Академический Документы

Профессиональный Документы

Культура Документы

Serviceability Limit States, Bar Anchorages and Lap Lengths in ACI 318-08 and BS 8110-97 - Comparative Study-ICJ-Nov 2013 PDF

Загружено:

Timothy Voo Khi SingОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Serviceability Limit States, Bar Anchorages and Lap Lengths in ACI 318-08 and BS 8110-97 - Comparative Study-ICJ-Nov 2013 PDF

Загружено:

Timothy Voo Khi SingАвторское право:

Доступные форматы

29 NOVEMBER 2013 THE INDIAN CONCRETE JOURNAL

Point of View

Serviceability, limit state, bar anchorage and lap lengths

in ACI318:08 and BS8110:97: A comparative study

Ali S. Alnuaimi and Iqbal Y. Patel

This paper presents a comparative calculation study

of the defection, control of crack width, bar anchorage

and lap lengths of reinforced concrete beams using the

ACI 318 and BS 8110 codes. The predicted defections

by the ACI code were larger than those by the BS. In

both the codes, the short-term deflection decreases

with the increase in the dead-to-live load ratio but the

long-term defection increases. In addition, the limits on

the maximum bar spacing to control crack width vary

signifcantly in the two codes. While the BS code predicts

a constant bar spacing regardless of the concrete cover,

the ACI reduces it with the increase in cover thickness. In

both codes, the tension anchorage length decreases with

the increase in concrete strength. The tension anchorage

and lap lengths vary with the values of the term

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

. The BS code requires a greater anchorage

length in compression than the ACI code does. The

compression lap length requirement in the BS is more

than that in ACI code for the concrete of compressive

strength less than 37 MPa and the former stipulates

longer lap lengths for higher concrete strengths.

In the absence of a national design code, the structural

engineers in Oman use the ACI 318 and BS 8110

structural design codes to calculate defections, crack

width, and anchorage and lap lengths.

1,2

They fnd these

codes useful for complying with the legal stipulations

there. However, designers and project owners frequently

compare the stipulations in the two codes seeking points

of similarities and differences. Yet, no comprehensive

work of this kind is available in literature, though

several researchers have used these codes for estimating

defection, crack control and lap length development

in reinforced concrete constructions. The following

highlights the fndings of select researchers.

Nayak and Menon, conducted experimental investigation

on six one-way slabs, monitored their short-term

defection and compared the existing provisions given

in IS 456:00, BS 8110, ACI 318 and Euro-code 2 with

the experimental results.

3,4,5

They found considerable

disparities among the three codes. The AC I318 and Euro

Code 2 generally predicted acceptable defection at the

least and largest defection points respectively whereas

the BS and IS codes gave an acceptable intermediate

value. Santhi et al compared the total defection including

the creep and shrinkage for a two-way slab using AC

I318:00, BS 8110:97 and IS 456:00 and found that the total

defection based on ACI 318:00 and BS 8110:97 were

almost similar for the different slab thicknesses studied

while the IS 456:00 gave much larger defection in most

of the cases.

6

THE INDIAN CONCRETE JOURNAL NOVEMBER 2013 30

Point of View

Bacinskas et al statistically investigated the accuracy

of the long-term defection predictions made by the

various design codes including Eurocode 2, ACI 318,

ACI 435, SP 52-101 and the fexural layered deformation

model proposed by Kaklauskas.

7,8

They found that the

Eurocode 2 overestimates the long-term defection while

ACI 318 and ACI 435 underestimate it. The SP 52-101

slightly overestimates the defection and has the lowest

standard deviation among the various code methods

studied. Lee and Scanlon conducted parametric study

on the control of defection of reinforced concrete slabs,

and compared the various design provisions in the ACI

318:08, BS 8110:97, Euro-code 2 and AS 3600:01.

9,10

They

concluded that although the minimum thickness values

are easy to apply, limitations need to be placed on the

applicability of current ACI 318:08 values due to the

assumption that the slab thickness is independent of

applied dead and live loads and no limits are specifed

on the applicable range of span lengths. They proposed a

unifed equation. Bischoff and Scanlon came to a similar

conclusion.

11

Bacinskas et al developed a model for calculating the

long-term defection of cracked reinforced concrete

beams considering creep, shrinkage and the tension-

stiffening.

12

They compared the ACI 318 and Eurocode

2 provisions with 322 experimental results. Their fnding

was that the defections predicted by the ACI 318 were

strongly dependent on the loading duration but the

results had high variations. However, the predicted

defections by the Eurocode 2 and the proposed model

were quite similar and independent of the loading

duration.

Subramanian suggested simple formulae, involving

the clear cover and calculated stress in reinforcement

at service load, to control crack width.

13

He criticised

the provision made in the Indian code IS 456:00 for

crack width calculation and commended the ACI 318:02

provisions. Alam et al criticised the Euro code 2 for under

estimating the crack width and crack spacing due to

neglecting the structural member size infuence which

they found had signifcant effect.

14

Khan et al compared the value of bar development

lengths obtained using ACI 318:99, BS 8110:85 and

IS 456:00. IS code gave the development length 8

percent and 11 percent more than that by BS and ACI

codes respectively. The development length obtained

in compression using IS code was 3.5 percent and 17

percent more than that used by BS and ACI codes

respectively.

15

Subramanian compared the IS 450:00

provisions for the development length with the ACI

code. He suggested a formula to improve the existing

IS provision.

16,4

The formula includes factors such as

bar diameter, concrete cover spacing of bars, transverse

reinforcement, grade and confinement of concrete

around the bars, type of aggregate, type of bars and

coating applied on bars, if any.

Haitao et al compared the experimental test results of lap

length development from eighteen reinforced concrete

beams with eight international codes requirements.

17

They found that all the codes were conservative in

specifying lap length development for small diameter

bars and that ACI 318:05 and ACI Committee 408

provided the worst agreement for large diameter bars.

Chul et al studied the experimental results of 72 test

specimens for compressive lap splices using concrete

compressive strengths of 80 and 100 MPa.

18

The effect

of concrete strength, splice length and transverse

reinforcement were assessed. They proposed a simple

equation, which provides shorter lengths than the ACI

318:08 does. Sarki et al reviewed the BS 8110 and Euro-

code 2 recommendations on steel bar lap lengths and

concluded that the British code gave the best safety

indices in all the cases they evaluated.

19

It is clear from these references that most of the research

work compare experimental results with the codes

requirements or proposed models. But no comprehensive

work was found in the literature comparing the ACI

318:08 and BS 8110:97 codes in terms of defection,

control of crack width, and anchorage and lap lengths for

different conditions including live-to-dead load ratios,

concrete strength, area of reinforcement, and bar type or

diameter. Accordingly, a comparative study with these

parameters was conducted on single-span, continuous

rectangular reinforced concrete beams.

Control of defection

ACI 318:08 provisions for defection calculation

ACI 318:08 has two approaches for controlling defection.

The frst indirect approach consists of setting suitable

upper limits on the span-depth ratio. In the second

approach, the defections are controlled directly by

limiting the computed defections to the values specifed

in the code (Table 9.5 (b)). In this study, the second

approach was adopted as follows:

Short-term defection

The initial or short-term defection

i

is calculated using

Equation 1. The PCA notes explain the details in this

Continued on page 35

35 NOVEMBER 2013 THE INDIAN CONCRETE JOURNAL

Point of View

regard particularly the ACI 318:05 sections 9.5.2.2 and

9.5.2.3:

20

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (1)

where, M

a

= service moment, I

e

is the effective moment of

inertia, and K = defection coeffcient given in Table 1.

M

o

= Simple span moment at mid-span

M

a

= Service support moment for cantilever or mid-span

moment for simple and continuous beams

For each load combination (i.e. dead + live) the defection

is calculated using an effective moment of inertia i.e. (I

e

)

d

,

(I

e

)

d+l

and (I

e

)

sus

with the appropriate service moment

M

a

. The incremental defection caused by the addition

of load, such as the live load, is then computed as the

difference between the defections computed for any

two-load combination. Therefore, immediate defection

due to the live load is given by Equation 2:

(

i

)

l

= (

i

)

d+l

(

i

)

d

...... (2)

This calculated deflection should be less than the

allowable deflection given in Table 9.5 (b) of ACI

318:08.

Long-term defection

According to section 9.5.2.5 of the ACI 318:08, an

additional long-term defection due to the combined

effects of shrinkage and creep from sustained loads is

given by Equation 3:

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (3)

where,

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

= multiplier for the long-term effect. As per

section 9.5.1 of ACI 318:08; the sustained load includes

dead load and that portion of the live load which is

sustained. Equation 4 gives total defection:

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (4)

This computed total defection should not exceed the

limits given in Table 9.5 (b) of ACI 318:08.

BS 8110-2:85 provisions for defection calculation

BS 8110-2 is based on the calculation of a sections

curvature subjected to the appropriate moments, with an

allowance for creep and shrinkage effects.

21

Defections

are calculated from these curvatures. In BS 8110-2, a

reduction in the applied moment causing defection is

made, as in reality the concrete below neutral axis can

carry limited tension between cracks. Its effect, called the

tension stiffening, can be looked upon as a reduction of

moment causing defection expressed as (M - M), where

M is the moment carried by the tension in concrete.

Short-term curvatures

The curvature of a section is the larger value obtained

by considering the section either un-cracked or cracked

as appropriate.

The curvature of the short-term defection for un-cracked

section is given by Equation 5:

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (5)

The curvature for the cracked section is given by

Equation 6:

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (6)

where, M = applied moment, E

c

= modulus of elasticity

of concrete, I

g

= gross moment of inertia, M

c

is the

moment of resistance of concrete in tension, and M-M

c

is the moment causing defection.

Long- term curvature

In calculating the long-term curvatures, the effects of

creep and shrinkage are considered.

Equation 7 gives the long-term curvature due to

permanent load:

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (7)

Equation 8 gives the curvature due to shrinkage:

Support type K

Cantilever 2.4

Simple beams 1.0

Continuous beams

Table 1. Defection coeffcient K (PCA Table 10.3)

THE INDIAN CONCRETE JOURNAL NOVEMBER 2013 36

Point of View

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (8)

where;

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

= modular ratio as per section 3.6 of BS 8110-2,

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

= free shrinkage strain as per clause 7.4 of BS 8110-

2, S

s

= the frst moment of area of reinforcement about

Neutral Axis and I= the moment of inertia either for

un-cracked or cracked section depending on whether the

curvature due to loading is derived from the un-cracked

or cracked section.

Total long-term curvature = long-term curvature due to

the permanent load plus short-term curvature due to the

non-permanent load plus the shrinkage curvature given

in section 3.6 of BS 8110-2:85.

Calculation of defection from curvature

The defection is given by Equation 9:

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (9)

Defection limits

Table 2 shows the total defection limits in the ACI and

BS codes.

Crack width control

ACI 318:08 provisions to control crack width

The section 10.6.4 of ACI 318 does not purport to predict

crack width and gives a simple equation which directly

limits the maximum reinforcement spacing as shown in

Equation 10.

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (10)

where; s is the maximum centre-to-centre spacing

of fexural tension reinforcement nearest to extreme

tension face, f

s

is the calculated stress in reinforcement

at service load and c

c

is the clear cover from the nearest

surface in tension to the surface of fexural tension

reinforcement.

BS 8110-2:85 provisions to control crack width

Two approaches are given for the control of crack width

in BS 8110-2:85. The frst approach is deemed-to-satisfy

approach, in which the maximum spacing of bar is

limited to control the cracking. The other approach

requires actually calculating the crack width and keeping

it within the limit.

Section 3.12.11.2.4 of BS 8110:97-1 specifes the clear

spacing between bars in tension as shown by Equation

11:

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (11)

where; f

s

is service stress in the reinforcement and d

b

is

the bar size.

Design surface crack width w is given by section 3.8.3

of BS 8110-2 as shown in Equation 12:

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (12)

where; a

cr

= distance from the compression face to the

point at which the crack width is being calculated,

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

= average strain, C

min

= minimum cover to the tension

steel, h = overall depth of the member and x = depth of

the neutral axis.

Anchorage length

ACI 318:08 provisions for anchorage length

Anchorage length in tension

For normal weight concrete, the anchorage length in

tension is specifed by section 12.2.3 of the ACI 318:08

as shown in Equation 13:

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (13)

where;

t

= reinforcement location factor (Taken as =1

for the bottom reinforcement),

e

= coating factor (taken

= 1 for uncoated reinforcement),

s

= reinforcement size

factor (taken = 0.8 for d

p

20 mm dia and = 1.0 for d

p

>

20 mm dia), c

b

= bar spacing or cover dimension = the

Situation

Defection limits

ACI BS

Members supporting non-structural

elements that are not likely to be

damaged by large defection

Span/240 Span/250

Members supporting non-structural

elements that are likely to be

damaged by large defection

Span/480 Span/500

20mm

Table 2. Limits of total defection using ACI and BS

codes

37 NOVEMBER 2013 THE INDIAN CONCRETE JOURNAL

Point of View

smaller of 1) distance from centre of bar being developed

to nearest surface and 2) one half the centre-to-centre

spacing of bars being developed, and K

tr

= transverse

reinforcement index =

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

where; A

tr

= total area of

all transverse reinforcement which is within the spacing,

S = maximum spacing of transverse reinforcement

within l

d

(centre-to-centre), and n = number of bars

being developed. The code permits to use K

tr

= zero as a

design simplifcation even if transverse reinforcement is

present. The term

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

cannot be taken greater

than 2.5 to safeguard against pull-out type failure. To

simplify computation of l

d

, preselected values for the

term

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

are chosen to as shown in section

12.2.2 of ACI 318;08.

Anchorage length in compression

The anchorage length in compression is given by section

12.3.2 of the ACI 318:08; as shown in Equation 14:

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

...... (14)

For f

c

> 32 MPa, (0.043f

y

)d

b

governs the length.

British Code (BS 8110:97) provisions for

anchorage length

Section 3.12.8.3 of the BS 8110:97 specifes anchorage

length in tension and compression as given by Equation

15:

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4 ...... (15)

where;

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

= is the bar size, f

s

= is the ultimate tensile or

compressive stress in reinforcement (0.95f

y

) and f

bu

=

the ultimate anchorage bond stress =

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

with

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

=

bond coeffcient = 0.5 for bar Type 2 in tension and =

0.63 in compression.

Lap length

ACI 318:08 provisions for lap length

Lap length in tension

Section 12.15.1 of the ACI 318:08 specifes the tension

lap lengths for class A and class B splice as 1.0l

d

and

1.3l

d

respectively but not less than 300 mm. Section

12.15.2 of CAI318:08 specifes tension lap splice

condition. Since in practice class B splice condition is

more common it was considered in this research.

Lap length in compression

Section 12.16.1 of the ACI 318:08 specifes the compression

lap length as 0.071f

y

d

b

for f

y

420MPa and 0.13f

y

24

for f

y

> 420MPa but not less than 300 mm in both cases.

These values are applicable for 21 < f

c

70 MPa (normal

strength concrete). For f

c

21 MPa, lap length shall be

increased by one-third.

BS 8110:97 provisions of lap lengths

Lap length in tension

As per section 3.12.8.13 of BS 8110:97; in general the lap

length in tension = 1.0 times tension anchorage length.

Lap length in compression

Section 3.12.8.15 of BS 8110:97 specifes the lap length

in compression = 1.25 times compression anchorage

length.

Results and discussion

Defection

From the equations presented above, it can be seen that

the BS method does not use I

eff

as does the ACI method.

Instead, E

c

I for short-term and long-term loadings are

calculated separately using appropriate E

c(short-term)

and

E

c(long-term)

. Further, in the ACI code, long-term defection

is calculated with the combined effect of creep and

Beam

No.

Service

DL,

kN/m

Service

LL,

kN/m

DL:LL

ratio

Ult. mom.

M

u

,

kN/m

Service

M

d

,

kN/m

Service

M

l

,

kN/m

Service

M

sus

,

kN/m

Tension

steel, A

s

,

mm

2

BR1.0 25 25 1.0 600 200 200 250 2754

BR1.3 25 20 1.3 536 200 160 240 2376

BR1.7 25 15 1.7 472 200 120 230 2029

BR2.5 25 10 2.5 408 200 80 220 1706

Table 3. Applied loads and provided reinforcement for simply supported beam using ACI and BS (Span, L = 8m)

THE INDIAN CONCRETE JOURNAL NOVEMBER 2013 38

Point of View

shrinkage, whereas in the BS code, defections due to

creep and shrinkage are calculated separately. The ACI

and BS limits on defection, for the same situations, are

close to each other.

Table 3 shows the applied loads and provided

reinforcement for simply supported beams using ACI

and BS codes having a span length (L) of 8m and

subjected to uniformly distributed loads with different

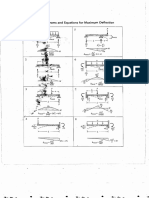

DL:LL ratios. Figures 1 and 2 show the total calculated

and allowable defections for the beams in Table 3. It is

assumed that the beam is supporting non-structural

elements that are not likely to be damaged by a large

defection. The beam was 350x750 mm with an effective

depth of 625 mm. The characteristic compressive strength

of concrete f

cu

was 30 MPa and the cylinder compressive

concrete strength f

c

was 24 MPa. The yield strength of

steel was taken as 460 MPa. It was assumed that 25% of

the live load as permanent. The time dependent factor for

sustained load, , as required in the ACI code, was taken

as 2.0 (i.e. factor for a period of 5 years or more). The 30

year creep coeffcient, , as required by the BS code, was

taken as 2.0 for ambient relative humidity of 60% and

age of loading as 14 days. The 30 years free shrinkage

strain,

cs

, as required in BS code, was taken as 0.000027

for ambient relative humidity of 60%. From Figure 1, it is

clear that the predicted short-term defection from both

codes, decreases with the increase of the dead load to

the live load ratio. Contrarily, the long-term defection

increases with increasing dead load to live load ratio.

Figure 2 shows that the predicted total defection is

almost constant for each code with a small drop when

the dead load to live ratio was 2.5. The maximum

allowable defections are constant for each code with

values of ACI being 4.2 per cent larger than that of the

BS. The predicted defections using ACI code are more

than those using BS code for short-term, long-term and

total defections. The differences between the ACI and

BS results in short-term, long-term and total defections

increase with the increase in dead load to live load

ratio the maximum values being 8.58, 20.68 and 27.51

per cent respectively for the given conditions. These

differences are attributed to the different approaches

adopted in ACI and BS for calculating EI, as discussed

earlier. The differences in the long-term case increase

at a larger rate than those in the short-term case. This

large difference could be attributed to the fact that in

the ACI code, a combined effect of creep and shrinkage

is considered, whereas in the BS code these effects are

calculated separately. This has in-turn affected the total

defection with difference increasing as the dead load

to live load ratio increases from 24.36 to 27.51 per cent.

While comparing the total predicted defection with

the defection limits (Figure 2), it was found that, in

the ACI code, the estimated defection is larger than

allowable limits, which means that the ACI limits can

be violated by the ACI equations used in estimating

the total defection. The BS code estimated defections

remain within the allowable limits. This indicates that

the ACI limits should always be observed for possible

violation.

Control of crack width

As pointed out earlier, ACI code does not give explicit

crack width calculation. The control of cracking is

deemed satisfactory as long as the limit on the bar spacing

is satisfed. The BS code furnishes two approaches, a

deemed-to-satisfy approach and the calculation of crack

width. In deemed-to-satisfy approach, the maximum

bar spacing is controlled in a similar way as in the

ACI code. It was shown in Equation 10 that the ACI

procedure is a function of service stress and concrete

cover, whereas the BS provision given in Equation 11 is

39 NOVEMBER 2013 THE INDIAN CONCRETE JOURNAL

Point of View

a function of service stress and bar size. Figure 3 shows

the effect of concrete cover on the bar spacing using

these equations. The values used were

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

, f

y

=

460 MPa, and d

p

= 20 mm. It is clear that the limits on

the maximum spacing between bars vary signifcantly

between ACI and BS codes. The BS code has a constant

spacing regardless of the concrete cover, whereas the

ACI bar spacing reduces with the increase in the concrete

cover thickness. The difference between the two codes

decreases as the concrete strength increases (Figure 3).

With the given data, the highest difference is 57.8% when

concrete strength is 30 MPa and the lowest is 0.6 %when

the concrete strength is 70 MPa.

Anchorage length in tension

From Equations 13 and 15 for anchorage length in

tension, it can be seen that both the ACI and BS codes

equations are the functions of concrete and reinforcement

yield strengths and bar diameter. However, the ACI

equation is more detailed and takes into account the

location of reinforcement, coating factor, bar spacing,

effects of small cover, and confnement provided by

transverse reinforcement. Table 4 shows the deduced

equations of tension anchorage

length using both the codes for

different values of f

c

which is

taken as 0.8 of f

cu

(using

t

=

e

= 1.0, and

s

= 0.8 for d

p

20mm

Dia and = 1.0 for d

p

>20mm Dia).

In the case of ACI, pre-selected

values of the term

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

were adopted which were 1.0, 1.5

and 2.5. The resulting anchorage

length in tension, (Table 4), are

plotted in Figure 4. It can be seen

that in both the codes, the tension

anchorage length decreases with

the increase in concrete strength.

When the term

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

has a

value of 1 and 1.5, ACI requires more tension anchorage

length than the BS does; varying from 14.1 to 114 percent

respectively for concrete strength change from 30 to 40

MPa. Whereas, when the term

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

has a value

of 2.5, BS requires more anchorage length; varying from

16.8 to 46 per cent for concrete strength change from 30

to 40 MPa. In this regard it clear that the ACI provision

Code f

cu

, MPa

30 35 40

d

b

20 d

b

>20 d

b

20 d

b

>20 d

b

20 d

b

>20

ACI

(ClassB)

(c

b

+K

tr

/d

b

)=1.0 (0.146f

y

)d

b

(0.185f

y

)d

b

(0.135f

y

)d

b

(0.169f

y

)d

b

(0.126f

y

)d

b

(0.158f

y

)d

b

(c

b

+K

tr

/d

b

)=1.5 (0.097f

y

)d

b

(0.121f

y

)d

b

(0.09f

y

)d

b

(0.113f

y

)d

b

(0.084f

y

)d

b

(0.105f

y

)d

b

c

b

+K

tr

/d

b

)=2.5 (0.058f

y

)d

b

(0.073f

y

)d

b

(0.054f

y

)d

b

(0.068f

y

)d

b

(0.040f

y

)d

b

(0.050f

y

)d

b

BS (0.087f

y

)d

b

(0.087f

y

)d

b

(0.09f

y

)d

b

(0.09f

y

)d

b

(0.076f

y

)d

b

(0.076f

y

)d

b

Table 4. Equations for anchorage length in tension, using both ACI and BS codes

THE INDIAN CONCRETE JOURNAL NOVEMBER 2013 40

Point of View

is more conservative since in most cases it requires a

longer anchorage length than the BS.

Anchorage length in compression

From the Equations 14 and 15 for compression anchorage

length, it can be seen that both codes equations are

functions of concrete and steel strengths and bar size.

Table 5 shows equations and calculated values for the

anchorage length in compression, as a multiple of bar

size, using both ACI and BS codes, for different values of

f

c

. It can be seen that the BS code requires approximately

40 per cent more anchorage length in compression than

the ACI code.

Lap length in tension

As discussed earlier, ACI and

BS codes take into account bar

coating factor, effect of small

cover and location of bars.

However, ACI further considers

the effect of close bar spacing

and confi nement provi ded

by transverse reinforcement.

Table 6 was prepared based

on the equations of tension lap

length in both codes for different

values of f

c

. The reinforcement

location factor was taken as 1.0

and reinforcement assumed as

uncoated. In the case of ACI, pre-

Concrete strength

f

cu

, MPa

Equation of anchorage length in

compression, l

dc

Anchorage length

in compression, l

dc

% Diff. of

l

dc

ACI BS ACI BS

30 (0.049f

y

)d

b

(0.069f

y

)d

b

23d

b

32d

b

40.5

35 (0.045f

y

)d

b

(0.071f

y

)d

b

21d

b

29d

b

40.5

40 (0.043f

y

)d

b

(0.060f

y

)d

b

20d

b

27d

b

38.6

Table 5. Equations for anchorage length in compression, using both ACI and BS codes, as multiple of bar size

f

y

= 460MPa, f

c

=0.8f

cu

f

cu

, MPa

30 35 40

d

b

20 d

b

>20 d

b

20 d

b

>20 d

b

20 d

b

>20

ACI

(ClassB)

(c

b

+K

tr

/d

b

)=1.0 (0.190f

y

)d

b

(0.24f

y

)d

b

(0.176f

y

)d

b

(0.22f

y

)d

b

(0.164f

y

)d

b

(0.205f

y

)d

b

(c

b

+K

tr

/d

b

)=1.5 (0.126f

y

)d

b

(0.158f

y

)d

b

(0.117f

y

)d

b

(0.146f

y

)d

b

(0.109f

y

)d

b

(0.136f

y

)d

b

c

b

+K

tr

/d

b

)=2.5 (0.075f

y

)d

b

(0.094f

y

)d

b

(0.070f

y

)d

b

(0.088f

y

)d

b

(0.052f

y

)d

b

(0.065f

y

)d

b

BS (0.087f

y

)d

b

(0.087f

y

)d

b

(0.090sf

y

)d

b

(0.09f

y

)d

b

(0.076f

y

)d

b

(0.076f

y

)d

b

Table 6. Equations for lap length in tension

selected values of term

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

are adopted which

are 1.0, 1.5 and 2.5. Figure 5 shows resulting lap length in

tension, as a multiple of bar size, using both ACI and BS

codes. It can be seen that when the term

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

is

1 or 1.5, ACI needs more lap length; varying from 48.4

to 178.2 percent. When the term

C

d

K

l

l

li

+ 4O

S

A

n

li

c

=

=

I

I

M

L

e

5

2

2

48

3

K

a

i

)

) )

d+1 d i

i i )

))

1

= -

(cp+sh) = )

sus i

)

) lolaI =

cp sh i

)

1

+ +

c

=

I

M

L

g

1

i

c

=

I

M-M

L

c

1

i

c

c (Ionglein)

=

=

=

=

=

M-M

3a

1.1

L

L

1+2

+

c

1

i

c

ci

cc

=

=

L

KL

S 1

1

i

i

cs

c

l

s

2

e s

1O64OO 84OOO

3OOnn

3OOnn

( O.O43

O.24

= - 2.5c

d

d

dc

- C

c

l

l

l

l l

li

s

s

s

c

s

47OOO

a

+

f

h - x

d

d

d d

l

s

s

v

n

y

y

y

y

s

lu

l e s

c

c

cu

ci nin

(

4

is 2.5, BS

asks for 12.3 percent more lap length than ACI when the

diameter of bar 20 mm but ACI required 11.3 percent

more lap length when the diameter of bar >20 mm.

41 NOVEMBER 2013 THE INDIAN CONCRETE JOURNAL

Point of View

Lap length in compression

The provision of compression lap length discussed

earlier suggests that in the ACI code, the compression

lap length is a function of bar size and yield strength

of steel and is independent of the concrete strength.

Whereas, in BS code, the compression lap length is equal

to 1.25 times the compression anchorage length. Table 7

gives the equations for lap length in compression, as a

multiple of bar size, using both ACI and BS codes and

Figure 6 shows the resulting values, for the different

grades of concrete. It can be seen that for concrete having

f

cu

= 30 MPa, BS required 10.5 per cent more lap length

than the ACI whereas for the higher concrete grades,

the differences of lap length is negligible as it varies

from -4.5% to 2.3%. It is clear that BS code requires

more compression lap length than does the ACI code till

concrete compressive strength is 37 MPa, beyond that,

ACI requires more compression lap length.

Concluding remarks

The predicted short-term defections from both

ACI and BS codes, decrease with the increase in

the dead load to the live load ratio; ACI values

being larger than the BS by a maximum 8.58

per cent for the given conditions. Contrarily,

the long-term defections increase with increase

in the dead load to live load; ACI values being

larger for a maximum of 20.68 per cent for the

given conditions.

In both codes, the total defection decreases with

the increase in the dead-to-live load ratio with

the ACI values being larger than the BS values

with a maximum 27.51 per cent for the given

conditions.

The values of the defection limits in both ACI and

BS codes are close to each other regardless of the