Академический Документы

Профессиональный Документы

Культура Документы

Air Compressor Maintenance Log PDF

Загружено:

Canh LuongtienИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Air Compressor Maintenance Log PDF

Загружено:

Canh LuongtienАвторское право:

Доступные форматы

Air Compressor Maintenance Log

Make: Model: Serial No.:

To use this maintenance log, check and sign in the appropriate boxes as routine maintenance is performed. Record any notes or information that could be used for future reference in the Maintenance Notes box.

Oil Filter Date Hours Oil Temp.

Part No.

Air Filter

Part No.

Air/Oil Sep.

Part No.

Lubricant

Part No.

Maintenance Notes

Initials

Download and print a new free maintenance log at www.IndustrialAirPower.com

parts@IndustrialAirPower.com

toll free 877-422-1717

www.IndustrialAirPower.com

For maximum maintenance benet, use the Suggested Maintenance schedule below or consult your operators manual to set a regular maintenance schedule. If you have any questions, please contact us at 877-422-1717 or www.IndustrialAirPower.com.

SYMPTOM

CAUSE Incompatible oil in compressor.

CORRECTION Review and analyze oil. Replace with proper lubricant. Rebuild or replace valve. Inspect inlet lter and air path, checking for voids.

Replace and repair as needed.

SUGGESTED MAINTENANCE

Every 1,500 - 2,000 hours Every 2,000 hours Up to every 4,000 hours (depending on air quality) Yearly OR when pressure dierential reaches 10 psi Change coolant lter Analyze lubricant Change air lter Change air/oil seperator

Frequent separator plug-up / collapse

Minimum pressure valve

sticking.

Ruptured intake air path/lter. Excessive air demand. Decreased discharge pressure Service valve open. Leaky service line. Plugged inlet air lter. Inlet valve partially closed.

Check plant air demand and inspect plant for air

leaks.

Close valve. Fix leaks. Clean or replace lter. Check inlet valve assembly and rebuild as needed. Re-set compressor safety. Check switch and verify that power is ON. Check power supply. Change separator element. Adjust setting. Clean after cooler. Inspect and replace as needed. Test and replace oil as needed. Drain receiver to proper level. Replace lubricant line. Inspect and clean coolers. Inspect temperature control valve. Check scavenge line connections. Make sure that scavenge line is cut at 45 angle,

reaches the bottom of the separator and isnt blocked.

SYMPTOM

CAUSE Sump lubricant low. Clogged or varnished heat

exchanger/oil cooler.

CORRECTION Fill lubricant. Inspect lubricant lines for blocks. Analyze lubricant. If varnish is present, ush with cleaner. Rebuild or replace by-pass valve.

Safety shut-down tripped. Failure to start Disconnected main switch. Power failure.

High discharge temperature

Faulty thermal by-pass valve. Restriction of heat exchanger

air ow.

Plugged air/oil separator. Remove restrictions. Check location and make sure there is no

restriction of cool fresh air.

Wrong air pressure setting. High power consumption Obstructed after cooler. Plugged inlet air lter. Lubricant viscosity issues. Overlled lubricant sump. Broken lubricant line. Excessive lubricant consumption High compressor discharge

temperature.

Insucient air circulation at

oil cooler.

Plugged oil lter element. Compressor operating too hot. Chemically active gases

present.

Replace oil lter element(s). See corrections for high discharge temperature. Review plant/operations/make-up air. Analyze oil and correct inlet air source as needed. Periodically drain receiver condensate. Inspect auto-drains, drain lines and valves. Drain, replace and analyze oil. Flush compressor with cleaner.

Premature lubricant breakdown

Improper receiver condensate

draining.

Improperly positioned Mixing incompatible lubricants.

lubricant return scavenge line.

Plugged scavenge line.

Вам также может понравиться

- Compressor ChecklistДокумент5 страницCompressor ChecklistJuanPabloAlvarezОценок пока нет

- Heating Plant Functional TestДокумент81 страницаHeating Plant Functional TestFederico BrigatoОценок пока нет

- Air Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationДокумент6 страницAir Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationGopinath GopiОценок пока нет

- Chiller ChecklistДокумент2 страницыChiller Checklistmk saravanan100% (1)

- Black Soldier Fly Larvae ManualДокумент14 страницBlack Soldier Fly Larvae ManualLeonardo Shibata100% (1)

- 12 Basic Exercises Molly GalbraithДокумент22 страницы12 Basic Exercises Molly GalbraithCanh LuongtienОценок пока нет

- SOP For Compressed Air SystemДокумент14 страницSOP For Compressed Air SystemAbeer arif100% (1)

- Grade 8 Science Activity 1 Quarter 4Документ8 страницGrade 8 Science Activity 1 Quarter 4yoshirabul100% (2)

- Air-Cooled Chiller Maintenance ChecklistДокумент2 страницыAir-Cooled Chiller Maintenance ChecklistMd Rizwan Khan100% (3)

- Utilities Weekly Maintenance Checklist Compressor-Sl270 Sno. Compressor Part Checks Manual RemarksДокумент7 страницUtilities Weekly Maintenance Checklist Compressor-Sl270 Sno. Compressor Part Checks Manual RemarksShahzad AhmedОценок пока нет

- Chilled Water Primary Pump ChecklistДокумент1 страницаChilled Water Primary Pump Checklistsiruslara6491Оценок пока нет

- Compressor ChecklistДокумент4 страницыCompressor ChecklistEber.CV100% (1)

- Chiller Maintenance ChecklistДокумент2 страницыChiller Maintenance ChecklistAssem Elhajj100% (15)

- JAFZA Construction Regulation - Third Edition 2003Документ73 страницыJAFZA Construction Regulation - Third Edition 2003Abdul JabbarОценок пока нет

- Software Version: Date: YVWE Chiller Performance SpecificationДокумент3 страницыSoftware Version: Date: YVWE Chiller Performance Specificationrega list100% (2)

- MEP Sanitary Fixtures Installation ChecklistДокумент36 страницMEP Sanitary Fixtures Installation ChecklistankurОценок пока нет

- Maintenance and Trouble Shooting of Hydraulic SystemsДокумент11 страницMaintenance and Trouble Shooting of Hydraulic SystemsKannan Devadass100% (1)

- cOMMISSIONING 1 - WorksheetДокумент60 страницcOMMISSIONING 1 - WorksheetPramod Dhir100% (1)

- Sop On Maintenance of Air Handling Unit - Pharmaceutical GuidanceДокумент3 страницыSop On Maintenance of Air Handling Unit - Pharmaceutical Guidanceruhy690100% (1)

- Chiller Compressor MaintenanceДокумент90 страницChiller Compressor MaintenanceBabak GhavidelОценок пока нет

- Air Handling Unit Preventive Maintenance Checklist PDFДокумент2 страницыAir Handling Unit Preventive Maintenance Checklist PDFAditya SuardiОценок пока нет

- Chapter 2 - Air Conditioning System - Part 2Документ23 страницыChapter 2 - Air Conditioning System - Part 2khairul izzudinОценок пока нет

- Chillers Daily Preventive MaintenanceДокумент2 страницыChillers Daily Preventive MaintenanceEhteshem Mazhari0% (1)

- Start-Up Checklist For Chiller SystemsДокумент4 страницыStart-Up Checklist For Chiller SystemsPraveenkumar Kashyab0% (1)

- Monthly HVAC Maint. ScheduleДокумент5 страницMonthly HVAC Maint. ScheduleTawfeeq AhmedОценок пока нет

- Maintenance Instruction V03Документ18 страницMaintenance Instruction V03Farooq AhmadОценок пока нет

- Torque SettingsДокумент3 страницыTorque Settingsgamedbk002Оценок пока нет

- Centrifugal Chiller Maintenance ChecklistДокумент1 страницаCentrifugal Chiller Maintenance Checklistosama alabsiОценок пока нет

- Casing Using A WrenchДокумент6 страницCasing Using A WrenchЭльчин ИсаевОценок пока нет

- Front Loader Maintenance PlanДокумент2 страницыFront Loader Maintenance PlanScribdTranslationsОценок пока нет

- Maintenance Schedule for Campus EquipmentДокумент7 страницMaintenance Schedule for Campus EquipmentHtet Linn Aung100% (2)

- CHILLER - Service SOPДокумент6 страницCHILLER - Service SOPsambasivamme100% (1)

- Oil-injected screw compressors from leading manufacturer GHH-RandДокумент8 страницOil-injected screw compressors from leading manufacturer GHH-Randcivodul100% (1)

- 03.SOP For Air CompressorДокумент4 страницы03.SOP For Air CompressorThangella Vijayaramaraju100% (2)

- Ukite 2011Документ123 страницыUkite 2011pikacu19650% (2)

- EVA and MVAДокумент19 страницEVA and MVATanveer Ahmad100% (1)

- OPERATION QUALIFICATION PROTOCOL FOR AIR HANDLING UNIT - Pharmaceutical GuidanceДокумент15 страницOPERATION QUALIFICATION PROTOCOL FOR AIR HANDLING UNIT - Pharmaceutical GuidanceMohamad IsmailОценок пока нет

- CMD Civil Shaft Construction Capability Statement 2015Документ20 страницCMD Civil Shaft Construction Capability Statement 2015aecom2009Оценок пока нет

- Water Cooled Screw Chiller Start-Up ReportДокумент4 страницыWater Cooled Screw Chiller Start-Up ReportAguzmuhhamadd Pecinthamusicksejathiand ThevikingspersibzОценок пока нет

- Boiler Mounting & AccessoriesДокумент14 страницBoiler Mounting & Accessoriesshiraj36100% (1)

- Testing and Commissioning Check ListДокумент1 страницаTesting and Commissioning Check ListarifzakirОценок пока нет

- Chiller Maintenance Procedure PDFДокумент4 страницыChiller Maintenance Procedure PDFMd. Yusuf100% (1)

- Weekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekДокумент8 страницWeekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekfcfernandoОценок пока нет

- Air handling unit startup log templateДокумент4 страницыAir handling unit startup log templateAhmed SofaОценок пока нет

- Air Compressor Maintenance Log PDFДокумент2 страницыAir Compressor Maintenance Log PDFCanh Luongtien100% (3)

- Air Compressor Maintenance Log PDFДокумент2 страницыAir Compressor Maintenance Log PDFCanh Luongtien100% (3)

- Respiratory Medicine 1 50Документ33 страницыRespiratory Medicine 1 50Ahmed Kh. Abu WardaОценок пока нет

- Air Cooled Chiller ChecklistДокумент3 страницыAir Cooled Chiller ChecklistDevendra DhumalОценок пока нет

- Axial & Jet Fans SpecificationДокумент8 страницAxial & Jet Fans SpecificationRamakrishnanОценок пока нет

- Anatomy of Lone Wolf Terrorism Special EДокумент30 страницAnatomy of Lone Wolf Terrorism Special EMika RainmanОценок пока нет

- Kaeser SK 26 Technical Manual PDFДокумент84 страницыKaeser SK 26 Technical Manual PDFSharad Kokate67% (3)

- Sanitisation of Water SystemДокумент4 страницыSanitisation of Water Systemmarkandey gupta100% (1)

- Dust Collector Service ChecklistДокумент1 страницаDust Collector Service ChecklistFatemeh AziziОценок пока нет

- Air-Cooled Chillers Maintenance & Inspection ChecklistДокумент3 страницыAir-Cooled Chillers Maintenance & Inspection ChecklistdjukalОценок пока нет

- Bry-Air Dehumidifier ManualДокумент17 страницBry-Air Dehumidifier ManualMaulik33% (3)

- Preventive Maintenance of Diesel Generator Sets Daily:: Specimen Check-List ForДокумент2 страницыPreventive Maintenance of Diesel Generator Sets Daily:: Specimen Check-List ForAndrewОценок пока нет

- Ventilation FanДокумент7 страницVentilation FanadamzulkarnainОценок пока нет

- Chemical Dosing PotsДокумент3 страницыChemical Dosing PotsBuddhika100% (1)

- PREVENTIVE MAINTENANCE CHECKLIST FOR POWER PRESS MACHINEДокумент1 страницаPREVENTIVE MAINTENANCE CHECKLIST FOR POWER PRESS MACHINESanjay MalhotraОценок пока нет

- Air Compressor ZR 160Документ20 страницAir Compressor ZR 160kattukoluОценок пока нет

- Climaveneta Mainternance Check ListДокумент2 страницыClimaveneta Mainternance Check ListNhật Phong Nguyễn100% (1)

- Boiler Water Management Guidelines For Black Liquor Recovery Boilers (April 2016)Документ58 страницBoiler Water Management Guidelines For Black Liquor Recovery Boilers (April 2016)OsniОценок пока нет

- Top Preventive Maintenance Tips For Your CNC Machine Tools - Hwacheon Asia Pacific Pte. Ltd.Документ11 страницTop Preventive Maintenance Tips For Your CNC Machine Tools - Hwacheon Asia Pacific Pte. Ltd.Saif Uddin AhmedОценок пока нет

- How to Start and Maintain an Air Washer SystemДокумент3 страницыHow to Start and Maintain an Air Washer SystemAmit Balot100% (1)

- 750 TR Chiller Load LineДокумент2 страницы750 TR Chiller Load Linecalvin.bloodaxe4478Оценок пока нет

- M Air-Cooled Chiller - Scroll TCIДокумент20 страницM Air-Cooled Chiller - Scroll TCIstetams.cervantesОценок пока нет

- Essential equipment maintenance checklistДокумент3 страницыEssential equipment maintenance checklistYonas AyeleОценок пока нет

- Sop For MeeДокумент1 страницаSop For MeeChirag Dobariya100% (1)

- Operation Manual: Air ConditionersДокумент10 страницOperation Manual: Air ConditionersTechbhushanОценок пока нет

- Solving Engine Loss Issues with Root Cause AnalysisДокумент13 страницSolving Engine Loss Issues with Root Cause AnalysisashishsinglaОценок пока нет

- Checklist FasilitiesДокумент2 страницыChecklist FasilitieszaindinОценок пока нет

- SKM Chiller Pre-Commissioning Check List Rev 20.06.2022Документ2 страницыSKM Chiller Pre-Commissioning Check List Rev 20.06.2022Riju Scaria/EMD/QTRОценок пока нет

- Suggested Installation Procedures and Instructions For Gasoline EnginesДокумент7 страницSuggested Installation Procedures and Instructions For Gasoline EnginesRyan Tai Hwa ChenОценок пока нет

- Kimair MAM880 User Manual en V.1vДокумент23 страницыKimair MAM880 User Manual en V.1vCanh LuongtienОценок пока нет

- TG19264A (L) : Tinsharp Electronics Co - LTDДокумент1 страницаTG19264A (L) : Tinsharp Electronics Co - LTDCanh LuongtienОценок пока нет

- Rotary Screw Air Compressor Instruction ManualДокумент36 страницRotary Screw Air Compressor Instruction ManualCanh LuongtienОценок пока нет

- External & Internal KM Locknut Socket: 44K7 64K7 44K8 64K8 1/2" 1/2" 3/4" 3/4"Документ1 страницаExternal & Internal KM Locknut Socket: 44K7 64K7 44K8 64K8 1/2" 1/2" 3/4" 3/4"Canh LuongtienОценок пока нет

- 도루코 200마력 소모품 견적서2015.01.21Документ1 страница도루코 200마력 소모품 견적서2015.01.21Canh LuongtienОценок пока нет

- Protecting Your Airend Is Our BusinessДокумент1 страницаProtecting Your Airend Is Our BusinessCanh LuongtienОценок пока нет

- AIR/OIL SEPARATORS TROUBLE SHOOTING GUIDEДокумент13 страницAIR/OIL SEPARATORS TROUBLE SHOOTING GUIDECanh LuongtienОценок пока нет

- The ProLogue One AABB Upgrade ReviewДокумент6 страницThe ProLogue One AABB Upgrade ReviewCanh LuongtienОценок пока нет

- Music and Poetry: Hifi Exclusive Integrated AmplifiersДокумент3 страницыMusic and Poetry: Hifi Exclusive Integrated AmplifiersCanh LuongtienОценок пока нет

- Biến tần any hz PDFДокумент187 страницBiến tần any hz PDFCanh LuongtienОценок пока нет

- Biến tần any hz PDFДокумент187 страницBiến tần any hz PDFCanh LuongtienОценок пока нет

- Oil Seal and Shaft SleeveДокумент6 страницOil Seal and Shaft SleeveCanh LuongtienОценок пока нет

- Orion Ice Dryer&FilterДокумент8 страницOrion Ice Dryer&FilterCanh LuongtienОценок пока нет

- Activated Remove Oil MistДокумент9 страницActivated Remove Oil MistCanh LuongtienОценок пока нет

- Centrifugal Compressor HandbookДокумент186 страницCentrifugal Compressor HandbookHalil İbrahim Küplü100% (1)

- MH EDM Environment en PDFДокумент6 страницMH EDM Environment en PDFCanh LuongtienОценок пока нет

- Oil Seal and Shaft SleeveДокумент6 страницOil Seal and Shaft SleeveCanh LuongtienОценок пока нет

- Donalson PDFДокумент347 страницDonalson PDFMiguel Angel Delgadillo Esquivel100% (1)

- EB Distributor Certificate PDFДокумент1 страницаEB Distributor Certificate PDFCanh LuongtienОценок пока нет

- Filsan Filter Cross Reference List 2013Документ78 страницFilsan Filter Cross Reference List 2013Daniel ArbeláezОценок пока нет

- Sotras: Filters & Products For CompressorsДокумент5 страницSotras: Filters & Products For CompressorsCanh LuongtienОценок пока нет

- An5030 PDFДокумент20 страницAn5030 PDFCanh LuongtienОценок пока нет

- Osp 37vanДокумент20 страницOsp 37vanJuan ManuelОценок пока нет

- Lịch Bảo Dưỡng Máy Nén Khí QuincyДокумент1 страницаLịch Bảo Dưỡng Máy Nén Khí QuincyCanh LuongtienОценок пока нет

- Synthetics History Qa BrochureДокумент24 страницыSynthetics History Qa BrochureCanh LuongtienОценок пока нет

- Calculation of shell and dish thicknessДокумент2 страницыCalculation of shell and dish thicknessThiru AnanthОценок пока нет

- Amazon To Unionize or NotДокумент4 страницыAmazon To Unionize or NotPatrick MutetiОценок пока нет

- Young-Hwa: (Model No.: Yhass)Документ8 страницYoung-Hwa: (Model No.: Yhass)Diki NugrahaОценок пока нет

- King Khalid University College of Engineering Department of Chemical EngineeringДокумент9 страницKing Khalid University College of Engineering Department of Chemical EngineeringbaderОценок пока нет

- Advantest R3131 Spectrum Analyzer Operator ManualДокумент277 страницAdvantest R3131 Spectrum Analyzer Operator ManualMartin Argay100% (1)

- Review of LitetaureДокумент8 страницReview of LitetaureeswariОценок пока нет

- B Fire BehaviorДокумент39 страницB Fire BehaviorDon VitoОценок пока нет

- The Payment of Bonus Act 1965 PDFДокумент30 страницThe Payment of Bonus Act 1965 PDFappu kunda100% (1)

- The Evolution of FungiДокумент15 страницThe Evolution of Fungi2010eon2010Оценок пока нет

- The International Research Congress On Integrative Medicine and Health 2014Документ159 страницThe International Research Congress On Integrative Medicine and Health 2014Sergio Jesús Huapaya GálvezОценок пока нет

- Time ManagementДокумент30 страницTime ManagementVaibhav Vithoba NaikОценок пока нет

- Mechanical Engineering Paper 1 SummaryДокумент20 страницMechanical Engineering Paper 1 SummaryK.v.SinghОценок пока нет

- Zannakeithley Com Affirmations For HeartbreakДокумент17 страницZannakeithley Com Affirmations For Heartbreakaida aОценок пока нет

- Ascha_ASJ19_Nonsurgical Management of Facial Masculinization and FeminizationДокумент15 страницAscha_ASJ19_Nonsurgical Management of Facial Masculinization and Feminizationallen.515Оценок пока нет

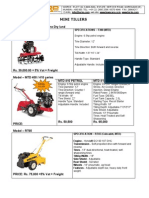

- Optimize soil preparation with a versatile mini tillerДокумент2 страницыOptimize soil preparation with a versatile mini tillerRickson Viahul Rayan C100% (1)

- 2 - Electrical Energy Audit PDFДокумент10 страниц2 - Electrical Energy Audit PDFPrachi BhaveОценок пока нет

- Development and Validation of Stability Indicating RP-HPLC Method For Simultaneous Estimation of Sofosbuvir and Ledipasvir in Tablet Dosage FormДокумент4 страницыDevelopment and Validation of Stability Indicating RP-HPLC Method For Simultaneous Estimation of Sofosbuvir and Ledipasvir in Tablet Dosage FormBaru Chandrasekhar RaoОценок пока нет

- Catalogo Presentacion Johnial UltimoДокумент10 страницCatalogo Presentacion Johnial UltimoEmerson BermudezОценок пока нет

- Metals and Metallurgy: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenДокумент43 страницыMetals and Metallurgy: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDheeraj KumarОценок пока нет

- Finding the Right Pharmacy for Your NeedsДокумент4 страницыFinding the Right Pharmacy for Your Needsprabakar VОценок пока нет

- Solution Manual For Safety Health and Environmental Concepts For The Process Industry 2nd EditionДокумент8 страницSolution Manual For Safety Health and Environmental Concepts For The Process Industry 2nd EditionRobert Hornback100% (34)

- Comparison Between China and Sri-Lanka GDPДокумент6 страницComparison Between China and Sri-Lanka GDPcracking khalifОценок пока нет