Академический Документы

Профессиональный Документы

Культура Документы

COMSOL - Workshop PDF

Загружено:

preethamismОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

COMSOL - Workshop PDF

Загружено:

preethamismАвторское право:

Доступные форматы

8/27/2012

1

Advanced COMSOL Multiphysics - WSU

2012 COMSOL. COMSOL and COMSOL Multiphysics are registered trademarks of COMSOL AB. Capture the Concept,

COMSOL Desktop, and LiveLink are trademarks of COMSOL AB. Other product or brand names are trademarks or registered

trademarks of their respective holders.

John Dunec, Ph.D.

COMSOL, Inc.

Agenda Morning Intro

Introduction

Worked Example: Joule Heating

Warmup: 3 Quick Problems

Hot Rod

Capacitor

Wrench

Multiphysics Problems:

Thermal Decomposition

H-Cell Microfluidics

Natural Convection in a Light Bulb

Agenda Afternoon Advanced

Worked Example: Magnetophoresis

Meshing Infinity

Infinite Elements

Perfectly Matched Layers

Meshing and Mesh Control

Basic Mesh Control

Interactive Mesh Control

Swept Meshing

ALE Moving Mesh

Postprocessing: The Results Node

Magnetic

Field

Flow Profile &

Particle Pathlines

Multiphysics: Multiple Interacting Phenomena

Could be simple:

Heat convected by Flow

Could be complex:

Local temperature sets

reaction rates

Multiple exothermic

reactions

Convected by flow in pipes

and porous media

Viscosity strongly

temperature dependent

COMSOL Multiphysics Solves These!

Multiphysics Everything can link to everything.

Flexible You can model just about anything.

Usable You can keep your sanity doing it.

Extensible If its not specifically thereadd it!

Trusted by 80,000+ Users Worldwide

Product Suite

AutoCAD and Inventor are registered trademarks of Autodesk, Inc. LiveLink for AutoCAD and LiveLink for Inventor are not affiliated with, endorsed by, sponsored by, or

supported by Autodesk, Inc. and/or any of its affiliates and/or subsidiaries. CATIA is a registered trademark of Dassault Systmes S.A. or its affiliates or subsidiaries. SolidWorks

is a registered trademark of Dassault Systmes SolidWorks Corporation or its parent, affiliates, or subsidiaries. Creo is a trademark and Pro/ENGINEER is a registered trademark

of Parametric Technology Corporation or its subsidiaries in the U.S and/or in other countries. MATLAB is a registered trademark of The MathWorks, Inc.

8/27/2012

2

Anywhere you can type a number

you can type an equation

Or an interpolation function

And it can depend on anything known in your problem

Example: Concentration-dependant viscosity:

( )

2

2 1 001 . 0 c + =

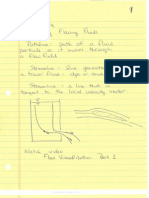

Low concentration,

High velocity

High concentration,

Low velocity

Add Your Own Equations to COMSOLs

Dont see what you need?

Add your own equation

ODEs

PDEs

Weak form PDEs

Just type them in

No Recompiling

No Programming

Capture the Concept

TM

Magnetophoresis Magnetophoresis

Blood Cell Separation with Magnetophoresis

Key Elements

Simulating a magnetic field from

a permanent magnet

Disturbing the B-field to produce

magnetic gradients

Simulating flow in a microfluidics

lab-on-a-chip set of flow channels

Using Particle Tracing to

concentrate blood cells responding

to magnetophoretic forces

Reference & Key Separation Property

Model Based on Paper Presented at 2009 COMSOL Conference:

G. Schiavone, D. Kavanagh, & M. Desmulliez, Design and Simulation of

a Microscale Magnetophoretic Device for the Separation of Nucleated

Fetal Red Blood Cells from Maternal Blood, Proceedings of the COMSOL

Conference 2009 Milan

Key Material Property:

The magnetic susceptibility

c

of red blood cells depends on the oxidation

state of the hemoglobin molecules. RBCs in a normal state exhibit an

extremely weak diamagnetic behaviour as

c

is negative and quite close to

zero.

c

= -3.9e-6 Therefore permeability = (1 3.9e-6)

3 Physics: Magnetics, Flow, & Particle Tracing

Magnetics Fluid Flow Particle Tracing

Particles respond to both Drag and Magnetophoretic Forces

8/27/2012

3

COMSOL Products Used This Tutorial

AutoCAD and Inventor are registered trademarks of Autodesk, Inc. LiveLink for AutoCAD and LiveLink for Inventor are not affiliated with, endorsed by, sponsored by, or

supported by Autodesk, Inc. and/or any of its affiliates and/or subsidiaries. CATIA is a registered trademark of Dassault Systmes S.A. or its affiliates or subsidiaries. SolidWorks

is a registered trademark of Dassault Systmes SolidWorks Corporation or its parent, affiliates, or subsidiaries. Creo is a trademark and Pro/ENGINEER is a registered trademark

of Parametric Technology Corporation or its subsidiaries in the U.S and/or in other countries. MATLAB is a registered trademark of The MathWorks, Inc.

COMSOL Multiphysics, AC/DC Module, Microfluidics Module

Along with the Particle Tracing Module

Tutorial Roadmap

First: Setup and Solve Magnetics & Flow

Choose two physics

Import geometry sequence

Define materials (Glass, Soft Iron, Water)

Set up Permanent Magnet

Set Flow Boundary Conditions

Mesh

Solve

Finally: Add Particle Tracing

Magnetic Field

Surrounding Neodymium

Magnets

Geometry

Glass Substrate

Two Neodymium

Permanent Magnets

Microfluidics Flow

Channel with 3 Outlets

Passive Array of Soft

Iron Patches

(Creates Field

Concentrators)

Array of Soft Iron Patches

Magnet

Flow Channel

Magnet

Magnetic Equations

Solve Magnetics based on the Scalar Magnetic Potential, V

m

Amperes Law relates H and B

In Permanent Magnets H related to B through Magnetism M

0 = V

V =

B

H

m

V

H B

r

0

=

M H B + =

0

Lets do this in COMSOL

Capture the Concept

TM

Step-by-step

Flow & Magnetics

Step-by-step

Flow & Magnetics

8/27/2012

4

First Solve for Magnetic Field and Flow

Choose File > New , 2D

Rt Click on AC/DC >

Magnetic Fields, No Currents

Add to Model

Rt Click on Fluid Flow

> Single- Phase Flow

> Creeping Flow

Add to Model

Choose Stationary

Units Meters

Highlight Geometry1

Leave units as m

Import Geometry Sequence

Right click on Geometry

Choose Import Sequence

from File

Navigate to File Location

Choose:

Magnetophoresis_GEOM_

SEQUENCE

Choose Build All

Limit Where Flow is Calculated

Do this before adding materials to

avoid unnecessary stop signs!

Highlight Creeping Flow

Clear ALL selections with broom

Select the flow channels (be sure

to include the small rectangle)

Materials Soft Iron

Rt Click on Materials

Choose Material Browser

Expand AC/DC

Rt click on

Soft Iron (without losses)

Add material to Model

Set mur to 4000

Materials Water and Glass

Pick Material Browser tab

Expand Built-in

Rt click on Water, liquid

Add material to Model

Select the flow channels (be sure

to include the small rectangle)

Set mur to 1

Pick Material Browser tab

Rt click on Glass (quartz)

Add material to Model

Select the outer circular domain

8/27/2012

5

Create a Material: NeodymiumMagnet

Rt Click on Materials

Choose Material

Name Material

Rt Click on Material 4

Rename to NeodymiumMagnet

Set Material Properties

Select the two magnet domains

Set mur as 1.05

Magnetize the Permanent Magnet

Rt Click on Magnetic Fields, No Currents

Choose Magnetic Flux Conservation

(This adds a 2

nd

Mag Flux Conserv. Node)

Select both Neodymium Magnet domains

Locate the Magnetic Field section

change Relative permeability to

Magnetization

Enter y component of M as 5.97e5

Avoid Field Distortion by Outer Boundary

Add Infinite Element Geometry

Expand Geometry 1

Highlight Circle 1 Overall

Expand Layers Section

Enter Layer Thickness as 0.005

Build all

Add Infinite Element Domains

Rt Click on Definitions

Choose Infinite Element Domains

Select the new outer layers

Change the Type to Cylindrical

Magnetic Potential Needs One Known Point

Set the magnetic value somewhere:

Rt Click on Magnetic Fields, No Currents

Choose Points > Zero Magnetic Scalar

Potential

Select the Leftmost Point to right of infinite

element domains

Flow Boundary Conditions: Inlet

Rt Click on Creeping Flow

Choose Inlet

Select the leftmost vertical flow

boundary

Change Boundary Condition

to Velocity

Enter Velocity as 0.5e-3

Flow Boundary Conditions: Outlet

Rt Click on Creeping Flow

Choose Outlet

Select the three right-most

vertical flow boundaries

Leave Boundary Condition

as Pressure,

Leave Pressure as 0

8/27/2012

6

Set Channel Depth

Highlight Creeping Flow

Change Compressibility to

Incompressible flow

Select Use shallow channel

approximation

Enter d

z

as 50e-6

Mesh the Infinite Element Domain

Rt Click on Mesh 1

Choose Mapped

Select the 4 Infinite Element domains

Rt Click on Mapped 1

Choose Distribution

Select the top vertical boundary

Number of Elements: 3

Rt Click on Mapped 1

Choose Distribution

Select the outer circle boundaries

Number of Elements: 15

Mesh the Inlet Flow Channel

Rt Click on Mesh 1

Choose Mapped

Select the inlet flow domain

Rt Click on Mapped 2

Choose Distribution

Select right vertical boundary

Number of Elements: 10

Rt Click on Mapped 2

Choose Distribution

Select top inlet channel boundary

Number of Elements: 1500

Mesh the Small Flow Rectangle

Rt Click on Mesh 1

Choose Mapped

Select the small flow domain

Rt Click on Mapped 3

Choose Distribution

Select top rectangle boundary

Number of Elements: 10

Build All

Mesh the Outlet Channels

Rt Click on Mesh 1

Choose Mapped

Select the 3 outlet flow domains

Build All

Distribution Upper Outlet

Rt Click on Mapped 4

Choose Distribution

Select BOTH the long upper outlet

boundaries

Change to Predefined distribution

Number of Elements: 70

Element Ratio: 10

Distribution method: Arithmetic seq

Build All

8/27/2012

7

Distribution Lower Outlet

Rt Click on Mapped 4

Choose Distribution

Select BOTH the long lower outlet

boundaries

Change to Predefined distribution

Number of Elements: 70

Element Ratio: 10

Distribution method: Arithmetic seq

Choose Reverse direction

Build All

Distribution Middle Outlet

Rt Click on Mapped 4

Choose Distribution

Select BOTH the long middle outlet

boundaries

Change to Predefined distribution

Number of Elements: 70

Element Ratio: 10

Distribution method: Arithmetic seq

Choose Reverse direction

Build All

Mesh the Remaining Glass

Rt Click on Mesh 1

Choose Free Triangular

Leave as Remaining

Rt Click on Free Triangular 1

Choose Size

Select ONLY the Glass Domain

Calibrate for General Physics

Set Size as Extra Coarse

Build All

Set up Two-Step Study

Rt Click on Study 1

Choose Study Steps

Choose Stationary

Highlight Step 1: Stationary

Deselect Calculating Flow

Highlight Step 2: Stationary 2

Deselect Calculating Magnetics

Rt Click on Study 1

Rename to Study 1 Flow and Magnetic Field

Solve for Flow and Magnetic Field

Rt Click on Study 1

Hit Compute

Magnetic Field

Magnetic Field

Flow Velocity

Solution Should be Done

164,000 Degrees of Freedom

37 seconds on my desktop

8/27/2012

8

Add Arrows for Magnetic Flux

Expand Results

Rt Click on Magnetic Flux Density

Choose Arrow Surface

Plot Magnetic Flux Density

X-points: 25

Y-points: 20

Scale Factor: 0.006

Color: Cyan

Capture the Concept

TM

Forces on Particles Forces on Particles

Next Add Particle Tracing for Blood Cells

Add 2

nd

Physics:

Particle Tracing, Transient

Define Particle Physics

Define the Particle Properties

Add the Drag Force, Link to velocity field

Add the Magnetophoretic Force, Link to B field

Create an Inlet (100 cells, velocity = V_inlet)

Set up Transient Study

Time Stepping

Link Transient Particle Tracing to Previous Study

Forces on the Blood Cells

Newtons Law recast to change in momentum

The magnetophoretic force is based on the gradient magnetic field

The fluid dynamic drag will be that predicted by Stokes law:

( ) ( ) v a F F F m

dt

d

m

D M

= = + =

2

, 0

3

2 H F V = K r

f r p M

t

( )

p p

p p

D

m

d

v u F =

2

18

Particle Properties

Density: 2200[kg/m^3]

Diameter: 6e-6[m]

Charge Number: 0

Permeability: (1 3.9e-6)

Red Blood Cells are somewhat donut shaped with a major

diameter of about 9 microns and a thickness of about 3 microns.

An equivalent sphere is roughly 6 microns in diameter.

Lets do this in COMSOL

8/27/2012

9

Capture the Concept

TM

Step-by-step

Particle Tracing

Step-by-step

Particle Tracing

Add Particle Tracing

Rt click on Model 1

Choose Add Physics

Choose Fluid Flow >

Particle Tracing for Fluid Flow

Choose the blue Next arrow

Choose Time Dependant

Deselect Solve For the other physics

Pick Finish Flag

Note: You need an additional study since particle tracing is transient

whereas the magnetic analysis was stationary.

Create Flow Channel Selection

Expand Materials

Highlight Water, Liquid

Choose the Create Selection

button

Name the Selection:

Flow Channels

Particles only in Fluid Domains

Highlight Particle Tracing for Fluid Flow

Go to Domain section

Pick Clear Selection button (the broom)

Choose Flow Channels domains in the

selection list

Walls Change to Bounce

Under Particle Tracing for Fluid

Flow

Highlight Wall 1

Change Wall Condition to

Bounce

Cells bounce back into main flow

Set Particle Properties

Under Particle Tracing for Fluid Flow

Highlight Particle Properties 1

Set to Specify particle density and

diameter

Enter Values:

Particle density: 2200[kg/m^3]

Particle diameter: 6e-6[m]

Charge Number: 0

Red Blood Cells are somewhat donut shaped with a major

diameter of about 9 microns and a thickness of about 3 microns.

This is an equivalent sphere.

8/27/2012

10

Add Fluid Drag Forces

Rt Click on Particle Tracing for Fluid Flow

Choose Drag Force

In Domain Selection section, choose

Flow Channels

In the Drag Force section, change velocity

field entry, u, to Velocity field (spf/fp1)

Add Magnetophoretic Forces

Rt Click on Particle Tracing for Fluid Flow

Choose Magnetophoretic Force

In Domain Selection section, choose Flow

Channels

In the Magnetophoretic Force section, change

Magnetic field, H, to Magnetic field (spf/fp1)

Enter values:

Particle relative permeability: 1-3.9e-6

(-3.9e-6 is the susceptibility)

Fluid relative permeability: 1

Boundary Cond: Particle Inlet

Rt Click on Particle Tracing for Fluid Flow

Choose Inlet

Select the left-most vertical flow boundary

Change Initial position to Uniform

Set N to 100

Set Velocity field to Velocity field (spf/fp1)

Boundary Cond: Particle Outlets

Rt Click on Particle Tracing for Fluid Flow

Choose Outlet

Select the 3 right-most vertical flow boundaries

Leave Wall Condition as Freeze

Assign Stationary Solver to Flow & Magnetics

Expand Study 1

Note: Both of the following are likely to

have been done for you already

Highlight Step 1: Stationary

In the Physics Selection:

Deselect Charged Particle Tracing

Highlight Step 2: Stationary 2

In the Physics Selection:

Deselect Charged Particle Tracing

Assign Transient Solver to Particle Tracing

Expand Study 2

Highlight Step 1: Time Dependant

In the Physics Selection:

Make sure Magnetic Fields is deactivated

Make sure Creeping Flow is deactivated

Rename Study

Rt Click on Study 2

Choose Rename

Change name to Study 2 Blood Cells

8/27/2012

11

Use Magnetics & Flow Solution from Study 1

Under Step 1: Time Dependant

Expand the Values of Dependent

Variables section

Select Values of variables not solve for

Method: Solution

Study: Study 1, Stationary

Stationary: Automatic

Set Times and Solve

Highlight Step 1: Time Dependant

Choose the Range button

Leave entry method as Step

Start: 0

Step: 0.1

Stop: 60

Pick Replace

Rt Click on Study 2

> Hit Compute

(Takes about 27 seconds)

Plot Particles as 3x Actual Size

Expand Particle Trajectories (cpt)

Highlight Particle Trajectories 1

Leave Type as Point

Change Radius expression to 6e-6

Select Radius Scale Factor

Enter Radius Scale Factor as 3

Plot

Zoom in on Y-Transition

Add Lines to Trajectories

Highlight Particle Trajectories 1

Change Type to Line

Plot

Add Arrow Plot

Expand Results

Rt Click on Particle Trajectories (fpt)

Choose Arrow Surface

Plot Flow Velocity (u, v)

Change x-Method to Coordinates

Set x coord to 0.0104

Change y-Method to Coordinates

Range: -0.0006 to 0.0006 in 65 steps

Scale Factor: 1

Compare with NO Magnetophoretic Force

Expand Particle Tracing For Fluid Flow

Rt Click on Magnetophoretic Force

Choose Disable

Rt Click on Study 2

Hit Compute

WITHOUT

Magnetophoretic Force

With

Magnetophoretic Force

8/27/2012

12

Capture the Concept

TM

PMLs & Infinite

Elements

PMLs & Infinite

Elements

You cannot model everything

You can never model the

entire universe

Boundary conditions

represent the outside

Two types: physical walls and

artificial boundaries

Use artificial boundaries to

model only the region of

interest

Model

Everything else

BC

BC

BC BC

Something else

Infinite Elements

Currently in AC/DC, Soon Throughout

Draw Rectangle, 2 Large Circles

Subdomain > Make Circles Not Active

Rectangle Boundaries ZeroCharge

Left Circle: V = 5 Right Circle V = -5

Solve; Contour Plot > 30 Contours

Geom Add Outer Inf Elem Geom

Subdomain Inf Elem Tab Match Matls

Inf Elems >Cartesian, Stretch in Proper Dir

Solve Hide Inf Element Subdomains

Perfectly Matched Layers

Absorbing Subdomain

Absorbs incident waves without reflection

Artificial boundary for non-enclosed spaces

Used instead of radiation boundary condition

Make thickness at least one wavelength

PML

Quick Example

Circle 1: R= 8 Center: (0,2)

Circle 2: R= 4 Center: (0,0)

f =100 Hz c =343 m/sec (air)

L=c/f = 3.4 Mesh Size = 3.4/5

Inner Circle Acceleration BC, a0=1

Add PML Circle 3: R=12 Center: (0,2)

Sound Hard Wall Radiation - Cylindrical PML - Cylindrical

Make PML at least one wavelength thick

Capture the Concept

TM

FEA Mesh

Descretization

FEA Mesh

Descretization

8/27/2012

13

The Machinery of the FE method

Strong

Form

Weak

Form

Galerkin

Form

Algebraic

Form

S W G A

Ax = b

( ) F b

t

a

t

b + V + I V =

c

c

+

c

c

u

2

2

Discretize in

time,

Linearize with

Newton-

Raphson

Shape Functions Approximate Solution

Assume a Shape of the answer inside an element

Equate flux out of one element to flux into neighboring element

( ) Q T k

t

T

C

p

= V V +

c

c

2

nd

or 3

rd

order elements

capture curvature inside

elements

Linear

elements

no curvature

Linearize with Newton Raphson

Here solution to f(x) = x

2

- 4 = 0

What kind of meshes can we use?

Tetrahedral

Most general, any 3D part

can be tet meshed. Use

this as much as possible.

Hexahedral Prismatic

- Only appropriate for certain geometries

- When solution is known to vary slowly in one axis

- Large deformations of the mesh

- Contact problems

Hybrid mesh

Boundary Layer Meshing

A semi-automatic hybrid approach between

prismatic and tetrahedral meshing.

It is meant for situations when you know

that there will be high gradients normal to

some surfaces, but you want the flexibility

of the tetrahedral mesh in the remainder of

the domains.

2

nd

Order Elements are more Efficient than 1st

A finite element basis function can only

approximately represent a true solution.

The error can be minimized by using smaller

elements, or increasing element order.

This is MESH or DISCRETIZATION error

10 1

st

order elements

16 1

st

order elements

4 2

nd

order elements

u

exact

-u

model

8/27/2012

14

When to use linear elements?

COMSOL uses linear elements by default for:

Fluid flow

Plasmas

Contact pressure in Solid mechanics

Temperature in Thermal stress

If you already have a very fine mesh due to geometric complexity

Very large models where you can only get low accuracy

Transient problems

Magnetic field with nonlinear material

2

nd

or 3

rd

order elements

capture curvature inside

elements

Linear

elements

no curvature

When To Use Higher Order Elements

Use for quick Accuracy Improvement Watch Out Though!

Can produce large (erroneous) numerical overshoots

Can make model size very large

Use higher order elements when calculating higher order derivatives

Field represented by 2

nd

order Shape Functions in Element

1

st

Spatial Derivative Linear Function in Element

2

nd

Spatial Derivative Constant in Element

3

rd

Spatial Derivative ZERO!

4

th

Spatial Derivative ZERO!

Linear

elements

no curvature

How to Change Element Order

Buttons at Top of Model Builder:

Turn On Visibility of Discretization

Highlight Individual Physics Nodes

Expand Discretization

Change order of elements

Sometimes, the geometry should be

adjusted to improve the model

1. Geometric Singularities

2. Fillets

3. Thin Regions & High

Aspect Ratios

4. Glancing Contact

5. Sliver Faces

6. Too Much Detail

7. Symmetry

8. Infinitely extended region

1. Geometric Singularities

Plate in tension with a sharp notch

The stresses at the notch will be

infinite, although the displacements

will be correct

Adding a small, physically realistic fillet,

will remove the singularity, but it will

increase the number of elements

2. Fillets

Overly detailed geometry

Sharp corner = singularity Compromise between lower

element count & accuracy

8/27/2012

15

3. Thin regions

t < L/100

Thin domains can often be represented

via boundary conditions that do not

require a volumetric mesh

3. High Aspect Ratios

L >> d

t << W, H

Aspect ratios > 1,000:1 require extreme care

Aspect ratios > 1,000,000:1 may require a different approach

4. Glancing contact

Instead, try:

Small Gap

Small Overlap

Perform convergence study

on gap/overlap size

5. Sliver faces

Small elements and high aspect

ratio elements are present

This usually requires re-drawing the CAD geometry

6. Too much detail

Remove as many of the small features as reasonable

Consider using Virtual

Operations on geometry

7. Use symmetry

Use symmetry planes

Model on reduced geometry

- Less mesh

- Less memory

- Less time

Consider using:

- 2D if there is no variation in

geometry and solution out-of-plane

- 2D axisymmetry if there is no

variation in geometry and solution

about an axis of revolution

8/27/2012

16

8. Infinitely Extended Region

Infinite Elements

Currently available for:

- Electrostatics and Magnetostatics

- Heat transfer

- Diffusion

- Structural Mechanics

Models an infinitely extended

region for time-invariant problems

Perfectly Matched Layer

Applicable to wave-type models:

Elastic waves in structures

Pressure waves in fluids (acoustics)

EM waves (RF)

Models an infinitely extended

region where the waves are

absorbed without reflection

Capture the Concept

TM

Meshing &

Mesh Control

Meshing &

Mesh Control

Simple Mesh Control Here 2D

Draw the Following Shapes

Explore Custom Parameters under Size Node

Predefined mesh options

9 options from Extremely Coarse to Extremely Fine

Custom mesh: Element Size Parameters

Maximum element size

Minimum element size

Maximum element growth rate

Resolution of curvature

Resolution of narrow regions

Maximum element size

This sets the maximum length of the edge of any element

Needs to be a positive number

If you do not pick a value, COMSOL uses L/10, where L is the maximum

dimension of the model

8/27/2012

17

Minimum element size

This sets the minimum length of the edge of any element

Needs to be a positive number

Useful to ensure that too many elements are not generated around

small curved parts

Maximum element growth rate

Rate at which the element size can grow from a region with small

elements to a region with larger elements

Needs to be a number between 1 and 2

Resolution of curvature

Determines the size of boundary elements compared to the curvature of

the geometric boundary

Max element size along boundary = curvature radius x resolution of

curvature

Needs to be a positive number

Smaller value gives finer mesh

Radius

Resolution of narrow regions

Control the number of layers of elements that are created in

narrow regions

A value between 0 to 1 produces anisotropic element

Needs to be a positive number

Resolution = 1

Resolution = 3

Interactive Meshing Piston Head Boundary Layer Meshing

Best for things that have boundary layer

details

New > 3D Geometry > Finish

Right Click on Geometry > Cylinder > Build

Right Click on Mesh > Boundary Layers

Right Click on Boundary Layers >

Boundary Layer Properties

Select the boundaries to have the boundary

details on (all the curved boundaries)

Build all

Change Stretching Factor to 1.1 (or 1.3)

Build all

8/27/2012

18

Interactive Meshing Chip and Solderballs

New > 3D > Finish Flag

Geom > Import > SolderJoints

Mesh with Default Tets (Size Coarse)

Delete Tets

Mesh Surface with Triangles

Sweep Solderballs

(Add Distribution > 5 layer)

Mesh IC Bottom with Free Triangles

Sweep IC (Distribution > 3 Layers)

Sweep Circuit Board

Boundary Layer Mesh Air Rectangle

Boundary Layer Props on Bottom of

Circuit Board Boundary > Mesh

Swept Meshing Exercise

Mesh All (Free)

Delete Mesh

Mesh Selected Faces

Undo Mesh

Increase Mesh Size

+ Mesh Selected (Swept)

Mesh Remaining (Free)

Mesh Selected (Swept)

Mixing Hex Meshes with Tet Meshes

New > 3D > Finish Flag

Geom > Block > 1x1x1

Geom > Block > 1x1x0.5

(Corner at 0,0,1)

Mesh Top Surface with Mapped

Sweep Top (Distribution: 5 layers)

Mesh Remaining Tets > ERROR

Remove last step

Mesh > More Operatns > Convert

Level = Boundary (Pick Shared)

Mesh Remaining Tets > WORKS

Capture the Concept

TM

ALE Moving

Mesh

ALE Moving

Mesh

ALE Moving Mesh

Think of the mesh as a bed of springs

As the boundary moves, the springs stretch

NOTE: Need special

effort to insure front

boundary of valve seat

block does not move

8/27/2012

19

ALE Moving Mesh

Think of the mesh as a bed of springs

As the boundary moves, the springs stretch

Two Coordinate Systems using Moving Mesh

Material Coordinate System: X,Y,Z (upper case)

This is the original (non-moving) system

Use this one to specify boundary motion

Spatial Coordinate System: x,y,z (lower case)

This one stretches and moves with mesh

It is used by the non-structural physics (here, flow)

X, Y, Z

x, y, z

Deformed mesh requires mesh smoothing

The smoothing equations try to keep the mesh elements

reasonably well-shaped

Option for Automatic Remeshing

Original mesh Deformed mesh

Smoothing algorithms in COMSOL

COMSOL solves additional equations to find the coordinates of

the moving mesh

Laplace

Default

Least computation expensive

Winslow

Nonlinear

More robust

Hyperelastic

Nonlinear

Smoother result than Winslow if mesh is stretched

Capture the Concept

TM

FSI Cantilever FSI Cantilever

Predefined: Fluid Solid Interaction

8/27/2012

20

PREDEFINED Moving Mesh: FSI

New > 2D

Fluid Flow > Fluid Solid Interaction

Stationary

Review Model Tree

Much is set up for you

Simply indicate what is elastic

Geometry

Geometry > Set units to mm

Rectangle

Width 300

Height 100

Corner (0,0)

Rectangle

Width 5

Height 50

Corner (100, 0)

Declare What is Solid in Fluid-Solid

Default is ALL fluid

Open Fluid-Structure Interaction

Highlight Linear Elastic Material

Choose the Flap

Everything is taken care of for you:

Moving Mesh in Solid

Free Mesh in Fluid

Linkage of Fluid Force on Structure

Boundary Conditions on ALE Mesh

Materials

Rt Click on Materials > Open Material Browser

Built-in: Water (Add to model)

Rt Click on Materials > Material

Rename to Flap

Choose Vertical Flap

Youngs Modulus = 1000

Poissons Ratio = 0.33

Density = 1000

Boundary Conditions

Structure: Rt Click on Fluid-Solid Interaction

Choose Solid Mech > Fixed Constraint

Pick Bottom Horiz Boundary of Flap

Fluid Inlet: Rt Click on Fluid-Solid Interaction

Choose Fluid Flow > Inlet

Choose Leftmost vertical inlet boundary

V = 0.010

Fluid Outlet: Rt Click on Fluid-Solid Interaction

Choose Fluid Flow > Outlet

Choose Rightmost vertical inlet boundary

P = 0

Mesh + Solve

Rt Click on Mesh

Free Triangular

Pick Size > Coarse

Build

Rt Click on Study

Compute

2D Plot 1 > Surface

Change to Total Velocity

Add Contour, Velocity

8/27/2012

21

Capture the Concept

TM

Data Sets,

Postprocessing

Data Sets,

Postprocessing

Results

Results = Postprocessing section

Working with Data Sets

Getting Derived Values

Creating plots

Export = Exporting numerical

data and images

Report = Generate HTML report

of the model

Data Sets Solution and Selection

Choose desired

geometric level

Select the desired

geometric entities

Results can be

visualized only on

the desired

geometric entities

1

2

3

Derived Values

Results > Derived Values

Allows you to evaluate and visualize numerical data

Automatically creates table under Results > Table

Evaluates a variable at a point

or geometric vertices

Evaluates global variables,

lumped parameters and built-in

physical constants

Menubar options

Point evaluation Cut lines Cut planes Slice

Isosurface

Volume

Surface

Line (edge)

Arrow (in volume)

Streamline

Animate

Exploring the Results Node

Define 3D Heat Transfer Problem

CAD Import > Piston for FEA

Top: T = 700

Bottom: T= 450

Bearing Surf: T = 400

Explore different plot types

Surface

Contour

Arrow 3D

Isosurfaces

Cut Planes

8/27/2012

22

Plot on a 2D Cut Plane

Right Click Data Sets

Add Cut Plane

x-y Plane z = -0.025 Plot

Add 2D Plot Group

Use Cut Plane 1

Add Surface T Plot

Right Click Data Sets

Add Mirror 2D

Select 2D Plot Group > Dataset Mirror 2D

Add Contours

Export Cut-Plane Data to File

(Same method could export 3D data to file)

Go to Data Sets Node

Right Click on the Dataset you want to export

Pick Add to Report

Go to Report Node > Data x

Choose the Variable (expression) to export

Set the filename path for a .txt file > Export

Open Text File with Excel (or equivalent)

Put a Cut-Line through the Cut Plane

Highlight 2D Plot Node

Pick Start Point

Pick End Point

Highlight 1D Plot Group

To Export Data:

Under Datasets:

Highlight 1D Cut Line

Right Click: Add to Report

Highlight: Data1 under

Report Export to Excel

Put a Cut-Line Through the 3D Object

Highlight Plot Group 1

Again Pick Start and End points

(This attach to the nearest surface)

Another Dataset Appears: Cut Line 3D

Can Plot it like any other 1D Dataset

Can Export it like any other Dataset

Axisymetric to 3D Visualization

Open Model Library > Acoustics Module >

Tutorial Models > PiezoAcoustic Transducer

View Plot Group 1

Right Click on Datasets Node

Add Revolution 2D

Open Revolution Layers: Change 360 to 135

Right Click on Results > Add 3D Plotgroup

Add Isosurface to 3D Plotgroup > Plot

Pressure (Increase to 10 levels)

Add a Slice Plot, Quick, xy-planes, 1

Plot Pressure

3D Slices in Time

Open Model Library > COMSOL

Multiphysics > Fluid Dynamics >

Cylindrical Flow

View Plot Group 1

Right Click on Datasets Node

Add Parametric Extrusion 2D

Change to Interpolated times

Start: 0, End: 7, Step: 1

Add 3D Plot Group

Add Surface Plot of Velocity

8/27/2012

23

Data Export: Value vs Time

Results vs Time

Model Library > Heat Transfer > Process &

Manufacturing > Disk Brake

Highlight Plot Group 1

Right Click Derived Values > Point Evaluation

Choose Point 5, Change units to degF

Choose Orange = sign creates table

Toggle Precision Button

Then the Plot Symbol

Open Excel (or equivalent)

Pick Copy table to Clipboard

Paste in Excel

Evaluate Average Disk Pad Temp vs Time

Open Model1 Node

Right Click on Definitions

Add Model Couplings > Average

Choose Brake Pad Domain

Operator Name: BreakPad_Ave

Update Solution

Add 1D Plot > Global Plot

Plot BreakPad_Ave(T)

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- PSE 9e CH 24 CH 25 26 Combined SerwayДокумент60 страницPSE 9e CH 24 CH 25 26 Combined SerwayYaas BahОценок пока нет

- MCQ of Villamor Electronics Books PDFДокумент234 страницыMCQ of Villamor Electronics Books PDFVincent SpadeОценок пока нет

- Demystifying The Brain PDFДокумент428 страницDemystifying The Brain PDFgoldfinger0007100% (1)

- MPTДокумент119 страницMPTShahazad Shaik100% (1)

- Choke DesignДокумент47 страницChoke DesignSaravanan.R100% (1)

- ABB-Electrical Switchgear ManualДокумент6 страницABB-Electrical Switchgear ManualElafanОценок пока нет

- Ruth v. Buckley (Auth.) - Electromagnetic Fields - Theory, Worked Examples and Problems-Macmillan Education UK (1981)Документ169 страницRuth v. Buckley (Auth.) - Electromagnetic Fields - Theory, Worked Examples and Problems-Macmillan Education UK (1981)Fabiana SinghОценок пока нет

- Numerical Methods in Heat, Mass, and Momentum TransferДокумент196 страницNumerical Methods in Heat, Mass, and Momentum TransferPallabi MitraОценок пока нет

- Allan H. Morrish-The Physical Principles of Magnetism-Wiley-IEEE Press (2001) PDFДокумент691 страницаAllan H. Morrish-The Physical Principles of Magnetism-Wiley-IEEE Press (2001) PDFEMANUEL TINOCO100% (1)

- Beamer TutorialДокумент58 страницBeamer TutorialAbdullah AlhmeedОценок пока нет

- Fourier TransformДокумент22 страницыFourier TransformpreethamismОценок пока нет

- Paper Summary TabularДокумент1 страницаPaper Summary TabularpreethamismОценок пока нет

- Fourier TransformДокумент22 страницыFourier TransformpreethamismОценок пока нет

- AdvertisementДокумент1 страницаAdvertisementpreethamismОценок пока нет

- COPUS ProtocolДокумент3 страницыCOPUS ProtocolpreethamismОценок пока нет

- Nonlinear VibrationsДокумент7 страницNonlinear VibrationspreethamismОценок пока нет

- Pharma Endo Cards 12Документ12 страницPharma Endo Cards 12sechzhenОценок пока нет

- Pharma Endo Cards 12Документ12 страницPharma Endo Cards 12sechzhenОценок пока нет

- Study Guide For IC Enignes QuizДокумент1 страницаStudy Guide For IC Enignes QuizpreethamismОценок пока нет

- Pharma Endo Cards 12Документ12 страницPharma Endo Cards 12sechzhenОценок пока нет

- Fluid Mechanics NotesДокумент20 страницFluid Mechanics NotespreethamismОценок пока нет

- Machine PressДокумент8 страницMachine PresspreethamismОценок пока нет

- Appendix 4: Curves and Arc LengthДокумент8 страницAppendix 4: Curves and Arc LengthpreethamismОценок пока нет

- Conservation Equations (Cont'd)Документ12 страницConservation Equations (Cont'd)preethamismОценок пока нет

- ModelДокумент82 страницыModelpreethamismОценок пока нет

- ModellingДокумент36 страницModellingpreethamismОценок пока нет

- Multivariable Differential Calculus: Definition 8.1: Function of Real Variables, VectorДокумент25 страницMultivariable Differential Calculus: Definition 8.1: Function of Real Variables, VectorpreethamismОценок пока нет

- Appendix 7: Evaluation of Volume ofДокумент7 страницAppendix 7: Evaluation of Volume ofpreethamismОценок пока нет

- Math 1Документ6 страницMath 1preethamismОценок пока нет

- Appendix 7: Evaluation of Volume ofДокумент7 страницAppendix 7: Evaluation of Volume ofpreethamismОценок пока нет

- Model 8Документ4 страницыModel 8preethamismОценок пока нет

- Appendix 2: Inverse FunctionsДокумент2 страницыAppendix 2: Inverse FunctionspreethamismОценок пока нет

- Numerical FluidsДокумент20 страницNumerical FluidspreethamismОценок пока нет

- Lecture NotesДокумент3 страницыLecture NotespreethamismОценок пока нет

- Lecture NotesДокумент3 страницыLecture NotespreethamismОценок пока нет

- Numerical FluidsДокумент20 страницNumerical FluidspreethamismОценок пока нет

- Gauss's LawДокумент3 страницыGauss's LawSanjay PandeyОценок пока нет

- Emft-Question BankДокумент3 страницыEmft-Question BankSARITHAОценок пока нет

- Chapter 2: Fundamentals of MagnetismДокумент20 страницChapter 2: Fundamentals of Magnetismagam YuliantoОценок пока нет

- Free Convection in A Water Glass, ReportДокумент19 страницFree Convection in A Water Glass, ReportEsra BelhajОценок пока нет

- Flow Separation Control Utilizing Plasma Actuators: Stefan NilssonДокумент70 страницFlow Separation Control Utilizing Plasma Actuators: Stefan NilssonAmr Ahmed El FekyОценок пока нет

- Fall 12 PHY 122 Homework Solutions #2 Chapter 21 Problem 40Документ18 страницFall 12 PHY 122 Homework Solutions #2 Chapter 21 Problem 40laura mezaОценок пока нет

- Inductance of A Straight ConductorДокумент11 страницInductance of A Straight ConductorAngel Sebastian Paz RocaОценок пока нет

- Getting Started With Maxwell:: Designing A Rotational ActuatorДокумент58 страницGetting Started With Maxwell:: Designing A Rotational ActuatorAnel HrusticОценок пока нет

- SchelkunoffElectromagnetic WavesДокумент542 страницыSchelkunoffElectromagnetic WavesPhewОценок пока нет

- Adobe Scan Dec 30, 2023Документ19 страницAdobe Scan Dec 30, 2023ayesha sheikhОценок пока нет

- Webb, Eckert - 1972 - Application of Rough Surfaces To Heat ExchangerДокумент12 страницWebb, Eckert - 1972 - Application of Rough Surfaces To Heat ExchangerKau Carlos XavierОценок пока нет

- Grad Div CurlДокумент13 страницGrad Div CurlMichael AdesanyaОценок пока нет

- Atmospheric Boundary Layer Flows PDFДокумент304 страницыAtmospheric Boundary Layer Flows PDFkarolinesuellyОценок пока нет

- Chapter5 Conductorand DielectricsДокумент21 страницаChapter5 Conductorand Dielectricsspong1ertzОценок пока нет

- Exner EquationДокумент8 страницExner Equationlomas3Оценок пока нет

- Wu-Abuaf-1981Study of Nonequilibrium Flashing... v2Документ170 страницWu-Abuaf-1981Study of Nonequilibrium Flashing... v2hamed0% (1)

- FR-D700 - Presentation 1207Документ23 страницыFR-D700 - Presentation 1207Jilani HayderОценок пока нет

- 160A Lab Manual-Student S2014Документ34 страницы160A Lab Manual-Student S2014Joel SanchezОценок пока нет

- Gauss's Law. Solutions of Home Work Problems: 24.1 Problem 24.6 (In The Text Book)Документ7 страницGauss's Law. Solutions of Home Work Problems: 24.1 Problem 24.6 (In The Text Book)AldairEviltonChGОценок пока нет

- Report 7 CE231 Real OneДокумент10 страницReport 7 CE231 Real OneMohammed KhalidОценок пока нет

- Class Notes of Unit Electrostatics Part-3Документ29 страницClass Notes of Unit Electrostatics Part-3Parth Sarthi SharmaОценок пока нет

- Vec 4Документ21 страницаVec 4SaquibОценок пока нет

- Module 4Документ10 страницModule 4Shubhankar AcharyaОценок пока нет