Академический Документы

Профессиональный Документы

Культура Документы

Applied Mechanics Lab - PGBDDF

Загружено:

yahska1305Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Applied Mechanics Lab - PGBDDF

Загружено:

yahska1305Авторское право:

Доступные форматы

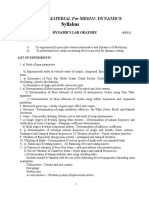

DELHI COLLEGE OF ENGINEERING

(Govt. of NCT of Delhi) Main Bawana Road, Delhi-42

Mechanical Engineering Department

Applied Mechanics Laboratory

Instruction Sheet -3

Aim: To measure the energy of a rotating fly wheel and determine the moment

of Inertia of the flywheel.

Apparatus: Fly wheel mounted on a wall, stop watch, Vernier calliper, thread

and weights (1/2kgf., 1kgf, 100gmf, 50gmf, 20gmf, 10gmf ), etc.

Theory: The principal of conservation of energy is made use of in determining

the M.I. of the fly wheel.

It states that the energy can neither be created nor destroyed though it

can be transferred from one form into any forms in which the energy

exist.

As the fly wheel revolves due to a falling weight attached to the axis. The

potential energy of the falling weight is equal to the K.E. of the falling

body when it drops off plus the energy stored in the fly wheel at that

instant plus the energy lost in the friction in bearings while the body is

descending. Even the energy stored in the fly wheel is lost in over coming

friction in bearing(after the weight has dropped off) bringing the wheel

to a stand still.

From law of conservation of energy:

Formulae:

2 2

I

2

1

v

g

W

2

1

H W e + =

(for negligible bearing

friction)

Where

at u v + =

and aH 2 u v

2 2

+ = ,

r

v

= e

W= weight falling in N

H = height from which the weight fall in meter

v= Linear velocity in m/s at the end of fall of H

I = Moment of Inertia of fly wheel in kgxm

2

e

=

Angular velocity of shaft in radian/sec.

r= Radius of shaft in m

Note : Assume, there is negligible bearing friction.

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

2

2

) v

g

W

2

1

( H W 2

I

e

(

=

Fig: Fly-Wheel Apparatus

Procedure:

1. Measure the diameter of the shaft with the help of vernier

calliper and find the mean radius of the shaft(r).

2. Wrap the cotton string round the shaft and suspend weight (W)

so that fly can rotate easily.

3. Now marked the height (H) for weight W from centre of mass of

Weight W to the earth and keep it same for different value of W

in each observation.

4. Place a weight (W) hold the Pan in which this weight is placed.

Release weight (W) and start the stop watch simultaneously. Stop

the watch as soon as the falling weight has touched the level

ground. This gives the time (t).

5. Repeat the experiment for different values of W. Repeat the

experiment ten times.

Observations:

1. Diameter of shaft = m

2. Radius of shaft (r) = m

3. Height of fall of weight W marked (H) = m

Weights

Diameter (2r)

Bearing

D

String

Shaft

Bearing

Fly-Wheel

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

S.

No.

Falling Weight

(W) in N

Time of fall of

weight (t) in

sec.

2

2

)

2

1

( 2

e

(

=

v

g

W

H W

I

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Calculations:

Result:

Precautions:

1. Note the time accurately to the fraction of a second.

2. Friction in the bearings should be minimum possible.

3. Overlapping of the string should be avoided.

4. Mark the height carefully from the centre of mass of weights to

the ground.

Sources of Error:

1. There may be positive or negative error in vernier calliper.

2. There may be error in recording time intervals ( in fraction of

seconds).

3. There may be little friction in bearings.

Discussion:

Note: 1. Draw the diagram for Experimental-Setup.

2. Draw the curve between Weight (W) at X-axis and rotational

kinetic energy of flywheel (

2

2

1

e I ) at Y-axis.

3. The standard value of Moment of Inertia for fly wheel is 0.5068

kgxm

2

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

DELHI COLLEGE OF ENGINEERING

(Govt. of NCT of Delhi) Main Bawana Road, Delhi-42

Mechanical Engineering Department

Applied Mechanics Laboratory

Instruction Sheet-7

Aim: To verify the law of polygon of forces (concurrent, co-planer which are in

equilibrium) with the help of Universal Force Table apparatus.

Apparatus: Force table with adjusting screws, Spirit level, pulleys, Brass ring,

Strings, Hangers, weights(50gmf-40Nos, 10gmf-4Nos),etc.

Theory: The experiment is for co-planer, concurrent forces (acting at a point).

Therefore a polygon can be drawn.

Law of Polygon of forces: If there are n number of co-planer concurrent

forces which are in equilibrium. A polygon can be drawn. Each side of

polygon represents the magnitude of forces and there will be vector

addition of each force. It conclude that the last side of polygon represents

the resultant of (n-1) forces.

The above experiment is for four co-planer concurrent forces which are

shown in

fig..

Force polygon

The experimental error can be calculated as given below:

100

F

F F

Error %

4

4 4

'

'

=

F1

F

2

F3

F

4

F

`

4

2

u

3

u

4

u '

4

u

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

procedure:

1. First of all adjust universal force table horizontally by using

adjusting screws and spirit level.

2. Take a brass circular ring and 4 threads tied with this ring and

adjust threads on pulleys and ring on nail.

3. Now fix one pulley on 0degree mark of table and other three

pulleys at desired angles.

4. Suspend weights at each thread such that each thread should

pass over the pulley and Brass ring should be concentric with nail.

5. Note down the weights F1, F2, F3 and F4 and angles

1

u ,

2

u ,

3

u and

4

u . Draw the force polygon on graph paper.

6. Repeat the experiment five times by changing angles of pulleys

and weights.

Observations:

S.

No.

Force in (gmf) Angles in degrees % Error

F1 F2 F3 F4

1

u

2

u

3

u

4

u

(F`4-

F4)x100/ F`4

(

4

u ' -

4

u )x100/

4

u '

1.

2.

3.

4.

5.

Calculations:

Result:

Precautions:

1. First of all Universal force table should be made horizontal

with the help of spirit level and levelling screw.

2. Centre of Brass ring should coincide with the centre of nail

on the table.

3. Direction of threads should be radial on the table and

vertically downward after passing the pulley. The threads

should be weightless and inextensible.

4. The weights should not oscillate while taking readings.

5. Friction in pulleys should be minimum and pulleys should

be free to move.

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Sources of Error:

1. Error in measurement of angles of threads.

2. The threads may not be perfect weightless and

inextensible.

3. There may be friction in pulleys and not free to move

properly.

4. Error to note coincide the centre of Brass ring and nail

of the table.

Discussion:

1. Give the significance of the experiment.

2. Give Lamis theorem and Baryganon theorem of

forces.

Note: 1. Draw the diagram for the experimental set-up.

3. Use graph paper to draw polygons.

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

DELHI COLLEGE OF ENGINEERING

(Govt. of NCT of Delhi) Main Bawana Road, Delhi-42

Mechanical Engineering Department

Applied Mechanics Laboratory

Instruction Sheet-4

Aim: To determine and verify the law of moments of forces for a simply

supported beam carrying transversal loads.

Apparatus: An uniform wooden beam of rectangular cross-section, Spring

balance (2 Nos), Scale, weights (1/2 kgf, 1kgf, 2kgf)

Theory:

The law of moments of forces states that the algebric sum of all

moments acting on a body which is in equilibrium is zero. i.e. the sum of

anticlockwise moments of forces is equal to the sum of clockwise

moments of forces.

Now, Take moment about A

g B B

x W x W x W x W l R + + + =

3 3 2 2 1 1

Therefore,

l

x W x W x W x W

R

g B

B

+ + +

=

3 3 2 2 1 1

Similary

B B A

R W W W W R + + + =

3 2 1

Where

B A B

R R W + = (without using weights)

Formula for % Error is given by

100

Pr

%

=

l Theoretica

actical l Theoretica

Error

Beam carrying loads

A

R

B

R

1

W

2

W

3

W

A B

B

W

G

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Procedure:

1. First of all find the weight of beam without using weights.

2. Measure the length of beam and length between two supports.

3. Now put three hangers(100gmf each) one by one and add weights

to the hangers.

4. Now measure the distance of each weights form end A.

5. Take the readings of Reactions

A

R and

B

R .

6. Repeat the experiment ten times.

Observations:

Weight of Beam

B A B

R R W + = (without using weights) = kgf

Length of Beam = cms

Distance between two supports of beam = cms

S.

No.

Weights applied

in kgf

Distance form

A in cms

Reaction

A

R in Kgf

Reaction

B

R in Kgf

%

Error

%

Error

W

1

W

2

W

3

x

1

x

2

x

3

The. Pra. The. Pra.

A

R

B

R

Calculations:

Result:

Precautions:

1. Place the beam gradually on the supports.

2. check the zero error of the spring balances.

3. Include the weight of hangers while taking readings for the

weight applied.

4. Locate the centre of gravity of beam

5. Include the weight of beam while taking moment.

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Sources of Error:

1. Wooden beam may not be uniform.

2. Locate the C.G. of beam carefully.

3. parallax should be removed while taking readings of

distances.

Discussion:

Note: 1. Draw shear force and Bending moment diagrams.

2. Draw diagram for experimental-setup.

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

DELHI COLLEGE OF ENGINEERING

(Govt. of NCT of Delhi) Main Bawana Road, Delhi-42

Mechanical Engineering Department

Applied Mechanics Laboratory

Instruction Sheet-8

Aim: To find out co-efficient of limiting friction between two surfaces using

inclined plane apparatus.

Apparatus: Wooden inclined plane having arrangement to read angle of

inclination, Boxes of different material (i.e. Wood, Glass, Aluminium,

Brass, etc.), weights (100gmf, 50gmf, 20gmf, 10gmf, etc.).

Theory:

Inclined plane

Under downward impending motion of the body (i.e. equilibrium under

downward movement or the body just tend to start downward), The equation

of equilibrium are

o Sin W R W

2 1

= +

o o Sin W Cos W W

2 2 1

= +

o

o

Cos W

W Sin W

2

1 2

=

Therefore can be calculated for the downward impending motion of

body from the above formula.

MOTION

R

W

1

W

2

R

W

2

Sin

W

2

Cos

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Inclined plane

Under upward impending motion of the body (i.e. equilibrium under

upward movement or the body just tend to start upward), The equation of

equilibrium are

o Sin W R W

2 1

+ =

o o Sin W Cos W W

2 2 1

+ =

o

o

Cos W

Sin W W

2

2 1

=

Angle of Repose() : The minimum angle of inclination at which body just

start to slide due to its own weight is called angle of Repose. It is equal to

the angle of friction.

| Tan =

% Error may be calculated as (ideal value of is calculated from angle of

repose and practical value is calculated from equation of motion either in

upward or in downward direction).

Formula for % Error is given by

100

Pr

%

=

Idealvalue

ue acticalval Idealvalue

Error

Procedure:

1. First of find the value of angle of repose() for different materials

(like wood, glass, aluminium, brass) by using inclined plane and

box at which the box just start to move downward due to its own

weight and calculate . It is supposed to be ideal value of . You

may tap gradually the plane to see the motion of box.

MOTION

R

W

1

W

2

R

W

2

Sin

W

2

Cos

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

2. Now for each box find the value of by applying weights into

string attached with box and tap the plane gradually until the box

just start to move either in downward or upward direction. You

may also put some weights in box to see the downward motion of

box. The value of is supposed to be practical value.

3. Now repeat the experiment for each box to find the for

different materials.

4. % Error can be calculated as the formula given above.

Observations:

Material: Wood vs Wood

Angle of Repose =

Ideal value of =

S.

No.

Weight W

1

Gmf

Weight W

2

gmf

Angle

in degrees

Co-efficient of friction

1. 30

0

2. 45

0

Material: Wood vs Glass

Angle of Repose =

Ideal value of =

S.

No.

Weight W

1

Gmf

Weight W

2

gmf

Angle

in degrees

Co-efficient of friction

1. 30

0

2. 45

0

Material: Wood vs Aluminium

Angle of Repose =

Ideal value of =

S.

No.

Weight W

1

Gmf

Weight W

2

gmf

Angle

in degrees

Co-efficient of friction

1. 30

0

2. 45

0

Material: Wood vs Brass

Angle of Repose =

Ideal value of =

S.

No.

Weight W

1

Gmf

Weight W

2

gmf

Angle

in degrees

Co-efficient of friction

1. 30

0

2. 45

0

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

S.

No.

Material % Error

1. Wood vs Wood

2. Wood vs Glass

3. Wood vs Aluminium

4. Wood vs Brass

Calculations:

Result:

Precautions:

1. Clean the surfaces of inclined plane and box while taking

readings.

2. Tapping should be done gradually to see the motion of box.

3. It is conventional that the level of the weighs and box

should be same.

4. The motion of the box should be such that it just tend to

start (impending motion) while taking readings.

5. The pulley should be frictionless.

Sources of Error:

1. There may be slight friction in pulley.

2. There may be improper tapping.

3. Threads may not be inextensible.

Discussion:

Note: Draw the diagram for the experimental set-up.

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

DELHI COLLEGE OF ENGINEERING

(Govt. of NCT of Delhi) Main Bawana Road, Delhi-42

Mechanical Engineering Department

Applied Mechanics Laboratory

Instruction Sheet-1

Aim: To find out stiffness and modulus of rigidity (shear modulus) for the

material of a closed coil helical spring under tensile loading conditions.

Apparatus used: Spring apparatus with closed coil helical spring, vernier

calliper, Steel scale, Hanger (1/2 kgf load), weights (1/2 kgf, 10 Nos), etc.

Theory:

Spring stiffness: spring stiffness is defined as the load applied per unit

elongation for a given spring material.

Elongation

d LoadApplie

fness SpringStif =

o

W

K =

Where K is the spring stiffness (N/m)

W is the Tensile load applied in Newton

o is the elongation in mete

(Inverse of slope of Final extension Load curve )=Tan = spring stiffness (K)

Modulus of Rigidity (Shear modulus):Modulus of rigidity or Shear modulus is

defined as the ration of Shear stress to shear strain.

n Shearstrai

s Shearstres

ulus hear igidityorS Modulusofr = mod

( )

|

A F

G

/

=

F

W (Kgf)

Final

reading

of scale

(cm)

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

For a spring material

4

3

8

d

n WD

G

o

=

Where

G is the shear modulus of spring material (N/mm

2

)

W is Load applied (N)

D is the mean coil diameter [(d

1

+d

2

)/2] in (mm)

d

1

is the inner diameter of spring coil in (mm)

d

2

is the outer diameter of spring coil`in (mm)

n is the effective number of turns = N+1

o is the net elongation of spring for load W in (mm)

d is the diameter of spring wire [(d

1

-d

2

)/2] in (mm)

Procedure:

1. First of all find the least count of the vernier scale.

2. Note initial reading of vernier scale without external load.

3. Gradually apply the load 1kg at first time and note final reading

vernier scale.

4. Now, increase the load with 1/2 kg increment and note final

reading of vernier scale.

5. Repeat the experiment for 10 readings.

6. Measure the internal and external diameters of spring with the

help of separate vernier calliper.

7. Count the no. of turns of the springs.

8. Add (1/2turn for upper bound coil+1/2turn for lower bound

coil)= 1 to N to get effective number of turns (n).

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Observations:

1. External diameter of spring d

1 = mm

2. Internal diameter of spring d

2 = mm

3. Number of turns (N) =

S.

No.

Weight

Applied

(W) in Kgf

Initial

reading of

vernier

scale in

(cm)

Final reading of vernier scale in

(cm)

Spring

stiffness

(k) in

N/mm

Ascending

order

Descending

order

Average

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Calculations:

Result:

Precautions:

1. Keep the spring in proper tensile position before applying load.

2. Vernier scale should be free to move at main scale.

3. Weight should be apply gradually.

4. Weights should be applied in ascending order and after that in

descending order

5. Parallax should be removed before taking vernier reading.

6. Internal and external diameters of spring should be checked from

three or four different positions.

Sources of Error:

1. There may be friction between main scale and vernier scale.

2. Spring may be not in right tensile loading position.

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Discussion:

Note: 1. Draw the diagram for experimental set-up.

2. Draw the graph between final reading of vernier scale at y-axis

and Load applied at x-axis.

3. The standard value of Spring stiffness is 10 N/mm and Modulus of

rigidity for steel is

2 11

m / N 0 ` 1 8

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Applied Mechanics Laboratory

Mechanical Engineering Department

DELHI COLLEGE OF ENGINEERING

(Govt. of NCT of Delhi) Main Bawana Road, Delhi-42

Instruction Sheet-2

Aim: To find the modulus of elasticity (Youngs modulus ) for a given material

of cantilever for concentrated load at free end.

Apparatus Used: Cantilever Apparatus, Fraction weight(5, 10, 20, 50, 100gmf),

Scale.

Theory : The cantilever beam with concentrated beam is shown in fig.

Cantilever with deflection(

max

o ) at free end due to concentrated load (W)

L

b

d

w

L

max

o

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

The maximum deflection of beam at free is given by the formula

EI

WL

3

3

max

= o

max

3

3 o I

WL

E =

Where

max

o = Maximum deflection at free end of cantilever (m)

W = Concentrated load at Free end (Newton)

L = Length of beam from support to the application of load

E = Modulus of elasticity (youngs modulus) for given

material of cantilever (N/m

2

)

I = Area-moment of Inertia of beam about neutral axis ( m

4

)

Moment of Inertia of Cantilever

12

3

bd

I =

Where I = Area-moment of Inertia of rectangular beam about N.A. (m

4

)

b = Width of x-section of rectangular beam (m)

d = Depth of x-section of rectangular beam (m)

Formula for % Error is given by

100

Pr

%

=

Idealvalue

ue acticalval Idealvalue

Error

Procedure:

1. First of all set the length of beam and mark the position of

cantilever end as (initial reading of deflection).

2. Apply the load (50gmf hanger) at free end and note the final

reading of deflection

3. Repeat the experiment 10 times.

b

d

N.A.

x x

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Observations:

1. Length of beam from fixed end to point of application (L)

=

m

2. Width of beam (b) = m

3. Depth (Thickness) of beam (d) = m

S.

No.

Load (W)

(Newton)

Deflection (

max

o ) (m)

Initial Final Net

Calculations:

Result:

Precautions:

1. Hold the cantilever with support carefully.

2. Note the reading of deflection after removing parallax.

3. Do not apply heavy loads at end of beam.

4. Deflection should be noted at point of application of load to get

maximum deflection.

5. Thickness should be measured either by vernier calliper ,

micrometer or screw gauge.

Sources of Error:

1. There may be positive or negative error in vernier calliper.

2. Point of application of load may be change.

Discussion:

Note: 1. Draw the diagram for the experimental set up.

2. Draw the curve between Load (x-axis) and maximum deflection

(y-axis)

3. Experiment may be repeated for different length.

4. Standard value of E for steel is

2 11

/ 0 ` 1 2 m N

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

DELHI COLLEGE OF ENGINEERING

(Govt. of NCT of Delhi) Main Bawana Road, Delhi-42

Mechanical Engineering Department

Applied Mechanics Laboratory

Instruction Sheet -5

Aim: To find out the coefficient of friction between flat pulley and rope with

the help of combined belt and rope friction apparatus using gradually

applied load.

Apparatus Used: Combined belt and rope friction apparatus , Rope , Weights

(500gmf, 1000gmf, 100gmf, 50gmf, 20gmf, 10gmf, etc.) and Hangers

(50gmf each).

Theory: For flat pulley and rope

u

e

T

T

=

2

1

2

1

1

T

T

Log

e

=

u

Where T

1

= Tight side tension (gmf)

T

2

= Slack side tension (gmf)

= co-efficient of friction

u

= Angle of Lap (radian)

W

1

W

2

T

1

T

2

t u =

Flat

Pulley

Rope

Weights

Angle

of Lap

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Procedure:

1. First of all put the rope on flat pulley.

2. Now put the hanger two sides of rope and make them at same

level.

3. Increase load on one side till the rope just start to move

(impending motion).

4. Note the readings of T

1

and T

2

(T1>T2).

5. Repeat the experiment 10 times for different values of T

2

.

Observations:

Angle of Lap

t u =

S.

No.

Tight side

Tension(T

1

) (gmf)

Slack side

Tension(T

2

) (gmf)

Co-efficient of friction ( )

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Calculations:

Result:

Precautions:1

1. Rope should be inextensible and weightless.

2. Tapping should be done gradually.

3. The ends of the rope should be at same level during experiment.

4. Weight should apply gradually at hanger.

5. The range of weight which has to apply is (5gmf to 1000gmf).

Sources of Error:

1. Rope may be extensible.

2. Tapping may be uneven.

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Discussion:

Note:

1. Draw the diagram for experimental set-up.

2. Draw the curve between T

1

(Y-axis) and T

2

(X-axis).

3. Draw the curve between (Y-axis) and

2

1

T

T

(X-axis).

4. The value of may lie between (0.2 to 0.3).

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

DELHI COLLEGE OF ENGINEERING

(Govt. of NCT of Delhi) Main Bawana Road, Delhi-42

Mechanical Engineering Department

Applied Mechanics Laboratory

Instruction Sheet 6

Aim: To determine Mechanical Advantage (M.A.), Velocity ratio (V.R.) and

efficiency (q ) for a given Screw-Jack (single start thread) Apparatus.

Also determine the law of machine and plot curve for:

(i) Load vs Effort

(ii) Load vs Mechanical Advantage (M.A.)

(iii) Load vs Efficiency (q )

Apparatus Used: Screw efficiency apparatus, inextensible strings, weights{1/2

kgf (10 nos), 100gmf (2 nos), 50gmf (3nos), 20gmf(1nos), 10gmf(1nos)},

vernier calliper, Outside calliper, scale, etc.

Theory:

Mechanical Advantage (M.A.) : Mechanical Advantage for a simple

machine is defined as the ratio of load lifted to the effort applied.

ied EffortAppl

LoadLifted

Advantage Mechanical =

P

W

A M = . .

Fig. (Simple pulley shows Load lifted and Effort applied)

Simple

Pulley

Load

Lifted

Effort

Applied

x

y

W

W

P

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Velocity Ratio (V.R.) : Velocity ratio is defined as the ratio of distance

moved by effort to the distance moved by load.

Load by moved Distannce

effort by moved Distannce

Ratio Velocity

=

x

y

. R . V =

Efficiency (q ): Efficiency of a simple machine is defined as the ratio of

out-put( work obtained as load lifted) to the input (work done at

other end of pulley).

100

Input

output

Efficiency =

100

y P

x W

= q

100

x y

P W

= q

100

Ratio Velocity

Advantage Mechanical

= q

Law of Machine : is mathematically defined as for a simple machine.

C mW P + =

Where P is the effort applied (kgf)

W is load lifted (kgf)

m is the slope or co-efficient of friction

C is the co-efficient of friction for machine

For single start screw thread

p

D

Ratio Velocity

t

=

Ideal Machine

Actual Machine

C

) m ( Tan

1

Load (W)

E

f

f

o

r

t

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

For double start screw thread

p 2

D

Ratio Velocity

t

=

Where D is the diameter of effort wheel (mm)

P is the pitch of the screw thread (mm)

Pitch : is defined as the axial displacement of load in one complete

rotation of effort wheel.

Fig. : Screw Jack Apparatus

Effort pulley

Guide

Pulley

Screw

Threads

Lifted

Load

Effort

Applied

Base

Motion

Screw

Spindle

Arms

Pitch

Motion Motion

Load

Hanger

Tap

here

Collar

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Procedure:

1. Measure the pitch of the screw with vernier calliper.

2. Measure the diameter of effort pulley with outside calliper and

meter scale.

3. Wrap the thread around the effort pulley passing over the guide

pulley and put the effort hangers at the ends of threads.

4. Place a known weight in the Load hanger with collar and start

hanging weights with the effort hanger gradually till the load

starts lifting.

5. Repeat the experiment at least 10 times with different weights

(Loads).

6. Calculate M.A., V.R. and % Efficiency.

Observations:

1. Diameter of Effort pulley =.Cm

2. Pitch of screw thread =..Cm

3. Velocity Ratio =..

S.

No.

Load Lifted

(kgf)

Effort Applied

(kgf)

Mechanical

Advantage (M.A.)

(%) Efficiency

( q)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Calculations:

Result:

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Precautions:

1. Wrap the string properly around effort pulley.

2. There may be Positive or negative error in vernier calliper.

3. Reading of pitch should be taken carefully.

4. It should be noted that whenever load lifted (means load

goes in upward direction), the effort should be applied in

downward direction.

5. Tapping should be done gradually and at right place.

Sources of Error:

1. There may be slight friction in pulleys.

2. Strings may be extensible and weightless.

Discussion:

Note: 1. Draw the diagram for the experimental set-up.

2. Draw various curves (Load W at x-axis) as indicated in Aim.

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

DELHI COLLEGE OF ENGINEERING

(Govt. of NCT of Delhi) Main Bawana Road, Delhi-42

Mechanical Engineering Department

Applied Mechanics Laboratory

Instruction Sheet 9

Aim: To locate the Centroid of given laminas

a. Sector of circle b. Trapezium c. Parallelogram d. Triangle

e. Irregular Body .

Apparatus Used: Laminas (Sector of circle, Trapezium, Parallelogram,

Triangular and Irregular body), Inextensible strings, Plumb, Rigid

support, Paper (A-3 size) and Pencil for marking.

Theory: A body which has negligible mass and thickness is called lamina. The

Centroid of lamina is the point at which the whole area of lamina is

supposed to be concentrated.

For Sector of Circle :

S.

No.

Shape Area

x

x

y

Y

1. Circular Sector

2

r u

u

u

3

sin r 2

0

x

Y

u

u

c

r

Origin

(0,0) O

x

X

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Fig. Circular sector

For Trapezium :

S.

No.

Shape Area

x

x

y

Y

1. Trapezium

( ) h b a

2

1

+

0

( )

b a

b a 2

3

h

+

+

For Parallelogram:

S.

No.

Shape Area

x

x

y

Y

1. Parallelogram h b

2

h

a

b

h

Origin

O (0,0)

c

Y

x

x

Y

Origin

O (0,0)

b

h

c

2

h

( )

b a

b a 2

3

h

+

+

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

For Triangle:

S.

No.

Shape Area

x

x

y

Y

1. Triangle

h b

2

1

3

h

Percentage Error may be calculated by following formula

100

F

F F

Error %

4

4 4

'

'

=

Y

x

b

h

c

3

h

Origin

O (0,0)

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

For Irregular Lamina:

S.

No.

Shape Area

x

x

y

Y

1. Irregular

Procedure :

1. Use different laminas wrap paper on them and suspend it from

point P with the help of a string.

2. Draw the line PP` by chalk or pencil on the lamina. PP` is the

extension of string line from P.

3. Similarly hang the lamina from point Q and draw the line QQ`

on the lamina. The QQ` is the extension of string line from Q.

4. The same procedure may be repeated by hanging the lamina

from point R.

5. The point at which the line PP`,QQ` and RR` cut gives the

Centroid of the lamina.

c

x

Y

P

P`

Q

Q`

R

R`

Origin

(0,0)

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

6. Measure the distance of the Centroid from the point P`.

Observaions:

S.

No.

Shape Area

x

x

y

Y

Calcu-

-lated

Obse-

-rved.

Calcu-

-lated

Obse-

-rved.

%

Error

1. Circular Sector

2.

Trapezium

3. Parallelogram

4. Triangle

5. Irregular Lamina

Result : The co-ordinates of Irregular lamina are =

Precautions:

1. The line PP` and RR` should be marked accurately.

2. The point of intersection of the lines should be located

accurately.

Discussion:

Note : 1. Draw the diagram for experimental set-up.

2. Attach paper of each lamina drawing.

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

DELHI COLLEGE OF ENGINEERING

(Govt. of NCT of Delhi) Main Bawana Road, Delhi-42

Mechanical Engineering Department

Applied Mechanics Laboratory

Instruction Sheet 10

Aim: To determine Mechanical Advantage (M.A.), Velocity ratio (V.R.) and

efficiency (q ) for given Single and double Winch-Crab Apparatus. Also

determine the law of machine and plot curve for:

(iv) Load vs Effort

(v) Load vs Mechanical Advantage (M.A.)

(vi) Load vs Efficiency (q )

Apparatus Used: Single and double purchase Winch-Crab apparatus,

inextensible strings, weights{1/2 kgf (10 nos), 100gmf (2 nos), 50gmf

(3nos), 20gmf(1nos), 10gmf(1nos)}, Outside calliper, scale, etc.

Theory:

Mechanical Advantage (M.A.) : Mechanical Advantage for a simple

machine is defined as the ratio of load lifted to the effort applied.

ied EffortAppl

LoadLifted

Advantage Mechanical =

P

W

A M = . .

Fig. (Simple pulley shows Load lifted and Effort applied)

Simple

Pulley

Load

Lifted

Effort

Applied

x

y

W

W

P

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Velocity Ratio (V.R.) : Velocity ratio is defined as the ratio of distance

moved by effort to the distance moved by load.

Load by moved Distannce

effort by moved Distannce

Ratio Velocity

=

x

y

. R . V =

Efficiency (q ): Efficiency of a simple machine is defined as the ratio of

out-put( work obtained as load lifted) to the input (work done at

other end of pulley).

100

Input

output

Efficiency =

100

y P

x W

= q

100

x y

P W

= q

100

Ratio Velocity

Advantage Mechanical

= q

Law of Machine : is mathematically defined as for a simple machine.

C mW P + =

Where P is the effort applied (kgf)

W is load lifted (kgf)

m is the slope or co-efficient of friction

C is the co-efficient of friction for machine

Ideal Machine

Actual Machine

C

) m ( Tan

1

Load (W)

E

f

f

o

r

t

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

For single purchase Winch-Crab

The unit consists of two axles called the effort axle and load axle.

Both these axles are mounted on rigid supports called strands. The effort

axle carries a teethed wheel called pinion meshes with a big teethed wheel

Spur gear.

Fig. : Single Purchase Winch-Crab

When the effort wheel completes one revolution, the distance moved

by the effort is D t for one revolution of pinion, the number of

revolution undergone by the spur gear is

2

1

T

T

.

Therefore, the displacement of load is given by:

2

1

T

T

d t

Load of nt Displaceme

Effort of nt Displaceme

(V.R.) Ratio Velocity =

Spur

Gear

Pinion

Load

D

d

1

T

2

T

Effort

Axle

Load Axle or Drum

Effort

Applied

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

2

1

T

T

d

D

(V.R.) Ratio Velocity

t

t

=

d

D

T

T

. R . V

1

2

=

Where D is the diameter of effort wheel (cm)

d is the diameter of Load drum (cm)

T

1

is number of teeth of Pinion

T

2

is number of teeth of Spur gear

P

W

A M = . .

100

Ratio Velocity

Advantage Mechanical

= q

2

1

T

T

D

d

P

W

= q

For Double purchase Winch-Crab

The system employs two pairs of gears for obtaining increased

velocity ratio. There are three axles. An effort axle , load axle and an

intermediate axle. The effort axle carries a pinion which gears with the

spur wheel of the intermediate axle.

The pinion of the intermediate axle meshes with the spur wheel

mounted on the load axle.

When the effort wheel completes one revolution, the distance moved

by the effort D t .

The effort axle and pinion (T

1

) mounted on it also turn one

revolution. This pinion gear meshes with spur gear (T

2

) fixed onto the

intermediate axle. The revolution made by one intermediate axle are =

2

1

T

T

1

The pinion (T

3

) mounted on the intermediate axle will also turn

through the same number of revolutions. This pinion meshes with spur

gear (T

4

) of the load axle.

Thus the revolution made by load axle and the load drum mounted

on it are =

4

3

2

1

T

T

T

T

1

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Distance moved by the load =

|

|

.

|

\

|

t

4

3

2

1

T

T

T

T

1 d

Load of nt Displaceme

Effort of nt Displaceme

(V.R.) Ratio Velocity =

4

3

2

1

T

T

T

T

d

D

(V.R.) Ratio Velocity

t

t

=

3 1

4 2

T T d

T T D

(V.R.) Ratio Velocity

=

Where D is the diameter of effort wheel (cm)

d is the diameter of Load drum (cm)

T

1

is number of teeth of Pinion with effort wheel

T

2

is number of teeth of Spur gear (intermediate axle)

T

3

is number of teeth of Pinion with intermediate axle

T

4

is number of teeth of Spur gear with load drum

4

T

D

Spur

Gear

Pinion

1

T

2

T

Spur

Gear

Load

d

Load Axle or Drum

Spur

Gear

2

T

Pinion

3

T

Effort

Applied

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Fig. : Double Purchase Winch-Crab

P

W

A M = . .

100

Ratio Velocity

Advantage Mechanical

= q

4

3

2

1

T

T

T

T

D

d

P

W

= q

Procedure:

1. Make strings for load drum to move upward and effort to move

upward.

2. Apply known load (initially 0.5 kgf) at load hanger and apply

corresponding effort (50-150gmf) at effort hanger in order that

the effort wheel just move on slight tapping at bearing.

3. Note the readings of load and effort and repeat the experiment

for different loads ten times.

Observations:

For single purchase Winch-Crab

1. Circumference of Effort wheel ( D t )= cm

2. Circumference of Load drum ( d t ) = cm

3. No. of teeth of pinion (T

1

) =

4. No. of teeth of Spur gear (T

2

) =

5. Velocity ratio (

d

D

T

T

. R . V

1

2

= ) =

S.

No.

Load Lifted

(kgf)

Effort Applied

(kgf)

Mechanical

Advantage (M.A.)

(%) Efficiency

( q)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

For double purchase Winch-Crab

1. Circumference of Effort wheel ( D t )= cm

2. Circumference of Load drum ( d t ) = cm

3. No. of teeth of pinion (effort wheel) (T

1

) =

4. No. of teeth of Spur gear (intermediate axle) (T

2

) =

5. No. of teeth of pinion (intermediate axle) (T

3

) =

6. No. of teeth of Spur gear (Load drum) (T

4

) =

7.

3 1

4 2

T T d

T T D

(V.R.) Ratio Velocity

=

=

S.

No.

Load Lifted

(kgf)

Effort Applied

(kgf)

Mechanical

Advantage (M.A.)

(%) Efficiency

( q)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Result:

Precautions:

1. Wrap the string properly around effort pulley.

2. It should be noted that whenever load lifted (means load goes in

upward direction), the effort should be applied in downward

direction.

3. Tapping should be done gradually and at right place.

Sources of Error:

1. There may be slight friction in pulleys.

2. Strings may be extensible and weightless.

Discussion:

Note: 1. Draw the diagram for the experimental set-up.

2. Draw various curves (Load W at x-axis) as indicated in Aim.

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

AglaSem - Moving to Next Semester

w

w

w

.

A

g

l

a

S

e

m

.

c

o

m

Вам также может понравиться

- P67821A IAL Physics WPH15 01 Jan21 4thMsДокумент32 страницыP67821A IAL Physics WPH15 01 Jan21 4thMsLittle WizardОценок пока нет

- 6 Forces in Equilibrium Support MomentsДокумент6 страниц6 Forces in Equilibrium Support MomentsKaren Tubby0% (1)

- Solucionario Cap 2 Máquinas EléctricasДокумент48 страницSolucionario Cap 2 Máquinas EléctricasfernandoОценок пока нет

- Department of Civil Engineering Lab Manual OF Structural Analysis-Ii (Ece-305)Документ30 страницDepartment of Civil Engineering Lab Manual OF Structural Analysis-Ii (Ece-305)doktorterОценок пока нет

- Dom Lab ManuelДокумент56 страницDom Lab ManuelMartin De Boras PragashОценок пока нет

- Em PracticalДокумент7 страницEm PracticaldanielОценок пока нет

- Structural Analysis LabДокумент29 страницStructural Analysis Labsamiee_meОценок пока нет

- Am LabДокумент22 страницыAm LabJayavel123Оценок пока нет

- Lab ManualsДокумент13 страницLab ManualssaqibОценок пока нет

- CEC 106 PracticalДокумент44 страницыCEC 106 PracticalSimon Watila67% (3)

- Vibration Engg. LabДокумент14 страницVibration Engg. LabHardial SinghОценок пока нет

- Dynamics LabДокумент14 страницDynamics LabDhiraj ThakurОценок пока нет

- Structural Engineering Laboratory: ImportantДокумент4 страницыStructural Engineering Laboratory: ImportantScott RandleОценок пока нет

- Civil Engineering: Lab ManualДокумент30 страницCivil Engineering: Lab ManualSaurabh SahuОценок пока нет

- Engineering Mechanics Lab ManualДокумент16 страницEngineering Mechanics Lab Manualprathameshbhat88100% (2)

- SA Lab ManualДокумент32 страницыSA Lab ManualAnonymous nSvmh3s67% (3)

- EXPERIMENTДокумент13 страницEXPERIMENTPrashant ViratОценок пока нет

- ME2307 Lab ManualДокумент14 страницME2307 Lab ManualAnirudhan RaviОценок пока нет

- Engineering Mechanics (Lab Manual)Документ27 страницEngineering Mechanics (Lab Manual)Sagheer AhmedОценок пока нет

- Engineering Mechanics Lab: PracticalДокумент27 страницEngineering Mechanics Lab: PracticalSagheer AhmedОценок пока нет

- Physics Practical ExperimentДокумент18 страницPhysics Practical ExperimentThanveer PutchakayalaОценок пока нет

- Machine Dynamics Lab ManualДокумент18 страницMachine Dynamics Lab ManualRishi ShuklaОценок пока нет

- Practical Manual Writeup1Документ10 страницPractical Manual Writeup1Piyush BhandariОценок пока нет

- Engineering Mechanics Lab PDFДокумент19 страницEngineering Mechanics Lab PDFDeepal Nandy100% (1)

- Structural Analysis IIДокумент16 страницStructural Analysis IIbaizubirajiОценок пока нет

- Structure Analysis Lab Subject Code:-Rce-453Документ25 страницStructure Analysis Lab Subject Code:-Rce-453Anubhav KumarОценок пока нет

- Ece Labmanual With VivaДокумент58 страницEce Labmanual With VivasathwikОценок пока нет

- Mechanics Lab ManualДокумент16 страницMechanics Lab ManualShravanОценок пока нет

- MEC 222 EXP-Lab-SOMДокумент69 страницMEC 222 EXP-Lab-SOMAbhijeeth NagarajОценок пока нет

- Civil Lab ManualДокумент17 страницCivil Lab ManualShakil KhanОценок пока нет

- Practice Test 6 Rotation Angular MomentumДокумент18 страницPractice Test 6 Rotation Angular MomentumLynn Hollenbeck BreindelОценок пока нет

- Bending - 2Документ8 страницBending - 2mohammadalhju12Оценок пока нет

- Dynamics Lab MANUAL New PrintДокумент56 страницDynamics Lab MANUAL New PrintMartin De Boras PragashОценок пока нет

- Cantilever Beam Long ReportДокумент21 страницаCantilever Beam Long ReportAbdul Azeez Ismaila ShuaibuОценок пока нет

- Buckling of Struts - MKMДокумент8 страницBuckling of Struts - MKMAbdur Rasheed RasheedОценок пока нет

- Reaction On BeamДокумент10 страницReaction On BeamNurul NadhirahОценок пока нет

- ME-222 Mechanics Manufacturing Lab-IДокумент50 страницME-222 Mechanics Manufacturing Lab-IMuhammad Haseeb JavedОценок пока нет

- Exp03 GyroДокумент4 страницыExp03 GyrocooljseanОценок пока нет

- Deflection of Beam PDFДокумент8 страницDeflection of Beam PDFSalam Albaradie100% (1)

- American International University-Bangladesh (Aiub)Документ9 страницAmerican International University-Bangladesh (Aiub)Shoaib KhanОценок пока нет

- Mechanics of Materials - Principal Stresses and StrainsДокумент14 страницMechanics of Materials - Principal Stresses and StrainsDavid Clark100% (5)

- Chapter4pp031 042 PDFДокумент12 страницChapter4pp031 042 PDFInderMaheshОценок пока нет

- Energy On An Inclined PlaneДокумент6 страницEnergy On An Inclined PlaneUgur ASİT100% (3)

- TOM CombinedДокумент20 страницTOM Combinedakshath.rk2002Оценок пока нет

- Lab # 09Документ8 страницLab # 09Muhammad WaqasОценок пока нет

- Index/ Instructor's Evaluation of Experiment ReportsДокумент22 страницыIndex/ Instructor's Evaluation of Experiment Reportssirajudeen IОценок пока нет

- MMMD 106 - Theory of Vibration LabДокумент26 страницMMMD 106 - Theory of Vibration LabNavdeep JainОценок пока нет

- Applied Mechanics Lab ManuaДокумент17 страницApplied Mechanics Lab ManuaFaisal AmeenОценок пока нет

- KOM Lab ManualДокумент24 страницыKOM Lab ManualMithra SОценок пока нет

- General Application To Elastic Materials: AM2540 Spring Sti Ness Test AM 2540: Strength of Materials LaboratoryДокумент17 страницGeneral Application To Elastic Materials: AM2540 Spring Sti Ness Test AM 2540: Strength of Materials LaboratoryAditya KoutharapuОценок пока нет

- Expt #3 (Circular Motion) Phys 1601 Fall 2019Документ3 страницыExpt #3 (Circular Motion) Phys 1601 Fall 2019HossОценок пока нет

- ME-346 Lab SheetДокумент17 страницME-346 Lab SheetZayed KhanОценок пока нет

- Mechanical Vibration Lab ManualДокумент22 страницыMechanical Vibration Lab Manualp07ip710Оценок пока нет

- Lab Session 4 MomДокумент5 страницLab Session 4 Momm.sheraz malikОценок пока нет

- Torsional - PendulumДокумент5 страницTorsional - Pendulumxogus6216Оценок пока нет

- Theory of Machines Lab ManualДокумент26 страницTheory of Machines Lab Manualvamsi krishna balagaОценок пока нет

- SuriyaДокумент36 страницSuriyakumaravel07Оценок пока нет

- ERT2016 Lab Sheet 20112012 MechanicsДокумент7 страницERT2016 Lab Sheet 20112012 MechanicsKesava ShankarОценок пока нет

- Gnitc/Set/Dme Kinematics&Dynamics LabДокумент32 страницыGnitc/Set/Dme Kinematics&Dynamics LabdivyanshОценок пока нет

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresОт EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresРейтинг: 4 из 5 звезд4/5 (1)

- Exercises On SPCДокумент2 страницыExercises On SPCyahska1305Оценок пока нет

- Exercises On Supply Process CapacityДокумент2 страницыExercises On Supply Process Capacityyahska1305100% (1)

- Second Law Analysis of A Waste Heat Recovery BasedДокумент9 страницSecond Law Analysis of A Waste Heat Recovery Basedyahska1305Оценок пока нет

- CHAPTER 3 ProbabilityДокумент55 страницCHAPTER 3 Probabilityyahska1305Оценок пока нет

- Solving Indeterminate Structures - CompatibilityДокумент24 страницыSolving Indeterminate Structures - CompatibilityY SAHITHОценок пока нет

- 2014 - Cigre - Past, Present and Future of Iec PDFДокумент62 страницы2014 - Cigre - Past, Present and Future of Iec PDFBertrandFocher100% (3)

- Chapter 7 Passive DevicesДокумент72 страницыChapter 7 Passive DevicessvijiОценок пока нет

- Encapsulados Ensayos E2 C2 F1Документ4 страницыEncapsulados Ensayos E2 C2 F1fgdfgdfОценок пока нет

- DOLGACHEV, I. Introduction To String Theory - PsДокумент83 страницыDOLGACHEV, I. Introduction To String Theory - PsMarcos PauloОценок пока нет

- Equilibrium of A Rigid BodyДокумент20 страницEquilibrium of A Rigid BodywaqarОценок пока нет

- Flinn Lab 1: Atomic Structure & Periodic Trends: Observe Part 1Документ7 страницFlinn Lab 1: Atomic Structure & Periodic Trends: Observe Part 1Angelo RayesОценок пока нет

- Moving Charges & Magnetism Lecture 7 @physicswallahlakshyavideos PhysicswallahlakshyavideosДокумент23 страницыMoving Charges & Magnetism Lecture 7 @physicswallahlakshyavideos PhysicswallahlakshyavideostanishsarmahОценок пока нет

- A Modal Pushover Analysis Procedure To Estimate Seismic Demands FДокумент54 страницыA Modal Pushover Analysis Procedure To Estimate Seismic Demands FnguyenvanduyetОценок пока нет

- Exe Melting and BoilingДокумент3 страницыExe Melting and BoilingKuan LoongОценок пока нет

- Nuclear Reaction ReviewДокумент3 страницыNuclear Reaction ReviewSeyi Martins ObandoОценок пока нет

- Struktur Beton 2-P-Delta Effect (Compatibility Mode)Документ19 страницStruktur Beton 2-P-Delta Effect (Compatibility Mode)Boy FirdausОценок пока нет

- Quizziz April 28 2021Документ1 страницаQuizziz April 28 2021Angel GonzalesОценок пока нет

- Transducer: Controller (Control Theory)Документ5 страницTransducer: Controller (Control Theory)Farrukh JamilОценок пока нет

- Centre of MassДокумент32 страницыCentre of MassR.Yashwanth Raj XBОценок пока нет

- CFD Cheat Sheet: December 15, 2014Документ2 страницыCFD Cheat Sheet: December 15, 2014Charles RobersonОценок пока нет

- Definition of Enthalpy, Internal-Energy, and Entropy Changes of Real GasesДокумент1 страницаDefinition of Enthalpy, Internal-Energy, and Entropy Changes of Real Gasesprashant_cool_4_u100% (1)

- Seismic Assessment of Hollow Core Concrete Bridge Piers: Research OnlineДокумент11 страницSeismic Assessment of Hollow Core Concrete Bridge Piers: Research Onlineshravan38Оценок пока нет

- IJIRAE::Seismic Pounding Between Adjacent Building StructuresДокумент4 страницыIJIRAE::Seismic Pounding Between Adjacent Building StructuresIJIRAE- International Journal of Innovative Research in Advanced EngineeringОценок пока нет

- Answer Ramp LabДокумент4 страницыAnswer Ramp LabjungdjudfОценок пока нет

- Experiment 5 - ResonanceДокумент6 страницExperiment 5 - ResonanceLeigh Dominique Zaragoza (Ji)Оценок пока нет

- Mind Map 13-10-2021: Hardhik Pinjala - MM19B043 - October 14, 2021Документ2 страницыMind Map 13-10-2021: Hardhik Pinjala - MM19B043 - October 14, 2021Hardy SPОценок пока нет

- Conservation of MomentumДокумент17 страницConservation of MomentumWilma Y. VillasanОценок пока нет

- Chapter 3 - Hydrostatic Forces On Submerged SurfacesДокумент17 страницChapter 3 - Hydrostatic Forces On Submerged SurfacesGSaurav DahalОценок пока нет

- Gourley DeclarationДокумент36 страницGourley DeclarationTechCrunchОценок пока нет

- Effect of Bolt Tightening Methods and Sequence On The Performance of Gasketed Bolted Flange Joint AssemblyДокумент10 страницEffect of Bolt Tightening Methods and Sequence On The Performance of Gasketed Bolted Flange Joint AssemblyHeviiОценок пока нет

- (Roger M. Wood) Laser-Induced Damage of Optical MaДокумент252 страницы(Roger M. Wood) Laser-Induced Damage of Optical MaRamin ShojaОценок пока нет

- PHY 107 Experiment 5Документ8 страницPHY 107 Experiment 5Abdurrahman AdigunОценок пока нет