Академический Документы

Профессиональный Документы

Культура Документы

IP - 15 - Calculations in Support of IP15-The Area Classification Code For Petroleum Installations - November 2001 PDF

Загружено:

mpicaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

IP - 15 - Calculations in Support of IP15-The Area Classification Code For Petroleum Installations - November 2001 PDF

Загружено:

mpicaАвторское право:

Доступные форматы

Calculations in Support of

IP15: The Area Classification Code

for Petroleum Installations

November 2001

By

P. T. Roberts

OGCH/2

HSE Business Group

Shell Global Solutions (UK), Cheshire Innovation Park,

P.O. Box 1, Chester CH1 3SH, England

Report No. OP.00.47110

Published by

The Institute of Petroleum, London

A charitable company limited by guarantee

Copyright 2001 by The Institute of Petroleum, London:

A charitable company limited by guarantee. Registered No. 135273, England

All rights reserved

No part of this book may be reproduced by any means, or transmitted or translated into

a machine language without the written permission of the publisher.

ISBN 0 85293 339 8

Published by The Institute of Petroleum

Further copies can be obtained from Portland Press Ltd. Commerce Way,

Whitehall Industrial Estate, Colchester CO2 8HP, UK. Tel: +44 (0) 1206 796 351

email: sales@portlandpress.com

v

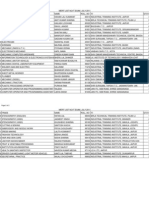

CONTENTS

Page

Foreword...................................................................................................................... vii

Acknowledgements .................................................................................................... viii

Executive summary .................................................................................................... 1

1. Introduction ..................................................................................................... 2

2. Flammability limits for two phase releases .................................................. 3

3. Shape factors and hazard radii for pressurised releases ........................... 6

4. Hazard radii from vents .................................................................................. 10

4.1 Vents from the storage of petroleum products ......................................... 11

4.2 Process vents........................................................................................... 20

5. Evaporation from pools and sumps.............................................................. 22

5.1 Vapour pressure comparisons of some commonly used

Category C fluids...................................................................................... 27

6. Releases into confined areas......................................................................... 29

7. Discussion and conclusions.......................................................................... 34

8. References....................................................................................................... 35

Appendix A:

Methodology................................................................................................................ 37

Appendix B:

Preliminary investigation of hazard radii and shape factors for the

Revision of IP15: the Area classification code for petroleum installations .......... 40

vi

vii

FOREWORD

The Institute of Petroleum commissioned this report to address concern over the effect

of a release containing droplets or a mist on the dispersion distances determined by the

methodology used in IP publication A Risk-Based Approach to hazardous area

classification, 1998. The report also reviews flammability limits, evaporation from pools

and releases into confined areas.

The aim of this publication is to provide a record of the calculations, methodology and

assumptions used to calculate dispersion distances. It provides a traceable scientific

basis that will be applied to the 2

nd

edition of IP publication Model Code of Safe Practice

Part 15: Area Classification code for petroleum installations 1

st

edition, 1990.

Although it is believed that the adoption of the recommendations of this report will assist

the user, the Institute of Petroleum cannot accept any responsibility, of whatsoever kind,

for damage or loss, or alleged damage or loss, arising or otherwise occurring as a result

of the application of this report.

viii

ACKNOWLEDGEMENTS

This report was prepared by Dr Peter Roberts and Dr Les Shirvill and was reviewed by

members of the Institute of Petroleums Area Classification Working Group:

Phil Cleaver Advantica Technology

Howard Crowther Consultant (formerly BP)

Kieran Glynn BP

Alan Tyldesley Health and Safety Executive

Mick Wansborough Shell

The Institute wishes to record its appreciation of the work carried out by the members of

the group.

The Institute also wishes to record its thanks to the Health and Safety Executive for co-

sponsoring this research.

1

Calculations in Support of IP 15: The Area Classification

Code for Petroleum Installations

Executive Summary

The Area Classification Code for Petroleum Installations published by the Institute of

Petroleum (IP 15) offers guidance on the immediate area of hazard associated with the

normal processing and handling of petroleum products and is in very wide use.

A major revision of IP 15 is being prepared which aims not only to update the guidance

based upon best current practice but also to provide a traceable and scientific basis for the

guidance given. This latter is not a trivial task and necessarily depends to a great extent on

the methodology developed for assessing the consequences of accidental releases on a

large scale - much larger than would arise from normal processing and handling. The

quantification of hazard necessarily starts with specifying the type of material and the size of

release which is very much unknown in the case of small spills and leaks. Material types

have been simulated using 5 example fluid compositions coded (A, B, C, G and Gii)

following earlier work to update IP 15. Release rate values used here represent the lower

end of the hazardous release scale. These should be larger than arise in normal handling

and certainly should not be taken as indicative of the magnitude of acceptable spills. In all

circumstances the potential for spills to occur should be rigorously assessed and a full

hazard assessment carried out where necessary.

This note contributes a methodology and the physical basis for the deriving several guidance

parameters relating to:

- the characteristics of two-phase releases compared to single phase releases.

- the definition of shape factors for pressurised releases of both heavier than air and lighter

than air fluids (fluid categories A, B, C, Gi, Gii).

- the flammability limits for the fluids used as examples of categories A, B, C, Gi, Gii.

- hazards arising from the evaporation of category C fluids.

- releases into confined areas.

The major findings arising from this work are summarised below. It has generally been

possible to defend the key recommendations of IP 15 as conservative. Where revisions are

recommended these are strongly dependent on scenario and fluid type.

- The hazard radii for pressurised releases of category B and C fluids should be derived

assuming a mechanically generated flammable mist; previously gaseous releases were

assumed. The Hazard radii for category B and C fluids are increased relative to previous

guidance.

- Numeric flammability limits published in Annex D of A Risk-Based Approach to

Hazardous Area Classification for the category B and C fluids have been updated to take

account of the composition of the flammable mist; previously low vapour components

were assumed to rain-out and not contribute to the lower flammability limit evaluation.

- Shape factors for pressurised releases are revised to take better account of the role of

initial jet momentum on the jet trajectory. In particular the lighter than air gases (category

Gi and Gii fluids) are found to have qualitatively more similar shape factors to the two-

2

phase category A, B and C releases; previously buoyancy was assumed to dominate their

dispersion.

- Hazard radii for discharges from vents are evaluated. The hazard radius varies from

slightly smaller to slightly larger than that in the existing guidance depending on the

properties of the vented vapour.

- The composition of vapour from vents on storage facilities maintained at atmospheric

pressure may be variable (in composition, density and flammability) and the user of the

new guidance should be aware of the effect of this variability because of the

consequence for hazard radii.

- The example range of venting rate and vent sizes used in the guidance are not wholly

consistent with the assumption that the discharge takes place at atmospheric pressure.

The relationship between venting rate and pressure of discharge is investigated and a

value of 300 mb suggested as a threshold above which the consequences of pressure

should be assessed. This is of significance for multicomponent fluids where

condensation may occur.

- The existing guidance for liquid spillages is conservative, judged by the volatility of the

model category C fluid. The guidance is applicable to materials with approximately twice

the vapour generation rate of category C fluid under the specimen conditions. Relative

vapour pressures for some common hydrocarbon compounds are listed.

- The existing guidance for sumps is conservative, judged by the volatility of the model

category C.

- Vapour generation at the source of spillage of category C fluids is a potential hazard

dictated by the spill rate and conditions and not the rate of evaporation of the liquid pool.

The new guidance should emphasise the role of release conditions in determining the

initial vapour generation from spills of category C fluids.

- For releases into confined areas the relative size of spillage and building are of key

importance. The classification Adequate ventilation has been assessed with respect to

these parameters.

1. Introduction

Shell Global Solutions, on behalf of the Institute of Petroleum (IP), has worked to establish a

methodology by which certain guidance parameters in the IP 15 document can be calculated

from specific scenarios. The benefit is two-fold. Firstly, the existence of a methodology

enables the guidance to be independently verified, secondly, it allows an end user to derive

specific fluid and process dependent values in a consistent way when required. The

methodology closely follows that used for assessing the consequence of hazardous events.

Several of the scenarios adopted to illustrate the effect, say on hazard radius, of changing

release scenarios were found to produce events that in practice would require a formal

assessment of risk; i.e. they fall outwith the definition of normal processing and handling of

petroleum products. None of the discharge rates used in this report should be taken as

representing normal or acceptable routine practice.

This work took place in two stages. A preliminary investigation was carried out for Shell

(UK) in order to verify the hazard radii reported in A Risk-Based Approach to Hazardous

Area Classification, Institute of Petroleum, November 1998 and to see if the shape factors

reported in IP 15 were adequate.

- the values of the hazard radius for category B and category C fluids in the Risk-Based

Approach Document were too small, and the release scenarios unrealistic.

- the shape factors for lighter than air gases (category Gi and Gii fluids), and to a lesser

extent, the low vapour pressure category B and C fluids needed to be revised.

3

An abridged version of the report of this preliminary investigation is included as Appendix B

to this note. The major findings are restated in the body of this note.

The implied changes to key values in IP 15 were significant. The Institute of Petroleum

requested that Shell Global Solutions pursue 6 work items to verify and quantify the

necessary changes for the revision to IP 15 . These were (in short)

Work Item 1: To examine results of the AIChE Release modelling program and other recent

data and derive, if possible, an improved estimate of the flammability limit for high flash-point

releases (e.g. taking account droplet size, rain-out) that would allow the category C hazard

radii to be better assessed.

Work Item 2: To describe the method used to calculate the hazard radii; define the shape

factors for the fluid releases; state the hazard radii.

Work Item 3: Cross check the hazard radii for the process vents.

Work Item 4: Liquid Pools due to Spillage (section 5.11) To determine the hazard

radii/shape factor for shallow liquid pools.

Work item 5: Open Sumps and Interceptors (section 5.12) To determine the hazard

radii/shape factor for deep liquid pools by taking the steady state evaporation rate and a

steady dispersion calculation.

Work item 6: Propose a simple low momentum calculation method; implement this method

and use it to assess the external hazard for releases of category A and category B fluid

inside a building and evaluate the hazard radii.

Progress on these work items was reviewed. Specific scenarios were discussed and

amended in discussion with the Area Classification Committee of the IP to give the results

below. These results are in a form suitable for inclusion in the IP 15 revision.

A consequence of changes to some scenarios is that numeric values obtained in the original

investigation on behalf of Shell (UK)(Appendix B) are changed. Only values from the main

body of this note should be transferred to the new guidance.

Where possible publicly available and publicly evaluated hazard assessment models have

been used in this work.

2. Flammability Limits for Two Phase Releases.

A major advance in hazard assessment has been the development of models capable of

describing the dispersion of two-phase liquids. The AEROPLUME model is one example,

being part of the HGSYSTEM v3.0 (1995) suite of models developed by Shell for industry

consortia as publicly available tools subject to peer review and acting as a standard

benchmark in model evaluation exercises.

Two-phase releases can arise in two ways:

- by the atomisation accompanying the expansion and phase change of material that is

liquid under storage conditions of high pressure, and gaseous at atmospheric

temperature and pressure.

4

- by the mechanical break-up of a (volatile) liquid into small droplets and their subsequent

evaporation.

Mists of fine droplets and dust clouds of combustible material can be very highly flammable.

Unlike a gaseous mixture that is combustible only within narrow flammability limits each

droplet can act as a fuel source surrounded by a plentiful air supply. Mists are optically thick

and, once ignition has occurred, heat transfer by radiation very effectively preheats

droplets/particles distant from the ignition front. In extreme cases and especially for dust

clouds, this preheating is sufficient for auto-ignition to take place causing the cloud to burn

throughout its volume. This can be a much more vigorous process than a gas cloud fire

where a flame-front passes through the mixture.

The flammability hazard arising from a two-phase release depends in a complicated way

upon the ease of ignition of the fluid, the droplet size distribution and the concentration of

droplets and vapour in air. Unfortunately very little is known about precise flammability

criteria for mists arising from real releases. The summary guidance based upon a review

of available literature (Appendix B, Lees, 1998) is that the potential of a mist to burn should

be assessed: take all the droplets present in a volume, evaporate them and see if the

resulting vapour and air mixture lies within the known vapour phase flammability limits. The

easiest way to evaluate this is to use a mass based flammability limit (kg fuel/m

3

air) in place

of the standard and familiar volume based limit (m

3

fuel/m

3

air) used for vapours.

This definition of a flammability limit:

- has NO effect on hazard distances calculated for gaseous mixtures or two-phase

mixtures of very volatile components

i

.

- has a profound effect on the hazard distances calculated for the category B and category

C example fluids resulting in a substantial INCREASE in hazard radius over previous

advice based upon volumetric flammability limit values.

Not all of the liquid released from a pressurised source might remain airborne. Thus, loss of

fluid to the ground through rain-out may mitigate the hazard associated with two-phase

releases with a low volatility component. The question of rain-out has been investigated at

length by the Center for Chemical Process Safety of the American Institute of Chemical

Engineers by means of a series of experiments and an extended modelling exercise.

Unfortunately the problem has not been satisfactorily solved. The combined results of this

study are reported by Johnson and Woodward (1999) and expressed in software form as a

model, called Release.

The Release model does not account for all of the physical processes involved in two-phase

releases of low volatility materials and is strongly tuned to account for the results of the

experiments that were carried out. These experiments aimed to measure the total liquid

deposition from pressurised releases of several materials under a limited and non-ideal set

of environmental conditions. An obvious concern is that the validity of the model outside of

the range of the calibration data is unknown. The model performance is also poor in several

respects.

i

This applies to the category A (two-phase), Gi and Gii (gaseous) example fluids used in the IP 15

revision at the reference atmospheric conditions and release conditions therein.

5

Two versions of the model are supplied on CDROM by AIChE; an original model and a

corrected model. These have different functionality. The corrected model is intended for

end-use and is referred to hereafter in this report.

The Release model was reviewed by AEA Technology for the UK Health and Safety

Executive (Ramsdale and Tickle (2000)). We conclude from the AEAT report, together with

our less detailed investigation of the model, that:

- the Release model would over-predict rain-out by a substantial margin for category C

fluids.

We also believe that the relationship between over-pressure and rain-out is not robustly

developed and may not be extrapolated to conditions outside of the tests. With these

reservations in mind, but for completeness, we used the Release model to calculate rain-out

for cyclo-hexane using the conditions of release temperature, pressure and hole size used in

this study for the IP. Cyclo-hexane is the closest to a category C fluid of those tested.

We found that:

- mass flow rates calculated by the Release model as a function of hole size and pressure

were realistic.

- rain-out as a fraction of mass-flow rate was independent of hole size and a function of

pressure only. The calculated rain-out values were:

Pressure (bar) Rain-out (fraction of mass released)

5 0.98

10 0.44

50 0

100 0

Table 1 Results of the Release model for Cyclo-Hexane.

- the rain-out fraction did not depend upon the axial location in the jet.(input parameter ZJ)

We do not believe that the values in Table 1 are necessarily correct although they confirm

our intuition that pressurised releases should become atomised. Further the consensus of

the model reviewers is that Release overestimates the amount of rain-out. For the purposes

of this work we therefore assume that:

- rain-out of liquid from pressurised releases can be neglected in calculating hazard radii.

This is in accord with the concluding remarks (5.2) of the AEAT review which suggest that

low volatility materials should conservatively be treated as a mist. There must be a lower

limit to the drive pressure for which this is true and further work is needed to establish the

proper limits.

It does seem credible, from intuition and from Table 1, that the 5 bar pressure releases

would rain-out. However, if they do not form a flammable mist they would instead form an

initially coherent liquid jet. The throw of a liquid jet can be quite substantial and could

credibly extend the same distance as we calculate here for dispersed phase jets. A liquid jet

of gasoline, say, would present a contact hazard to electrical equipment on exposed

surfaces and also form a liquid pool on the ground that will flow away from the source. The

result on ignition would be a pool fire rather than a jet-fire or cloud deflagration. For these

reasons we retain the hazard radii for Category C fluid down to the 5 bar condition.

6

It is worth noting that, for flammable as opposed to toxic hazards, the Release model

prediction of total rain-out does require qualification as to at what distance from the source

the rain-out occurs. Clearly to mitigate the hazard this must be smaller than the calculated

hazard radius. For toxic hazards (evaluated at a long distance from the release point) only

the total released needs to be known.

The revision of the IP guidelines is based on model fluids for the five fluid categories. These

first appeared in the Addendum to IP 15: A Risk Based Approach to Hazardous Area

Classification. The fluid properties are quoted in Table 2. We note:

- The vapour phase flammability limits have been re-calculated and differ from those in the

risk-based addendum to IP 15. The derivation of those flammability limits is not known.

However, we infer that this is because of a changed assumption that all of the released

material might participate in a fire. Certainly the previously published values are

consistent with the assumption that only the light ends of the mixture would burn and

match those calculated for a pseudo-mixture of hydrocarbons smaller than C8.

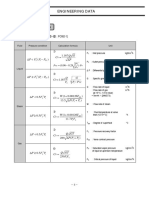

Stream

component

(mol %)

Fluid

Cat. A

Fluid

Cat. B

Fluid

Cat. C

Fluid

Cat. G

(i)

Fluid

Cat. G

(ii)

Comp.

LFL

(vol %)

MW Boiling

point C

N

2

Nitrogen 0.00 0.00 0.00 2.00 2.00 - 28.01 -196

C

1

Methane 0.00 4.00 0.00 88.45 10.00 5.00 16.04 -161

C

2

Ethane 0.00 0.00 0.00 4.50 3.00 3.00 30.07 -87

C

3

Propane 70.00 6.00 1.00 3.00 3.00 2.10 44.09 -42

C

4

Butane 30.00 7.00 1.00 1.00 1.00 1.80 58.12 -1

C

5

Pentane 0.00 9.00 2.00 1.00 0.00 1.40 72.15 36

C

6

Hexane 0.00 11.00 3.00 0.00 0.00 1.20 86.17 69

C

7

Heptane 0.00 16.00 3.00 0.00 0.00 1.05 100.20 98

C

8

Octane 0.00 22.00 27.00 0.00 0.00 0.95 114.23 126

C

9

Nonane 0.00 0.00 25.00 0.00 0.00 0.85 128.26 151

C

10

Decane 0.00 25.00 38.00 0.00 0.00 0.75 142.28 173

H

2

O Water 0.00 0.00 0.00 0.05 0.00 - 18.02 100

Carbon

Dioxide

0.00 0.00 0.00 0.00 1.00 - 44.01 -78

(sub)

Hydrogen 0.00 0.00 0.00 0.00 80.00 4.00 2.02 -253

Average

MW

48.30 100.06 125.03 18.74 7.03

LFL (vol %) 2.00 1.05 0.86 4.6 4.00

LFL (kg/m

3

) 0.039 0.042 0.043 0.034 0.011

Table 2 Composition of the example category A,B,C, G(i) and G(ii) Fluids and their lower

flammability limits (LFL)

3. Shape Factors and Hazard Radii for Pressurised Releases

The major findings of this study, compared with earlier guidance are that:

- Pressurised releases give rise to an approximately spherical hazard zone

ii

for all

categories of fluid, except where the release comes into ground contact where the hazard

distance is extended.

ii

In the context of flammable hazards.

7

- Hazard radii for category B and category C fluids are substantially greater than those

quoted in the Addendum to IP 15: A Risk-Based Approach to Hazardous Area

Classification.

- The increase in hazard radius is due to the redefinition of flammability limit and not to

substantial differences in modelling changes.

The new shape factors are shown in Figure 1. The shape factor depends upon the height

of the release and the hazard radius.

8

R

1

Source

(a) Releases where H > R

1

+ 1

R

1

1

m

R2

Source

H

b) Releases where 1 < H s R

1

+ 1

Source

R

1

R2

1

m

c) Releases where H s 1

Figure 1 Shape Factors for Pressurised Releases

9

The key features are:

- Releases below a height (H) of 1 m are declared to be influenced by the ground and to

have a hazard radius R

2

.

- Releases above 1 m, but at heights below the hazard radius R

1

+ 1 m are declared to be

influenced by the ground if the release is directed downward and passes below 1 m.

- Releases at a height above the hazard radius R

1

+1 m are declared independent of the

ground.

The Hazard radii are given in

Table 3 for the primary radius R

1

and in Table 4 for the ground radius R

2

. For small

releases, giving a dimension R

1

not substantially larger than 1 m, the radii are similar.

The numerical values given in

Table 3 and Table 4 are specific to the example fluids. The release rate for these fluids is

only weakly dependent upon small variations in the assumed storage temperature about 20

C, which is chosen to reflect a daily average UK summer temperature. Other fluids may be

more sensitive to temperature changes.

Release flow rate

(kg/s)

Hazard radius R

1

(metres)

Fluid

Category

Release

pressure

Release hole diameter Release hole diameter

(bara) 1mm 2mm 5mm 10mm 1mm 2mm 5mm 10mm

A 5

*

0.01 0.04 0.3 1.0 2 4 8 14

10 0.01 0.06 0.4 1.5 2.5 4 9 16

50 0.03 0.14 0.9 3.5 2.5 5 11 20

100 0.05 0.2 1.20 5.0 2.5 5 11 22

B 5 0.01 0.04 0.30 1.0 2 4 8 14

10 0.02 0.07 0.40 1.7 2 4 9 16

50 0.04 0.15 1.0 4.0 2 4 10 19

100 0.06 0.2 1.4 5.5 2 4 10. 20

C 5 0.01 0.06 0.3 1.1 2 4 8 14

10 0.02 0.1 0.4 1.7 2.5 4.5 9 17

50 0.04 0.2 1.0 4.0 2.5 5 11 21

100 0.06 0.25 1.4 6 2.5 5 12 22

G(i) 5 0.001 0.002 0.02 0.06 < 1 < 1 <1.0 1.5

10 0.001 0.005 0.03 0.10 < 1 < 1 1.0 2

50 0.007 0.03 0.2 0.7 < 1 1.0 2.5 5

100 0.015 0.06 0.4 1.5 < 1 1.5 4.0 7

G(ii) 5 0.0004 0.001 0.01 0.04 < 1 <1 1.5 3

10 0.001 0.003 0.02 0.07 < 1 1 2 4

50 0.004 0.02 0.1 0.4 < 1 2 4 8

100 0.007 0.03 0.2 0.7 1 2 6 11

Table 3 Primary Hazard radius, R

1

for example releases. (Rounded figures)

*At the fluid storage temperature of 20

o

C the nominal discharge pressure of 5 bara is below

the saturated vapour pressure of the category A fluid. The saturated vapour pressure (6.8

bara) was used to calculate the discharge rate and dispersion.

10

Release flow rate

(kg/s)

Hazard radius R

2

(metres)

Fluid

Category

Release

pressure

Release hole diameter Release hole diameter

(bara) 1mm 2mm 5mm 10mm 1mm 2mm 5mm 10mm

A 5

*

0.01 0.04 0.3 1.0 2 4 16 40

10 0.01 0.06 0.4 1.5 2.5 4.5 20 50

50 0.03 0.14 0.9 3.5 3 5.5 20 50

100 0.05 0.2 1.2 5.0 3 6 20 50

B 5 0.01 0.04 0.3 1.0 2 4 14 40

10 0.02 0.07 0.4 1.7 2.5 4 16 40

50 0.04 0.15 1.0 4.0 2.5 5 17 40

100 0.06 0.2 1.4 5.5 3 5 17 40

C 5 0.01 0.06 0.3 1.1 2.5 4 20 50

10 0.02 0.1 0.4 1.7 2.5 4.5 21 50

50 0.04 0.2 1.0 4.0 3 5.5 21 50

100 0.06 0.25 1.4 6 3 6 21 50

G(i) 5 0.001 0.002 0.02 0.06 < 1 < 1 1.0 2

10 0.001 0.005 0.03 0.10 < 1 < 1 1.5 3

50 0.007 0.03 0.2 0.7 < 1 1.5 3.5 7

100 0.015 0.06 0.4 1.5 1.0 2.0 5 11

G(ii) 5 0.0004 0.001 0.01 0.04 < 1 < 1 2 4

10 0.001 0.003 0.02 0.07 < 1 1 2.5 5

50 0.004 0.02 0.1 0.4 1 2 6 11

100 0.007 0.03 0.2 0.7 2.0 3 8 14

Table 4 Hazard Radius at Ground level, R

2

, for the example releases

For larger releases R

2

can be approximated from R

1

using Table 5. The ratio decreases as

the release pressure increases because mixing improves.

Fluid Category R

2

/R

1

Low pressure High Pressure

A 3.0 2.2

B 2.6 2.0

C 3.5 2.0

G(i) 1.4 1.5

G(ii) 1.3 1.3

Table 5 Quick estimator for the hazard radius at ground level, R

2

.

4. Hazard Radii from vents

In this chapter we address hazard radii for discharges from vents using a standard matrix of

conditions and ambient conditions of neutral atmospheric stability and a temperature of

30 C. A vent is defined as a means of release of vapour at or near to atmospheric

pressure. This is distinct from the pressurised releases considered in section 3.

The results of the calculations for the storage of petroleum products are given in section 4.1

and for process vents in section 4.2. The main findings, which result from the use of the

prescribed matrix of conditions, are that:

11

- low flow rates through the larger orifices implies insufficient exit momentum to disperse

the vented material as a jet. The dispersion process then becomes dependent on the

detailed flow interaction at the vent tip. Downwash, contacting of material below the vent

height and dense vapours in the vicinity and below the vent exit are to be expected in

these cases.

- some combinations of venting rates and vent sizes are incompatible with the assumption

of discharge at atmospheric pressure.

- a guideline value of 300 mb for the pressure drop across a vent is suggested as an

upper bound to atmospheric pressure releases. Above this pressure account needs to

be taken of density changes due to pressure differences in calculating discharge rates for

ideal gases. The effect of pressure on vapour composition should be screened because

components of high flashpoint fluids may condense.

- Emissions from the storage of category B and category C fluids necessarily imply that the

fluid vapour are in some admixture with air or an inert gas. Hazard radii are derived for a

range of possible vapour compositions treated as ideal gases with molecular weights

between 48 and 100. The impact of vapour composition on flammability limits is also

taken approximately into account.

- The shape factor from the existing guidance is retained. The actual shape of the plume

from a vent varies from an upright jet, to a bent-over plume, to a plume subsiding below

the vent height depending upon the released gas composition, flow rate, vent size and

wind speed. With this complexity it is appropriate and conservative to retain a spherical

hazard radius around the exit plane.

- The hazard radii vary from just smaller to just larger than those in the existing guidance

depending upon the vapour composition and flammability limit.

- The existing guidance for process vents is in agreement with these results.

4.1. Vents from the Storage of Petroleum products

Section 3.2.5 of Revision 6 of IP 15 provides hazard radii for differing emission rates and

vent sizes for Class I, II(2) and III(2) materials. Model fluids are used to derive the hazard

radii. The composition of these fluids was given Table 2. It is assumed that the vents are

remote from any structure and, if attached, are elevated sufficiently for the dispersion to the

lower flammability limit to be unaffected by building induced flow. The comments below are

specifically addressed for the early stages of dispersion for flammability assessments. Other

problems, such as the assessment of odours, assessment of health impacts or

environmental impacts, require a more detailed treatment.

Work Item 3 is to verify/update the hazard radii given in the original report according to the

matrix given in Table 6 for materials in Categories B and C.

Vapour Emission Rate

(filling rate) m

3

/h

Vent diameter (mm)

50 80 100 250

250 x x x x

500 x x x x

1000 x x x x

2500 x x x x

Table 6. Matrix of vent flow rates and diameters used in this study

Flow from a vent is of vapour only and it is implicit that there is only a small pressure drop

across the vent. This contrasts with releases from pressurised containment which may

exhibit two-phase behaviour as well as density changes near to the discharge point.

12

Venting usually takes place in a vertical direction. Material vented upwards will rise above

the vent stack as a consequence of vertical momentum. As it mixes with the ambient air it

acquires horizontal momentum and bends over toward the horizontal. If the vented gas is

less dense than air it will then slowly rise, if it is heavier than air it will slowly subside. The

extent to which the plume path is affected by density differences depends upon the gas

properties, the venting rate and the prevailing atmospheric conditions.

The degree of plume rise in the immediate vicinity of the vent depends mainly upon the exit

momentum and hence on the fluid density as well as the exit velocity. However, most of the

modelling that has been carried out is for stack gas effluent and uses velocity based criteria

for design purposes. The most commonly applied rule is to guard against plume downwash.

Experiment shows that, when the exit velocity is less than 1.5 times the wind speed at the

vent height, the aerodynamic interaction between the wind and the vent stack causes the

pollutant to be drawn down into the near wake of the vent tip. This is called downwash and

results in a reduction in the height of release, extra mixing of the pollutant and contacting of

the pollutant with the external stack.

For releases where the flow rate is sufficient to fully avoid downwash then dilution to below

flammable concentrations will occur in the vicinity of the vent and through the mechanism of

jet mixing rather than ambient turbulence.

In order to be conservative we have neglect the effect of downwash on plume dilution. An

ambient wind speed of 2 m/s at the vent top is assumed for these calculations.

We observe that: for wind speeds greater than 2 m/s the plume trajectory will be flattened

toward the horizontal. The shape factor is thus conservative in the vertical for wind speeds

of 2 m/s and higher. For wind speeds less than 2 m/s the hazard will be above the vent

point so that the shape factor is conservative in the downwind direction. The hazard radii

given in this report take account of the contribution of the 2 m/s wind speed to the

downstream extent of the plume. This should render the estimation of hazard radius

conservative for lower wind speeds. In critical cases the user should check by calculation.

The shape factor given in the existing guidance is retained because it is conservative.

For very slow venting rates and under low-wind conditions denser than air gases might flow

down the outside of the vent pipe. The situation should not occur for simple vents, designed

with an adequate exit velocity. It is more likely to occur for large area vents on a structure.

There is no simple model available to treat this problem which needs experimental or

computational investigation on a case by case basis. The flow phenomenon is complicated

and may involve substantial mixing within the exit of the vent pipe. We believe that it is

necessary, but conservative, to retain the zone 2 classification outside of and beneath the

zone 1 hazard radius to account for this possibility.

Nominal exit velocities for the vent matrix are given in Table 7. These cover a large range.

We observe that:

- For the range of flow rates shown the 250 mm diameter vent in particular shows nominal

exit velocities below and close to 10 m/s. This implies downwash under common wind

conditions and so these vent combinations may not be realistic in practice for continuous

emissions.

- Exit velocities above 100 m/s are indicated for the 50 and 80 mm diameter vents at the

higher flow rates. The implications of this are assessed below for the different fluids.

13

Vapour Emission Rate

(filling rate) m

3

/h

Exit Velocity m/s

Vent diameter (mm)

50 80 100 250

250 35 14 9 1

500 71 28 18 3

1000 141 55 35 6

2500 283 110 71 11

Table 7. Nominal exit velocity based on vent area (m/s). The shaded cells represent

combinations of vapour rate and vent diameter that need special consideration. Exit velocities

below 10 m/s in the top right of the table imply possible downwash effects. Exit velocities above

100 m/s in the bottom left imply a significant pressure forcing.

The exit velocity of the vented flow is illustrative but, because it is the exit momentum of the

flow that determines the rate of dispersion, the density of the effluent needs to be taken into

account as well.

We assume that the effluent is an ideal gas with properties evaluated at atmospheric

pressure. In reality any rate of discharge requires some driving force and a positive

pressure differential is the most common. We need to evaluate what a negligible pressure

is and how it affects the realistic range of vent sizes and venting rates for the different

category fluids. We also need to assess what are the likely properties of the material that is

vented. For liquid storage at atmospheric pressure the vapour space will necessarily be

occupied by some mixture of fluid vapour and air or fluid vapour and an inert gas. The

mixture composition should not be flammable but will be variable according to the filling level

and the history of changes in level, ambient conditions etc. Thus for vents :

- The vented mixture may vary in composition.

- The flammability limit and physical properties of the vapour may vary.

- For some conditions (high venting rates and small vents) it may be necessary to take

account of the effects of pressure on the release.

- If the release does not take place close to atmospheric pressure then the ideal gas

assumption may not be appropriate for mixtures with low vapour pressure components.

Because the effective molecular weight, and hence density, of the vented vapour is not

closely defined it is appropriate to make some example calculations using a range of values.

We assume

iii

that the average molecular weight of the gas vented from the storage of

category B and C fluids will lie in the range 48 - 100.

Figure 2 shows how the mixture molecular weight varies with dilution. For no-added air the

molecular weight is that of the pure vapour (Table 2) and as more and more air is added

then the mixture molecular weight tends to that of air (29) or if mixed with nitrogen (28).

iii

Note: because the model fluids are illustrative we have made no attempt to reconcile the example

ideal gas properties with the actual equilibrium air-vapour-liquid compositions of the model fluids at

atmospheric pressure and the reference temperature of 30 C used throughout this guidance

14

0

20

40

60

80

100

120

140

0 0.2 0.4 0.6 0.8 1

M

i

x

t

u

r

e

M

o

l

e

c

u

l

a

r

W

e

i

g

h

t

Mol fraction of Air in Mixture

Mean Molecular Weight for Mixtures of Category A, B, C fluids with Air, g/mol

MW 48 - A

MW 100 - B

MW 125 - C

Figure 2 The effect on mixture molecular weight of mixing category C (top), category B

(middle) and category A vapour with air assuming volatilisation of all components.

The upper flammability limits of the Category B and C fluids lie far to the right of Figure 2 as

shown in Table 8.

Fluid Upper Flammability Limit of vapour

%

Mol fraction Air in mixture

B 6.84 0.93

C 6.08 0.94

Table 8. Upper Flammability limits of Category B and C vapour. The mol fraction of air in the

vapour in a storage tank must be substantially less than these values to avoid

flammable/explosive mixtures.

The mixture molecular weight of 48 corresponds to the following mixtures, Table 9:

Fluid Type Mol Fraction Air Mol Fraction Fluid Vapour

A 0 1

B 0.72 0.28

C 0.81 0.19

Table 9: Equivalent mixtures for a vapour molecular wt of 48.

The Category B and C fluids Table 2 have a lower flammability limit falling into a narrow

range of 0.039-0.043 kg/m

3

, 0.86-2.0 %v. We also included Category A vapour as an

additional example in this sensitivity analysis although, of course, for practical reasons it is

not stored at atmospheric pressure and temperature.

15

As the pure vapour becomes diluted then the lower flammability limit of the mixture

increases. The effect of dilution on the flammability limit of the mixture is shown

qualitatively in Figure 3 where we have used Le Chateliers law and treated air as inert fuel

component. This is not strictly accurate for high dilutions but it does illustrate that lower

flammability limit increases as air is added. Only mixtures initially richer than the upper

flammability limit are considered which is why the mol fraction of air is terminated at 0.9.

0.1

1

10

100

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

M

i

x

t

u

r

e

L

o

w

e

r

F

l

a

m

m

a

b

i

l

i

t

y

L

i

m

i

t

,

%

Mol fraction of Air in Mixture

Lower Flammability Limit for Mixtures of Category A, B, C fluids with air, %

MW 48 - A

MW 100 - B

MW 125 - C

Figure 3. Lower Flammability limits of the three model fluids used in the Area Classification

guidance as a function of dilution with air. Only mixtures originally above the upper

flammability limit are considered.

We now verify and quantify the range of venting rates and vent diameters that qualify as

negligible pressure. Figure 4 shows the variation in mass-flow rate from a short pipe as

the applied pressure, expressed in millibar gauge, increases.

Specific calculations (points) were calculated for an ideal gas of molecular weight 48 and for

a pipe diameter of 50 mm. At low drive pressure the mass flow rate is proportional to the

square root of the applied pressure as would be expected from the Bernoulli equation for an

incompressible fluid i.e. keeping the density unchanged from its base value. A correlation

line

iv

is drawn to indicate this relationship. At high pressure the mass flow rate (points)

increases more quickly with increasing pressure than indicated by the correlation line. This

is because the increase in fluid density in the vent is significant. To identify a suitable cut-off

we compared the goodness of fit of the Bernoulli equation to the flow calculations. We found

that the fit became progressively worse as we included results for pressures above 300 mb.

Therefore we adopt 300 mb as marking the upper limit of negligible pressure.

iv

A correlation line was used for convenience. Equally the slope could be derived from the discharge

model for an ideal gas through a round hole using a discharge coefficient of 0.8. This was the basis

for the model calculations to which the regression line was fitted.

16

To see the consequence of this for the flow conditions in Table 6 we take the maximum flow

rate of 1.34 kg/s corresponding to the volume flow-rate of 2500 m

3

/h (evaluated at 1 atm.

pressure and 30 C) and plot this as a horizontal line on Figure 4. We then construct the

(incompressible) flow rates for the additional hole sizes of 80, 100 and 250 mm as parallel

lines to the 50 mm pipe calculations. Figure 4 shows that for pipes smaller than 80 mm

diameter the 2500 m

3

/h flow rate implies a drive pressure greater than 300 mb.

0.001

0.01

0.1

1

10

0.1 1 10 100 1000 10000

m

a

s

s

f

l

o

w

r

a

t

e

i

n

k

g

/

s

over-pressure, mb

Mass flow rate as a function of applied pressure

Mol. Wt 48

50 mm pipe

80 mm pipe

100 mm pipe

250 mm pipe

2500 m3/hr

Figure 4. Mass Flow rate through pipes of different diameter for an ideal gas of molecular

weight 48. Points denote calculations with a discharge model. Lines denote a correlation based

on drive pressures less than 300 mb. The horizontal line denotes the mass flow rate consistent

with a volume flow rate of 2500 m

3

/h at atmospheric pressure and 30 C.

Figure 5 shows the equivalent graph for a vapour of molecular weight 100. For the larger

molecular weight greater pressures are needed to achieve a given volumetric flow. We find

that pipe diameters smaller than 100 mm require a drive pressure greater than 300 mb to

achieve a flow rate of 2500 m

3

/h.

17

0.001

0.01

0.1

1

10

0.1 1 10 100 1000 10000

m

a

s

s

f

l

o

w

r

a

t

e

i

n

k

g

/

s

over-pressure, mb

Mass flow rate as a function of applied pressure

Mol. Wt. 100

50 mm pipe

80 mm pipe

100 mm pipe

250 mm pipe

2500 m3/hr

Figure 5. Mass Flow rate through pipes of different diameter for an ideal gas of molecular

weight 100. Points denote calculations with a discharge model. Lines denote a correlation

based on drive pressures less than 300 mb. The horizontal line denotes the mass flow rate

consistent with a volume flow rate of 2500 m

3

/h at atmospheric pressure and 30 C

These calculations suggest that for ideal gases a threshold of 300 mb is a suitable choice to

distinguish between vent flows where difference in the physical properties of the vapour

within the vent and at atmospheric pressure can be neglected. If the vent design implies

higher over-pressures then the implications for the possible change in properties of mixtures

with low vapour pressure components needs to be assessed.

Hazard radii were obtained for vertical discharges of an ideal gas with molecular weight in

the range 48 - 100 fluid. The effect of changing flammability limit was tested using values

appropriate to mixtures of category B and category C vapour with air and including category

A vapour as a worse case. Results are given in Table 10 and have been rounded. Values

marked with a double asterisks(**) are conservative, at such low exit velocities mixing is

dependent on the detail flow in the vent exit.

18

Vapour Emission Rate

(filling rate) m

3

/h

Hazard radius, m

Vent diameter (mm)

50 80 100 250

250 2 2.0 2.5 3**

500 2.5 2.5 2.5 4

1000 3 3.5 3.5 6.

2500 4 5 5 7

a) Assuming category B vapour mixed with air. The shaded cells require a drive pressure

greater than 300 mb to achieve

Vapour Emission Rate

(filling rate) m

3

/h

Hazard radius, m

Vent diameter (mm)

50 80 100 250

250 2 2.0 2 3**

500 2.5 2.5 2.5 4.0

1000 3.0 3.5 3.5 5.5

2500 4.0 5.0 5 6

b) Assuming category C vapour mixed with air. The shaded cells require a drive pressure

greater than 300 mb to achieve

Vapour Emission Rate

(filling rate) m

3

/h

Hazard radius, m

Vent diameter (mm)

50 80 100 250

250 2.5 4.0 6.0 6**

500 3.5 3.5 4.5 6.5

1000 4.5 4.5 5.0 9

2500 6.5 7 7 13

c) Assuming pure category A vapour. The shaded cells require a drive pressure greater than

300 mb to achieve

Table 10. Hazard radii for a fluid of molecular weight 48 g/mol treated as an ideal gas and

three example flammability limits

The results show a trend for the hazard radius to increase as the lower flammability limit of

the mixture decreases as would be expected. The hazard radius values for the category B

and category C vapour/air mixtures are quite similar but substantially smaller than those for

the pure vapour category A simulation. This suggests that the dilution with air that

characterises an open venting system is key to reducing hazard distances and should be

taken account of in any specific site assessment.

Table 11 below gives results for a molecular weight 100 fluid, evaluated as a mixture of

category C fluid and air and as pure category B fluid. This is almost certainly an extreme

example but, when compared to Table 10, illustrates that as the molecular weight of the

19

mixture increases the hazard radius also increases for a fixed volume flow rate. We also

notice in the detailed calculations and showing in Table 11 that, for a fixed venting rate and

increasing vent diameter, the trajectory of the vent gases alters as the exit velocity

decreases. At low exit velocities the vent gases subside quite quickly after leaving the vent

and the downward path of the gases passes relatively close to the vent. The hazard radius,

measured from the exit plane to the point of dilution to LFL starts to decrease because of the

trajectory whereas, for lighter (but still dense) gases the vented material passes away from

the stack and the hazard radius increases as the exit velocity and hence the jet mixing

component of entrainment decreases.

When the molecular weight is as large as 100 g/mol then discharge from a vent sized 250

mm or larger has insufficient bulk velocity to disperse the gases according to the

assumptions made here.

In practice, and especially for substantially larger vents, such as hatches, complicated flow

interactions can take place in the actual opening with a dense gas flow preferentially around

the edges and a degree of inflow and mixing taking place inside the centre of the vent

opening. A different methodology, such as computational fluid dynamics or experimental

measurement must be used if the mixing within the geometric features of the holding vessel

is to be understood and quantified.

Vapour Emission Rate

(filling rate) m

3

/h

Hazard radius, m

7 Vent diameter (mm)

50 80 100 250

250 4 6.5 6 n/a

500 5 5.5 8 n/a

1000 6.5 7 7 n/a

2500 9 10 10 11

a) Assuming category C vapour mixed with air

Vapour Emission Rate

(filling rate) m

3

/h

Hazard radius, m

7 Vent diameter (mm)

50 80 100 250

250 3.5 6.5 6.0 n/a

500 5 6 8.5 n/a

1000 6.5 7 7.5 n/a

2500 9.5 10.5 10.5 11.5

**

b) Assuming pure category B vapour

Table 11. Hazard radii for a fluid of molecular weight 100 g/mol, treated as ideal gas. For

venting rates less than 2500 m

3

/h the vent of 250 mm diameter gives too small an exit velocity to

assure dilution of the gas and a down flow in the vicinity of the vent stack is to be expected.

Affected combinations of vent rate and vent size are marked as n/a.

In Table 10 and Table 11 we note that, for the highest flow rates and the smaller vent sizes,

the hazard radius is shaded. This denotes that more than 300 mb pressure drop is needed

to achieve this flowrate and a check on the vapour composition should be carried out to see

if condensation of any components is implied.

20

Comparison with section 3.2.5 of revision 6 of IP 15 shows that hazard radii range from just

below (molecular weight 48) to just above (molecular weight 100) the existing guidance

using flammability limits for category B and category C vapour diluted with air.

4.2. Process vents

Section 5.7 of Revision 6 describes releases from process vents to atmosphere. It is again

assumed that venting is restricted to vapour phase releases. Release rates in the guidance

and required for work item 3 follow the matrix shown in Table 12 within which the implied exit

velocities are included. We note that the range of values is extremely small compared with

those used above for vents from storage. This seems counter intuitive as one might expect

venting from a process to involve quite large flow rates.

Vapour Emission Rate

m

3

/h

Exit Velocity

m/s

Vent diameter (mm)

50 100 250

10 1.5 0.5 0.1

100 14 3.5 1

250 35 9 1.5

Table 12. Matrix of conditions for assessing hazard radii from process vents and their

associated exit velocity. Shading denotes combinations prone to downwash.

The exit velocity from a vent should exceed the wind speed by a factor 1.5 if downwash is to

be avoided and exit velocities less than about 10 m/s may be assumed to give rise to

downwash under common meteorological conditions. Downwash is to be avoided as it can

lead to soiling and corrosion of the vent pipe and to low level exposure of structures and

personnel to the emitted gases.

Table 12 shows exit velocities very substantially less than 10 m/s for a majority of cases.

Where the exit velocity is less than 1 m/s some very complicated interactions between the

external flow and the pipe flow can occur. It is known that for lighter than air gases the

external flow can enter the vent pipe from above and that mixing can take place within the

vent pipe itself to a good degree. Experimental and/or computational fluid calculations are

needed to make accurate calculations for these cases.

Hazard radii are calculated in the same manner as for the vents from storage. The vented

fluid is assumed to be an ideal gas of molecular weight, 7, 19 and 48 corresponding to the

category G(ii), G(i), and A fluids used in the guidance.

The hazard radii are given in Tables 13-15 below. In view of our comments above with

respect to the overall low flow rates in the guidance we have included larger values in the

tables.

21

Vapour Emission Rate

m

3

/h

Hazard radius, m

Vent diameter (mm)

50 100 250

10 < 2** < 2.5** < 5**

100 < 2** < 2.5** < 5**

250 2 3 < 5**

500 2 3 < 5**

1000 3 3.5 < 5**

2500 4.5 4.5 5.5

Table 13. Hazard radii for Fluid category G(ii) as ideal gas of Molecular weight 7 g/mol.

Vapour Emission Rate

m

3

/h

Hazard radius, m

Vent diameter (mm)

50 100 250

10 < 1** < 2** < 4**

100 1 < 2** < 4**

250 1.5 2 < 4**

500 2 2 < 4**

1000 3 3 4

2500 4 4 5

Table 14. Hazard radii for Fluid category G(i) as ideal gas of Molecular weight 19 g/mol.

Vapour Emission Rate

m

3

/h

Hazard radius, m

Vent diameter (mm)

50 100 250

10 2.5 < 4.5** < 6**

100 2 5 < 6**

250 2.5 6 < 6**

500 3.5 4.5 7

1000 4.5 5 9

2500 6.5 7 13

Table 15. Hazard radii for Fluid category A as ideal gas of Molecular weight 48 g/mol.

No solutions were obtainable for the smallest releases. The dilution is entirely dominated by

the flow interactions at the vent tip. We suggest that, to be conservative, the largest

calculated hazard radius for a given vent diameter is used. These values are indicated by a

double asterisk(**) in the tables.

The results are in agreement with those in the existing guidelines.

22

5. Evaporation from pools and sumps.

IP 15 provides good qualitative guidance on the evaporation and dispersion of vapour from

category B and C fluids discharged to pools and from sumps. This work sets out to derive

the relevant hazard radii as requested in work items 4 and 5.

The transient nature of a spill problem and the multicomponent nature of category C and B

fluids leads to a semantic problem when providing a reference document for the IP

guidance.

The hazard radius defined for a pool of specific size should reflect the hazard from the pool

itself and be independent of the manner of release of the fluid if it is to be of generic use.

Investigation of several scenarios leads to the conclusion that the evaporation rate of the

heavier components of category C fluid is very low under the reference conditions. The

evaporation rate of the lighter components on the other hand is rapid such that the maximum

vapour generation rate is actually dictated by amount and rate of release of the liquid.

Consequently we find that:

- the existing guidance for liquid spillages and for sumps is conservative in so far as it

applies to the hazard posed by the residual liquid in a spill of category C fluid. The

guidance is appropriate to a spill with an average double the evaporation rate of category

C fluid.

- the hazard arising early in a spill arises from the more volatile components and is dictated

by the conditions of the release rather than the size of the pool itself.

- the existing guidance may still be conservative because the transient nature of the vapour

release results in a rapidly dispersing puff of vapour rather than a large cloud. Some

scenario investigation suggests that releases would have to be large ones to present

substantial hazards and thus be more typical of incidents as opposed to more commonly

occurring events.

- evaporation from sumps will be less than from pools and therefore the existing guidance

is conservative for sumps as well. This is verified for releases of temperature 50

o

C.

In this section the basic phenomenology of liquid spills is described and the hazards

quantified.

We define:

- a pool to contain a shallow layer of liquid e.g. arising from the spillage of a category C

fluid onto a surface such as concrete.

- a sump to contain a much deeper layer of liquid; possibly floating upon a sub-layer of

water.

This distinction is necessary because the physical process of evaporation requires the

supply of energy equal to the latent heat of evaporation of the fluid. For a shallow layer this

energy can be obtained from the substrate by conduction. Clearly the availability of energy

depends on the actual depth of the pool, the temperature and physical properties of the

substrate and the external conditions but, for very shallow pools, evaporation will take place

at a rate determined by the ground temperature. For a deep layer this energy is obtained

from the internal energy of the spilled fluid. The temperature of the pool will drop until a heat

balance is reached between the evaporation rate and the total energy transfer to the liquid

by conduction and insolation. As the liquid cools then the evaporation rate decreases.

23

Clearly these are extremes and spills can behave as shallow or deep or have mixed

behaviour depending upon the fluid properties and spill conditions and whether or not the

spill is physically contained. For a given fluid we would generally expect a greater

evaporation rate from a shallow spill onto a warm substrate than from a deep pool. Implicit

in this expectation is some consideration as to how the fluid enters the pool or sump, how

long it remains there and what the time history of the event is.

A pool will originate with a breach in a tank or pipe containing liquid. As the spill

commences, liquid spreads out over the ground until it meets a restriction or until the pool

thickness has reached a limiting value determined by surface tension. While the spill is

spreading over warm ground the lighter components evaporate preferentially. There may

also be some vapour released at the early in the spill which adds to the overall vapour

generation rate. The rate of total evaporation increases until the pool stops spreading. If the

pool is unconfined then the vapour generation rate then falls quickly because the pool dries

out. If the spread of liquid is confined by a bund or similar then a finite depth of liquid

remains. The vapour generation rate will then remain constant or decline gradually in time

depending on the overall heat balance on the pool. When the pool reaches the minimum

depth then the evaporation rate will fall rapidly as the pool dries.

A sump may behave as a deep pool or may contain a residual amount of material that is

refreshed with new releases. If the fill-up rate exceeds the potential evaporation rate of the

fluid components then the sump will behave as a deep pool. If the fill up rate is smaller than

the evaporation rate of the lighter components then the sump will behave more like a shallow

pool.

For work items 4 and 5, hazard radii are sought for pools of 5, 10, 15 and 20 m diameter

v

formed by the retention of spilled materials by planned bunds, naturally occurring blockages

such as kerbs, or emergency measures.

There are a number of ways in which such pools can occur:

- A fixed volume of fluid could be spilled. If this is captured in bunds of the different sizes

above then the smallest pool will be deeper than the largest pool.

- A variable volume of fluid could be spilled. This could result in the different sized pools

having more similar depth.

Each of these scenarios will result in a different evaporation history. Quantifying all of the

possible scenarios is a large task. Before investigating some actual releases we consider

the simpler problem of steady state evaporation of a category C fluid.

Using the steady state modelling assumptions for the model category C fluid and for pools of

size 5 - 15 m it can be shown that the evaporation flux must exceed certain limits if the

existing guidance is correct. Some example hazard distances are given in Table 16. The

pool size is the length of the pool in the wind direction and the hazard distance is the

distance to LFL measured from the downward edge of the pool. Two values are given for

the hazard distance. The minimum value uses a lower flammability limit appropriate to the

lightest vapour components of a category C fluid. The maximum uses the lower flammability

limit appropriate to the heaviest components of a category C fluid, c.f. Table 2,

v

For practical reasons the hazard radii are calculated for square sources of equivalent area as

described in Appendix A: Methodology.

24

Evaporation Flux

(kg/m

2

/s)

Evaporation Rate

(kg/s)

Pool Size L

(m)

Min. Hazard

Distance D

(m)

Max. Hazard

Distance D

(m)

0.002 0.05 5 2.9 5.2

0.45 15 13.0 21

0.0015 0.04 5 0 3.2

0.36 15 7.5 14.5

0.001 0.03 5 0 0

0.23 15 0 0

Table 16. Hazard distance ranges for category C vapour from area sources

The existing guidance gives hazard distances for ranges of pool sizes, Table 17:

Pool Size L (m) Hazard distance D (m)

Less than 5 3

Between 5 and 10 7.5

Greater than 10 15

Table 17. Original Hazard distances from the Guidance.

Comparing Table 16 and Table 17 and taking the maximum hazard distance we see that the

existing guideline is equivalent to a source with an evaporation flux of between 0.0015 and

0.002 kg/m

2

/s depending upon the flammability limit that is used. Indeed, considering that

the more volatile components evaporate first, the existing guidance is equivalent of a source

decreasing in strength from a flux of 0.002 to 0.0015 kg/m

2

/s over the life of the spill.

These points are illustrated with some examples below:

Figure 6 shows the time dependent evaporation flux for 4.5 m

3

of category C fluid rapidly

dumped into a 15 m pool. This volume is chosen to adequately fill the pool and leave fluid

still present after a time of 30 minutes (1800 s). Details are given in the methodology

section, Appendix A.

The horizontal lines show the evaporation flux range 0.0015 - 0.002 kg/m

2

/s relevant to the

existing guidance. For the release the evaporation flux decreases from a value of 0.0012

kg/m

2

/s to a value of 0.0005 kg/m

2

/s after a time of 300 s. This marks the end of the period

in which the lighter components are evolved. Subsequently the evaporation rate is nearly

constant. In fact it shows a slight increase because the simulations assume noon-time

insolation and the pool is in fact warming slightly over the later period of the modelled spill.

Thus a rapid spill of category C fluid gives evaporation fluxes a fraction 0.6-0.4 smaller than

accounted for by the existing guidance.

25

0.0001

0.001

0.01

-200 0 200 400 600 800 1000 1200 1400 1600 1800

e

v

a

p

o

r

a

t

i

o

n

f

l

u

x

k

g

/

m

2

/

s

time from spill start, s

Spill rate 0.45 m3/s

15m pool 10 s

2.e-3

1.5e-3

Figure 6. Evaporation rate of a rapid dump of category C fluid

Figure 7 shows the effect of spilling the same volume over the longer period of 300 s. Again

there is no special significance to the choice of a volume of 4.5 m

3

other than that this is

sufficient to adequately fill a pool of 15 m diameter.

Here three stages of the spill can be seen. There is an initial high rate as the liquid spreads

to fill the pool and is passing over a hot concrete substrate. The liquid quickly reaches the

bund walls and the pool depth starts to increase. The vapour generation rate falls because

the substrate and pool are cooled by the evaporation. The evaporation of the light

components of the newly spilled fluid is visible as a plateau lasting just longer than the 300 s

of the actual spill. Thereafter the evaporation rate falls again to give results similar to those

for the rapid spill.

26

0.0001

0.001

0.01

-200 0 200 400 600 800 1000 1200 1400 1600 1800

e

v

a

p

o

r

a

t

i

o

n

f

l

u

x

k

g

/

m

2

/

s

time from spill start, s

Spill rate 0.015 m3/s

15m pool 300 s

2.e-3

1.5e-3

Figure 7. Time history of a five minute spill of 4.5 m

3

of category C fluid.

For sumps there is a concern that hot liquid may be introduced. Figure 8 shows that

preheating the fluid to 50 C from 20 C enhances the vapour rate in the early spill stages

by a factor of about two. Even so it only reaches the 0.002 kg/m

2

/s value for the few

seconds in which the liquid spreads to cover the pool. For a sump, where liquid is being

added to existing material, this initial transient would be absent. It is notable that over a half-

hour period the effect of the initial temperature difference on evaporation rate has

disappeared.

27

0.0001

0.001

0.01

-200 0 200 400 600 800 1000 1200 1400 1600 1800

e

v

a

p

o

r

a

t

i

o

n

f

l

u

x

k

g

/

m

2

/

s

time from spill start, s

Spill rate 0.015 m3/s Storage Temperature 50 C

15m pool 300 s

2.e-3

1.5e-3

Figure 8. Time history of evaporation for liquid initially at 50 C. The liquid in the pool rapidly

cools so that the residual evaporation rate is similar to the other cases.

These calculations show that in so far as the evaporation of the model category C fluid is

concerned the existing guidance is conservative with respect to the evaporation of the bulk

of the fluid. They also show that the manner of discharge itself (rate, amount) coupled to the

initial volatilisation of light components determines the early peak in vapour rate. This

cannot be characterised simply in terms of a pool dimension. For the example we have

used here - the release of 4.5 m

3

of fluid into a 15 m bund over time scales of 10 to 300 s -

which perhaps is not an unreasonable scenario, the guidance is conservative even for this

initial spill period. Larger spill possibilities would likely occur as incidents and thus require

explicit modelling.

5.1. Vapour pressure comparisons of some commonly used Category C fluids.

Table 18 shows the vapour pressures of some hydrocarbons (C7+) relative to n-octane.

Liquid Spill Hazard for all of these compounds exceeds that of n-octane and specific account

of volatility must be taken into account when the ratio exceeds 2.

Name Formula Vapour Pressure

relative to n-octane

at 30 C

n-octane C8H18 1

cis 1,2-dimethylcyclohexane C8H16 1.02

3-vinylcyclohexene C8H12 1.09

2,2,4-trimethylhexane C9H20 1.13

isopropyl cyclopentane C8H16 1.14

di-sec-butyl ether C8H18O 1.15

2,2,5-trimethylhexane C9H20 1.17

trans-2-octene C8H16 1.19

28

octene-1 C8H16 1.23

tra 1,3-dimethylcyclohexane C8H16 1.24

cis 1,4-dimethylcyclohexane C8H16 1.26

2-methyl bicyclo 221 heptane C8H14 1.29

tra 1,2-dimethylcyclohexane C8H16 1.35

3-methyl heptane C8H18 1.38

2-methyl-1-heptene C8H16 1.39

2,4-heptadiene C7H12 1.41

3-ethyl hexane C8H18 1.42

1,7-octadiyne C8H10 1.43

2-methyl heptane C8H18 1.45

1,7-octadiene C8H14 1.49

cis 1,3-dimethylcyclohexane C8H16 1.5

cycloheptane C7H14 1.52

3,4-dimethylhexane C8H18 1.52

1,1-dimethylcyclohexane C8H16 1.58

3-methyl 3-ethyl pentane C8H18 1.6

2,3-dimethylhexane C8H18 1.64

2-methyl 3-ethyl pentane C8H18 1.67

di-tert-butyl peroxide C8H18O2 1.78

2,3,3-trimethylpentane C8H18 1.87

2,3,4-trimethylpentane C8H18 1.88

1,1,2-trimethyl cyclopentane C8H16 1.93

toluene C7H8 1.98

3,3-dimethylhexane C8H18 1.99

2,4-dimethylhexane C8H18 2.11

2,5-dimethylhexane C8H18 2.12

2,2,3-trimethylpentane C8H18 2.22

1,3-heptadiene C7H12 2.24

2,2-dimethylhexane C8H18 2.36

1,6-heptadiyne C7H8 2.38

2,4,4-trimethyl pentene-2 C8H16 2.5

heptyne-1 C7H12 2.73

2,2,3,3-tetramethylbutane C8H18 2.73

ethyl cyclopentane C7H14 2.75

2,4,4-trime-1-pentene C8H16 3.06

n-heptane C7H16 3.15

cis-2-heptene C7H14 3.15

methyl cyclohexane C7H14 3.17

trans-2-heptene C7H14 3.21

cis 1,2-dimethylcyclopentane C7H14 3.24

2,2,4-trimethylpentane C8H18 3.37

trans-3-heptene C7H14 3.5

cis-3-heptene C7H14 3.52

1,4-heptadiene C7H12 3.67

1,5-heptadiene C7H12 3.75

heptene-1 C7H14 3.86

3-ethyl pentane C7H16 3.97

3-methyl hexane C7H16 4.21

2-methyl-1-hexene C7H14 4.22

1,6-heptadiene C7H12 4.31

tra 1,2-dimethylcyclopentane C7H14 4.35

29

tra 1,3-dimethylcyclopentane C7H14 4.39

2-methyl hexane C7H16 4.49

cis 1,3-dimethylcyclopentane C7H14 4.56

2,3-dimethylpentane C7H16 4.68

1,1-dimethylcyclopentane C7H14 5.12

3,3-dimethylpentane C7H16 5.58

2,4-dimethylpentane C7H16 6.63

2,2,3-trimethylbutane C7H16 6.85

2,2-dimethylpentane C7H16 7.06

Table 18 vapour pressures of some hydrocarbons (C7+) relative to n-octane

6. Releases into confined areas.

A release of flammable material into a confined space, such as a building, is potentially an

extremely hazardous event. Ignition may lead to the development of over-pressure causing

structural damage to the enclosure and neighbouring buildings. Consequently, any events

leading to a sustained release of flammable material should not be considered as normal

operation but be subject to a detailed consequence analysis.

For the purposes of area classification there is a need to quantify the difference between an

event definitely leading to a hazardous condition and an event that is potentially hazardous

but which might be managed by precautionary action such as the active control of ignition

sources near to the point of handling of flammable material.

A key concern is how to assess the conditions under which a release might escape a

building at a flammable concentration and require external ignition prevention precautions.

General guidance for the safe ventilation of building enclosures given in IP 15 is, quite

soundly given by dividing activities that may lead to releases into categories requiring

different grades of ventilation. Grades of ventilation are then parameterised by the air

change rate, o, expressed as the number of times per hour that the air in the building is

changed. Four categories are identified:

Adequate

Ventilation:

To quickly reduce possibly flammable concentrations to safe

concentrations in the event of a leak or spillage, and following

action to stop the fluid source, 12 air changes per hour is

recommended.

Dilution Ventilation: Forced ventilation at sufficient rate to limit the formation of a

gas volume at a concentration of 20% of the Lower

Flammability limit is recommended. Typically dilution

ventilation will be vigorous (30 - 90 air changes per hour) and

the output diverted to vents.

Local Artificial

Ventilation:

The use of either small scale dilution ventilation (use of

extractors etc.) or an enhancement of flow in obstructed areas

to attain adequate ventilation is recommended.

30

Overpressure

Ventilation:

Prevention of the ingress of flammable material to a confined

area by maintaining an over-pressure within it is

recommended for cases where buildings are close to potential

sources but do not contain sources themselves.

Of these categories we need only to try to quantify the first, Adequate Ventilation as

applying generally to small spills. The Dilution Ventilation rate needs to be specially

designed for each application. Local Artificial Ventilation is essentially the same as

Adequate Ventilation for small enclosures within a larger confined workplace, unless the

effluent is ducted to a vent in which case it is an example of Dilution Ventilation.

Overpressure ventilation precludes the need for assessment.

What does adequate ventilation mean in terms of a release? Let V be the ventilated

volume. Consider the volume to be well mixed then the concentration within the enclosure

of a gaseous flammable material released at time 0 at a constant rate m

-

kg/s is given by a

simple mass balance:

o V

dC

dt

m VC =

-

where o s

-1

, is the air change rate, kg/m

3

, is the density of the flammable gas and C m

3

/m

3

is the volumetric (molar) concentration. This equation has the solution:

( ) C

m

V

e