Академический Документы

Профессиональный Документы

Культура Документы

Spray-Type Deaerating Heaters: TABLE 12.2

Загружено:

Yanuar KrisnahadiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Spray-Type Deaerating Heaters: TABLE 12.2

Загружено:

Yanuar KrisnahadiАвторское право:

Доступные форматы

Spray-Type Deaerating Heaters Spray-type deaerating heaters work on the same general philosophy as the tray-type, but differ

in their operation. Spring-loaded nozzles located in the top of the unit spray the water into a steam atmosphere that heats it. Simply stated, the steam heats the water, and at the elevated temperature the solubility of oxygen is extremely low and most of the dissolved gases are removed from the system by venting. The spray will reduce the dissolved oxygen content to 20-50 ppb, while the scrubber or trays further reduce the oxygen content to approximately 7 ppb or less. During normal operation, the vent valve must be open to maintain a continuous plume of vented vapors and steam at least 18 inches long. If this valve is throttled too much, air and nonconclensable gases will accumulate in the deaerator. This is known as air blanketing and can be remedied by increasing the vent rate. For optimum oxygen removal, the water in the storage section must be heated to within 5 F of the temperature of the steam at saturation conditions. From inlet to outlet, the water is deaerated in less than 10 seconds. Storage Section The storage section is usually designed to hold enough water for 10 minutes of boiler operation at full load. Limitations Inlet water should be virtually free of suspended solids that could clog spray valves and ports of the inlet distributor and the deaerator trays. In addition, spray valves, ports and deaerator trays may become plugged with scale that forms when the water being deaerated has high hardness and alkalinity levels. In this case, routine cleaning and inspection of the deaerator is very important.

TABLE 12.2 Deaerating Heater Troubleshooting Guide

Symptom Excessive oxygen content in deaerator effluent

Remedy 1. Insufficient venting-increase vent rate by opening the manually operated air vent valve. 2. Check steam pressure reducing valve for improper operation and hookup. Check valve for free operation, and see that control line is connected to the connection provided in the deaerator and not to the piping downstream of the valve. 3. Check water and, if possible, steam flow rates vs. design. Trays or scrubber and inlet valves are designed for specific flow ranges.

Temperature in storage tank does not correspond within 5 F of saturation temperature of the steam

1. Improper spray from spray nozzle. Check nozzle for sediment or deposit on seat or broken spring. 2. Excessive free air due to leaking stuffing boxes on pumps upstream of deaerator that have negative suction head. Repair stuffing box or seal with deaerated water.

Excessive consumption of oxygen scavenger

1. Trays collapsed-possibly from interrupted steam supply or sudden supply of cold water causing a vacuum. 2. Condensate may be too hot. Water entering the deaerating heater must usually be cooled if the temperature is within 20 F of saturation temperature of the steam. Check the design specification to determine what inlet water temperature was originally intended.

High or low water level

1. Improper operation of inlet control valve. Adjust as necessary. 2. Check faulty operation of steam pressure reducing valve.

3. Check relief valves on the deaerator and in the main steam supply system for proper operation. Low pressure 1. Check for improper operation of steam pressure reducing valve.

Rule of Thumb The temperature of the bulk water in the storage section should be at least 2 F for each I psig of the steam supply, up to 30 psig. Example 5 psig steam 2F x 5 = 10F Mimimum bulk water temperature 10 psig steam 2F x 10 = 20F Minimum bulk water temperature Saturation temperature = 227 F 212F + 10F = 222F 222 F Saturation temperature = 240F 212 F + 20 F = 232 F 232 F

Вам также может понравиться

- Mep Hvac 3Документ133 страницыMep Hvac 3Muhammad Musa100% (1)

- Rolling Element Bearing Failure AnalysisДокумент4 страницыRolling Element Bearing Failure AnalysisYanuar KrisnahadiОценок пока нет

- ASHRAE Psychrometric ChartДокумент1 страницаASHRAE Psychrometric ChartKenneth Dale San JuanОценок пока нет

- Cap Screws: Sae J429 Grade IdentificationДокумент6 страницCap Screws: Sae J429 Grade IdentificationHomer SilvaОценок пока нет

- Fluid Mechanics and Hydraullic Machines Lab ManualДокумент43 страницыFluid Mechanics and Hydraullic Machines Lab Manualm udaya kumarОценок пока нет

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsДокумент26 страницWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraОценок пока нет

- Air Driven EngineДокумент19 страницAir Driven EngineVivek PatilОценок пока нет

- Bearing SelectionДокумент6 страницBearing SelectiondaryonoОценок пока нет

- Chapter Three DesignДокумент20 страницChapter Three DesignADEFRIS BELACHEWОценок пока нет

- Sensor Devices Mechanical SensorsДокумент41 страницаSensor Devices Mechanical Sensorsdesaivilas60100% (1)

- Heatload Calculation - Kirloskar Ferrous - UPS RoomДокумент6 страницHeatload Calculation - Kirloskar Ferrous - UPS Roomsenthil kumarОценок пока нет

- PLCДокумент19 страницPLCassaultquirasОценок пока нет

- Basic Control Valve Sizing and SelectionДокумент38 страницBasic Control Valve Sizing and SelectionmohamedОценок пока нет

- Process Equipment Design-1Документ15 страницProcess Equipment Design-1Nikunj Thummar100% (1)

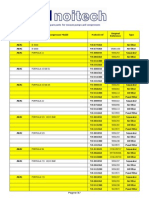

- NoitechДокумент265 страницNoitechbinhleduc36Оценок пока нет

- 722222-CD-000-PIP-MTO-001 - Piping, Fitting, Flange, Gasket, Bolt - Nut - RA (Aboveground)Документ16 страниц722222-CD-000-PIP-MTO-001 - Piping, Fitting, Flange, Gasket, Bolt - Nut - RA (Aboveground)rianafrian2611Оценок пока нет

- Paint For PipeДокумент12 страницPaint For PipeuzairmetallurgistОценок пока нет

- VFD Panels and SCCR: Short-Circuit Current Rating (SCCR) Is A Number You Need To HeedДокумент5 страницVFD Panels and SCCR: Short-Circuit Current Rating (SCCR) Is A Number You Need To HeedelengineerОценок пока нет

- Piping Plans Poster - Flex - A - Seal PDFДокумент1 страницаPiping Plans Poster - Flex - A - Seal PDFAnatoli KarpobОценок пока нет

- Volume CalcДокумент6 страницVolume CalcNikhil Ashok Badgu100% (1)

- Main Pivot Pin Dia CalculationДокумент2 страницыMain Pivot Pin Dia Calculationjdutia83100% (1)

- Welcome To The Bill Pentz Cyclone Design Spreadsheet.: 0 No 1 YesДокумент10 страницWelcome To The Bill Pentz Cyclone Design Spreadsheet.: 0 No 1 YesMarcelo MoraisОценок пока нет

- Technological Institute of The PhilippinesДокумент25 страницTechnological Institute of The PhilippinesJohn Leonard FazОценок пока нет

- Time To Empty Out Vessel No Dished EndsДокумент2 страницыTime To Empty Out Vessel No Dished EndsHeiner PalaciosОценок пока нет

- Air Blower Haya Water VerfДокумент9 страницAir Blower Haya Water Verfgharsallah mounaОценок пока нет

- Length Power Dynamic Viscosity Heat FluxДокумент9 страницLength Power Dynamic Viscosity Heat FluxAnubhav KhandelwalОценок пока нет

- Taco Air SeparatorДокумент12 страницTaco Air Separatoremongclooney11Оценок пока нет

- Teaching PLC Chap3Документ39 страницTeaching PLC Chap3bhagirath kansaraОценок пока нет

- Fault Finding Flowchart For Landis & GyrДокумент2 страницыFault Finding Flowchart For Landis & GyrNiel Uys100% (1)

- Chap 15 CLX Math, Comparison, and Move InstructionsДокумент20 страницChap 15 CLX Math, Comparison, and Move Instructionsjameesng69Оценок пока нет

- WL705 Ultrasonic Water Level SensorДокумент1 страницаWL705 Ultrasonic Water Level SensorEdward YaoОценок пока нет

- 2 Caterpillar Drive ChainДокумент1 страница2 Caterpillar Drive ChainFernando Mendoza0% (1)

- Pivot PinДокумент1 страницаPivot Pinsourajpatel001100% (1)

- Lecture 5 - Power SuppliesДокумент48 страницLecture 5 - Power SuppliesNimsiri AbhayasingheОценок пока нет

- Young's ModulusДокумент7 страницYoung's ModulusNgatno100% (1)

- Solar PV Balance of SystemДокумент24 страницыSolar PV Balance of SystemKishore Krishna50% (2)

- Evaporative Cooler CalculatorДокумент1 страницаEvaporative Cooler CalculatorLeandro FelipeОценок пока нет

- Preconstruction MeetingДокумент32 страницыPreconstruction MeetingMar OlacsОценок пока нет

- Pneumatic Control Valve Sizing GuideДокумент1 страницаPneumatic Control Valve Sizing GuideJOSE MARTIN MORA RIVEROSОценок пока нет

- F-03 Self-cleaningFiltersManual & AutomaticAIRPELДокумент4 страницыF-03 Self-cleaningFiltersManual & AutomaticAIRPELdevang asher100% (1)

- Introduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. SpencerДокумент26 страницIntroduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. SpencerKunal PandeyОценок пока нет

- Psychrometry. Heat Recovery Air Handling Unit (Ahu) - by Ömer Faruk DДокумент13 страницPsychrometry. Heat Recovery Air Handling Unit (Ahu) - by Ömer Faruk DKarl WeierstrassОценок пока нет

- Overview of Ventilation CalculationДокумент47 страницOverview of Ventilation CalculationDixter CabangОценок пока нет

- Improvement of Gas Turbine Performance TestДокумент4 страницыImprovement of Gas Turbine Performance TestKrishna VenkataramanОценок пока нет

- L9 Fastening SystemДокумент6 страницL9 Fastening Systemcontact@coreeslОценок пока нет

- Centrifugal Pump Temperature Rise CalculationДокумент1 страницаCentrifugal Pump Temperature Rise CalculationJohn PacelloОценок пока нет

- 5-50t Electric Hook Overhead CraneДокумент28 страниц5-50t Electric Hook Overhead Cranemohamed100% (1)

- Tube Temperature Distribution in Water Tube Boiler - A - 2 PDFДокумент14 страницTube Temperature Distribution in Water Tube Boiler - A - 2 PDFYanuar KrisnahadiОценок пока нет

- Document'S Code Attachment 10.3 Revision 0: ClientДокумент4 страницыDocument'S Code Attachment 10.3 Revision 0: ClientrfriosEP100% (1)

- Project Engineering of Process Plants PDFДокумент364 страницыProject Engineering of Process Plants PDFJoão Carlos Protz Protz58% (12)

- Rules of Thumb For Pumps 2-7: Pump BasicsДокумент5 страницRules of Thumb For Pumps 2-7: Pump BasicsYinka AkinkunmiОценок пока нет

- Burner DatasheetДокумент6 страницBurner DatasheetHafiz Muhammad AbubakarОценок пока нет

- Properties of Liquid Operating Conditions Per Pump SEAL SELECTION (To Be Furnished by Seal Vendor)Документ1 страницаProperties of Liquid Operating Conditions Per Pump SEAL SELECTION (To Be Furnished by Seal Vendor)mahesh_eilОценок пока нет

- Design and Implementation of Liquid Level Detector Using Ultrasonic SensorДокумент6 страницDesign and Implementation of Liquid Level Detector Using Ultrasonic SensorInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Pump NPSH CalculationДокумент18 страницPump NPSH CalculationDarwinОценок пока нет

- Application of DryingДокумент31 страницаApplication of Dryinguzzal ahmedОценок пока нет

- SCFM Vs ACFM Conversion Guide PDFДокумент16 страницSCFM Vs ACFM Conversion Guide PDFasteriskinОценок пока нет

- Catalogo Geral 2013 SchneiderДокумент216 страницCatalogo Geral 2013 SchneiderGersel RodriguesОценок пока нет

- Fume Exhaust Duct Catalog 10 12 8 PDFДокумент86 страницFume Exhaust Duct Catalog 10 12 8 PDFJonathan Arboleda GenesОценок пока нет

- Knife Gate Valve Selection Guide 10.00 15Документ6 страницKnife Gate Valve Selection Guide 10.00 15dsyashankaОценок пока нет

- Chibro Press Fit Piping Data SheetДокумент5 страницChibro Press Fit Piping Data SheetBoyd JohnstonОценок пока нет

- Dayamas Rotational Molded PE Tank Brochures-09Документ4 страницыDayamas Rotational Molded PE Tank Brochures-09Amoolia Ngo0% (1)

- Meta MEC Adjustable MCCBДокумент16 страницMeta MEC Adjustable MCCBECATOnlineОценок пока нет

- Inquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteДокумент5 страницInquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteCik MinnОценок пока нет

- Design-Iv: Machinery and Electrical System Technical Spesification of Bilge SystemДокумент44 страницыDesign-Iv: Machinery and Electrical System Technical Spesification of Bilge SystemMohammad Ibnu SabilillahОценок пока нет

- Ccs CatalogДокумент35 страницCcs CatalogRicardo Betancourt MaldonadoОценок пока нет

- Schneider GV2 Motor Circuit BreakerДокумент19 страницSchneider GV2 Motor Circuit BreakercatalinccОценок пока нет

- Materials Handling and HoistingДокумент6 страницMaterials Handling and HoistingNARGISОценок пока нет

- Chiller Types and Application Guide - The Engineering MindsetДокумент7 страницChiller Types and Application Guide - The Engineering MindsetFaizanKhanОценок пока нет

- SAE Steel Grades: Steels and Other Iron-Carbon Alloy PhasesДокумент10 страницSAE Steel Grades: Steels and Other Iron-Carbon Alloy PhasesCalcgen EngineeringОценок пока нет

- Spray-Type Deaerating HeatersДокумент1 страницаSpray-Type Deaerating HeatersPSK2014Оценок пока нет

- Identification of A Shaft Thermal Bow by Means of Model-Based Diagnostic TechniquesДокумент11 страницIdentification of A Shaft Thermal Bow by Means of Model-Based Diagnostic TechniquesYanuar KrisnahadiОценок пока нет

- Lubricants 03 00027 PDFДокумент27 страницLubricants 03 00027 PDFYanuar KrisnahadiОценок пока нет

- Solving The Vibration Problem of A Vertical Multistage Cryogenic PumpДокумент11 страницSolving The Vibration Problem of A Vertical Multistage Cryogenic PumpYanuar KrisnahadiОценок пока нет

- 1 s2.0 S2215098616304815 Main PDFДокумент12 страниц1 s2.0 S2215098616304815 Main PDFYanuar KrisnahadiОценок пока нет

- Improvement of Steam Boiler Plant Efficiency Based On Results of On-Line Performance MonitoringДокумент5 страницImprovement of Steam Boiler Plant Efficiency Based On Results of On-Line Performance MonitoringYanuar KrisnahadiОценок пока нет

- 13 Weibull DistributionДокумент6 страниц13 Weibull DistributionRashika AggarwalОценок пока нет

- Online TextbookДокумент6 страницOnline TextbookYanuar KrisnahadiОценок пока нет

- Deaerator Inspection/Condition Assessment Brief DescriptionДокумент3 страницыDeaerator Inspection/Condition Assessment Brief DescriptionYanuar KrisnahadiОценок пока нет

- HIS KIT Includes THE Following Parts: Installation ManualДокумент4 страницыHIS KIT Includes THE Following Parts: Installation ManualOPER123Оценок пока нет

- SGEG Rezidential Hibrid 2023Документ2 страницыSGEG Rezidential Hibrid 2023AlexОценок пока нет

- R2S Turbo SystemsДокумент22 страницыR2S Turbo SystemsderekrichnerОценок пока нет

- Air Compressors#61Документ26 страницAir Compressors#61Gala BanneringgiОценок пока нет

- Turbines 14Документ21 страницаTurbines 14Izal FrdsОценок пока нет

- API 610 Centrifugal Pump Types - OH, BB & VSДокумент17 страницAPI 610 Centrifugal Pump Types - OH, BB & VSDANISH ALIОценок пока нет

- ABS Guide For Enhanced Fire Protection ArrangementsДокумент100 страницABS Guide For Enhanced Fire Protection ArrangementsIsa KumОценок пока нет

- STP 210ms 229Документ2 страницыSTP 210ms 229TATA URUSAN TEKNOLOGI & JARINGANОценок пока нет

- Prospekt - SCROLL - ENG RENNERДокумент8 страницProspekt - SCROLL - ENG RENNERAriantoОценок пока нет

- Thermal Power StationДокумент18 страницThermal Power Stationkamal_rohilla_1Оценок пока нет

- Thermal and Nuclear Power Plant Assignment QuestionsДокумент3 страницыThermal and Nuclear Power Plant Assignment QuestionsAshok KumarОценок пока нет

- SOEДокумент21 страницаSOERnldo de CabrioОценок пока нет

- Diesel Fire Pumps DNF HSF Hfpa 20 GBДокумент84 страницыDiesel Fire Pumps DNF HSF Hfpa 20 GBJustin Reyes0% (1)

- Progressive Cavity PumpsДокумент2 страницыProgressive Cavity PumpsGerardo BautistaОценок пока нет

- 503 Data SheetДокумент2 страницы503 Data Sheetklmsllm7002Оценок пока нет

- Equipment Master (R) - TemplateДокумент137 страницEquipment Master (R) - TemplateruchitlpatelОценок пока нет

- MWP3 Fire Water Network SketckДокумент3 страницыMWP3 Fire Water Network SketckYaser AhmadОценок пока нет

- WIMSD5Документ35 страницWIMSD5SurbaktiОценок пока нет

- Graduation Project 2 1Документ44 страницыGraduation Project 2 1bashar ibrahimОценок пока нет

- Reavell 4-20 HP Air Cooled Reciprocating CompressorДокумент2 страницыReavell 4-20 HP Air Cooled Reciprocating Compressorscrollock0428Оценок пока нет

- A Study On Operation And-Maintenance of Mechanical and Power Generation Equipment at Rim Dyeing LTDДокумент92 страницыA Study On Operation And-Maintenance of Mechanical and Power Generation Equipment at Rim Dyeing LTDshakib nazmusОценок пока нет

- ASC Presentation PDFДокумент89 страницASC Presentation PDFAhmadHussain09Оценок пока нет