Академический Документы

Профессиональный Документы

Культура Документы

Dockgates and Lockgates PDF

Загружено:

Elizabeth HarrisИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Dockgates and Lockgates PDF

Загружено:

Elizabeth HarrisАвторское право:

Доступные форматы

dock and lock gates

Renowned the world over for the design of gates for dry docks, locks and impounded basins, Royal Haskoning has carried out hundreds of gate projects since the early 1960s, designing and developing some of the worlds largest and most innovative gates. As well as carrying out the structural design of dock and lock gates by finite element analysis, our service includes preparation of ballasting, buoyancy and stability calculations and procedures for the installation, operation and maintenance of gates. All our gate designs have a high level of innovation leading to significant cost savings through steelwork reduction. We take full account of the unique parameters of each gate design, including operation, manoeuvring and maintenance. Our track record covers the full spectrum of gate sizes and operational features both new and replacement:

l

Dry Dock Entrance Gates

l l l

Flap Gates: Box, Cantilever, Modular Propped Caisson Gates Floating Mitre Gates Inverted Y Lambda L Ship lock sliding, rolling Marina lock double sector, single sector, delta, mitre, flap, half-tide

Dry Dock Intermediate Gates

l l l

Lock Gates

l l

Water Control Gates

Royal Haskoning gate designs

Flap gates are supported by hinges to the entrance sill of a dock or basin and are opened

by lowering them down into the water so they lie on the seabed below the sill. Flap gates are usually provided with buoyancy tanks to minimise the operating load on the winches or hydraulic rams. This type of gate can be used to maintain water levels in a wet dock during low tide. Larger gates are usually installed in modern ship repair docks where speed of operation is important. Flap gates can be designed to either span an entrance (up to around 80m) or are cantilevered or propped off the sill.

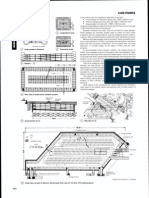

Images from left to right:

Flap Gate Propped, Floating Caisson Gate, Sliding Gate, Intermediate Gate Lambda

Floating caisson gates are one of the most common forms of dock gate. Because they

have to be pumped out, floated and manoeuvred, they are not generally considered for modern ship repair docks, but used mainly for shipbuilding dock entrances where the time to open and close the gate is not critical. We have developed the inverted T shaped floating gate design especially for very wide shipbuilding docks. As a gravity-stabilised gate, there is no limit to entrance width it can be designed for. The widest at present is 131m. The unique feature of this gate is that it can be fully maintained while in service.

Intermediate gates are used in large dry docks to subdivide the dock into two sections.

Generally the gates comprise either inverted Y or Lambda shaped modular steel units which are erected in the dry at fixed locations on the dock floor.

Sliding and rolling caisson gates are generally used for large ship locks and are opened

by withdrawing them into a chamber on one side of the lock entrance. The caisson is lightly ballasted so it can be slid or rolled on a track to and from its closed position across the entrance. These caissons are usually moved using winches with continuous chains or wire ropes.

Sector gates are usually installed in small locks often at an entrance to a marina. They are

installed in pairs or as a single gate and actuated by hydraulic rams which rotate them on a vertical axis. Their two main advantages are that they can be operated when there is a water head differential across, so they can be used for sluicing, and resist a water head on either side and hence protect against high tides and storm surges.

Mitre gates are one of the oldest types of gate, used as impounding gates in ports and

dry dock entrance gates. They are used particularly in small canal locks, where they are only required to resist water pressure from one direction. Historically constructed in timber, larger modern examples are fabricated in steel. A particularly economic form of gate design, they are arranged in pairs and hinge on vertical axis.

For more information contact:

David Greenhalgh, Tel: +44 (0) 1444 476 604, E-mail: d.greenhalgh@royalhaskoning.com

www.royalhaskoning.co.uk www.maritime-rh.com

Вам также может понравиться

- AUV Design - Shape, Drag and Practical IssuesДокумент5 страницAUV Design - Shape, Drag and Practical Issuesleiser123Оценок пока нет

- ZSoil GettingStartedДокумент287 страницZSoil GettingStartedRyszard TęczaОценок пока нет

- SimFlex Navigator - List of Ship Model +++Документ9 страницSimFlex Navigator - List of Ship Model +++Lala RadinaОценок пока нет

- Multipurpose Vessel: Rolldock SUNДокумент40 страницMultipurpose Vessel: Rolldock SUNChockalingam Ganesh K R0% (1)

- Concrete0709 PDFДокумент144 страницыConcrete0709 PDFlu190765Оценок пока нет

- Pavement TypesДокумент20 страницPavement TypesAnonymous 9iK0i8h0dPОценок пока нет

- Dredging and ReclamationДокумент8 страницDredging and ReclamationSAMSON WERESON100% (1)

- TrelleborgДокумент10 страницTrelleborgrofiqq4Оценок пока нет

- Caisson Production On Floating DockДокумент19 страницCaisson Production On Floating DockThet Naung OoОценок пока нет

- Guide To GeoinformaticsДокумент14 страницGuide To GeoinformaticskkkpkОценок пока нет

- Kashec Proposals For East CoastДокумент43 страницыKashec Proposals For East CoastAM004Оценок пока нет

- Cranes With Brains: Euromax - The Modern Automatic Container TerminalДокумент4 страницыCranes With Brains: Euromax - The Modern Automatic Container TerminalElafanОценок пока нет

- Massie1976 3Документ183 страницыMassie1976 3Harun CingozОценок пока нет

- BreakwatersДокумент26 страницBreakwatersnithesh kumar jОценок пока нет

- Permanent Anchor MooringДокумент2 страницыPermanent Anchor MooringVIVEK JOYОценок пока нет

- Truxor 09 ENG2 PDFДокумент16 страницTruxor 09 ENG2 PDFProjetos TonioloОценок пока нет

- Fentek CatalogДокумент48 страницFentek Catalogjoseherreramogollon100% (1)

- Design of Durbale Prestressed Concrete For Dabhol TrestleДокумент10 страницDesign of Durbale Prestressed Concrete For Dabhol TrestleKalipada SenОценок пока нет

- Kate Spade CatalogueДокумент57 страницKate Spade CatalogueLadybugStoreОценок пока нет

- Full Paper 200 PDFДокумент16 страницFull Paper 200 PDFMahdi FekiОценок пока нет

- Technical Description - MA520 Rev1Документ4 страницыTechnical Description - MA520 Rev1indra celthicОценок пока нет

- Designing For Vehicles PDFДокумент3 страницыDesigning For Vehicles PDFNerinel CoronadoОценок пока нет

- Port Facilities: Waim Akshay RavindraДокумент16 страницPort Facilities: Waim Akshay RavindraAkshay Waim100% (1)

- Brochure Ej BeanДокумент5 страницBrochure Ej Beanipman99Оценок пока нет

- Ferro Cement 2Документ22 страницыFerro Cement 2Abhishek DorugadeОценок пока нет

- Underwater ConstructionДокумент11 страницUnderwater ConstructionOmar HaroonОценок пока нет

- Haldia General Info - Inside DockДокумент7 страницHaldia General Info - Inside DockIan RidzuanОценок пока нет

- m1100 v1.2 en s08 - Safety ProductsДокумент4 страницыm1100 v1.2 en s08 - Safety ProductsMa ProvoloneОценок пока нет

- The Bombardon' Floating Breakwater: Rahul Jindal 11NA10028 Ajit Kumar 11NA30024 Prof. T SahooДокумент25 страницThe Bombardon' Floating Breakwater: Rahul Jindal 11NA10028 Ajit Kumar 11NA30024 Prof. T SahooJipin KumarОценок пока нет

- AMCRPS - AS 500 Design & Execution ManualДокумент64 страницыAMCRPS - AS 500 Design & Execution Manualphilou6259Оценок пока нет

- GMB Sor Effect 11112013 Notifications PDFДокумент243 страницыGMB Sor Effect 11112013 Notifications PDFJalpesh PatelОценок пока нет

- DynaMoor Brochure PDFДокумент20 страницDynaMoor Brochure PDFKahina BennacerОценок пока нет

- FM 5-134 - Pile ConstructionДокумент176 страницFM 5-134 - Pile ConstructionMarshall BravestarОценок пока нет

- ISKAR Catalogue PDFДокумент32 страницыISKAR Catalogue PDFSACHINОценок пока нет

- Docks Harbours Day3Документ28 страницDocks Harbours Day3Gopi RajuОценок пока нет

- Accropode Brochure 2014Документ4 страницыAccropode Brochure 2014Pn EkanayakaОценок пока нет

- MIKE21Документ16 страницMIKE21Defza HuristuОценок пока нет

- Extension of Existing Quay Wall - ACRPS - Cadiz - SpainДокумент4 страницыExtension of Existing Quay Wall - ACRPS - Cadiz - SpainIgnatius SamrajОценок пока нет

- Design PrinciplesДокумент173 страницыDesign PrinciplesZainab Hamayun LodhiОценок пока нет

- Schilling Rudder - Wikipedia, The Free EncyclopediaДокумент3 страницыSchilling Rudder - Wikipedia, The Free EncyclopediaAhmad HajivandОценок пока нет

- Tipe Perlengkap Pengerukan Types of Dredging Equipment Part 1. Mechanical DredgesДокумент15 страницTipe Perlengkap Pengerukan Types of Dredging Equipment Part 1. Mechanical Dredgesfathurahmad 2205Оценок пока нет

- Dredging PDFДокумент9 страницDredging PDFHorea Cordunianu100% (1)

- Chapter 10. Hydraulic Failure 185Документ1 страницаChapter 10. Hydraulic Failure 185Yasonsky CaptainОценок пока нет

- AZ 300FT: Deck Cargo Barge SpecificationsДокумент1 страницаAZ 300FT: Deck Cargo Barge SpecificationsFandy SipataОценок пока нет

- Harbour EngineeringДокумент64 страницыHarbour EngineeringshankaregowdaОценок пока нет

- Current Practice of Cfa Piling in Australia and New Zealand: Martinla@fcc - Co.nzДокумент9 страницCurrent Practice of Cfa Piling in Australia and New Zealand: Martinla@fcc - Co.nzpabulumzengОценок пока нет

- Safety of Breakwater Armour Layers With Special Focus On Monolayer Armour UnitsДокумент12 страницSafety of Breakwater Armour Layers With Special Focus On Monolayer Armour UnitsRaed Naim KhammashОценок пока нет

- Ship Concepts Methods, Stealth Performance and Resistance Reduction of DFT2 Case StudyДокумент13 страницShip Concepts Methods, Stealth Performance and Resistance Reduction of DFT2 Case StudyInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Jurnal 6 CoastalДокумент11 страницJurnal 6 CoastalkhananadiraОценок пока нет

- Primary StructureДокумент8 страницPrimary StructureKentОценок пока нет

- Dolphins: Hamburg-Finkenwerder Berthing Basin For Large VesselsДокумент12 страницDolphins: Hamburg-Finkenwerder Berthing Basin For Large VesselshermansuyudiОценок пока нет

- Exogenic Processes (Erosion and Deposition) : 30 August 2018 1Документ78 страницExogenic Processes (Erosion and Deposition) : 30 August 2018 1Marjorie BrondoОценок пока нет

- Dock and Lock GatesДокумент2 страницыDock and Lock Gateskharis abdullah100% (1)

- Dock and Lock Gates Royal HaskoningDHV BrochureДокумент16 страницDock and Lock Gates Royal HaskoningDHV BrochureJorge LafontantОценок пока нет

- Catalogo Puerta MANIVAДокумент64 страницыCatalogo Puerta MANIVAleroniusОценок пока нет

- Gates 1Документ30 страницGates 1Caliwan CarlsonОценок пока нет

- Phase 1 - Watertight DoorsДокумент39 страницPhase 1 - Watertight DoorsAmy Castaneda100% (2)

- Water GatesДокумент11 страницWater GatesEhlma LacuarenОценок пока нет

- Chapter - III - B - Design - Requirements - of - Ports - HarborsДокумент37 страницChapter - III - B - Design - Requirements - of - Ports - HarborsFrancis Ko Badongen-Cawi Tabaniag Jr.Оценок пока нет

- Types of Hydraulic Steel StructuresДокумент7 страницTypes of Hydraulic Steel StructuresBelia LongalongОценок пока нет

- 2013-11-14 MECH479 AnsysWorkbench Tutorial PDFДокумент27 страниц2013-11-14 MECH479 AnsysWorkbench Tutorial PDFElizabeth HarrisОценок пока нет

- ABS EH36 Steel Plate, ABS EH36 Steel Sheet, ABS Grade EH36 Shipbuilding Steel Price, ABS Grade EH36 Steel Supplier and ManufacturerДокумент3 страницыABS EH36 Steel Plate, ABS EH36 Steel Sheet, ABS Grade EH36 Shipbuilding Steel Price, ABS Grade EH36 Steel Supplier and ManufacturerElizabeth HarrisОценок пока нет

- Accessory Catalog 2011Документ134 страницыAccessory Catalog 2011Elizabeth HarrisОценок пока нет

- Jackson, StuartДокумент40 страницJackson, StuartElizabeth HarrisОценок пока нет

- LiftДокумент30 страницLiftElizabeth HarrisОценок пока нет

- Fluid PowerДокумент88 страницFluid PowerGabriel Ak100% (3)

- Miller SyncrowaveДокумент8 страницMiller SyncrowaveElizabeth HarrisОценок пока нет

- B and US Guide E-Feb14Документ83 страницыB and US Guide E-Feb14Mohd Shahrom IsmailОценок пока нет

- Floline Hydraulic CylindersДокумент6 страницFloline Hydraulic CylindersElizabeth HarrisОценок пока нет

- Ansys Examples and Problems PDFДокумент231 страницаAnsys Examples and Problems PDFElizabeth HarrisОценок пока нет

- Excalibur Screwbolt 20mmДокумент1 страницаExcalibur Screwbolt 20mmAlphaОценок пока нет

- Life-Cycle Costing in The Construction SectorДокумент5 страницLife-Cycle Costing in The Construction SectorFrancisco AguinagaОценок пока нет

- FRP Hdpe ComparisonДокумент3 страницыFRP Hdpe ComparisonbcsmurthyОценок пока нет

- Cau 2014Документ25 страницCau 2014vinay1999Оценок пока нет

- List of Articles & BooksДокумент2 страницыList of Articles & BooksHarshil SafiОценок пока нет

- 8 - House BigДокумент32 страницы8 - House Biggiovanni100% (1)

- "Monorail" - Monorail Beam Analysis: Program DescriptionДокумент14 страниц"Monorail" - Monorail Beam Analysis: Program DescriptionYash SutharОценок пока нет

- Chain Crosby® Grade 100Документ1 страницаChain Crosby® Grade 100CROSBYОценок пока нет

- Demister Beam Calculation - Final PDFДокумент4 страницыDemister Beam Calculation - Final PDFGauravОценок пока нет

- Jaina Safe Prefab HutДокумент26 страницJaina Safe Prefab Hutamritesh pandeyОценок пока нет

- MSB03 ActionsДокумент47 страницMSB03 Actionsanil97232Оценок пока нет

- Inspecting Bellows DamageДокумент1 страницаInspecting Bellows DamageSeungmin PaekОценок пока нет

- M04 Read and Interpret PlansДокумент113 страницM04 Read and Interpret Plansmustied mohammed100% (1)

- 5 (1) .Recent IRC Codes On Waste Plastic, Warm - SK NirmalДокумент33 страницы5 (1) .Recent IRC Codes On Waste Plastic, Warm - SK NirmalSoni JitubhaiОценок пока нет

- Ventilation WorksheetДокумент1 страницаVentilation WorksheetIskandar 'muda' AdeОценок пока нет

- Caterpillar Disassembly and Assembly Transmission 950g and 962g Wheel LoaderДокумент20 страницCaterpillar Disassembly and Assembly Transmission 950g and 962g Wheel Loaderpatrick100% (39)

- Factors Influencing Project Delay: A Case Study of The Vale Malaysia Minerals Project (VMMP)Документ8 страницFactors Influencing Project Delay: A Case Study of The Vale Malaysia Minerals Project (VMMP)LOKESH KUMAR SINHAОценок пока нет

- Fatigue Calculation of Concrete According To EC2: Severe or Not?Документ9 страницFatigue Calculation of Concrete According To EC2: Severe or Not?ShamaОценок пока нет

- Root Cause AC Motor Failure Analysis With Focus On Shaft FailuresДокумент43 страницыRoot Cause AC Motor Failure Analysis With Focus On Shaft Failuresharshal161987100% (1)

- Production RateДокумент50 страницProduction RateFührer Magdi Badran100% (2)

- 01 The Law and Practice of Delay Claims A Practical Introduction TrainorДокумент19 страниц01 The Law and Practice of Delay Claims A Practical Introduction TrainorMOHОценок пока нет

- F002 76-10526-Detail DesignДокумент1 страницаF002 76-10526-Detail DesignMazen IsmailОценок пока нет

- Development Authority: Bhubaneswar Development Authority RFP Document For EPC contractor-ISBT Baramunda, BhubaneshwarДокумент8 страницDevelopment Authority: Bhubaneswar Development Authority RFP Document For EPC contractor-ISBT Baramunda, BhubaneshwarSARIT SEKHAR MUKHERJEEОценок пока нет

- Tigges Catalogue PDFДокумент119 страницTigges Catalogue PDFwal1547Оценок пока нет

- Chilled Water Qty Take OffДокумент20 страницChilled Water Qty Take OffProject enghvacОценок пока нет

- Typical Specifications: Model: Description: CertificationsДокумент1 страницаTypical Specifications: Model: Description: CertificationsLeo2pbОценок пока нет

- Bottle PozzДокумент19 страницBottle Pozzattarsf1952Оценок пока нет

- Fire Damaged Concrete StructuresДокумент11 страницFire Damaged Concrete StructuresbarouniamineОценок пока нет

- Astm A 48-2016Документ6 страницAstm A 48-2016Mohammed AliОценок пока нет

- 4935-w0 Standard For Purchase of Full-Encirclement Welded Split SleevesДокумент3 страницы4935-w0 Standard For Purchase of Full-Encirclement Welded Split SleevesLorenaОценок пока нет