Академический Документы

Профессиональный Документы

Культура Документы

Role of Additives in XLPE PDF

Загружено:

bitconceptsОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Role of Additives in XLPE PDF

Загружено:

bitconceptsАвторское право:

Доступные форматы

Role of Semiconducting Compounds in Water Treeing of XLPE Cable Insulation

S.A. Boggs and M.S. Mashikian, Electrical Insulation Research Center, University of Connecticut Introduction

Water trees are known to be associated with reduction of dielectric strength and eventual failure of polyethylene-insulated cable which does not incorporate an effective moisture barrier [1,2]. However, past studies of this phenomenon often correlated poorly with data gathered from field-aged cable [3,4]. In particular, chemical analysis of water treed regions of laboratoryaged polyethylene demonstrated substantial differences from field-aged cable. Such results cast doubt on the usefulness of typical laboratory studies. A 1983 survey of solid dielectric cable technology conducted on behalf of EPRI indicated that several cable manufacturers in Europe and Japan placed great emphasis on the properties of the semiconducting shields used to manufacture power distribution and transmission cables. The carbon blacks used in North America differed substantially from those used by these offshore manufacturers. As a result of this finding, the Department of Energy initiated a project titled Interfacial Ageing Phenomena in Power Cable Insulation Systems. The findings of this project have been reported in several technical publications [4-7] which form the basis for the present summary. remains dry. This facilitates a direct comparison of the semicon-dielectric interface when maintained under wet and dry conditions. Ageing was carried out over long periods of time (typically 3500 and 7000 hours) at moderate stress (3.4 kV/mm or 85 V/mil and 2.6 kV/mm or 65 V/mil). Direct comparison of trees grown in this cell configuration and at these stresses with trees taken from field-aged cables indicated very similar tree chemical characteristics. Experiments were carried out using four commercial semiconducting insulation shield materials (C1 to C4) and four model shield materials (M1 to M4) formulated to vary such properties as the amount of sulfur in the shield. The dielectric used in all cases was a commercial cross-linkable polyethylene resin in the form of pellets which had been subjected to 100% optical inspection.

Raw Material Impurities

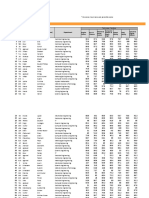

Analysis of the cell water showed that in all cases, the ion concentration of the distilled, deionized water increased during ageing, and after as little as 100 hours of ageing, many ion species could be identified which were not initially in the water. This effect was indeTable I [4] Contaminant Content of Raw Material (weight %) Sample C1 C2 C3 C4 C5 M1 M2 M3 M4 Surface .0513 .0306 .0994 .3992 .2484 .0818 .0180 .3892 .0494 Bulk .0746 .1038 .1072 .2970 .0286 .0355 .0860 .1430 .0581 Cleaned Surface .0087 .0096 .0100 .0110 .0010 .0090 .0013 .0101 .0091

Experimental Test Program

The test program was based on a sample configuration which incorporates the interface between the semiconducting compound and the polyethylene dielectric. The sample cell used in this project (Fig. 1) is a modification of a sample configuration originated by Union Carbide. This cell provides a well which allows one semiconducting layer to be maintained in a controlled, wet environment while the other semiconducting layer

Fig. 1. Test cell design which provides wet and dry semicon-dielectric interfaces [4].

Fig. 2. Contaminants on the surface of Compound C5 (a pellet of polyethylene resin).

Fig. 3. Detail of the interface between two pellets after melting. The defect in the interface caused by contamination on the surface of the pellets is obvious.

pendent of electrical stress. Various analytical techniques were used to evaluate contaminants in and on the raw material pellets. The results of this analysis are shown in Table I. In addition, the pellets were cleaned through bathing in hot, distilled, deionized water. As seen in Table I, the surface contamination generally differs from the bulk contamination. As well, the surface contamination can be reduced substantially through cleaning in hot, distilled water, which indicates that the contaminants are water soluble. The surface contamination is believed to come from processing water used during the pelletizing process. As seen in Fig. 2, the surface contamination is substantial and as shown in Fig. 3, it can interfere with the quality of the pellet-to-pellet interface. This effect may be much less pronounced in extruded cable; however, the ionic contaminants must still end up dispersed throughout the dielectric.

Results

Fig. 4 shows vented water tree length vs. ageing time for an old technology commercial semiconductive shielding compound while Fig. 5 shows a similar graph for a model shielding compound formulated with acetylene black. Note the difference in vertical scales. Obviously the cleaner model compound results in the growth of substantially fewer and smaller water trees. Evidently, tree growth is saturated by 7000 hours. As the tree growth was thought to be related to the supply of ions, tree growth might be limited as the supply of ions is depleted. While this could easily occur in the test geometry used during this project, it is less likely to occur in the field, as installed cables are subjected to ground water containing an ample supply of ions and which can pick up more ions from the cable conductor which is not included in this study. To test this hypothesis, water containing ions extracted from soil

Fig. 4. Vented water tree length distribution for several ageing times. The semiconducting compound was an old technology commercial shielding compound. The cell was aged at 3.4 kV/mm (85 V/mil) [7].

Fig. 5. Vented water tree length distribution for several ageing times. The semiconducting compound was formulated with acetylene black, and the cell was aged at 3.4 kV/mm (85 V/mil) [7].

Fig. 6. The importance of ions for tree initiation is demonstrated through comparison of the number of trees vs. time for cells filled with deionized, distilled water and cells filled with water containing ions extracted from soil and semiconducting shield material. In the case of distilled, deionized water, the ions from the sample shield become depleted after about 7000 hours and tree initiation stops. Tree initiation continues in the other samples, which have an ample supply of ions. Ageing was carried out at 3.4 kV/mm (85 V/mil) [7].

Fig. 7. Comparison of vented water tree length distributions for cells fabricated with cleaned and as-received old technology commercial shielding compound [7].

material after cleaning to remove water-extractable contamination. The effect of cleaning is dramatic. Previous literature indicates that surfactants (detergent-like materials which reduce surface tension) increase tree initiation and growth. However, the surfactants used in previous studies were ionic. Fig. 8 shows a comparison of tree growth for cells in which the semicon-dielectric surface was treated with an ionic surfactant, a nonionic surfactant, and no surfactant. As is clear from the figure, the effect on water treeing is the result of added ions, not the added surfactant. During the extensive tree counting required to assemble the data presented in the above figures, a number of effects were noted. For example, asperities at the semicon-dielectric interface did not generally result in

and from semiconducting compound was added to a cell after 7000 hours of ageing. As seen in Fig. 6, the number of vented water trees increased at a fairly steady rate for the samples which had an adequate supply of ions, whereas the number of trees leveled off for the sample which did not. Likewise, the effect of waterextractable contaminants on tree growth could be demonstrated. Fig. 7 shows a comparison of the vented water tree length distribution for cells manufactured with as-received old technology semiconducting shield and cells made with the same semiconducting

Fig. 8. Influence of ionic and nonionic surfactants on the number of vented water trees after 7000 hours of ageing at 3.4 kV/mm (85 V/mil). Evidently, water treeing is stimulated by ions rather than surfactants [7].

Fig. 9. Silicon ion profile as a function of position from the semiconducting compound into the dielectric. The transition is sharp for the dry electrode but is smeared out by ion migration from the wet semicon to the wet dielectric. The sample has been aged for 7000 hours at 2.6 kV/mm (65 V/mil) [4].

Fig. 10. Silicon ion profile as a function of position from a second semiconducting compound into the dielectric. The transition is sharp for the dry electrode but is smeared out by ion migration from the wet semicon to the wet dielectric. The sample has been aged for 7000 hours at 2.6 kV/mm (65 V/mil) [4].

Fig. 11. Change in chemical potential with change in ion concentration as calculated by Zeller for two water-filled cavities connected by a thin channel [9]. A change in chemical potential over about 1 eV is sufficient to drive an electrochemical process such as water treeing.

the growth of water trees unless they were accompanied by some form of contamination. Thus such asperities appear to have much less influence on water tree initiation than does contamination. Clearly, the above results suggest that ions are migrating from the semiconducting material into the dielectric and water tree. Several studies within the project demonstrated beyond any doubt that this can occur. For example, Figs. 9 and 10 show the profile of silicon (ion) concentration from within the semicon to within the dielectric for the wet and dry semicon-dielectric interfaces of the same samples. Clearly the transition is very abrupt on the dry side but has become smeared as a result of ion mobility on the wet side. Virtually no vented water trees grew at the dry semicon-dielectric interface, while many vented water trees grew on the wet interface.

3. The growth of water trees does not depend solely on ions originating from the semiconducting shields. Ground water will generally carry substantial ionic contamination. 4. The tree length and size distribution differs significantly for the semiconducting compounds tested, with the newer technology products which incorporate the cleanest carbon black showing a trend toward reduced propensity for the growth of vented water trees. 5. While the propensity toward treeing appears to depend on the degree of surface and volume contamination of the shield material pellets, the role of each impurity constituent has yet to be determined. 6. Surface contamination of the insulation pellets remains segregated at the interpellet interfaces and stimulates the initiation of bowtie trees.

Conclusions

1. As noted above, detailed comparisons of the chemistry of trees grown during this project with trees from field-aged cable demonstrated excellent correlation in all parameters which could be measured. Thus the test protocol employed in this study appears to mimic field ageing accurately. 2. As a result of the extensive testing carried out during this project, we can conclude that the initiation of water trees at a semicon-polyethylene interface requires ions and that the required ions are generally present in and on the semiconducting material. The concentration of water soluble ions on the surface of semiconducting material can be reduced through simple water extraction, and such reduction has a substantial effect on the number and length of water trees.

Technology Transfer

Various aspects of the technology developed during this Department of Energy-supported work have been transferred to Cablec Polymers, Inc., Dow Corning, Inc., Union Carbide, Elastimold Corporation, Cabot Corporation, Uniroyal, AT&T, Exxon, and BP Polymers. This research has resulted in substantial changes to semiconducting shield technology and compounds which have improved the reliability of solid dielectric cable.

Theoretical Context (Speculation)

A full theory for water treeing is still lacking. However, the outlines of a theory are available. H.R. Zeller has published two seminal papers in the field [8,9]. One paper outlines the basis for condensation of water within a polymer. Using basic thermodynamics, Zeller points out that water dispersed in a hydrophobic material which contains hydrophilic regions will condense

into those hydrophilic regions [8]. In the second paper, Zeller provides a credible basis for the driving function of water treeing [9]. He points out that the change in chemical potential with ion concentration is sufficient to drive water treeing. Fig. 11 shows the change in chemical potential (in electron volts) which accompanies the change in ion concentration from zero to the stated value for two small cavities connected by a small channel. Anything over 1 eV can drive a chemical reaction. Thus this mechanism has the potential to drive water treeing over a wide range of concentration. However, the driving function drops at sufficiently high and low concentrations. These computed data can be taken as qualitative and suggestive; they are not definitive computations of the driving force for a realistic geometry. Recently published experimental data indicate that water trees consist of cavities connected by channels of altered material [10]. Taken together, these results suggest that water treeing results from a localized chemical reaction which changes the polymer from hydrophobic to hydrophilic. Water and ions can travel along and condense into these hydrophilic paths from cavity to cavity. The combination of water, ions, and (possibly) cavities results in a chemical reaction at the channel tip which converts material from hydrophobic to hydrophilic and propagates the water tree as a myriad of such channels. Initially, the channels are probably not tunnels but rather paths of polymer in which the material has been reacted to change from hydrophobic to hydrophilic. Unfortunately, the channels tend to be from factions of a micrometre to a micrometre in diameter, so analysis of the material in a channel to determine the precise chemical reactions therein poses a substantial challenge which has yet to be overcome.

Matthew Mashikian was graduated from the American University of Beirut and received his Dr. of Engineering degree from the University of Detroit. Matt worked for ASEA from 1958 to 1962 as an application engineer for lightning arresters. From 1963 to 1979, he was in the Engineering Research Department of Detroit Edison where he rose to the position of Supervisor of Electrical Equipment and instrumentation. After early retirement from this position in 1979, he started his own consulting company, Mashikian & Associates, Inc. Since 1983, he has been Director of the Electrical Insulation Research Center at the University of Connecticut. Matt was elected a Fellow of the IEEE for his contributions to the technology of solid dielectric power cables. Matt is presently Secretary of the PES Insulated Conductors Committee and Chairperson of the DEIS Education Committee.

References

1. Lawson, J.H. and W.A. Thue. Summary of Service Failures of High Voltage Extruded Dielectric Cables in the United States. 1980 IEEE International Symposium on Electrical Insulation, pp. 100-104. 2. Lawson, J.H. and W. Vahlstrom. Investigation of Insulation Deterioration in 15 kV and 22 kV Polyethylene Cables Removed from Service - Part II. IEEE Trans. PAS-92, pp. 824-835 (1973). 3. Patsch, R. Water Treeing in Cable Insulation - Are Laboratory Tests Meaningful? 1988 IEE Conference on Solid Dielectrics, pp. 242-245. 4. Mashikian, M.S., J.H. Groeger, S. Dale, and E. Ildstadt. Role of Semiconducting Compounds in the Premature Ageing of XLPE Cable Insulation. 1988 IEEE International Symposium on Electrical Insulation, pp. 314-320, IEEE Publication 88CH2594-0. 5. Groeger, J.H., J. Henry, and A. Garton. Location and Concentration of Ionic Impurities in Polymeric Cable Insulation. 1988 IEEE International Symposium on Electrical Insulation, pp. 300-305, IEEE Publication 88CH2594-0. 6. Mashikian, M.S. and J.H. Groeger. Ionic Impurities in Extruded Cable Insulation: Analytical Detection Techniques, Sources, Nature, and Effects. Proceedings of the Jicable Conference, Versailles, 1987. 7. Mashikian, M.S. and J.H. Groeger. Ageing Phenomena at Cable-Shield Interfaces Affecting the Propensity of the Insulation to Develop Water Trees. Proceedings of the Jicable Conference, 1991. 8. Zeller, H.R. Thermodynamics of Water Treeing. IEEE Trans. EI-22, p. 677 - 681, 1987. 9. Zeller, H.R. Noninsulating Properties of Insulating Materials. 1991 Annual Report of the Conference on Electrical Insulation and Dielectric Phenomena. p. 19 - 47. 10. Moreau, E., C. Mayoux, C. Laurent, and A. Boudet. The Structural Characteristics of Water Trees in Power Cables and Laboratory Specimens. IEEE Trans. EI-28, No. 1, February 1993. pp. 54-64.

Acknowledgements

The experimental research described in this article was carried out by Matthew Mashikian, Joseph Groeger, and others at the Electrical Insulation Research Center (EIRC), University of Connecticut. The article was written by Steven Boggs, who recently joined EIRC. Steven Boggs was graduated from Reed College and received his Ph.D. and M.B.A. degrees from the University of Toronto. He conducted research for 12 years with Ontario Hydro, primarily in the areas of SF6 gasinsulated substations, solid dielectrics, and partial discharge detection. Prior to joining the Electrical Insulation Research Center as Associate Director, he was Director of Engineering and Research at Underground Systems, Inc. (Armonk, NY). Steve was elected a Fellow of the IEEE for his contributions to gas-insulated substation technology.

Вам также может понравиться

- The Influence of Different Post-Drying Procedures On Remaining Water Content and Physical and Electrochemical Properties of Lithium-Ion BatteriesДокумент11 страницThe Influence of Different Post-Drying Procedures On Remaining Water Content and Physical and Electrochemical Properties of Lithium-Ion BatteriesMDR0% (1)

- A - Piping Joint HandbookДокумент161 страницаA - Piping Joint HandbookCharles Tauk100% (30)

- Project Demo On Pet Shop: Group Members: Muhammad Talha Malik Shamook Saad Muhammad HamzaДокумент10 страницProject Demo On Pet Shop: Group Members: Muhammad Talha Malik Shamook Saad Muhammad HamzaRaja Saad0% (1)

- Guideline For Grade and Compensation FitmentДокумент5 страницGuideline For Grade and Compensation FitmentVijit MisraОценок пока нет

- Role of Semiconducting Compounds in Water Treeing of XLPE Cable InsulationДокумент5 страницRole of Semiconducting Compounds in Water Treeing of XLPE Cable InsulationWhite HeartОценок пока нет

- Effect of Acidic Rain On Hydrophobicity of Silicon RubberДокумент4 страницыEffect of Acidic Rain On Hydrophobicity of Silicon RubberAlberto BonsantoОценок пока нет

- 1 s2.0 S0263224113006519 MainДокумент11 страниц1 s2.0 S0263224113006519 MainAnonymous R9u2vabQ7sОценок пока нет

- Composite Assignment-II EditrdДокумент5 страницComposite Assignment-II Editrdsai andeОценок пока нет

- Water Trees in Cables-Generation and DetectionДокумент7 страницWater Trees in Cables-Generation and DetectionMariut Elena LarisaОценок пока нет

- Cable Sheaths and Water Permeability PDFДокумент17 страницCable Sheaths and Water Permeability PDFsdvijayОценок пока нет

- Influence of High Levels of Water Absorption On The Resistivity and Dielectric Permittivity of Epoxy CompositesДокумент6 страницInfluence of High Levels of Water Absorption On The Resistivity and Dielectric Permittivity of Epoxy CompositesNavid HoseiniОценок пока нет

- Hofs BSep Pur Tech 201179365Документ11 страницHofs BSep Pur Tech 201179365pinitОценок пока нет

- 8 ZubairДокумент4 страницы8 ZubairMark Tambus JhonsОценок пока нет

- Study On Leakage Current Waveforms and Flashover of Ceramics For Outdoor Insulators Under Artificially-Simulated PollutionsДокумент7 страницStudy On Leakage Current Waveforms and Flashover of Ceramics For Outdoor Insulators Under Artificially-Simulated PollutionsnelmaheshОценок пока нет

- Numerical and Experimental Investigation On Salt-Fog Aging of Silicone InsulatorsДокумент4 страницыNumerical and Experimental Investigation On Salt-Fog Aging of Silicone InsulatorsFari PratomosiwiОценок пока нет

- Carbon Black / PTFE Composite Hydrophobic Gas Diffusion Layers For A Water-Absorbing Porous Electrolyte Electrolysis CellДокумент8 страницCarbon Black / PTFE Composite Hydrophobic Gas Diffusion Layers For A Water-Absorbing Porous Electrolyte Electrolysis Cellfitri mahmudahОценок пока нет

- CIGRE-119 Rejuvenation of Insuslation in Aged Power CablesДокумент11 страницCIGRE-119 Rejuvenation of Insuslation in Aged Power CableskamuikОценок пока нет

- A Novel System For The Prolongation of The Lifetime Power Transformers by Reduced Oxidation and AgingДокумент4 страницыA Novel System For The Prolongation of The Lifetime Power Transformers by Reduced Oxidation and AgingSergio Trujillo AranaОценок пока нет

- The Fatigue Performance of Electrofusion Tapping Tees Subject To Contamination - Final VersionДокумент25 страницThe Fatigue Performance of Electrofusion Tapping Tees Subject To Contamination - Final VersionrsahaОценок пока нет

- T4-86 Hydrophobic EPДокумент5 страницT4-86 Hydrophobic EPWalter CataldoОценок пока нет

- Comparative Tests On RTV Silicone Rubber Coated Porcelain Suspension Insulators in A Salt-Fog ChamberДокумент7 страницComparative Tests On RTV Silicone Rubber Coated Porcelain Suspension Insulators in A Salt-Fog ChamberDebojyoti MukherjeeОценок пока нет

- Fracture Toughness Investigation On Long Kenaf/Woven Glass Hybrid Composite Due To Water Absorption EffectДокумент7 страницFracture Toughness Investigation On Long Kenaf/Woven Glass Hybrid Composite Due To Water Absorption Effect000Оценок пока нет

- Cracking Deteriorates The Efficiency in Die-Sensitized Solar CellsДокумент4 страницыCracking Deteriorates The Efficiency in Die-Sensitized Solar CellsbasauleetoОценок пока нет

- Long Term Stability of Capacitive De-Ionization Processes For Water Desalination: The Challenge of Positive Electrodes CorrosionДокумент10 страницLong Term Stability of Capacitive De-Ionization Processes For Water Desalination: The Challenge of Positive Electrodes CorrosionPaulo Ossandon SanchezОценок пока нет

- Negative Lead-Acid Battery Electrodes Doped With Glass FibresДокумент14 страницNegative Lead-Acid Battery Electrodes Doped With Glass FibresalzyoudОценок пока нет

- Cable Sheaths and Water PermeabilityДокумент17 страницCable Sheaths and Water PermeabilityAHMED YOUSEFОценок пока нет

- I.TUDOSE-Comparative Study On Field Collected Samples of Aged Silicon Rubber Composite Coatings For High Voltage InsulatorsДокумент14 страницI.TUDOSE-Comparative Study On Field Collected Samples of Aged Silicon Rubber Composite Coatings For High Voltage InsulatorsAldo Córdoba GuerreroОценок пока нет

- Polymer MEMS ActuatorsДокумент9 страницPolymer MEMS ActuatorsAmir ReuvenyОценок пока нет

- Resnik MEET2019Документ7 страницResnik MEET2019Surya Chandra NamahaОценок пока нет

- FRP Rods For Brittle Fracture ResistantДокумент9 страницFRP Rods For Brittle Fracture Resistantdmsoares1989Оценок пока нет

- Condition Assessment of InstrumentДокумент5 страницCondition Assessment of InstrumentNelson VelosoОценок пока нет

- Experimental Investigation of The Operating Parameters AffectingДокумент4 страницыExperimental Investigation of The Operating Parameters AffectingJonas Drumond Alves SoaresОценок пока нет

- Artificial Accelerated Ageing Test of Silicone Rubber Housing Material For Lightning ArresterДокумент6 страницArtificial Accelerated Ageing Test of Silicone Rubber Housing Material For Lightning ArrestersygabrielaОценок пока нет

- Effect On Superhydrophobic Surfaces On ElectricalДокумент12 страницEffect On Superhydrophobic Surfaces On Electricalhadi ebrahimfathОценок пока нет

- Soon To A: Reliability of Optical Fibres Impact On Cable DesignДокумент6 страницSoon To A: Reliability of Optical Fibres Impact On Cable DesignHakimHabibiОценок пока нет

- Water-Tree Degradation in Power Cable Insulation - Understanding and PreventionДокумент4 страницыWater-Tree Degradation in Power Cable Insulation - Understanding and PreventionNoé Rafael Colorado SósolОценок пока нет

- Ageing Deterioration of Silicone Rubber Polymer Insulator Under Salt Water Dip Wheel TestДокумент7 страницAgeing Deterioration of Silicone Rubber Polymer Insulator Under Salt Water Dip Wheel TestRahul TripathiОценок пока нет

- Antifouling of Conducting Rubbers in Fishing NetsДокумент7 страницAntifouling of Conducting Rubbers in Fishing NetsjshreyaОценок пока нет

- Modeling Flashover of AC Outdoor Insulators Under Contaminated Conditions With Dry Band Formation and Arcing PDFДокумент7 страницModeling Flashover of AC Outdoor Insulators Under Contaminated Conditions With Dry Band Formation and Arcing PDFdaaanuОценок пока нет

- Electrolyser 1Документ10 страницElectrolyser 1Society for Social Orientation and Human RightsОценок пока нет

- Mohd Nasrullah Et Al., (2020) Crecimiento Del FlocДокумент11 страницMohd Nasrullah Et Al., (2020) Crecimiento Del FlocAndrea Carolina Cubillos OnateОценок пока нет

- RTV Coating Suwarno Fari FinalДокумент6 страницRTV Coating Suwarno Fari FinalFari PratomosiwiОценок пока нет

- Effect of Various Parameters On Different TypesДокумент6 страницEffect of Various Parameters On Different TypeslinhОценок пока нет

- Effectiveness of Electro Chemical Disinf-1 PDFДокумент9 страницEffectiveness of Electro Chemical Disinf-1 PDFsumit dekateОценок пока нет

- Teflon AF 2400 ElectrospunДокумент10 страницTeflon AF 2400 ElectrospunDavid MoureauОценок пока нет

- Electric Field Computation of Water Droplets On A Model InsulatorДокумент5 страницElectric Field Computation of Water Droplets On A Model Insulatordemy antonyОценок пока нет

- Durability of PEM Water Electrolyzer Against Wind Power Voltage FluctuationДокумент9 страницDurability of PEM Water Electrolyzer Against Wind Power Voltage FluctuationMarcello SaviniОценок пока нет

- Understanding Moisture Dynamics and Its Effect On The Dielectric Response of Transformer InsulationДокумент11 страницUnderstanding Moisture Dynamics and Its Effect On The Dielectric Response of Transformer Insulationalireza shaОценок пока нет

- Overview of Solar DesalinationДокумент17 страницOverview of Solar Desalinationalagar krishna kumarОценок пока нет

- A Review in ElectrospinningДокумент8 страницA Review in ElectrospinningMuaathe IbrahimОценок пока нет

- Environmental Effects On The Mechanical Properties of Glass-Fiber Epoxy Composite Tubular SpecimensДокумент12 страницEnvironmental Effects On The Mechanical Properties of Glass-Fiber Epoxy Composite Tubular SpecimensMuhammed MinhajОценок пока нет

- Preliminary Electrochemical Cementation of High Volume Fly Ash MortarsДокумент8 страницPreliminary Electrochemical Cementation of High Volume Fly Ash MortarsVivian Elisa RODRIGUEZ MORENOОценок пока нет

- Energy Harvesting With Micro Scale Hydrodynamic Cavitation-Thermoelectric Generation CouplingДокумент12 страницEnergy Harvesting With Micro Scale Hydrodynamic Cavitation-Thermoelectric Generation CouplingEurotech Tra TranОценок пока нет

- High Voltage - 2019 - Haque - Studies On The Effects of Moisture and Ageing On Charge de Trapping Properties ofДокумент7 страницHigh Voltage - 2019 - Haque - Studies On The Effects of Moisture and Ageing On Charge de Trapping Properties ofNasirul HaqueОценок пока нет

- Electrical and Material Characterization of Field-Aged 400 KV Silicone Rubber Composite InsulatorsДокумент9 страницElectrical and Material Characterization of Field-Aged 400 KV Silicone Rubber Composite InsulatorsdaaanuОценок пока нет

- The Swelling and Dissolution of Cellulose Crystallites in Subcritical and Supercritical WaterДокумент14 страницThe Swelling and Dissolution of Cellulose Crystallites in Subcritical and Supercritical WaterMoqeet AwanОценок пока нет

- Brauns 2021 J. Electrochem. Soc. 168 014510Документ14 страницBrauns 2021 J. Electrochem. Soc. 168 014510RaulОценок пока нет

- Porous Silicon Based Humidity Sensor: E. KayahanДокумент3 страницыPorous Silicon Based Humidity Sensor: E. KayahanhesoyamyecgaaaОценок пока нет

- дудышев новая эн 10-19 PDFДокумент3 страницыдудышев новая эн 10-19 PDFAleksandrОценок пока нет

- Article On Tree RetardantДокумент4 страницыArticle On Tree Retardantsansui227kssОценок пока нет

- Nio ReductionДокумент9 страницNio ReductionAziz SulaimanОценок пока нет

- Biohydrogen III: Renewable Energy System by Biological Solar Energy ConversionОт EverandBiohydrogen III: Renewable Energy System by Biological Solar Energy ConversionОценок пока нет

- Biofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationОт EverandBiofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationОценок пока нет

- Long-Life Xlpe Insulated Power Cable PDFДокумент6 страницLong-Life Xlpe Insulated Power Cable PDFbitconceptsОценок пока нет

- Fatigue Life Estimation Non Linear System Random 2008 FДокумент11 страницFatigue Life Estimation Non Linear System Random 2008 FbitconceptsОценок пока нет

- Bolt Pressure DistributionДокумент24 страницыBolt Pressure DistributionbitconceptsОценок пока нет

- Design Guide PDFДокумент117 страницDesign Guide PDFAndres FacuОценок пока нет

- 25 Permanent Magnet Motor Design PDFДокумент39 страниц25 Permanent Magnet Motor Design PDFbitconcepts60% (5)

- WTR XLPE - Development PDFДокумент4 страницыWTR XLPE - Development PDFbitconceptsОценок пока нет

- 04-0507-Electronics Packaging Considerations For Space ApplicationsДокумент6 страниц04-0507-Electronics Packaging Considerations For Space ApplicationsbitconceptsОценок пока нет

- Solder ReliabilityДокумент12 страницSolder ReliabilitybitconceptsОценок пока нет

- XMR AzДокумент9 страницXMR AzbitconceptsОценок пока нет

- DC Generator PDFДокумент108 страницDC Generator PDFSaeed Osman MohamedОценок пока нет

- 1 Numerical Analysis of Shock ResponseДокумент115 страниц1 Numerical Analysis of Shock ResponseLeonichevОценок пока нет

- Synchro and Resolver Hand BookДокумент35 страницSynchro and Resolver Hand BookAbdul KurniadiОценок пока нет

- Thermoelectric Cooling WhitepaperДокумент9 страницThermoelectric Cooling WhitepaperbitconceptsОценок пока нет

- CFX TutДокумент149 страницCFX Tutthiagopalmieri3253Оценок пока нет

- Labview Modbus EngДокумент6 страницLabview Modbus EngSri Natha DesikanОценок пока нет

- Condenser Design in Aspen PlusДокумент9 страницCondenser Design in Aspen Plusvsraochemical1979100% (7)

- Basics of Heat Transfer - Water Cooling Systems, PC Liquid Cooling Kit, Cpu, Video Card, Hard DriveДокумент2 страницыBasics of Heat Transfer - Water Cooling Systems, PC Liquid Cooling Kit, Cpu, Video Card, Hard DrivebitconceptsОценок пока нет

- Forecasting The Return Volatility of The Exchange RateДокумент53 страницыForecasting The Return Volatility of The Exchange RateProdan IoanaОценок пока нет

- Business Decision MakingДокумент5 страницBusiness Decision MakingShafiya CaderОценок пока нет

- Mission Statement Generator WorksheetДокумент9 страницMission Statement Generator WorksheetMohamed SururrОценок пока нет

- About Karmic Debt Numbers in NumerologyДокумент3 страницыAbout Karmic Debt Numbers in NumerologyMarkMadMunki100% (2)

- Retail Analysis WalmartДокумент18 страницRetail Analysis WalmartNavin MathadОценок пока нет

- D062/D063/D065/D066 Service Manual: (Book 1 of 2) 004778MIU MainframeДокумент1 347 страницD062/D063/D065/D066 Service Manual: (Book 1 of 2) 004778MIU MainframeevpsasaОценок пока нет

- 2nd Announcement 13th InaSH Meeting 2019Документ14 страниц2nd Announcement 13th InaSH Meeting 2019adinda permataОценок пока нет

- EEM336 - 01 - Introduction To The Microprocessor and ComputerДокумент53 страницыEEM336 - 01 - Introduction To The Microprocessor and ComputersakalanОценок пока нет

- 2011bibliography Part I (Preparation and Initial Assessment)Документ188 страниц2011bibliography Part I (Preparation and Initial Assessment)Espiritu MineralОценок пока нет

- A History of The Faculty of Agriculture, University of Port HarcourtДокумент56 страницA History of The Faculty of Agriculture, University of Port HarcourtFACULTY OF AGRICULTURE UNIVERSITY OF PORT HARCOURTОценок пока нет

- 432 HZ - Unearthing The Truth Behind Nature's FrequencyДокумент6 страниц432 HZ - Unearthing The Truth Behind Nature's FrequencyShiv KeskarОценок пока нет

- 5300 Operation Manual (v1.5)Документ486 страниц5300 Operation Manual (v1.5)Phan Quan100% (1)

- P1 88thminutesДокумент42 страницыP1 88thminutesVaishnavi JayakumarОценок пока нет

- Message Staging and Logging Options in Advanced Adapter Engine of PI - PO 7.3x - 7.4 - SAP Blogs PDFДокумент26 страницMessage Staging and Logging Options in Advanced Adapter Engine of PI - PO 7.3x - 7.4 - SAP Blogs PDFSujith KumarОценок пока нет

- Skripsi Tanpa Bab Pembahasan PDFДокумент67 страницSkripsi Tanpa Bab Pembahasan PDFaaaaОценок пока нет

- Master SC 2015 enДокумент72 страницыMaster SC 2015 enNivas Kumar SureshОценок пока нет

- Criminal Behavior and Learning TheoryДокумент8 страницCriminal Behavior and Learning TheoryRobert BataraОценок пока нет

- ParallelДокумент4 страницыParallelShanntha JoshittaОценок пока нет

- 9 Clonezilla LiveДокумент4 страницы9 Clonezilla LivegixplayОценок пока нет

- SAHCorporateBrochure WEBДокумент72 страницыSAHCorporateBrochure WEBKrsna SinghОценок пока нет

- Membrane TypesДокумент92 страницыMembrane TypesVanditaa Kothari100% (1)

- Abstract On Budgetary ControlДокумент22 страницыAbstract On Budgetary ControlIhab Hosny AhmedОценок пока нет

- PV Quick StartДокумент61 страницаPV Quick StartMayur PatelОценок пока нет

- Innoventure List of Short Listed CandidatesДокумент69 страницInnoventure List of Short Listed CandidatesgovindmalhotraОценок пока нет

- Oakwood, Ub CityДокумент18 страницOakwood, Ub CityAfreen BandayОценок пока нет

- Natural Law and The Theory of Society 1500 To 1800 (Scan Perso) PDFДокумент508 страницNatural Law and The Theory of Society 1500 To 1800 (Scan Perso) PDFjcfichte100% (1)

- Youtube Poop: Subverting Art OnlineДокумент14 страницYoutube Poop: Subverting Art OnlineWill KurlinkusОценок пока нет

- Ad For Natbps WB PDFДокумент7 страницAd For Natbps WB PDFrajpal singhОценок пока нет