Академический Документы

Профессиональный Документы

Культура Документы

Elkem 13 Compacted Graphite Iron

Загружено:

marcotulio123Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Elkem 13 Compacted Graphite Iron

Загружено:

marcotulio123Авторское право:

Доступные форматы

Technical Information 13 Compacted Graphite Iron

Compacted graphite irons (CG-irons) are a range of cast irons having mechanical and physical properties intermediate between those of flake graphite and nodular graphite cast irons. They are of interest to engineers because of their useful combination of strength, thermal conductivity and other properties. They have good founding characteristics and their production requires controls similar to those applied in the manufacture of ductile iron castings. This Information Sheet summarizes a successful production route for CG-iron that has been developed by Elkem, as well as examples of structures and properties for such materials. Treatment is based on a high rare earth containing magnesium-ferrosilicon alloy designed specially for compacted graphite iron production. No introduction of such elements as titanium or nitrogen is necessary with the present alloying concept. Recommended composition of treatment alloy : Si 44 - 48 Mg 5.0 - 6.0 Ca 1.8 - 2.3 RE 5.0 - 7.0 Al max. 1.0 Balance iron % % % % %

Recommendations for Compacted Graphite Iron Production Base Iron Composition Base iron composition should preferentially be hypereutectic with a carbon equivalent of about C.E. = 4.3 - 4.5. Impurities should be kept low. Suggested base iron composition is: C Si S P 3.7 - 3.9 % 1.5 - 2.0 % 0.005 - 0.010 % max. 0.03 %

Alloy Addition The addition rate of the alloy described above has to be adjusted according to base metal composition and treatment process for each individual foundry. Base metal sulphur level and treatment temperature are important parameter that strongly affect the required alloy addition rate. Experiences with the base iron composition given above have shown best results for addition rates between : 0.3 - 0.4 weight percent addition of alloy specified above The addition method may be an ordinary ladle treatment process as for ductile iron production (sandwich or tundish ladle).

Elkem ASA, Silicon Division

Postal address: P.O.Box 5211 Majorstua N-0303 Oslo Norway Office address: Hoffsveien 65 B Oslo Telephone: 47 22 45 01 00 Telefax 47 22 45 01 52 Revision No. 2 14.03.1997

Inoculant Addition It is recommended to add a high efficiency inoculant for production of CG-irons. Barium and Strontium containing ferrosilicon inoculants are found to give good results. Inoculant addition rate should be similar to that for ductile irons, i.e. between 0.3 and 0.8 wt percentage. The higher levels giving a fine distribution of compacted graphite throughout castings and less sensitivity to carbide (cementite) formation. Microstructures The Figures below shows examples of microstructures obtained for a CG-iron casting produced from a high RE-containing MgFeSi-alloy. Structures in both thin (5 mm) and thick (35 mm) section sizes are given to show the limited section sensitivity obtained. Homogeneous CG-structures throughout all section sizes are a characteristic feature obtained by the high RE-containing alloy in comparison to an ordinary lower RE-containing MgFeSi-alloys.

(a) (b) Figure 1: Microstructure of compacted graphite iron produced from a high RE-containing MgFeSialloy, (a) 5 mm section size, (b) 35 mm section size (100X).

CG-Iron Composition Example of final CG-iron chemical composition obtained from the given parameters: %C 3.8 % Si 2.5 % Mn 0.20 %P 0.02 %S 0.007 % Ti 0.012 % La 0.008 % Ce 0.015 % Mg 0.010

Mechanical Properties Mechanical properties of CG-iron will of course be affected by the ferrite/pearlite-ratio, but for a predominantly ferritic grade properties may be (from 25 mm diameter separately cast test bar) : Yield strength Tensile Elongation strength (MPa) (%) (MPa) 310 - 340 340 - 400 3-6

For more information, see the Elkem Product Data Sheet CompactMag.

Вам также может понравиться

- Technical InformationДокумент78 страницTechnical InformationCarlos Barrachina Martínez100% (2)

- Swing Bolt CalculationДокумент2 страницыSwing Bolt CalculationNicolaSavili100% (2)

- ELMAGДокумент2 страницыELMAGthomazfabricioОценок пока нет

- O HC HCДокумент101 страницаO HC HCIndustrial Infra Jobs100% (1)

- Iso TC 25 N 292Документ70 страницIso TC 25 N 292marcotulio123Оценок пока нет

- ASM Practical Fractography PDFДокумент159 страницASM Practical Fractography PDFmarcotulio123100% (9)

- Elkem 19 Aluminum in Cast IronДокумент2 страницыElkem 19 Aluminum in Cast Ironmarcotulio123Оценок пока нет

- How Can A Particle Absorb More Than The Light Incident On ItДокумент6 страницHow Can A Particle Absorb More Than The Light Incident On Itslysoft.20009951Оценок пока нет

- Seminar S.G IronДокумент32 страницыSeminar S.G Ironravikataria02Оценок пока нет

- Compacted Graphite IronДокумент2 страницыCompacted Graphite Ironarnaldorcr8646Оценок пока нет

- Late Metal Stream InoculationДокумент2 страницыLate Metal Stream Inoculationarnaldorcr8646Оценок пока нет

- Oxidation of Ferrosilicon Alloys During StorageДокумент1 страницаOxidation of Ferrosilicon Alloys During Storagearnaldorcr8646Оценок пока нет

- Recovery of Magnesium in A Ductile Iron Process.: AbstractДокумент8 страницRecovery of Magnesium in A Ductile Iron Process.: AbstractJorge Prado DiazОценок пока нет

- Elkem 10 Tundish Cover Ladle NodularizationДокумент2 страницыElkem 10 Tundish Cover Ladle Nodularizationmarcotulio123Оценок пока нет

- Partition of Slag Phases in The Treatment and Pouring of Ductile IronДокумент2 страницыPartition of Slag Phases in The Treatment and Pouring of Ductile Ironarnaldorcr8646Оценок пока нет

- 5 Mechanisms Graphite Nucleation Cast IronДокумент2 страницы5 Mechanisms Graphite Nucleation Cast Ironmarcotulio123Оценок пока нет

- Sampling of Liquid Cast IronДокумент2 страницыSampling of Liquid Cast Ironarnaldorcr8646Оценок пока нет

- Factors Influencing The Recovery and Addition of MagnesiumДокумент4 страницыFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646Оценок пока нет

- Shrinkage in Iron CastingsДокумент10 страницShrinkage in Iron CastingskarthikkandaОценок пока нет

- S.G IronДокумент6 страницS.G IronQasim BarkatОценок пока нет

- Selection of Inoculants For Grey Cast IronДокумент2 страницыSelection of Inoculants For Grey Cast Ironarnaldorcr8646Оценок пока нет

- Heat Conservation in Liquid IronДокумент2 страницыHeat Conservation in Liquid Ironarnaldorcr8646Оценок пока нет

- Ferroalloy Storage Bin DesignДокумент2 страницыFerroalloy Storage Bin Designarnaldorcr8646Оценок пока нет

- Compression MountingДокумент12 страницCompression MountingEden HazardОценок пока нет

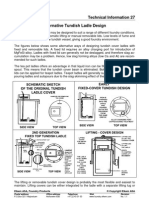

- Alternative Tundish Ladle DesignДокумент2 страницыAlternative Tundish Ladle Designarnaldorcr8646Оценок пока нет

- AntiSegregation HopperДокумент5 страницAntiSegregation Hoppermecaunidos7771Оценок пока нет

- Chunky GraphiteДокумент16 страницChunky GraphitesachinguptachdОценок пока нет

- Effect of Minor and Trace Elements in Cast IronДокумент2 страницыEffect of Minor and Trace Elements in Cast IronsachinguptachdОценок пока нет

- Elkem 07 Magnesiun Contents in Ductile IronДокумент2 страницыElkem 07 Magnesiun Contents in Ductile Ironmarcotulio123Оценок пока нет

- 1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFДокумент23 страницы1996 Bombay Foundry Congress - Inoculation of Grey and Ductile Iron PDFhabibi1328100% (1)

- Common Metallurgical Defects in Grey Cast IronДокумент9 страницCommon Metallurgical Defects in Grey Cast IronRolando Nuñez Monrroy100% (1)

- 3 Inoculant Alloy CompositionДокумент2 страницы3 Inoculant Alloy CompositionAdams GodoyОценок пока нет

- Manganese, Sulfur and Manganese-Sulfur Ratio Effects in Gray Cast IronДокумент30 страницManganese, Sulfur and Manganese-Sulfur Ratio Effects in Gray Cast IronNetoОценок пока нет

- SG Iron ProductionДокумент20 страницSG Iron ProductionShreyashri Nayak100% (1)

- Cold Mounting EnglishpdfДокумент6 страницCold Mounting EnglishpdfJorge BonillaОценок пока нет

- Cast Iron SolidificationДокумент12 страницCast Iron Solidificationkatchani123100% (1)

- Using Microsilica to Improve Refractory CastablesДокумент28 страницUsing Microsilica to Improve Refractory CastablesSachin SahooОценок пока нет

- Lecture - Magnesium Alloys - Hue'sДокумент29 страницLecture - Magnesium Alloys - Hue'sMurali ManuОценок пока нет

- Elkem 04 Inoculation PracticesДокумент2 страницыElkem 04 Inoculation Practicesmarcotulio123Оценок пока нет

- Carbide Dissolution in Thin Wall Ductile Iron PDFДокумент8 страницCarbide Dissolution in Thin Wall Ductile Iron PDFsachinguptachdОценок пока нет

- Magnesium Contents in Ductile IronДокумент2 страницыMagnesium Contents in Ductile Ironarnaldorcr8646Оценок пока нет

- Tundish Cover Ladle Nodularization Technical InfoДокумент2 страницыTundish Cover Ladle Nodularization Technical InfoAnonymous iztPUhIiОценок пока нет

- Common Metallurgical Defects in Ductile Iron EnglishДокумент1 страницаCommon Metallurgical Defects in Ductile Iron EnglishedgarestevessОценок пока нет

- Offsetting Macro-Shrinkage in Ductile IronДокумент13 страницOffsetting Macro-Shrinkage in Ductile IronmetkarthikОценок пока нет

- BLUESIL BP 9710 RepelenteДокумент3 страницыBLUESIL BP 9710 Repelentehector mauricio paez cantorОценок пока нет

- AFS Thermal Analysis of CupsДокумент12 страницAFS Thermal Analysis of Cupsyash_ganatraОценок пока нет

- Surface Graphite Degeneration in Ductile Iron CastДокумент8 страницSurface Graphite Degeneration in Ductile Iron CastKhairul MuzafarОценок пока нет

- Back to BASICS: Nitrogen fissures defects in iron castingsДокумент2 страницыBack to BASICS: Nitrogen fissures defects in iron castingsJustin DixonОценок пока нет

- BCIRA Broadsheet 41Документ4 страницыBCIRA Broadsheet 41Justin Dixon100% (1)

- Effect of Minor and Trace Elements in Cast IronДокумент2 страницыEffect of Minor and Trace Elements in Cast IronsachinguptachdОценок пока нет

- Thermal Analysis Optimization of Gray and Ductile Iron ProductionДокумент18 страницThermal Analysis Optimization of Gray and Ductile Iron ProductionslagmercuryОценок пока нет

- Effect of Bismuth in Ductile IronДокумент4 страницыEffect of Bismuth in Ductile Ironmarcotulio123100% (2)

- T-18 - Recommended Target Analysis For Ductile IronsДокумент2 страницыT-18 - Recommended Target Analysis For Ductile Ironscrazy dОценок пока нет

- Cast Iron BrochureДокумент12 страницCast Iron BrochureFlamarion BadaroОценок пока нет

- GraphiteStructuresInCI PDFДокумент1 страницаGraphiteStructuresInCI PDFAnonymous B3I6zYNhqdОценок пока нет

- Shrinkage in Ductile IronДокумент5 страницShrinkage in Ductile Ironkarthikkanda100% (1)

- Carbon Dioxide Moulding ProcessДокумент17 страницCarbon Dioxide Moulding ProcessqwertyuioОценок пока нет

- Cast Iron DampingДокумент5 страницCast Iron Dampinggabs88Оценок пока нет

- Ductile Dross Formation MonitoringДокумент27 страницDuctile Dross Formation MonitoringsachinguptachdОценок пока нет

- MagnesiumДокумент3 страницыMagnesiumIsidoro LópezОценок пока нет

- Ductile Iron Specifications for Design EngineersДокумент17 страницDuctile Iron Specifications for Design Engineersante_zivkovic1Оценок пока нет

- Effect of Basic Chemical Element in Sgi Ductile Iron IJERTV1IS7135Документ7 страницEffect of Basic Chemical Element in Sgi Ductile Iron IJERTV1IS7135Uma KoduriОценок пока нет

- Analysis of Quality and Cost of FeSiMg Treatment Master Alloy vs. Cored Wire in Production of Ductile Cast IronДокумент4 страницыAnalysis of Quality and Cost of FeSiMg Treatment Master Alloy vs. Cored Wire in Production of Ductile Cast IronAdams GodoyОценок пока нет

- Engineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeОт EverandEngineering Equipment for Foundries: Proceedings of the Seminar on Engineering Equipment for Foundries and Advanced Methods of Producing Such Equipment, Organized by the United Nations Economic Commission for EuropeОценок пока нет

- Effect of Bismuth in Ductile IronДокумент4 страницыEffect of Bismuth in Ductile Ironmarcotulio123100% (2)

- Livro Malleable Cast Iron PDFДокумент198 страницLivro Malleable Cast Iron PDFmarcotulio123Оценок пока нет

- Grinding TheoryДокумент47 страницGrinding Theorymarcotulio123Оценок пока нет

- SiC Most Efficiente Addition To Increase The Nodule in DI PDFДокумент12 страницSiC Most Efficiente Addition To Increase The Nodule in DI PDFmarcotulio123Оценок пока нет

- The Text Mining HandbookДокумент423 страницыThe Text Mining Handbookmarcotulio123Оценок пока нет

- Austenitic Manganese SteelДокумент6 страницAustenitic Manganese Steelmarcotulio123Оценок пока нет

- Diseno de Mazarotas PDFДокумент45 страницDiseno de Mazarotas PDFAriel GarciaОценок пока нет

- Nickel and Gray Iron Influence On Structure and PropertiesДокумент16 страницNickel and Gray Iron Influence On Structure and PropertiesIjabiОценок пока нет

- Steel Castings HandbookДокумент58 страницSteel Castings Handbookgalici2002100% (3)

- Duplex Stainless Steel 3rd EditionДокумент68 страницDuplex Stainless Steel 3rd EditionPhani Sridhar Ch100% (3)

- Abrasion-Resistant Steel PlateДокумент16 страницAbrasion-Resistant Steel Platemarcotulio123Оценок пока нет

- The Text Mining HandbookДокумент423 страницыThe Text Mining Handbookmarcotulio123Оценок пока нет

- Filter NotesДокумент46 страницFilter Notestanzil10100% (1)

- 133Документ8 страниц133marcotulio123Оценок пока нет

- The Samurai Sword Design Project and Opportunities For Metallurgical ProgramsДокумент11 страницThe Samurai Sword Design Project and Opportunities For Metallurgical Programsmarcotulio123Оценок пока нет

- RECHUPEДокумент7 страницRECHUPEmarcotulio123Оценок пока нет

- Elkem 06 Fading of InoculationДокумент2 страницыElkem 06 Fading of Inoculationmarcotulio123Оценок пока нет

- Elkem 04 Inoculation PracticesДокумент2 страницыElkem 04 Inoculation Practicesmarcotulio123Оценок пока нет

- Analysis of Reasons Causing Riser Feeding FailureДокумент8 страницAnalysis of Reasons Causing Riser Feeding Failuremarcotulio123Оценок пока нет

- DI1Документ13 страницDI1Getapune PunegetaОценок пока нет

- Elkem 06 Fading of InoculationДокумент2 страницыElkem 06 Fading of Inoculationmarcotulio123Оценок пока нет

- Draftsigth Getting Started GuideДокумент186 страницDraftsigth Getting Started GuideAndrés Gilberto Catalán HernándezОценок пока нет

- Luva Exotermica Patente Us06360808b1Документ16 страницLuva Exotermica Patente Us06360808b1marcotulio123Оценок пока нет

- 5 Mechanisms Graphite Nucleation Cast IronДокумент2 страницы5 Mechanisms Graphite Nucleation Cast Ironmarcotulio123Оценок пока нет

- ARTIGO Chapter 8 Solidification ShrinkageДокумент67 страницARTIGO Chapter 8 Solidification Shrinkagemarcotulio123Оценок пока нет

- Elkem 07 Magnesiun Contents in Ductile IronДокумент2 страницыElkem 07 Magnesiun Contents in Ductile Ironmarcotulio123Оценок пока нет

- Analysis of Simple Connections in Steel Structures Subjected To Natural Fires - 2010Документ320 страницAnalysis of Simple Connections in Steel Structures Subjected To Natural Fires - 2010José Pedro Casagrande TrentínОценок пока нет

- Design of Machine ElementДокумент68 страницDesign of Machine Elementmanish3247Оценок пока нет

- Laminar and Turbulent in Pipe-2 PDFДокумент20 страницLaminar and Turbulent in Pipe-2 PDFBoos yousufОценок пока нет

- 9003-01-4 Carbopol Thickener Carbomer in Cosmetics 980 White Powder EP980 INCI Name & CAS No. Carbomer 9003-01-4 DescriptionДокумент2 страницы9003-01-4 Carbopol Thickener Carbomer in Cosmetics 980 White Powder EP980 INCI Name & CAS No. Carbomer 9003-01-4 Descriptionshreeket3953Оценок пока нет

- Geotechnical Engineering - Conference PDFДокумент180 страницGeotechnical Engineering - Conference PDFcokiaaОценок пока нет

- Normalizing - Heat TreatmentДокумент3 страницыNormalizing - Heat TreatmentferozОценок пока нет

- Chapter6 Development LengthДокумент13 страницChapter6 Development LengthYo Fangirls100% (1)

- CPN 35 - Fibres in ConcreteДокумент12 страницCPN 35 - Fibres in ConcreteRavi7654Оценок пока нет

- AN EXPERIMENTAL INVESTIGATION AND VALIDATION OF THERMO-ELASTIC MODELS ON THERMAL CONDUCTIVITY BEHAVIOUR OF Al 6061-SILICON CARBIDE-GRAPHITE HYBRID METAL MATRIX COMPOSITESДокумент15 страницAN EXPERIMENTAL INVESTIGATION AND VALIDATION OF THERMO-ELASTIC MODELS ON THERMAL CONDUCTIVITY BEHAVIOUR OF Al 6061-SILICON CARBIDE-GRAPHITE HYBRID METAL MATRIX COMPOSITESijsretОценок пока нет

- 1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceДокумент12 страниц1.2 Mechanical Design: 1.2.1 Material Selection Based On Corrosion ResistanceYusuf Shano100% (1)

- Addition PDFДокумент18 страницAddition PDFAdheep DasОценок пока нет

- Budget of Work in Science Vi First QuarterДокумент3 страницыBudget of Work in Science Vi First QuarterSonny MatiasОценок пока нет

- Ansys TutorialДокумент7 страницAnsys Tutoriallooking4manish100% (2)

- Thin Walled Pressure VesselДокумент13 страницThin Walled Pressure VesselaalijanaabОценок пока нет

- Material Selection Guide - Endura PlasticsДокумент29 страницMaterial Selection Guide - Endura PlasticsvadiОценок пока нет

- NanoTechnology in Construction Carbon Nano TubeДокумент53 страницыNanoTechnology in Construction Carbon Nano TubekumarОценок пока нет

- 10 1016@j Matchemphys 2019 05 033Документ13 страниц10 1016@j Matchemphys 2019 05 033Deghboudj SamirОценок пока нет

- Assignment PhyChemДокумент4 страницыAssignment PhyChemimPERFECTme09Оценок пока нет

- Foundation Example 9.7Документ14 страницFoundation Example 9.7Deana WhiteОценок пока нет

- Liquid Pipeline Hydraulics GuideДокумент131 страницаLiquid Pipeline Hydraulics GuideJohn Jairo Ramos100% (1)

- Translate Clause in TCVN 5575Документ2 страницыTranslate Clause in TCVN 5575Phương Do QuangОценок пока нет

- C17 LightДокумент26 страницC17 LightFatima FaizanОценок пока нет

- Minggu 3 Klasifikasi Massa BatuanДокумент23 страницыMinggu 3 Klasifikasi Massa Batuanarwan_sipilОценок пока нет

- Abstract Book2018Документ243 страницыAbstract Book2018SaravananОценок пока нет

- Section5 Chemical Products Services, HalliburtonДокумент26 страницSection5 Chemical Products Services, HalliburtonVGОценок пока нет

- An Investigation of Tio2-Znfe2o4 Nanocomposites For Visible LightДокумент124 страницыAn Investigation of Tio2-Znfe2o4 Nanocomposites For Visible LightVăn Đại - BKHN100% (1)

- Production of Foam Using Plastic Support: Submitted By: Hritik Lal ID:2018A1PS0281GДокумент10 страницProduction of Foam Using Plastic Support: Submitted By: Hritik Lal ID:2018A1PS0281GHritik Lal100% (1)