Академический Документы

Профессиональный Документы

Культура Документы

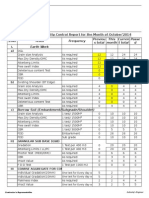

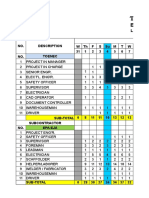

Quality Control Check List

Загружено:

SARANYAKRISHNAKUMARОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Quality Control Check List

Загружено:

SARANYAKRISHNAKUMARАвторское право:

Доступные форматы

Quality Control I) Density of Raw Materials S.

No 1 2 3 4 5 Material Coarse Aggregate Sand Bricks Cement Gypsum Unit kg/m3 kg/m3 kg/m3 kg/m3 kg/m3 Density 1700 1800 1750 1450 1600

II) List of Mandatory Tests S.No Material 1 Water IS Code IS 3025 Frequency Water from each source shall be got tested befor the commencement of work and thereafter once in every 3 months till the completion of work. Water from municipal sources need to be tested once in six months. Number of Tests for each source will be 3

2 Cement III) Relevant Data 1 Reduction in Strength of Cement S.No 1 2 3 4 5 Storage Period of Cement Fresh 3 months old 6 months old 12 months old 24 months old

IS 4031

Every 50 MT or part thereof

Strength Reduction Nil 20% 30% 40% 50%

Quality Control IV) Grading of Sand for use in Masonry as per IS 2116-1980 S.No 1 2 3 4 5 6 IS Sieve Designation 4.75 mm 2.36 mm 1.18 mm 600 micron 300 micron 150 micron Percentage passing by Mass 100 90-100 70-100 40-100 5-70 0-15

V) Grading of Sand for use in Plaster as per IS 1542-1977 S.No 1 2 3 4 5 6 7 VI) VII) S.No 1 2 3 VIII) S.No 1 2 3 4 5 IS Sieve Designation 10 mm 4.75 mm 2.36 mm 1.18 mm 600 micron 300 micron 150 micron Cement Bag Plain Cement Concrete Grade M15 M20 M25 Reinforced Cement Concrete Grade M20 M25 M30 M35 M40 Minimum Cement Content (kg) 300 300 320 340 360 Water Cement Ratio 0.55 0.5 0.45 0.45 0.4 Minimum Cement Content (kg) 240 260 280 Water Cement Ratio 0.6 0.45 0.4 Percentage passing by Mass 100 95-100 95-100 90-100 80-100 20-65 0-50 50 kg 0.035 m3

Quality Control IX) Removal of Formwork Minimum Period before striking Formwork 16 to 24 hours 3 days

S.No Type of Formwork 1 Vertical Formwork 2 Soffit formwork to Slabs ( Props to be refixed immedialely after removal of formwork) 3 Soffit formwork to Beams ( Props to be refixed immedialely after removal of formwork) 4 Props to Slabs spanning upto 4.5 m 5 Props to Slabs spanning over 4.5 m 6 Props to Beams spanning upto 6 m 7 Props to Beams spanning over 6 m X) S.No 1 2 3 4 5 6 XI)

7 days

7 days 14 days 14 days 21 days

Quantity of different material to get 1 m3 of Concrete Mix Proportion 1:1:2 1:1.5:3 1:2:4 1:3:6 1:4:8 1:5:10 Cement (kg) 61 40 32 22 17 13 Sand (m3) 0.45 0.441 0.47 0.485 0.5 0.475 Aggregate 40 mm Aggregate 20 mm 0.675 0.662 0.705 0.727 0.275 0.258

0.688 0.662

Cube Samples for Compressive Strength Each sample consists of 3 cubes of size 15 x 15 x 15 cm S.No Quantity (m3) No. of Samples 1 Less than 5 1 2 6 to 15 2 3 16 to 30 3 4 31 to 50 4 5 51 and above 4 plus one additional sample for each additional 15 m3 or part thereof

Quality Control XII) Bricks Compressive Strength S.No 1 2 3 4 Class/ Designation 10 7.5 5 3.5 Compressive Strength (N/mm2) 10-12.5 7.5-10 5-7.5 3.5-5

XIII) Testing of Bricks a) For Visual and Dimensional Characteristics S.No No. of Bricks in Lot No. of Bricks to be selected for individual characteristics 1 2001-10000 2 10001-35000 3 35001-50000 b) For Physical Characteristics S.No No. of Bricks in Lot 20 32 50

Permissible no. of defective in the sample 1 2 3

No. of Bricks for dimensional characteristics 40 60 80

Sample Size for compressive strength, water absorbtion, and efflorescence 5 10 15

Permissible No of defectives for efflorescence 0 0 1

1 2001-10000 2 10001-35000 3 35001-50000 c) XIV) Average Water Absorbtion should be less than 20 % by weight Bond Stones 1 Single Bond Stone for 60 cm thickness of wall 2 For wall above 60 cm two bond stones with overlap of 15 cm to be provided 3 1 Bond stone to be provided every 0.5 m2 area Holes in brick masonry left for scaffolding should be filled with PCC 1:3:6

XV)

Quality Control XVI) Concrete Blocks A Density, Compressive Strength S.No Type

Grade

Density of Block (kg/m3)

Minimum Average Compressive Strength of Units (N/mm2) 3.5 4.5 5.5 7 2 3 5 1.5 5 4

1 Hollow Load Bearing Unit

A (3.5) A (4.5) A (5.5) A (7) B (2.0) B (3.0) B (5.0) 2 Hollow Non Load Bearing Unit C (1.5) 3 Solid Load Bearing Unit D(5.0) D(4.0) Water Absorbtion shall not be more than 10% by mass.

Not less than 1500 Not less than 1500 Not less than 1500 Not less than 1500 Not less than 1000 Not less than 1000 Not less than 1000 Not less than 1000 Not less than 1800

Minimum Average Compressive Strength of Individual Units (N/mm2) 2.8 2.6 4.4 5.6 1.6 2.4 4 1.2 4 3.2

XVII) Teak Wood 1 Average Moisture Content of all the samples from a lot shall be within +3% and moisture content of individual samples within +5% of maximum permissible moisture content XVIII) Plywood Moisture content shall not be less than 5% and not more than 15%. Plywoods to be tested as per IS 303

Вам также может понравиться

- Ebsm Upgrading Project Daily Report: 30 April 2013 29 April 2013 08.00-22.00Документ1 страницаEbsm Upgrading Project Daily Report: 30 April 2013 29 April 2013 08.00-22.00ebsmsartОценок пока нет

- 08 04 13 PDFДокумент1 страница08 04 13 PDFebsmsartОценок пока нет

- Dashboard: MT/PT Status Joints Status Welded Joints StatusДокумент1 страницаDashboard: MT/PT Status Joints Status Welded Joints StatusZaidiОценок пока нет

- Form RegisterДокумент12 страницForm RegisterCRISTIAN SILVIU IANUCОценок пока нет

- Weekly Report Proteksi Petir #Minggu - 05 (OKI Pulp & Paper Mills)Документ1 страницаWeekly Report Proteksi Petir #Minggu - 05 (OKI Pulp & Paper Mills)Kusnadi AnginОценок пока нет

- Monthly QCR ReportsДокумент58 страницMonthly QCR ReportsAshok Kumar KollaОценок пока нет

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesДокумент8 страницWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195Оценок пока нет

- Document ListДокумент28 страницDocument ListAmila PushpakumaraОценок пока нет

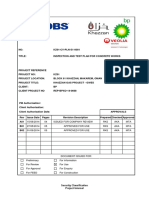

- 04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTAДокумент5 страниц04 Issued For Company Review RKS AKA MTA 05 Approved For Use RKS AKA MTA 05 Approved For Use RKS AKA MTAjay2kay5793Оценок пока нет

- Breakdown Price Piping, Instrument Metering-Subcont Rev-0Документ4 страницыBreakdown Price Piping, Instrument Metering-Subcont Rev-0yuwonoОценок пока нет

- 439-Fabrication Status Report-111Документ1 страница439-Fabrication Status Report-111Zain AbidiОценок пока нет

- 100 GPP GHX 00011 000 Crane and Lifting Operation ProcedureДокумент19 страниц100 GPP GHX 00011 000 Crane and Lifting Operation ProcedureNadia AfifahОценок пока нет

- Material Billing Rate SpreadsheetДокумент6 страницMaterial Billing Rate SpreadsheetmdalgamouniОценок пока нет

- CCK VNT DuplexДокумент4 страницыCCK VNT DuplexNikki RobertsОценок пока нет

- QAQC Presentation - GIS - DAYДокумент28 страницQAQC Presentation - GIS - DAYsrsureshrajanОценок пока нет

- Finishing Manpower Project Manpower Structure & Finishing Blockwork Masons Plastering Work Masons Blockwork Mason HelpersДокумент5 страницFinishing Manpower Project Manpower Structure & Finishing Blockwork Masons Plastering Work Masons Blockwork Mason HelpersshankarswaminathanОценок пока нет

- Plan of Piping 3 Week Plan PDFДокумент1 страницаPlan of Piping 3 Week Plan PDFebsmsartОценок пока нет

- 1.1 Welder Test 86,350,000: PackageДокумент2 страницы1.1 Welder Test 86,350,000: PackageAhmad Dzulfiqar RahmanОценок пока нет

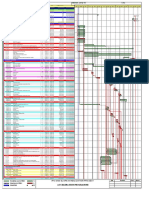

- 2 Months Lookahead Plan & Major Material RequirmentsДокумент110 страниц2 Months Lookahead Plan & Major Material RequirmentsshankarswaminathanОценок пока нет

- KKPE/PBHS/WPC11/GF021/Rev 01Документ6 страницKKPE/PBHS/WPC11/GF021/Rev 01collinОценок пока нет

- Fitup Progress Report - PipingДокумент447 страницFitup Progress Report - PipingTanver AliОценок пока нет

- Brief General Contract Data Work Progress Summary: Notice To Commence Extension of Time Revised Completion DateДокумент4 страницыBrief General Contract Data Work Progress Summary: Notice To Commence Extension of Time Revised Completion Datesidiq7Оценок пока нет

- Quotation Comparing AbhishekДокумент50 страницQuotation Comparing AbhishekAbhishek KumarОценок пока нет

- Bill ESSEM (TRV-II)Документ42 страницыBill ESSEM (TRV-II)sanjoybapiОценок пока нет

- 05-66 Webbing Sling 100mmx2m4tonДокумент1 страница05-66 Webbing Sling 100mmx2m4tontaufikzainОценок пока нет

- SMU - RFQ Register 15 Sep 2015Документ5 страницSMU - RFQ Register 15 Sep 2015asmuviqОценок пока нет

- 23.11 - Material I.R LogДокумент20 страниц23.11 - Material I.R LogsyedAtifОценок пока нет

- CON 311 V00 Method Statement For Structural Steel and Pipe Support Fabrication PDFДокумент22 страницыCON 311 V00 Method Statement For Structural Steel and Pipe Support Fabrication PDFfurkanОценок пока нет

- Concrete Flatwork Calculator: DateДокумент3 страницыConcrete Flatwork Calculator: DateSebastian GusetuОценок пока нет

- PO Monitoring Sheet Ver 1 31-03-08Документ225 страницPO Monitoring Sheet Ver 1 31-03-08api-3700469Оценок пока нет

- Aecon Construction Company CanadaДокумент22 страницыAecon Construction Company CanadaSrinivasa MurthyОценок пока нет

- Total Bid Amount P 13,747,562.21Документ2 страницыTotal Bid Amount P 13,747,562.21Alvin Dela CruzОценок пока нет

- J910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)Документ13 страницJ910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)rudi sarifudinОценок пока нет

- Doubledragon Center West Internal ScheduleДокумент20 страницDoubledragon Center West Internal SchedulejeromesdfurtoОценок пока нет

- Project Client Consultant Main Contractor MEP ContractorДокумент1 страницаProject Client Consultant Main Contractor MEP ContractorishtiyaqОценок пока нет

- 03 Fish Bone DiagramДокумент1 страница03 Fish Bone DiagramShannon MacDonaldОценок пока нет

- Ipo Dam Slope Stabilization Project Acceleration ProgrammeДокумент2 страницыIpo Dam Slope Stabilization Project Acceleration Programmeedla3710Оценок пока нет

- Uma Material ScheduleДокумент2 страницыUma Material ScheduleEmmanuel OtienoОценок пока нет

- Fabrication Daily ReportДокумент2 страницыFabrication Daily ReportlangcvОценок пока нет

- Agro-Industrial Group Aig Engineering DepartmentДокумент12 страницAgro-Industrial Group Aig Engineering DepartmentKiel CorpuzОценок пока нет

- Construction Baseline Book Development Time FrameДокумент4 страницыConstruction Baseline Book Development Time Framesohail2006Оценок пока нет

- Control Flow Diagram For Gacc'S New and Trained Welders: JCC IssuedДокумент1 страницаControl Flow Diagram For Gacc'S New and Trained Welders: JCC IssuedSiddiqui Abdul KhaliqОценок пока нет

- Standard QAPДокумент9 страницStandard QAPsivaОценок пока нет

- Project:-Rabab Harweel Power Plant & HRSG Project (Contract No.C311530)Документ7 страницProject:-Rabab Harweel Power Plant & HRSG Project (Contract No.C311530)Nadim JilaniОценок пока нет

- DWR Piping Indosol1Документ84 страницыDWR Piping Indosol1mizwarОценок пока нет

- Primavera P6 Manual EditedДокумент271 страницаPrimavera P6 Manual EditedCamille GОценок пока нет

- MTO For StructureДокумент2 страницыMTO For StructureRajnath Rajbhar PanchamОценок пока нет

- Dashboard C-1101 MR 2013 Fox HillsДокумент10 страницDashboard C-1101 MR 2013 Fox HillsrmdarisaОценок пока нет

- Project CurvesДокумент1 страницаProject CurvesakinsdОценок пока нет

- Gantry Setup: Step 1 - Setup Form Step 2 - Set Rebar Cage Step 3 - Pour SegmentДокумент1 страницаGantry Setup: Step 1 - Setup Form Step 2 - Set Rebar Cage Step 3 - Pour SegmentgfgfОценок пока нет

- Qualification RangeДокумент1 страницаQualification RangeSARSAN NDTОценок пока нет

- Cost Estimate Template ExcelДокумент12 страницCost Estimate Template Excelgopi piratiОценок пока нет

- Format-Welder Qualification Record (WQR)Документ1 страницаFormat-Welder Qualification Record (WQR)groshan20Оценок пока нет

- TOENEC Manpower Report (JTI) 2020Документ8 страницTOENEC Manpower Report (JTI) 2020mark lester caluzaОценок пока нет

- 01 40 00 - Quality RequirementsДокумент27 страниц01 40 00 - Quality RequirementsshauhramОценок пока нет

- Bending ProcedureДокумент1 страницаBending ProcedureabbasОценок пока нет

- Materials Engineering Review TablesДокумент8 страницMaterials Engineering Review Tablesxyza1234100% (1)

- TCVN 1451.1998 Solid Clay BricksДокумент3 страницыTCVN 1451.1998 Solid Clay BricksNgo Tien VinhОценок пока нет

- Maiti Fly Ash ConcreteДокумент19 страницMaiti Fly Ash ConcreteBilal Ahmed BarbhuiyaОценок пока нет

- FinalДокумент52 страницыFinalJessie Radaza Tutor100% (1)

- Volume of ConcreteДокумент4 страницыVolume of ConcreteAshok BasantaniОценок пока нет

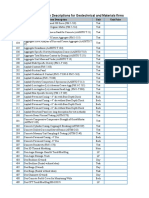

- Quality Control Check ListДокумент5 страницQuality Control Check ListSARANYAKRISHNAKUMAR0% (1)

- BBSДокумент2 страницыBBSSARANYAKRISHNAKUMARОценок пока нет

- Tender Conditions For Safety: Ref. No.: DBP/PROJ/GMS/13-14/TENDER/01Документ2 страницыTender Conditions For Safety: Ref. No.: DBP/PROJ/GMS/13-14/TENDER/01SARANYAKRISHNAKUMARОценок пока нет

- BBSДокумент2 страницыBBSSARANYAKRISHNAKUMARОценок пока нет

- Safety and Environment ManualДокумент12 страницSafety and Environment ManualSARANYAKRISHNAKUMARОценок пока нет

- Guidelines On Labour LawsДокумент29 страницGuidelines On Labour LawsSARANYAKRISHNAKUMARОценок пока нет

- Water Levels Forecast in Thailand: A Case Study of Chao Phraya RiverДокумент6 страницWater Levels Forecast in Thailand: A Case Study of Chao Phraya RiverErna UtamiОценок пока нет

- 7FA Upgrade Combustion HardwareДокумент2 страницы7FA Upgrade Combustion Hardwaresauerbach1Оценок пока нет

- Chapter One PDFДокумент74 страницыChapter One PDFAdelu BelleteОценок пока нет

- Business Analytics Data Analysis and Decision Making 6th Edition Albright Solutions ManualДокумент24 страницыBusiness Analytics Data Analysis and Decision Making 6th Edition Albright Solutions ManualAngelaLewisyqza100% (26)

- Angular AccuracyДокумент4 страницыAngular AccuracySwatilekha ChowdhuryОценок пока нет

- Data and Specifications: HMR Regulated MotorsДокумент21 страницаData and Specifications: HMR Regulated MotorsBeniamin KowollОценок пока нет

- RTL8139D DataSheetДокумент60 страницRTL8139D DataSheetRakesh NettemОценок пока нет

- SR-X Script Reference - EДокумент24 страницыSR-X Script Reference - EDomagoj ZagoracОценок пока нет

- Q2. Give An Example of Each A. Stochastic Model B. Continuous Model C. Discrete Model D. Static Model E. Dynamic ModelДокумент2 страницыQ2. Give An Example of Each A. Stochastic Model B. Continuous Model C. Discrete Model D. Static Model E. Dynamic Modelsheena RomОценок пока нет

- Learning MenuДокумент8 страницLearning Menuapi-464525668Оценок пока нет

- C191HM Powermeter and Harmonic Manager CommunicationsДокумент30 страницC191HM Powermeter and Harmonic Manager CommunicationsRoberto GarridoОценок пока нет

- Infinera Ds Isfp Timedivision Multiplexing ModulesДокумент3 страницыInfinera Ds Isfp Timedivision Multiplexing ModulesAnonymous bpf0OZSd9Оценок пока нет

- Air Movements 06-26-2019 - Full ScoreДокумент5 страницAir Movements 06-26-2019 - Full ScoreMichael CrawfordОценок пока нет

- Optimizing AOD Refractory PerformanceДокумент10 страницOptimizing AOD Refractory PerformanceJulio PurezaОценок пока нет

- K20 Engine Control Module X3 (Lt4) Document ID# 4739106Документ3 страницыK20 Engine Control Module X3 (Lt4) Document ID# 4739106Data TécnicaОценок пока нет

- Fiberlogic CarrierEthernet 842 5300 PresentationДокумент41 страницаFiberlogic CarrierEthernet 842 5300 PresentationDuong Thanh Lam0% (1)

- University of Cambridge International Examinations General Certificate of Education Advanced LevelДокумент4 страницыUniversity of Cambridge International Examinations General Certificate of Education Advanced LevelHubbak KhanОценок пока нет

- Introduction To Java Programming ReviewerДокумент90 страницIntroduction To Java Programming ReviewerJohn Ryan FranciscoОценок пока нет

- Fire Dynamic Damper Installation InstructionsДокумент18 страницFire Dynamic Damper Installation InstructionsJohnMerrОценок пока нет

- Satisfaction and Revisit Intentions at Fast Food RestaurantsДокумент12 страницSatisfaction and Revisit Intentions at Fast Food RestaurantsKunal LodhiОценок пока нет

- Ethoxy 1Документ77 страницEthoxy 1HoshiОценок пока нет

- Ways To Multiply and Divide: Maniratnam - The CashierДокумент17 страницWays To Multiply and Divide: Maniratnam - The CashierSundari MuruganОценок пока нет

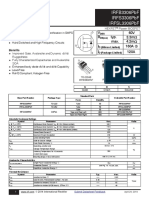

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120AДокумент12 страницIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligОценок пока нет

- Redox TitrationДокумент5 страницRedox TitrationchristinaОценок пока нет

- Relay Maintenance and Testing: BenefitsДокумент2 страницыRelay Maintenance and Testing: BenefitsojoladapoОценок пока нет

- Driver LCI 150W 500-850ma FlexC NF h28 EXC3 enДокумент7 страницDriver LCI 150W 500-850ma FlexC NF h28 EXC3 enMoustafa HelalyОценок пока нет

- Question IARДокумент4 страницыQuestion IARAryan jay vermaОценок пока нет

- Chapter 6 AssignmentДокумент6 страницChapter 6 AssignmentRohit RajeevОценок пока нет

- Entropy and The Second Law of Thermodynamics Disorder and The Unavailability of Energy 6Документ14 страницEntropy and The Second Law of Thermodynamics Disorder and The Unavailability of Energy 6HarishChoudharyОценок пока нет

- CSC:361-Software Engineering: Semester: Fall2020Документ39 страницCSC:361-Software Engineering: Semester: Fall2020hamsfayyazОценок пока нет