Академический Документы

Профессиональный Документы

Культура Документы

Chap02b.advanced Process Control PDF

Загружено:

Anthony PattersonИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chap02b.advanced Process Control PDF

Загружено:

Anthony PattersonАвторское право:

Доступные форматы

Advance Topics in Process Control CHE 522

CHAPTER 2 SISO Linear System Analysis

4. Analysis of first order systems A First order system is that whose output is modeled by a first order differential equation. (1) first order lag (self-regulating)

a0

dy + a1 y = bu (t ) dt

a 0 dy b + y = u (t ) a1 dt a1

dy + y = k p u (t ) dt kp = b a1

where

a0 ; a1

Taking Laplace transform with all variables are in deviation form we get: y(s) = kp s + 1 u (s)

The term, (time constant) and kp (static gain) characterize the first order system.

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

Time constant: characterize the speed of response of a first-order system. It is a measure of the time necessary for a process to adjust to a change in the input. Static gain: characterize the sensitivity of the output to the input signal. Dynamic response: The dynamic response for a step change in u of magnitude of a: u(s)=a/s y (t ) = k p a (1 e t / )

The transient response for step change is shown in Figure (2).

a kp a u(t) y(t)

0 Time Figure 1: Response of a first-order lag system to step change in the input

Dynamic characteristics: For a step change in the input, the process reaches a new steady state. The ultimate value of the output is kp a, which can be found from the last Equation by setting t � The time constant, can be found be setting t = in the last equation which gives y = 0.632 kp a. Then from Figure2, the time needed for y to reach 0.632 kp a is . The smaller the value of , the steeper is the initial response of the output. The larger static gain of a process, the larger steady state value of its output for the same input change.

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

y(t) kp1a kp2a kp2< kp1 0 Time kp1 kp2

y(t) kpa

1< 2 Time

Figure 2: Effect of static gain, time constant on the response of first-order lag system

(2) Pure capacitive system (integrator)

a0 dy = bu (t ) dt

Example: Liquid storage tank with fixed outlet flow

&(t ) = F (t ) F Ah i

h( s ) =

1 1 Fi ( s ) F; � As As

kp s u (s)

kp 1/A

y(s) =

Dynamic response: For a step change in u of magnitude of a: u(s) = a/s

y ( s) = k pa s2

which have the following time response:

y (t ) = k p at

The transient response looks like this:

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

u(t)

y(t) kp a 0 Time Figure 3: Response of an integrator first-order system to a step change

Apparently, the ultimate value for the output is not achievable, y � as t � . A pure capacitive process causes serious control problem because it can not balance itself. For small change in the input, the output grows continuously. This attribute knows as non-self-regulating (integrator) process.

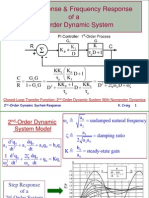

5. Analysis of second order system

A second order system is that whose output is modeled by a second order differential equation.

a0 d2y dt 2 + a1 dy + a 2 y = bu (t ) dt

a0 d 2 y a1 dy b + + y = u (t ) a 2 dt 2 a 2 dt a2

d2y dt

2

+ 2

dy + y = k p u (t ) dt

kp u (s)

y( s) =

2 s 2 + 2s + 1

= natural period of oscillation (characteristic time constant)

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

kp

= damping ratio = static gain

Sources of second order dynamics in the chemical industries come from a series of first-order systems, or a processing system with a controller.

Dynamic response: For input step change of magnitude of a, u(s) = a/s we have:

y(s) = k pa s ( 2 s 2 + 2s + 1) k p a / 2 s ( s p1 )( s p 2 )

where

2 1 p1 = +

2 1 p1 =

Case A: (over-damped) when > 1, we have two distinct and real poles

t t t / 2 2 cosh( 1 ) + sinh( 1 ) y (t ) = k p a 1 e 2 1

Case B: (critically-damped) when = 1, we have two equal poles

t y (t ) = k p a 1 1 + e t /

Case C: (under-damped) when < 1, we have two complex conjugate poles

1 y (t ) = k p a 1 e t / sin( wt + ) 2 1

The dynamic response for all cases is shown in Figure (4)

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

u(t)

<1

=1

y(t)

>1

Time

Figure 4: The response of second order system to step change

The over-damped response is sluggish and resembles a little the response of a first-order system. IT becomes more sluggish with larger values of . The critically damped response is faster than the over-damped one. The under-damped response is faster than the others, but oscillates. The oscillatory behavior becomes pronounced with smaller values .

Characteristics of under-damped system Overshoot, A/B A / B = exp 1 2 Decay ratio, C/A 2 C / A = exp 1 2 Period of oscillation

1 2 = radian frequency =

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

T = period of oscillation =

2 1 2

Rise time, tr: is the time the output takes to first reach the new steady state value Process time, tp: is the time required for the output to reach its first peak. Settling time, ts: is the time required for the output to reach within 5% of the new steady state value.

ts Time Figure 5: characteristics of second-order under-damped response

tr

tp

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

6. Delay time

The delay time known as transportation time is basically the time required for a material to move a specific distant. However, time delay is an inherent property of any chemical process.

G ( s ) = e s

u(t) y(t)

delay time

Sources: The use of chromatography to measure composition of liquids or gases is another source of dead time. Flow in a long pipe. Time lag produced from staged processes. Therefore, a first-order system with dead-time is:

Ke s G ( s) = 1s + 1

Therefore, a second-order system with dead-time is:

G ( s) = Ke s s 2 + 2s + 1

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

7. Approximation of higher order systems

Systems with order higher than one can be represented by:

G ( s ) = Gi ( s ) =

i =1 n

( i s + 1)

i =1

It can be approximated by low order transfer function with dead time as follows:

Ke s G ( s) = 1s + 1

where 1 is the dominant time constant and the dead time is:

= i

i=2

8. Transfer function and Block diagram Transfer function relates the process input to the process output in a linear mathematical function. Therefore, Transfer Function: is the Laplace transform of the output, y(s) divided by the Laplace transform of the process input, u(s), with all initial conditions are zero (deviation form)

G( s) =

y(s) u ( s)

Example: For the storage tank we have:

h( s ) K = G p ( s ) ; with = AR, K = 1/R F ( s ) s + 1

Example: For the heated tank we have:

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

10

T ( s) K = G p ( s) ; Q( s) s + 1

with = V/F, K = 1/FCp

Example: For the CSTR we have:

C A (s) K = G p ( s ) ; with = V/(F+Vk), K = F/(F+Vk) C Ai ( s ) s + 1

8.1 Properties of Transfer Function

Order: The order of the system is the highest derivative of the output variable in the defining differential equation. For Transfer Function, it is the highest power of s in the denominator. Pole: is the root of the denominator of the transfer function, i.e. the root of the characteristic polynomial. It directly determines: The stability of the system (positive poles) The potential of periodic transient (imaginary poles) Zero: is the root of the numerator of the transfer function. It determines an inverse response (positive zero). Casuality: A physical system is causal when the order of the denominator is greater than the numerator, and when the transfer function goes to 0 as s � , the system is hence strictly proper. If the transfer function contains es or the order of numerator is higher than the denominator, then the system is non-casual or not realizable because the current values of the system depends on the future values of the variables. Steady state gain: is the steady state value of the transfer function, is evaluated by setting s = 0 in the stable transfer function.

8.2 Effect of poles and zeros The poles and zeros of a transfer function affect the dynamic of a process. Consider a particular transfer function:

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

11

G(s) =

K s(1 s + 1)( s + 2s + 1)

2 2

The poles, i.e. the roots of the characteristic equation are:

s1 = 0

s2 =

1 1

1 2 s3 = + j 2 2

s4 = 1 2 j 2 2

The poles can be represented in the complex plane as follows:

imaginary axis X

+

1 2 2

2

X

X 1 1

Real axis

1 2 2

Figure 6: roots of the characteristic equation of G(s)

Complex poles indicate the response will contain sine and cosine modes, i.e. will exhibit oscillation. Negative poles will result in a stable decaying response.

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

12

Positive poles indicate that the response will have unstable mode.

The transfer function can be written as follows:

G (s) = bm ( s z1 )( s z 2 ) L ( s z m ) a n ( s p1 )( s p 2 ) L ( s p n )

Positive zero leads to inverse response. Zero-pole cancellation occurs when a zero has exactly the same numerical value as a pole. A zero can exert a profound effect on the coefficient of response mode.

8.3 Block diagrams Block diagram is a graphical representation of transfer functions and their interactions. Block diagram assist the engineer in determining the quantitative aspects of dynamic performance and in understanding the qualitative features of the system.

y(s)= G(s)u(s)

u(s)

y(s)=A+B

G(s)

y(s)

+ +

y(s)

B

y(s)=G1(s)G2(s)u(s)

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

13

u(s)

G1(s)

G2(s)

y(s)

y(s)=G1(s)A G2(s)B

A B

G1(s) G2(s)

+ _

y(s)

y(s) = G1(s)(AB)

A B

+ _

G1(s)

y(s)

8.4 Input-output relation Direct action: an increase in the input lead to an increase in the output.

I/I

Reverse action: an increase in the input lead to a decrease in the output.

I/D

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

14

Fi h F

Fi h F

A series of I/I blocks always result in I/I action:

I/I

I/I

An odd series of I/D blocks results in I/D action:

I/I

I/D

An Even series of I/D blocks results in I/I action:

I/D

I/D

Chemical Engineering Department King Saud University, 2003

Advance Topics in Process Control CHE 522

15

It is important that the overall system has an I/D action (negative feedback), therefore, the controller action must be adjusted such that the overall action of the closed-loop be I/D or reveres action. Alternatively:

k c k p = + ve

Chemical Engineering Department King Saud University, 2003

Вам также может понравиться

- Class20 (Second Order)Документ11 страницClass20 (Second Order)Audrey Patrick KallaОценок пока нет

- 10 1 1 623 275 PDFДокумент28 страниц10 1 1 623 275 PDFDamir MiletaОценок пока нет

- Dynamic Behavior of More General SystemsДокумент32 страницыDynamic Behavior of More General Systemsjasonbkyle9108Оценок пока нет

- 7 Dynamics Tutorial AnsДокумент20 страниц7 Dynamics Tutorial AnsselmanОценок пока нет

- HVVHVДокумент28 страницHVVHVফারহান আহমেদ আবীরОценок пока нет

- Empirical Models PDFДокумент11 страницEmpirical Models PDFAhmed HummerОценок пока нет

- Experiment E. Liquid Level Control Using Coupled TanksДокумент29 страницExperiment E. Liquid Level Control Using Coupled Tanks파랑Оценок пока нет

- Sinusoidal Response.: S A S XДокумент15 страницSinusoidal Response.: S A S XManidhar ThulaОценок пока нет

- 6-Dynamics Worked ExamplesДокумент7 страниц6-Dynamics Worked ExamplesselmanОценок пока нет

- Note 5 Time Response: Lecture Notes of Control Systems I - ME 431/analysis and Synthesis of Linear Control System - ME862Документ10 страницNote 5 Time Response: Lecture Notes of Control Systems I - ME 431/analysis and Synthesis of Linear Control System - ME862Dhinesh PeriyasamyОценок пока нет

- Dynamic Behavior of First - Second Order SystemsДокумент19 страницDynamic Behavior of First - Second Order SystemsCuong TranОценок пока нет

- Z TransformДокумент22 страницыZ Transformvignanaraj100% (1)

- Dynamic Response of Complex ProcessesДокумент19 страницDynamic Response of Complex ProcessesGiancarloErrigoОценок пока нет

- 09 1st and 2nd Order Approximations PDFДокумент9 страниц09 1st and 2nd Order Approximations PDFErgys LikaОценок пока нет

- 09 1st and 2nd Order ApproximationsДокумент9 страниц09 1st and 2nd Order ApproximationsSudheerKumarОценок пока нет

- Experiment - 2a: First Order DynamicsДокумент9 страницExperiment - 2a: First Order DynamicsSisay AmareОценок пока нет

- Transient & Steady State Response AnalysisДокумент46 страницTransient & Steady State Response AnalysisSwati AgarwalОценок пока нет

- Identification and Estimation (Empirical Models) : D T U G T yДокумент11 страницIdentification and Estimation (Empirical Models) : D T U G T yAnonymous JDXbBDBОценок пока нет

- Modelling Second Order Systems and Examples: CL-417 Process Control Prof. Kannan M. MoudgalyaДокумент29 страницModelling Second Order Systems and Examples: CL-417 Process Control Prof. Kannan M. MoudgalyaVivekОценок пока нет

- Z TransformДокумент22 страницыZ TransformcivaasОценок пока нет

- Chapter 5 - Dynamic Behavior of First-Order and Second-Order ProcessesДокумент44 страницыChapter 5 - Dynamic Behavior of First-Order and Second-Order ProcessesFakhrulShahrilEzanieОценок пока нет

- Zero DynamicsДокумент27 страницZero DynamicsManash Protim DeoriОценок пока нет

- 4 Microsoft Word - L-12 - SS - IA - C - EE - NPTELДокумент10 страниц4 Microsoft Word - L-12 - SS - IA - C - EE - NPTELRicky RawОценок пока нет

- T2Документ3 страницыT2Kiran Jot SinghОценок пока нет

- Ziegler-Nichols Controller Tuning ExampleДокумент6 страницZiegler-Nichols Controller Tuning ExampleChristine AvdikouОценок пока нет

- Systems and Control PDFДокумент9 страницSystems and Control PDFHamid Farhan0% (1)

- Sheet 4 PDFДокумент53 страницыSheet 4 PDFxtito2Оценок пока нет

- Control System Manual 1 To 5Документ23 страницыControl System Manual 1 To 5Eashan PendseОценок пока нет

- Ae Lab ManualДокумент52 страницыAe Lab ManualaryakalekattuОценок пока нет

- Time Respons: Dasar Sistem KontrolДокумент13 страницTime Respons: Dasar Sistem KontrolitmyОценок пока нет

- Notes LT3Документ12 страницNotes LT3veteron56Оценок пока нет

- Chapter 5Документ20 страницChapter 5Ana PereiraОценок пока нет

- Chapter 1 IntroductionДокумент32 страницыChapter 1 IntroductionYucheng XiangОценок пока нет

- Chapter 2.2 Response Ist Order SystemsДокумент30 страницChapter 2.2 Response Ist Order SystemsSyed AliОценок пока нет

- Second-Order Dynamic Systems KCC 2011Документ39 страницSecond-Order Dynamic Systems KCC 2011Naguib NurОценок пока нет

- Chapter 4Документ28 страницChapter 4Kelvin CyhОценок пока нет

- ME 475 Mechatronics: Semester: February 2015Документ15 страницME 475 Mechatronics: Semester: February 2015ফারহান আহমেদ আবীরОценок пока нет

- Control Systems Unit-2 Time Response Analysis: Ms. P. Geethanjali Asst. Professor (SR) SelectДокумент157 страницControl Systems Unit-2 Time Response Analysis: Ms. P. Geethanjali Asst. Professor (SR) SelectVijay IndukuriОценок пока нет

- Process ControlДокумент55 страницProcess ControlUmair IqbalОценок пока нет

- Mathematical Madeling and Block DiagramaaДокумент93 страницыMathematical Madeling and Block Diagramaaabdul.azeezОценок пока нет

- Lect Note 1 IntroДокумент28 страницLect Note 1 IntroJie RongОценок пока нет

- (Subjective) EE211 Linear Control Systems - Mid Term Question-1Документ14 страниц(Subjective) EE211 Linear Control Systems - Mid Term Question-1Ayush BhattОценок пока нет

- 8-Test Input Signal Transient and Steady-State Response of 1st Abd 2nd Order SystemsДокумент32 страницы8-Test Input Signal Transient and Steady-State Response of 1st Abd 2nd Order SystemsAzhar AliОценок пока нет

- Exp 2 - I and II Order ProcessДокумент4 страницыExp 2 - I and II Order ProcessErmias NigussieОценок пока нет

- Process Dynamics and Control, Ch. 8 Solution ManualДокумент12 страницProcess Dynamics and Control, Ch. 8 Solution ManualBen SpearmanОценок пока нет

- Chemical Kinetics1Документ59 страницChemical Kinetics1farooq_bagbanОценок пока нет

- L2 - Modelling SystemsДокумент21 страницаL2 - Modelling SystemsOmer AhmedОценок пока нет

- G K S S: Che381 Process Dynamics & Control Jan-Apr 2014 End-Semester Exam 3 Hours 100 PointsДокумент4 страницыG K S S: Che381 Process Dynamics & Control Jan-Apr 2014 End-Semester Exam 3 Hours 100 PointsSushmitaОценок пока нет

- ME361 System PDFДокумент7 страницME361 System PDFAnonymous DuEhOZОценок пока нет

- 1 Lab Manual-Final-Control-System-1Документ35 страниц1 Lab Manual-Final-Control-System-1Shimalis RetaОценок пока нет

- Experiment No: 2 Determine The Step Response of First Order and Second Order System and Obtain Their Transfer FunctionДокумент11 страницExperiment No: 2 Determine The Step Response of First Order and Second Order System and Obtain Their Transfer FunctionYAKALA RAVIKUMARОценок пока нет

- 6 - Time Response Analysis 2Документ21 страница6 - Time Response Analysis 2حساب ويندوزОценок пока нет

- Chapter 4Документ39 страницChapter 4Joseph IbrahimОценок пока нет

- Lecture - 6: Transient ResponseДокумент19 страницLecture - 6: Transient ResponseSakib RushdiОценок пока нет

- hw2 SolДокумент11 страницhw2 SolSaied Aly SalamahОценок пока нет

- Signals & SystemsДокумент48 страницSignals & SystemsailamrudhulaОценок пока нет

- Green's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)От EverandGreen's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)Оценок пока нет

- The Spectral Theory of Toeplitz Operators. (AM-99), Volume 99От EverandThe Spectral Theory of Toeplitz Operators. (AM-99), Volume 99Оценок пока нет

- Seborg Chapter 1Документ3 страницыSeborg Chapter 1maykesguerraОценок пока нет

- NMEAДокумент38 страницNMEADavidОценок пока нет

- Omnibus Risk EstimatorДокумент6 страницOmnibus Risk EstimatorConta do CerberusОценок пока нет

- La 3391p Rev0.3novo DesbloqueadoДокумент48 страницLa 3391p Rev0.3novo DesbloqueadoRogeriotabiraОценок пока нет

- LC08 L1TP 120065 20180318 20180403 01 T1 MTLДокумент4 страницыLC08 L1TP 120065 20180318 20180403 01 T1 MTLrendy aswinОценок пока нет

- Chapter 11Документ53 страницыChapter 11Vijendhar ReddyОценок пока нет

- Fiat Barchetta: EngineДокумент20 страницFiat Barchetta: EngineHallex OliveiraОценок пока нет

- HCS2000Документ6 страницHCS2000Nermin PalićОценок пока нет

- Nut & Bolt ScienceДокумент3 страницыNut & Bolt SciencetanujaayerОценок пока нет

- 4.uses of Metals - 1-32 For StudentsДокумент13 страниц4.uses of Metals - 1-32 For StudentsnergisalihpasaogluОценок пока нет

- Unit 1Документ29 страницUnit 1Biswajit MishraОценок пока нет

- CDB Aia - Data Integration - Internship - Detailed HandbookДокумент3 страницыCDB Aia - Data Integration - Internship - Detailed HandbookRama KrishnanОценок пока нет

- Concrete Mix DesignДокумент11 страницConcrete Mix DesignV Vinoth Edac100% (1)

- Fourier Transform: MATHS (Hons), Second YEARДокумент120 страницFourier Transform: MATHS (Hons), Second YEARmanish chauhanОценок пока нет

- Cayenne 5Документ17 страницCayenne 5Marcelo AndradeОценок пока нет

- An Isogeometric Analysis Approach For The Study of Structural VibrationsДокумент59 страницAn Isogeometric Analysis Approach For The Study of Structural VibrationsBharti SinghОценок пока нет

- Whinner y 1990Документ5 страницWhinner y 1990LGОценок пока нет

- Piaggio X8 250 I.E. (EN)Документ289 страницPiaggio X8 250 I.E. (EN)Manualles100% (8)

- Wood Conserving StovesДокумент117 страницWood Conserving Stovesalitoparana100% (1)

- Battery SubsystemДокумент7 страницBattery SubsystemahmaborashedОценок пока нет

- Pre-Assessment Form Problem Solving Techniques (2 Day Course)Документ1 страницаPre-Assessment Form Problem Solving Techniques (2 Day Course)sumit1975Оценок пока нет

- Kou2003 PDFДокумент6 страницKou2003 PDFGe EffgenОценок пока нет

- Rsa Netwitness Logs and Packets: Server, Dac and San HW SpecificationsДокумент10 страницRsa Netwitness Logs and Packets: Server, Dac and San HW SpecificationsfunyiroemberОценок пока нет

- Ordered Groups and Infinite Permutation Groups PDFДокумент252 страницыOrdered Groups and Infinite Permutation Groups PDFmc180401877Оценок пока нет

- 04 Extended Graphics DesignДокумент34 страницы04 Extended Graphics DesignEngenheiro AmoedoОценок пока нет

- FPM 2004Документ257 страницFPM 2004Srikant SuruОценок пока нет

- Proportional Directional Valves: Series LVS08 and LVS12 - Preferred Products ProgrammeДокумент66 страницProportional Directional Valves: Series LVS08 and LVS12 - Preferred Products ProgrammealeksandrОценок пока нет

- 8051 Serial CommunicationДокумент35 страниц8051 Serial CommunicationSanthosh CricketОценок пока нет

- Regression Analysis AssignmentДокумент8 страницRegression Analysis Assignmentضیاء گل مروت100% (1)

- Cost Center Budget Availability Control - S - 4 HANA 1909Документ24 страницыCost Center Budget Availability Control - S - 4 HANA 1909sekhar dattaОценок пока нет