point test in OC 3) Ductility test at 27Oc in cm

Therefore, grade of the bitumen sample tested is 90 (80/100) PROPERTIES OF MIX FOR 75mm THICK BM: 1) Sample No. 1 2) Sample No. 2 3) Sample No. 3 4) Sample No. 4 5) Sample No. 5 6) Bitumen (P.C. on weight of dry aggregate) 7) Marshall Stability in Kg. 8) Marshall flow in mm 9) Percent air voids in mix 10) Percent air voids in material Agg. (VMB) 11) Percent air voids in material Agg. Filled with Bitumen (VFB) 12) Binder Content P.C. by weight of mix 13) Laboratory (Design) Density in gm/cc (By Weight) (By Weight) (By Weight) (By Weight) (By Weight) = 25% = 25% = 20% = 20% = 10% = 3.636 = 1500 = 2.50 = 3.793 = 12.750 = 68.797 = 3.508 = 2.384

COMPUTATION OF MATERIALS REQUIRED FOR 10 M2, AREA OF 75 MM THICK BM Sample No. Sample No. 1 Sample No. 2 Sample No. 3 Sample No. 4 Sample No. 5 Bitumen Materials by Weight in Kg. 431.317 431.317 345.053 345.053 172.526 62.730 Kg Materials by Volume in m3 0.280 0.286 0.231 0.231 0.103 62.730 Kg

Research Asstt. RRL, PWD, Ghy-25

Asstt. Engineer RRL, PWD, Ghy-25

Research Officer Road Research Laboratory PWD (R&B) Ambari, Guwahati-25

FOR 25mm THICK SEMI DENSE BITUMINOUS CONCRETE 1. 2. 3. 4. For 75mm thick BM: For 25mm thick SDBC the above three samples were utilized for grading of materials and are shown below: Sample No 3 IS Sieve Percentage Designation Passing 13.2 mm 100 11.2 mm 81.539 5.6 mm 2.087 2.8 mm 0.695 710 Mic 0.525 355 Mic 0.497 180 Mic 0.468 90 Mic 0.355 Sample No 4 IS Sieve Percentage Designation Passing 13.2 mm 100 11.2 mm 100 5.6 mm 83.850 2.8 mm 30.755 710 Mic 0.429 355 Mic 0.397 180 Mic 0.350 90 Mic 0.286 Sample No 5 IS Sieve Percentage Designation Passing 13.2 mm 100 11.2 mm 100 5.6 mm 100 2.8 mm 100 710 Mic 99.60 355 Mic 67.40 180 Mic 55.00 90 Mic 20.20 Sample No. 3 Sample No. 4 Sample No. 5 Sample No. 6 = = = = 11.2mm down chips 5.6mm down chips Crusher Dust Bitumen 80/100

Aggregate were blended in the ratio (By weight of dry aggregate) in a manner shown below: 3 : 4 : 5 = 40 : 40 : 20 So, actual grading is achieved after blending the sample in above proportions are shown below: IS Sieve Designation 13.2 mm 11.2 mm 5.6 mm 2.8 mm 710 Mic 355 Mic 180 Mic 90 Mic Percentage Passing 100 92.615 54.374 32.500 13.861 11.356 8.047 4.296 Percentage by weight Passing the IS Sieve 100 88 100 42 64 22 38 11 24 7 18 5 13 39

PROPERTIES OF MIX FOR 25mm THICK SDBC: 1) Sample No. 3 2) Sample No. 4 3) Sample No. 5 4) Bitumen (P.C. on weight of dry aggregate) 5) Marshall Stability in Kg. 6) Marshall flow in mm 7) Percent air voids in mix 8) Percent air voids in material Agg. (VMB) 9) Percent air voids in material Agg. Filled with Bitumen (VFB) 10) Binder Content P.C. by weight of mix 11) Laboratory (Design) Density in gm/cc (By Weight) (By Weight) (By Weight) = 40% = 40% = 20% = 4.181 = 1300 = 2.666 = 4.924 = 14.298 = 65.561 = 4.013 = 2.336

COMPUTATION OF MATERIALS REQUIRED FOR 10 m2, AREA OF 25 mm THICK SDBC

Sample No. Sample No. 3 Sample No. 4 Sample No. 5 Bitumen

Materials by Weight in Kg. 224.225 224.225 112.112 23.437 Kg

Materials by Volume in m3 0.150 0.150 0.067 23.437 Kg

Research Asstt. RRL, PWD, Ghy-25

Asstt. Engineer RRL, PWD, Ghy-25

Research Officer Road Research Laboratory PWD (R&B) Ambari, Guwahati-25

Вам также может понравиться

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIIОт EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIITatsuki OhjiОценок пока нет

- Material Testing Laboratory ManualДокумент22 страницыMaterial Testing Laboratory ManualSamirHashimОценок пока нет

- Advances in Ceramic Armor XIОт EverandAdvances in Ceramic Armor XIJerry C. LaSalviaОценок пока нет

- DBM Final ReportДокумент7 страницDBM Final ReportBilal Ahmed BarbhuiyaОценок пока нет

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesОт EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghОценок пока нет

- Mix Design 8 2Документ6 страницMix Design 8 2Eulogio JameroОценок пока нет

- NH Traning 6Документ9 страницNH Traning 6Bilal Ahmed BarbhuiyaОценок пока нет

- ESP Lesson 7 (Industrial Applications For Fabric Filters)Документ24 страницыESP Lesson 7 (Industrial Applications For Fabric Filters)jkaunoОценок пока нет

- By: Hiralal Agrawal: Executive EngineerДокумент38 страницBy: Hiralal Agrawal: Executive EngineerCheng EngiОценок пока нет

- ACI Mix-Design-8-2Документ6 страницACI Mix-Design-8-2Aboalmaail AlaminОценок пока нет

- Aci Method of Proportioning Concrete Mixes: Step 1. Choice of SlumpДокумент6 страницAci Method of Proportioning Concrete Mixes: Step 1. Choice of SlumpEulogio JameroОценок пока нет

- Quality Control Measures in Asphalt Pavement Constructio BetongДокумент125 страницQuality Control Measures in Asphalt Pavement Constructio BetongMark James MateoОценок пока нет

- Soundness of Aggregate Using Sodium Sulfate or Magnesium SulfateДокумент11 страницSoundness of Aggregate Using Sodium Sulfate or Magnesium SulfatelitrakhanОценок пока нет

- Testing - Concrete - FinalДокумент94 страницыTesting - Concrete - FinalParvatham SubbuОценок пока нет

- Material - Testing-lab-manual-Test #4Документ4 страницыMaterial - Testing-lab-manual-Test #4Scarlet Kaye DelivigneОценок пока нет

- Concrete AggregatesДокумент34 страницыConcrete AggregatesjesОценок пока нет

- Fineness Modulus of Fine Aggregate: Test Procedure ForДокумент2 страницыFineness Modulus of Fine Aggregate: Test Procedure ForMarhoum Amboloto AbdulhalimОценок пока нет

- DO - 013 - S2013 Generic Specs For SmaДокумент7 страницDO - 013 - S2013 Generic Specs For SmaAndrei AlidoОценок пока нет

- University of Duhok College of Engineering Civil Department 2 Year, 2017-2018Документ11 страницUniversity of Duhok College of Engineering Civil Department 2 Year, 2017-2018Dakheel malekoОценок пока нет

- Diagnostic Study For Cement Mill OptimizationДокумент9 страницDiagnostic Study For Cement Mill OptimizationHilmy MuhammadОценок пока нет

- Aashto t27 t11Документ22 страницыAashto t27 t11Mariana CabralОценок пока нет

- Bituminous Mix DesignДокумент62 страницыBituminous Mix Designer_kenedy75% (12)

- Ball Mill - Operation, Inspection & OptimizationДокумент38 страницBall Mill - Operation, Inspection & OptimizationMadang Wijaya100% (2)

- 2015 - Standard Method of Test For Sieve Analysis of Fine and Coarse AggregatesДокумент9 страниц2015 - Standard Method of Test For Sieve Analysis of Fine and Coarse AggregatesSameh AhmedОценок пока нет

- Slump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45Документ37 страницSlump Test: Sourse /location:: CC Pavement Grade of Concrete:: M30 Water Cement Ratio:: 0.45ChManikumarОценок пока нет

- Fineness Modulus PDFДокумент2 страницыFineness Modulus PDFArvind Kumar ShawОценок пока нет

- Lab 5 - Los Angeles Index Abrasion TestДокумент6 страницLab 5 - Los Angeles Index Abrasion TestankeshОценок пока нет

- Constructio and QC in Rigid Pavements As Per IRC 15 and 58 201Документ192 страницыConstructio and QC in Rigid Pavements As Per IRC 15 and 58 201Vizag Roads100% (39)

- C4 - Sieve Analysis (Aggregate Grading) For Fine and Coarse AggregateДокумент6 страницC4 - Sieve Analysis (Aggregate Grading) For Fine and Coarse AggregateHui Edrox57% (7)

- Spierings 2011 Influence of The Particle Size Distribution On Surface Quality and Mechanical Properties in AДокумент10 страницSpierings 2011 Influence of The Particle Size Distribution On Surface Quality and Mechanical Properties in ARaj RajeshОценок пока нет

- Mix Design ProgramДокумент32 страницыMix Design ProgramBilal Ahmed Barbhuiya67% (3)

- Specification For Concrete (Haunching)Документ11 страницSpecification For Concrete (Haunching)jenОценок пока нет

- Mortar Strength & SoundnessДокумент21 страницаMortar Strength & Soundnessdardar curryОценок пока нет

- NAM Road Project Technical SpecificationДокумент6 страницNAM Road Project Technical SpecificationikreddyОценок пока нет

- (2004) Design and Operation of Vertimill For Secondary GrindingДокумент12 страниц(2004) Design and Operation of Vertimill For Secondary GrindingLuis Miguel La TorreОценок пока нет

- Tyre Flap (EPDM) Specification306 - 83 - SEP - 2016Документ5 страницTyre Flap (EPDM) Specification306 - 83 - SEP - 2016Purchase and Stores Officer Contract Cell-IIОценок пока нет

- Fabric Technical Specifications: AppendixДокумент4 страницыFabric Technical Specifications: AppendixAani MazharОценок пока нет

- Conversion FactorsДокумент10 страницConversion FactorsJohn MofireОценок пока нет

- Cement Mill 1 Optimization Case Study - Part 2Документ18 страницCement Mill 1 Optimization Case Study - Part 2mohamed abd el attyОценок пока нет

- Marshall Stability TestДокумент10 страницMarshall Stability TestBVS NAGABABUОценок пока нет

- Machinery & YarnДокумент7 страницMachinery & YarnVastramWordwideОценок пока нет

- Ministry of Transportation - Field Services, PavingДокумент12 страницMinistry of Transportation - Field Services, PavingukruegerОценок пока нет

- CBR OsjiДокумент6 страницCBR OsjiSA023Оценок пока нет

- Materials of Construction Laboratory: Sieve Analysis of Aggregate (ASTM C136Документ38 страницMaterials of Construction Laboratory: Sieve Analysis of Aggregate (ASTM C136Mohammed JberОценок пока нет

- FinalДокумент52 страницыFinalJessie Radaza Tutor100% (1)

- Presentation Coupler SystemДокумент21 страницаPresentation Coupler SystemPralhad Kore100% (1)

- Methodology 9.0 Bituminous Concrete (BC)Документ12 страницMethodology 9.0 Bituminous Concrete (BC)Eppili AdinarayanaОценок пока нет

- Civil - Highway Lab Manual - 2018Документ17 страницCivil - Highway Lab Manual - 2018Altamash NadimallaОценок пока нет

- Marshall Method of Mix Design (Compatibility Mode)Документ34 страницыMarshall Method of Mix Design (Compatibility Mode)Farah MujahidОценок пока нет

- C & D Waste - Use of Recycled Aggregates: Vir Vikram AroraДокумент34 страницыC & D Waste - Use of Recycled Aggregates: Vir Vikram Aroramazhar khanОценок пока нет

- Marshall Stability TestДокумент10 страницMarshall Stability Testanon_789699787Оценок пока нет

- Asphalt Concrete Core Rockfill DamДокумент7 страницAsphalt Concrete Core Rockfill DamDion Eko FebriantoОценок пока нет

- 08 Shotcrete Quality Control & Testing For An Underground Mine in CanadaДокумент42 страницы08 Shotcrete Quality Control & Testing For An Underground Mine in Canadajusselino100% (3)

- Wsdot Errata To Waqtc Fop For Aashto T 27 - T 11: Sieve Analysis of Fine and Coarse AggregatesДокумент30 страницWsdot Errata To Waqtc Fop For Aashto T 27 - T 11: Sieve Analysis of Fine and Coarse AggregatesWaqas Ahmad AbbasiОценок пока нет

- Procedure For The Petrographic Analysis of Coarse AggregateДокумент23 страницыProcedure For The Petrographic Analysis of Coarse Aggregateswapon kumar shillОценок пока нет

- Coarse Aggregate and Fine AggregateДокумент37 страницCoarse Aggregate and Fine AggregateDanao ErickОценок пока нет

- Impact of Ferrochrome Jricehusk Jflyash Aggrigate On ConcreateДокумент17 страницImpact of Ferrochrome Jricehusk Jflyash Aggrigate On ConcreateDaina MallikОценок пока нет

- Mix Design and Strength Properties of GPCДокумент19 страницMix Design and Strength Properties of GPCpsuvarnasОценок пока нет

- D 5159 - 91 R97 AstmДокумент6 страницD 5159 - 91 R97 AstmLoanОценок пока нет

- BS 594.1-92 - Hot Rolled Asphalt For Roads and Other Paved Areas (Spec For Constituent Materials and Asphalt Mixtures)Документ21 страницаBS 594.1-92 - Hot Rolled Asphalt For Roads and Other Paved Areas (Spec For Constituent Materials and Asphalt Mixtures)Michael VeneerОценок пока нет

- Staad Input File RCC Drain 3 M X 3 MДокумент2 страницыStaad Input File RCC Drain 3 M X 3 MBilal Ahmed BarbhuiyaОценок пока нет

- Box Culver 1 X 4 X 3Документ97 страницBox Culver 1 X 4 X 3Bilal Ahmed BarbhuiyaОценок пока нет

- Box Culvert 1.5 X 1.5Документ2 страницыBox Culvert 1.5 X 1.5Bilal Ahmed Barbhuiya50% (2)

- Wildlife Crossing Design Based On AASHTO-17th & ACI 318-14Документ1 страницаWildlife Crossing Design Based On AASHTO-17th & ACI 318-14Bilal Ahmed BarbhuiyaОценок пока нет

- Appendix C.26 D: Single Cell RCC Box Culvert of Size 2 X 3 (U/S & D/S Pitching)Документ7 страницAppendix C.26 D: Single Cell RCC Box Culvert of Size 2 X 3 (U/S & D/S Pitching)Bilal Ahmed Barbhuiya100% (1)

- Design of A R.C.C Mountable Drain Slab CoverДокумент4 страницыDesign of A R.C.C Mountable Drain Slab CoverBilal Ahmed Barbhuiya100% (8)

- Analysis of A RCC Underpass Box-Bridge: Surabhi Tiwari, A.M.Gharad, P.D.PachporДокумент4 страницыAnalysis of A RCC Underpass Box-Bridge: Surabhi Tiwari, A.M.Gharad, P.D.PachporBilal Ahmed BarbhuiyaОценок пока нет

- Drain DesignDPRДокумент94 страницыDrain DesignDPRBilal Ahmed Barbhuiya100% (1)

- Summary of Findings and Recommendations:: Appointment of A Safety ConsultantДокумент2 страницыSummary of Findings and Recommendations:: Appointment of A Safety ConsultantBilal Ahmed BarbhuiyaОценок пока нет

- MX PresentationДокумент48 страницMX PresentationBilal Ahmed BarbhuiyaОценок пока нет

- Design 12.9 X 22 MДокумент214 страницDesign 12.9 X 22 MBilal Ahmed BarbhuiyaОценок пока нет

- Estimate For Pitching & ApronДокумент63 страницыEstimate For Pitching & ApronBilal Ahmed Barbhuiya67% (3)

- Culvert EssttДокумент51 страницаCulvert EssttBilal Ahmed BarbhuiyaОценок пока нет

- Drain DesignДокумент106 страницDrain DesignBilal Ahmed Barbhuiya100% (2)

- Eq. DesignДокумент15 страницEq. DesignBilal Ahmed BarbhuiyaОценок пока нет

- My - Spreadsheet - SlabДокумент26 страницMy - Spreadsheet - SlabBilal Ahmed Barbhuiya50% (2)

- 5span Contineous BeamДокумент22 страницы5span Contineous BeamBilal Ahmed Barbhuiya100% (1)

- Staad Input File RCC Drain 3 M X 3 MДокумент2 страницыStaad Input File RCC Drain 3 M X 3 MBilal Ahmed BarbhuiyaОценок пока нет

- Drainage DPR PDFДокумент184 страницыDrainage DPR PDFBilal Ahmed BarbhuiyaОценок пока нет

- Statement of Quantity of Concrete, P.C.C. & Soling Per 'M' of Rectangular R.C.C. Drain With Cover at StretchesДокумент18 страницStatement of Quantity of Concrete, P.C.C. & Soling Per 'M' of Rectangular R.C.C. Drain With Cover at StretchesBilal Ahmed BarbhuiyaОценок пока нет

- DPR BridgesДокумент65 страницDPR BridgesBilal Ahmed Barbhuiya100% (2)

- (Contractor or His Authorized Agent.) (Sign - of Contractor or His Authorized Agent.)Документ2 страницы(Contractor or His Authorized Agent.) (Sign - of Contractor or His Authorized Agent.)Bilal Ahmed BarbhuiyaОценок пока нет

- Drain Design by STADDДокумент78 страницDrain Design by STADDBilal Ahmed BarbhuiyaОценок пока нет

- Hyd. Design Drain GU BypassДокумент4 страницыHyd. Design Drain GU BypassBilal Ahmed BarbhuiyaОценок пока нет

- Operational Categorization STДокумент3 страницыOperational Categorization STFalcon Peregrine100% (1)

- Ted Owens - Flying Saucer Intelligences SpeakДокумент34 страницыTed Owens - Flying Saucer Intelligences SpeakHomers SimpsonОценок пока нет

- Schumann Piano Concerto in A Minor Op 54 SM PDFДокумент101 страницаSchumann Piano Concerto in A Minor Op 54 SM PDFMKGUОценок пока нет

- EpdmДокумент2 страницыEpdmhappale2002Оценок пока нет

- UK Environment Agency RM-QG6 - Calibrating Particulate-Monitoring Continuous Emission Monitoring Systems (CEMs), Especially For Low Concentrations of Particulate MatterДокумент7 страницUK Environment Agency RM-QG6 - Calibrating Particulate-Monitoring Continuous Emission Monitoring Systems (CEMs), Especially For Low Concentrations of Particulate MatterTomy SetiyadiОценок пока нет

- Ghis Manual (New)Документ18 страницGhis Manual (New)rookie100% (1)

- A2 UNIT 1 Culture Teacher's NotesДокумент1 страницаA2 UNIT 1 Culture Teacher's NotesCarolinaОценок пока нет

- HO4 EstimationДокумент9 страницHO4 EstimationMirza Naveed BaigОценок пока нет

- Ethical Theories AssignmentДокумент6 страницEthical Theories AssignmentHarvard TutorОценок пока нет

- Nalsar 2006Документ84 страницыNalsar 2006anuragchoubey1Оценок пока нет

- Stereotypes in General-Advantages and Disadvantages: Being Typically EnglishДокумент2 страницыStereotypes in General-Advantages and Disadvantages: Being Typically EnglishDiana IrimieaОценок пока нет

- The Determinants of MoralityДокумент10 страницThe Determinants of MoralityKaimi Ardee BorjaОценок пока нет

- Marchel Solis Research PerseveranceДокумент10 страницMarchel Solis Research PerseveranceTata Duero LachicaОценок пока нет

- Chapter 4 Genes Evolution and BehaviourДокумент13 страницChapter 4 Genes Evolution and BehaviourAlex LiОценок пока нет

- Roles of A System AnalystДокумент17 страницRoles of A System AnalystMohan William SharmaОценок пока нет

- ACCT561 Quiz Week 3Документ2 страницыACCT561 Quiz Week 3alparktuckerОценок пока нет

- E Book Communication and Development Everest M. Roger (1976)Документ43 страницыE Book Communication and Development Everest M. Roger (1976)jefri PandianganОценок пока нет

- The Template For Physics EssayДокумент13 страницThe Template For Physics Essaylarisa2697Оценок пока нет

- Managing Linen at Apollo HospitalsДокумент7 страницManaging Linen at Apollo HospitalsSrijon Moitra0% (2)

- 4 Clay ChemistryДокумент41 страница4 Clay ChemistryMohamed HamdyОценок пока нет

- LittleProfessor ManualДокумент48 страницLittleProfessor ManualÜMineiroОценок пока нет

- Lesson 7 Identifying and Analyzing ClaimsДокумент11 страницLesson 7 Identifying and Analyzing ClaimsConnieRoseRamosОценок пока нет

- Investment Appraisal ThesisДокумент31 страницаInvestment Appraisal Thesisjanakadisa86% (7)

- MCU ArchitectureДокумент232 страницыMCU Architecturesachinshetty001Оценок пока нет

- INVESTIGATION REPORT eFNCR 076 - BOP Test Plug Stuck in CHHДокумент4 страницыINVESTIGATION REPORT eFNCR 076 - BOP Test Plug Stuck in CHHOmer Abd Al NasserОценок пока нет

- Issai 1530 PNДокумент5 страницIssai 1530 PNMian Tahir WaseemОценок пока нет

- DB Qwik Site 5Документ382 страницыDB Qwik Site 5vhin_d_2005Оценок пока нет

- Inquiries, Investigations and Immersion: Quarter 3 - Module 1Документ8 страницInquiries, Investigations and Immersion: Quarter 3 - Module 1Kenneth BautistaОценок пока нет

- YDH FEED VerificationДокумент10 страницYDH FEED VerificationbillОценок пока нет

- An Introduction To Windows Communication FoundationДокумент18 страницAn Introduction To Windows Communication FoundationArdit MeziniОценок пока нет