Академический Документы

Профессиональный Документы

Культура Документы

02 - Petm Tic P00014 M Spe 0001 PDF

Загружено:

lucianduИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

02 - Petm Tic P00014 M Spe 0001 PDF

Загружено:

lucianduАвторское право:

Доступные форматы

Petrofac Production Solutions

COMPROIECT-92

Client: Facility: Project Title: Project Number: Document Number:

PETROFAC TICLENI PILOT WATER FLOOD PROJECT P00014 PETM-TIC-P00014-M-SPE-0001

Document Title:

Piping classes specification Specificatie clasa de conducte

Revision Record Rev A01 Issue For comment Date Issued

01.2011

Origin By M. Costache

Checked By I. Vlad

Approved By I.Vlad

This Document is the property of Petrofac Facilities Management LTD and is not to be copied nor shown to a third party without written consent

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

2 of 25

TABLE OF CONTENTS

CUPRINS

1.0 GENERALS .................................................. 3 1.0 GENERALITATI ............................................ 3 2.0 ABBREVIATIONS ........................................ 3 2.0 ABREVIERI................................................... 3 3.0 REFFERENCES ........................................... 3 3.0 REFERINTE .................................................. 3 3.1 3.2 3.3 3.4 3.5

3.5.1 3.5.2 3.5.3 3.5.4 3.5.5

Design codes .............................................. 3 3.1. Coduri de proiectare.................................... 3 Standards and Codes ................................. 3 3.2. Standarde si Coduri .................................... 3 Design Condition ........................................ 7 3.3. Conditii de proiectare .................................. 7 Nominal size ............................................... 7 3.4. Dimensiuni nominale ................................... 7 Piping classes ............................................. 7 3.5. Clase conducte ........................................... 7

General ........................................................ 7 Identification System for Piping Classes ....... 8 Carbon and low alloy steels.......................... 9 Welds .......................................................... 9 Cold deformation and thermal stress relief .... 9 3.5.1. 3.5.2. 3.5.3. 3.5.4. 3.5.5. Generalitati ................................................... 7 Identificarea claselor de conducte ................. 8 Oteluri carbon si slab aliate........................... 9 Sudurile ........................................................ 9 Deformarea la rece si detensionarea termica 9

3.6 4.1 4.2 5.1 5.2 6.1 6.2 6.3 6.4 6.5 6.6 6.7

Certification ............................................... 10 3.6. Certificari................................................... 10 Pipe Wall Thickness All Classes ............ 10 4.1. Grosime Perete Teava Toate Clasele .... 10 Corrosion Allowance ................................. 10 4.2. Adaos de coroziune .................................. 10 Non metallic flat gaskets ........................... 11 5.1. Garnituri plate nemetalice ........................ 11 Spiral Wound Gaskets .............................. 11 5.2. Garnituri Spiral Wound............................ 11 Class ACM3A ........................................... 12 6.1. Clasa ACM3A ........................................... 12 Class ACP3A ............................................ 14 6.2. Clasa ACP3A ............................................ 14 Class HCM3A ........................................... 16 6.3. Clasa HCM3A ........................................... 16 Class HCN3A............................................ 18 6.4. Clasa HCN3A............................................ 18 Class HCP3A ............................................ 20 6.5. Clasa HCP3A ............................................ 20 Class HCR3A............................................ 22 6.6. Clasa HCR3A............................................ 22 Class FSM1H............................................ 24 6.7. Clasa FSM1H............................................ 24

4.0 PIPES ......................................................... 10 4.0 TEVI ............................................................ 10

5.0 GASKETS .................................................. 11 5.0 GARNITURI ................................................ 11

6.0 PIPING CLASSES LIST ............................. 11 6.0 LISTA CLASELOR DE CONDUCTA .......... 11

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

3 of 25

1.0

GENERALS

1.0

GENERALITATI

This specification covers the minimum design Aceasta specificatie acopera cerintele minime requirements for piping components to be used pentru calculul componentelor conductelor for process and utility systems for this project. utilizate pentru process si sistemele utilitare in acest proiect. 2.0 ABBREVIATIONS 2.0 ABREVIERI

PO crude oil WP Produced Water TW Treated water IW injection water PN nominal pressure ND nominal diameter (mm) NPS nominal pipe size (inch) 3.0 3.1 REFFERENCES DESIGN CODES

PO titei brut WP Apa bruta TW Apa tratata IW Apa de injectie PN presiunea nominala DN diametru nominal (mm) NPS diametru nominat al tevii (inch) 3.0 REFERINTE

3.1. CODURI DE PROIECTARE - Conducte Industriale Metalice - Technical Specification for Piping Material Classes Design According to EN 13480 3.2. STANDARDE SI CODURI

Metallic Industrial piping - Part 1: General Metallic Industrial piping - Part 2: Materials Metallic Industrial piping- Part3: Design and calculation Metallic Industrial piping-Part4: Fabrication and installation Metallic Industrial piping - Part 5: Inspection and testing Met al l i c I ndust ri al pi pi ng - Part 6: Addi ti onal requi rem ent s f or buried piping Met allic I ndustri al pi pi ng - Part 7: G ui dance on the use of conf ormity assessment procedures Unfired pressure v essels - Part 3: Design Technical requirements for erection, using, repairing and inspection of metallic pipelines Radi ographic t esti ng of butt wel ded j oi nt s on pressuri zed mechani cal syst em s and hoi sting syst em component s Flanges and their joint s. Circul ar f langes f or pi pes, v alv es, f i t t i n g s a n d a c ce sso r i e s, Cl a ss d e si g n at e d. P a r t 1 : St e el flanges, NPS 1/2 to 24 Flanges and their joint s. Circul ar f langes f or pi pes, v alv es, f it ti ngs and accessori es, Cl ass de si gnat ed. Part 3: Copper alloy flanges Flanges and their joint s. Circul ar f langes f or pi pes, v alv es, fittings and ac cessories, Class designat ed. Part 3:

SR EN 13480 EP FA MP 03 TS 3.2

STANDARDS AND CODES

SR SR SR SR SR EN 13480-1 EN 13480-2 EN 13480-3 EN 13480-4 EN 13480-5

SR EN 13480-6 CEN/TR 13480-7 EN 13445-3 ISCIR PT C6-2003 ISCIR PT CR 13-2003 SR EN 1759-1

SR EN 1759-3 SR EN 1759-4

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

4 of 25

STAS 6150-84 STAS 7451-88 STAS 8121/1 STAS 8121/2 STAS 8121/3 DIN 2501 SR ISO 7005-1 SR ISO 7005-2 SR ISO 7005-3 SR EN 1092-1 SR EN 1514-1

SR EN 1514-2

SR EN 1514-3

SR EN 1514-4

SR EN 1514-6

SR EN 1514-7

SR EN 1514-8 SR EN 12560-1 SR EN 12560-2 SR EN 12560-3 SR EN 12560-4 SR EN 12560-5 SR EN 12560-6 SR EN 12560-7

Alumi ni um all oy f l anges Circular neck flanges f or welding on pipe head -PN 64. Sizes Steel f langes. Blind f langes: PN 6; PN 10; PN 16; PN 25; PN 40; PN 64; PN 100; PN 160. Sizes Threaded elements for flanges assembling General technical quality conditions T hreaded elem ent s f or f langes assembli ng - Doubl e ended bolt s-dim ensi ons Threaded elements f or f langes assem bling - Hexagonal nutdi m ensi ons Fl anges - mati ng dimensi ons Metallic flanges. Part 1: Steel flanges Metallic flanges. Part 1: Cast iron flanges Metallic flanges. Part 3: Copper alloys and com posi t e flanges Flanges and their joint s. Circul ar f langes f or pi pes, v alv es, f i t t i n g s a n d a c c e s s o r i e s, P N d e si g n a t e d - P a r t 1 : S t e e l flanges F l an g e s a n d t h ei r j oi nt s - Di m e n si o n s of g a sk et s f or PN designated flanges - Part 1: Non-metallic flat gaskets with or without inserts F l an g e s a n d t h ei r j oi nt s - Di m e n si o n s of g a sk et s f or PN de si gnat e d f l ange s - Part 2: Spi ral woun d ga sket s f or use with steel flanges F l an g e s a n d t h ei r j oi nt s - Di m e n si o n s of g a sk et s f or PN de si g n at e d f l ange s - Pa rt 3: N on -m et al l i c PT F E env el ope gaskets F l anges and t hei r j oi nt s - Dim ensi ons of gasket s f or PN desi gnat ed f l anges - Part 4: Corrugat ed, f l at or groov ed metallic and filled metallic gaskets for use with steel flanges F l an g e s a n d t h ei r j oi nt s - Di m e n si o n s of g a sk et s f or PN designat ed f langes - Part 6: Cov ered serrat ed met al gasket s f or use with steel flanges F l an g e s a n d t h ei r j oi nt s - Di m e n si o n s of g a sk et s f or PN designat ed f langes - Part 7: Cov ered metal jacketed gasket s f or use with steel flanges F l anges and t hei r j oi nt s - Dim ensi ons of gasket s f or RN desi gnat ed f langes - Part 8: Pol ymeric 0-ri ng gasket s f or groov ed flanges Flanges and their joints-Gaskets for Cl ass-desi gnat ed flanges-Part 1:Non-metallic flat gaskets with or without inserts Flanges and t h ei r j oi n t s - G a sk et s f or Cl a ss - d e si g n at e d f l anges - Part 2: Spi ral wo und ga sket s f or use wi t h st eel flanges Flanges and t h ei r j oi nt s - G a sk et s f or Cl a ss - d e si g n at ed flanges - Part 3: Non metallic PTFE env elope gasket s Flanges and t h ei r j oi n t s - G a sk et s f or Cl a ss - d e si g n at e d f langes - Part 4: Corrugat ed, f lat or groov ed met allic and filled metallic gaskets f or use with ste el flanges Flanges and t h ei r j oi n t s - G a sk et s f or Cl a ss - d e si g n at e d flanges - Part 5: Metallic ring joint gaskets for use with steel flanges Flanges and t hei r j oi nt s - G a sk et s f or Class-designated flanges - Part 6: Covered serrated metal gaskets for use with steel flanges Flanges and t h ei r j oi n t s - G a sk et s f or Cl a ss - d e si g n at e d

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

5 of 25

SR EN 10208 2 SR EN 10216-1

SR EN 10216-2 SR EN 10216-3 SR EN 10216-4 SR EN 10216-5 SR EN 10217-1

SR EN 10217-2 SR EN 10217-3 SR EN 10217-4

SR EN 10217-5

SR EN 10217-6 SR EN 10217-7 SR EN 10028-1 SR EN 10028-2 SR EN 10028-3 SR EN 10028-4 SR EN 10028-5 SR EN 10028-6 SR EN 10028-7 SR EN 10222-1 SR EN 10222-2

flanges - Part 7: Covered metal jacketed gaskets for use with steel flanges St eel pi pes f or pi peli nes f or combusti bl e f l ui ds . T echnical deliv ery conditions - Part 2: Pipes of requirements class- B Seam l e ss st eel t u be s f or pre ssu re pur p o se s T ech ni cal del i v ery condi t i o n s Pa rt 1: No n-al l oy st e el t ub e s wi t h specif ied room temperature properties. Seam l e ss st eel t u be s f or pre ssu re pur p o se s T ech ni cal delivery conditions Part 2: Non-alloy and alloy steel tubes with specified elev ated temperature properties. Seam l e ss st eel t u be s f or pre ssu re pur p o se s T ech ni cal delivery conditions Part 3: Alloy tine grain steel tubes. Seam l e ss st eel t u be s f or pre ssu re pur p o se s T ech ni cal delivery conditions Part 4: Non-alloy and alloy steel tubes with specif ied low temperat ure properties. Seam l e ss st eel t u be s f or pre s su re pur p o se s T ech ni cal delivery conditions Part 5: Stainless steel tubes. Welded st eel t ubes f or pressure purposes Technical delivery conditions Part 1: Non-al l oy st eel t ubes wi t h specif ied room temperature properties. W el ded st e el t ub e s f or pr e ssur e p ur po se s T echni cal deliv ery conditions Part 2: Electric welded non-alloy and a l l o y st e e l t u b e s wi t h sp e c i f i e d e l e v a t e d t e m p e r a t u r e properties. W el ded st e el t ub e s f or pr e ssur e p ur po se s Technical delivery conditions Part 3: Alloy fine grain steel tubes. Welded st eel t ubes f or pressure purposes Technical delivery conditions Part 4: Electric welded non-alloy steel tubes with specified low temperature properties. W el ded st e el t ub e s f or pr e ssur e p ur po se s Technical deliv ery condi tions Part 5: Submerged arc wel ded nona l l o y a n d al l o y st e el t u b e s wi t h sp e c i f i ed e l ev a t e d temperat ure properties W el d e d st e e l t u b e s f o r p r e s su r e p u r p o se s T e c h n i c a l del iv ery condi ti ons Part 6: Subm erged arc wel ded non alloy steel tubes with specif ied low temperature properties W elded st eel t ubes f or pressure purposes - T echni cal deliv ery conditions - Part 7: Stai nless st eel T ubes Flat product s made of steel f or pressure purposes - Part 1: General requirement s Flat product s made of st eel f or pressure purposes - Part 2: Non -al l oy a nd al l oy ste el wi th sp eci f i ed el ev ated temperat ure properties Flat product s made of steel f or pressure purposes - Part 3: W eldable fine grain steels, normalized Flat product s made of steel f or pressure purposes - Part 4: Nickel alloy steels with specified low temperature properties Flat product s made of steel f or pre ssure purposes - Part 5: W eldable f ine grain steel s, thermo -mechanically rolled Flat product s made of steel f or pressure purposes - Part 6: W eldable f ine grain steel s quenched and tempered Flat product s made of steel f or press ure purposes - Part 7: Stainless steel Steel f orgings f or pressure purposes - Part 1 : General requirement s f or open die f orgings Steel forgings for pressure purposes - Part 2: Ferritic martensitic steels with specified elevated t em perat ure

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

6 of 25

SR EN 10222-3 SR EN 10222-4 SR EN 10222-5 SR EN 10213-1 SR EN 10213-2 SR EN 10213-3 SR EN 10213-4 SR EN 10204 SR EN 10253-2 SR EN 10253-4 SR EN 10269 ISO 898-1 SR EN 1515-1 SR EN 1515-2 EN 1503-1 EN 1983 EN 1984 EN 12266-1

EN 12266-2 EN 13709 EN 14141 EN 14341 ISO/FDIS 7121 ISO 17292 ASME B31. 3 ASME B16. 48 API 6D/SR ISO 14313 API 600/SR EN ISO 10434 API 602/SR EN ISO 15761 API 607/ISO 10497-5:2004 MSS-SP-97

properties St eel f orgi ngs f or pressure purposes - Part 3: Nickel st eel s with specif ied low temperat ure properties Steel f orgings f or pressure purposes - Part 4: W eldable fine grain steels with high proof strength St eel f orgi ngs f or pressure purposes - Part 5: Mart ensiti c, austenitic and austenitic-f erritic stainless steels T echni cal deliv ery conditions f or st eel casti ng f or pressure purposes - Part 1: General T echni cal deliv ery conditions f or st eel casti ng f or pressure purposes - Part 2: Steel grades f or use at room temperature and elevated temperature T echni cal deliv ery conditions f or st eel casti ng f or pressure purposes - Part 3: Steel grades f or use at l ow temperature T echni cal deliv ery conditions f or st eel casti ng f or pressure purpo se s - Part 4: Aust e ni t i c and aust e ni t i c -f erri t i c st eel grades Metallic Product s - Types of Inspection Document s Butt-welding pipe fittings. Part 2: Non alloy and ferritic alloy steel s with specif ied inspection requirements Butt-welding pipe f ittings. Part 4: W rought aust enitic and a u st e ni t i c -f e rri t i c ( du pl ex ) st ai nl e ss st el s wi t h sp eci f i c inspection requirement s Steel and nickel alloys for fasteners with specified elevated and/or low temperature properties M ec h a ni c al p r op e rt i e s of f a st e n er s m a de of c a rb o n st e el and alloy steel - Part 1: Bolts, screw and studs Flanges and their joints-Bolting - Part 1: Selection of bolting F l anges a nd t hei r j oi nt s - Bol t i ng --Part 2: Clasi f i cati on of bolt materials f or steel flanges, PN designated Valv es - Material s f or bodies, bonnet s and covers - Part 1: Steels specified in European Standards Industrial valves - Steel ball valves Industrial valves - Steel gate valves Indust rial v alv es - testing of v alv es - Part 1: Pressure test s, te st pr oc ed ur e s an d acc ept a nc e cri t eri a - Man d ato ry requirement s I n du st ri al v alv e s - t e st i n g of v alv e s - P ar t 2 : T e st s, t e st procedure s an d accept ance cri t eri a - Supl em ent ary requirement s I nd u st ri al v alv es - St eel gl ob e a nd gl o be st o p a nd c he ck valves Valves for natural gas transportation in pipelines Perf ormance requirements and tests Industrial v alv es - Steel check valves Steel ball v alves f or general -purpose industrial applications Metal b al l v alv s f o r pe t r ol e um , p et r oc hem i c al a n d a l l i e d industries Process piping Steel Line Blanks Pipeline Transport ation Syst ems - Specif ication f or Pipeline Valves Steel Gate Valv es - Flanged and Butt W elding Ends Com pact Carbo n St eel Gate Valves- Flanged, Threaded, W eldi ng and Ext ended Body Ends Fire Test for Soft Seated Quarter Turn Valves Forged Carbon Steel Branch Outlet Fittings Socket

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

7 of 25

NACE MR 0175/ISO 15156-1 NACE MR 0175/ISO 15156-2

NACE MR 0175/ISO 15156-3

W elding, Threaded and Butt weld Ends Petroleum and natural gas industries-Material for use in H2S containing environments in oil and gas production-Part1: General principles for selection of cracking-resistant materials Petroleum and natural gas industries-Material for use in H2S containing environments in oil and gas production-Part2: Cracking resistant carbon and low alloy steels and the use of cast irons Petroleum and natural gas industries-Material for use in H2S containing environments in oil and gas production-Part3: Cracking resistant CRAs (corrosion resistant alloys) and other alloys

3.3

DESIGN CONDITION

3.3. CONDITII DE PROIECTARE Aceasta specificatie este destinata proiectarii tuturor elementelor de conducta (piping), elemente desemnate prin PN (16, 25, 40, 100), in baza SR EN 13480-3. Limitele de temperatura si presiune aratate in clasele materialelor de conducte sunt in baza conditiilor de proiectare ale flanselor cuprinse in SR EN 1092-1. Estimarea clasei pentru alte componente trebuie sa fie in conformitate cu standardele dupa care ele sunt fabricate. Categoriile de conducta sunt selectate in conformitate cu Directiva pentru echipamente sub presiune 97/23/EC a Parlamentului European si a Consiliului din 29 mai 1997 si , in acest caz , PT ISCIR PT C6-2003, trebuie mentionat. 3.4. DIMENSIUNI NOMINALE

These specifications is intended for design of all the in-plant pipes (piping), for PN (16, 25, 40, 100) designated piping elements and is based on SR EN 13480-3 The pressure and temperature limits shown in piping material classes are based on flange design conditions per SR EN 1092-1. The rating for other components shall be as specified in the standards to which they are manufactured. The piping category is selected in accordance to Pressure Equipment Directive 97/23/EC of European Parliament and of the Council of 29 May 1997, and PT ISCIR PT C6-2003, should be mentioned in this case. 3.4 NOMINAL SIZE

For steel piping systems the nominal diameters Pentru sistemele de conducta de otel, (ND) are equivalent to the following imperial size diametrele nominale (DN) sunt echivalente cu (NPS): urmatoarele dimensiuni imperiale (NPS): ND NPS 6 1/8 8

1/4

10 3/8

20 3/4

25 1

32 1

40 1

50 2

65 2

80 3

ND NPS 3.5 3.5.1 General

100 4

125 5

150 6

200 8

250 10

300

12

350 14

400 16

500 20

600 24

PIPING CLASSES

3.5. CLASE CONDUCTE 3.5.1. Generalitati

Piping components are assembled into Componentele conductelor sunt impartite in compatible groups called piping classes. The grupe compatibile numite clase de conducte material class for any line is determined by the tehnologice . Clasa de material pentru orice linie temperature, pressure, fluid and service. este determinata de temperatura, presiune, fluid si destinatie .

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

8 of 25

The piping class details are according to the applicable standards and codes, and respect the PETROM recommendations from EP FA MP 03 TS. The heading of each piping class shows typical fluids, maximum and/or minimum temperature limit and the nominal corrosion allowance. Within each piping class there are several piping categories, acc. To appendix A of EP FA MP 03 TS. 3.5.2 Identification System for Piping Classes

Detaliile claselor de conducte sunt in conformitate cu standardele si codurile aplicabile si respecta recomandarile PETROM din EP FA MP 03 TS. Denumirea fiecarei clase de conducte va arata tipul fluidului, limita de temperatura, maxima si / sau minima si adaosul de coroziune nominal. Pentru fiecare clasa de conducta exista cateva categorii, conform anexei A din EP FA MP 03 TS.

3.5.2. Identificarea claselor de conducte

The follow identification system will be Urmatorul sistem de identificare se va considered for piping class classification. considera in clasificarea claselor de tevi. The piping class specifications are classified Denumirile claselor de conducta sunt using a five-digit (four letters and one number) clasificate utilizand un cod de identificare de cinci identification code. caractere (patru litere si o cifra). The code sequence is X1 X2 X3 Y X4, where: Secventele codurilor sunt X1 X2 X3 Y X4, unde: 1st Letter / Prima litera Fluid main processes code Cod Fluid process principal 2nd Letter / A doua litera Basic material Group/ Grupa materialului de baza 3nd Letter / A treia litera PN flange rating/ Presiunea nominala a flansei Fluid main processes code / Cod Fluid process principal Code Fluid Well gas Crude oil Condensate Natural gas Well gas injection (gas lift) Injection water Produced water Type of fluid Fluid group Temp. [C] -30 +160 -30 +100 Main Processes X1 X2 X3 Y X4

4 nd Letter / A patra litera Material code/ Cod material 1st Number / Primul numar Corrosive Allowance/ Adaos de coroziune

Gas

Gas and oil production plants Injection plants

Liquid

Basic Material Group / Grupa materialului de baza: C = Carbon Steel, Low Alloyed Steel / Otel carbon, Otel slab aliat S = Stainless Steel / Otel inox

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

9 of 25

Pressure Class / Flange Rating / Ratingul flansei/clasei : M = PN 16 N = PN25 P = PN 40 R = PN 100 Corrosion allowance / Adaos de coroziune : 3 = 3mm 1 = 0mm Material Code / Codul materialului: A = Carbon and Low Alloyed Steel / Otel carbon si slab aliat H = Stainless Steel / Otel inox 3.5.3 Carbon and low alloy steels The maximum operating temperature for carbon and low alloy steels is 60 C. The maximum operating pressure for carbon and low alloy steels is 64 bar. Requirements : a) Maximum hardness shall equal or less than 22 HRC. b) Nickel content is less than 1 %. c) The steels are not free-machining. d) Heat treatment are one of listed bellow: - Hot-rolled (carbon steel only); - Annealed; - Normalized; - Normalized and tempered; - Normalized, austenitized, quenched and tempered; - Austenitized, quenched and tempered. 3.5.4 Welds Processes and consumables should be selected in accordance with good engineering practice and must achieve the required cracking resistance. Piping shall be butt weld construction. O-lets may be used only for instrumentation connections and for ND < 40 piping. 3.5.5 Cold deformation and thermal stress relief Carbon and low alloy steels shall be thermally stress-relived following any cold deforming by rolling, cold forming, or others manufacturing processes if the permanent outer fibre deformation is greater than 5%. Thermal stress relief shall be performed in accordance with an appropriate code or standard. 3.5.3. Oteluri carbon si slab aliate Temperatura maxima de operare pentru otel carbon si slab aliat este 60C. Presiunea maxima de operare pentru otel carbon si slab aliat este 64 bar. Cerinte: a) Duritatea maxima trebuie sa fie mai mica sau egala cu 22HRC b) Continutul de nichel este sub 1% c) Otelul nu este strunjit d) Tretamentul termic este unul din lista: - Laminat la cald (doar pt. otel carbon) - Recoacere - Normalizare - Normalizare si revenire - Normalizare austenitica, calire si revenire - Austenitizare, calire si revenire. 3.5.4. Sudurile Procedeele de sudare si electrozii trebuiesc alese conform practicilor ingineresti si trebuie sa indeplineasca cerintele de rezistentala rupere. Conductele trebuie sa fie in constructive sudata cap la cap. O-leturile trebuie utilizate doar pentru conectarea instrumentatiei si doar pentru tevi cu DN<40. 3.5.5. Deformarea la rece si detensionarea termica Otelurile carbon si slab aliate trebuie sa fie detensionate dupa orice deformare la rece prin laminare, formare la rece sau alte procedee de fabricatie daca defarmarea remanenta permanenta a fibrei este mai mare de 5%. Detensionarea termica trebuie realizata conform codurilor si standardelor adecvate.

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

10 of 25

3.6

CERTIFICATION

3.6. CERTIFICARI Rapoartele testelor de materiale sunt cerute pentru toate tevile si componentele de tevi, inclusiv suruburi si piulite si garnituri. Rapoartele testarilor trebuie sa includa toate rezultatele testarilor cerute de standardele aplicabile. Certificatele de conformitate oferite in loc de raportul de testare a materialului nu sunt acceptate. Toate partile supuse presiunii si elementele de teava trebuie sa aiba certicat de conformitate dupa SR EN 10204 tip 3.1 (pt. categ. de conducta 0 si I) ca minim de cerinta sau 3.2 * (pt. categ. de conducta II si III) cand este cerut si sa includa toate certificatele originale sau copii ale certificatelor (pentru detalii vezi capitolul 6). Toate celelalte parti (ce lucreaza in medii non acide) trebuie sa aiba certificate conform SR EN 10204 tip 2.2. *NOTA: Se accepta certificat tip 3.1 in loc de 3.2, daca furnizorul de materiale are implementat un sistem de management al calitatii certificat de un organism competent avand ca obiectiv de activiate evaluarea specifica pentru materiale. 4.0 TEVI

Material test reports are required for al pipe and piping components, including bolts and gaskets. The test reports shall include all results of testing required by applicable standard. Certificates of compliance offered in lieu of material Test report, are not acceptable. All pressure containing parts and piping elements shall have material certification in compliance with SR EN 10204 type 3.1 (for piping category 0 and I) as a minimum, or 3.2 * (for piping category II and III) when required, and include original mill certificates or certified copies (see chapter 6 for details). All other parts (non-sour service) shall be provided with certification to SR EN 10204 type 2.2. *NOTE: 3.1 type certificate is accepted instead of 3.2 type provided that the supplier of materials has implemented a certified quality management system that enables the specific evaluation of materials. 4.0 PIPES 4.1 PIPE WALL THICKNESS ALL CLASSES

4.1. GROSIME PERETE TEAVA TOATE CLASELE Grosimile de perete ale tevilor prevazute in clasele conductelor sunt calculate in baza limitelor de presiune si temperatura, si unde este posibil sunt grosimi comercial disponibil conform SR EN 10216-3. 4.2. ADAOS DE COROZIUNE Adaosul de coroziune pentru tevi din otel si otel aliat trebuie sa fie in conformitate cu capitolul 6 din acest document. Unde otelul carbon trebuie sa fie expus la un mediu coroziv, un adaos de coroziune va fi prevazut in baza unor rapoarte de coroziune predictive. Toate elementele de otel carbon (care nu lucreaza in medii acide) vor avea un adaos de coroziune de 3.0mm. Tevile din otel carbon care lucreaza in medii non-acide si contin fluide nepericuloase (apa potabila, aer industrial etc.) vor avea un adaos de coroziune de 1.5mm.

Pipe wall thickness stated in the piping material classes are calculated based on the pressure and temperature limits, and wherever possible are commercially available schedules as specified as SR EN 10216-3. 4.2 CORROSION ALLOWANCE

Corrosion allowance for steel and alloy steel piping shall be in accordance with the Chapter 6 of this document. When carbon steel (CS) is to be exposed to a corrosive environment an appropriate corrosion allowance will be provided, based on predicted corrosion rates over the life of the asset. All CS items (non-sour service) containing hazardous or hydrocarbon process fluids will have a corrosion of 3.0 mm. Non-sour CS piping containing non-hazardous commodities (i.e. plant air, potable water, etc) will have a corrosion allowance of 1.5 mm.

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

11 of 25

5.0

GASKETS

5.0

GARNITURI

Asbestos containing gaskets shall be not used. 5.1 NON METALLIC FLAT GASKETS

Garniturile cu continut de azbest nu sunt premise. 5.1. GARNITURI PLATE NEMETALICE

Non metallic flat gaskets should be used for Garniturile plate nemetalice trebuie folosite PN 16, PN 25, and PN 40. pentru PN 16, PN 25 si PN 40. Non-metallic flat gasket type IBC, type B, for Trebuiesc folosite garniturile plate nemetalice raised face flanges (RF) according to SR EN tip IBC, tipB, conform SR EN 1514-1, pentru 1514-1 shall be used. flansele cu fete plane (RF). 5.2 SPIRAL WOUND GASKETS 5.2. GARNITURI SPIRAL WOUND Garniturile spirometalice trebuiesc folosite pentru flansele PN100. Garniturile spirometalie pentru flansele RF vor fi prevazute cu inel interior si exterior. Trebuiesc folosite garnituri spirometalice tip C/I, conform SR EN 1514-2, pentru flanse cu fete plane (RF). Toate garnturile Spiral wound trebuie sa fie marcate si cu codul culorilor conform SR EN 1514-2. 6.0 LISTA CLASELOR DE CONDUCTA

Spiral wound gasket should be used for PN 100 flanges. Spiral wound gasket for use with raised face flanges (RF) shall be provided with both inner compression ring and outer centring ring. Spiral wound gasket type C/l, for raised face flanges (RF) complies with SR EN 1514-2 shall be used. All spiral wound gaskets shall be marked and color coded in accordance with SR EN 1514-2. 6.0 PIPING CLASSES LIST

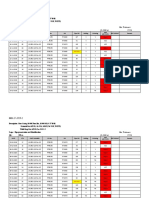

The piping systems from this project are Sistemele de conducta din acest proiect sunt presented in the table below: prezentate in tabelul urmator:

Process Param. / Param. de proces Class / Clasa Fluid / Fluid Temp. [C] Press. [bar] Design Param. / Param. de calcul Temp. [C] Press. [bar] Corrosion Allowance / Adaos de coroziune 3.0

Flange PN / PN flanse

Material / material Piping / Conducte Size NPS

ACM3A

PO

15

23

-2950

16

16

P275NL1

26

ACP3A

PO

15

2024

-2950

40

40

3.0

P275NL1

34

HCM3A

WP, TW TW

15

16

-2950

16

16

3.0

P275NL1

210

HCN3A

15

-2950

25

25

3.0

P275NL1

HCP3A

TW

15

624

-2950

40

40

3.0

P275NL1

HCR3A

IW

15

90

-2950

100

100

3.0

P355NL1

24

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

12 of 25

6.1

CLASS ACM3A

6.1. CLASA ACM3A

Material group: carbon steel Rating : PN 16 1)

DN / NPS Category Wall 5) thickness Pipe schedule Piping components Pipe Fittings Elbow 45 Elbow 90 Returns 11) Reducer Straight tee Reducing tee Cap O-let 12) 13) Weldolet Sockolet, 14) thredolet 9) Flanges Weld-neck flange type 11 Blind flange type 05 Line blanks Gaskets Bolting Bolts type 2.A Nuts type 1 15) Valve DN Ball valves Gate valves Globe valves Check valves

8) 4)

Service / Fluids: OIL Code Design: SR EN 13480-3 Flange facing: 0.8 to 3.2 Ra Type B2 2)

15 1/2 0 5 20 3/4 0 5.6 25 1 0 5.6 40 1 I 5 50 2 I 5.6

Corrosion Allowance: 3 mm Design temperature C Design pressure bar PO 3) P.W.H.T No required

65 2 II 5.6 80 3 II 5.6 100 4 II 6.3 150 6 II 7.1

-2960 16

CLASS ACM3A

Notes

SR EN10216-3 grade P275NL1, group 1.1, plain ends DN40, beveled ends DN50 6) or 7) 6) or 7) 7) 9) 10) SR EN 10253-2 type B, beveled ends , radius = 2D, 3D and 5D Grade P265 NL, group 1.1 or [Grade P285 NH, group 8E2 (1.2) forging] Grade P285 NH, group 8E2 (1.2) Grade P285 NH, group 8E2 (1.2) Grade P285 NH, group 8E2 (1.2) SR EN 10224-4 grade P285NH group 8E2 (1.2) Dimension comply with MSS SP97 The O-let size (DN) comply with Branch-Chart classes ACM3A Wall thickness to mach pipe SR EN 1092-1, material SR EN 10222-4 grade P285NH group 8E2 (1.2) PN 40 PN 16 SR EN 1092-1, material SR EN 10028-3 grade P275NH group 8E2 (1.1) PN 40 PN 16 Similar to ASME B16.48 , material SR EN 10028-3 grade P275NH group 8E2 (1.1) SR EN 1514-1 , non metallic flat gasket type IBC, expended graphite with insertion PN 40 PN 16 Dimensions and fabrication STAS 8121/3-84, Material 42CrMo4 QT SR EN 10269 Dimensions and fabrication STAS 8121/2-84, Material 42CrMo4 QT SR EN 10269 15 20 25 40 50 65 80 100 150 ISO 17292 Flanged ends PN16 Floating ball Trunnion SR EN 1984 Flanged ends PN16 SR EN 13709 Flanged ends PN16 SR EN 14341 Flanged ends PN16

Seamless Seamless

Forging Forging Forging Forging

Forging Forging Forging

Full bore Full bore Full bore

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

13 of 25

Notes:

1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11) 12) 13) 14) 15) Rating for material group 8.E2 (SR EN 1092-1). For all flanges inclusive for valves. Gas, Fluid Group 1 complience with CEN / TR 13480-7. Complies with SR EN 13480-1. The piping category is done by the maximum DN of the components. The pipe wall thickness was calculated at pressure limit and upgraded up the fittings wall thickness. If stress induced by the assembly of the piping on the supports and also by the thermal stress are larger than the stress from pressure limit, the designer shall calculate the new wall thickness for pipe DN600 = 12.5mm. For piping category 0 and I: pipe test category TC1 (SR EN 10216-3), inspection certificate type 3.1 (SR EN 10204), ordering options comply with Table 3.1 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. For piping category II and III: pipe test category TC2 (SR EN 10216-3), inspection certificate type 3.2 (SR EN 10204), ordering options comply with Table 3.1 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. Inspection certificate SR EN 10204: (piping category 0 and I type 3.1) and (piping category II and III type 3.2), ordering options comply with Table 7.1 and paragraph 7.2.1 of the EP FA MP 03 TS. Beveled end shall comply with SR EN 1092-1. Preferable use R = 5D, use 3D or 2D only if is not possible to use 5D. (ex: the space for piping is too small). Preferable use concentric reducer. Inspection certificate SR EN 10204: (piping category 0 and I type 3.1) and (piping category II and III type 3.2), ordering options complies with paragraph 7.2.1 of the EP FA MP 03 TS. The range of the O-let shall match with the outside diameter of the pipe. The threads size shall meci with the instrumentation equipment size see Branch Chart Classes ACM3A. Valves body and bonnet shall have pressure/temperature rating at least as for material group 8E2.

CLASS ACM3A BRANCH CHART instrumentation conection

mm (inch) 50 (2) 65 (2 ) 80 (3) 100 (4) 15 (1/2) SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL 20 (3/4) 25 (1) 40 (1 1/2)

LEGEND SL- Sockolet TL- Thredolet* * Thredolets threads shall match with the instrumentations threads

CLASS ACM3A BRANCH CHART pipe conection

mm (inch) 15 (1/2) 20 (3/4) 25 (1) 40 (1 ) 50 (2) 65 (2 ) 80 (3) 100 (4) 15 (1/2) ET RT RT RT WL WL WL WL ET RT RT RT WL WL WL ET RT RT RT WL WL ET RT RT RT RT ET RT RT RT ET RT RT ET RT

LEGEND ET- Buttwelded Equal Tee RT- Buttwelded Reduced Tee WL Weldolet RP - Reinforcing

20 (3/4)

25 (1)

40 (1 )

50 (2)

65 (2 )

80 (3)

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

14 of 25

6.2

CLASS ACP3A

6.2. CLASA ACP3A

Material group: carbon steel Rating : PN 40 1)

DN / NPS Category 5) Wall Thickness Pipe schedule Piping components Pipe Fittings 8) Elbow 45 Elbow 90 Returns Reducer Straight tee Reducing tee Cap O-let 12) 13) Weldolet Sockolet, thredolet14) Flanges 9)

Weld-neck flange type 11

11) 4)

Service / Fluids: OIL Code Design: SR EN 13480-3

Corrosion Allowance: 3 mm Design temperature C Design pressure bar PO 3) P.W.H.T No required

65 2 II 6.3 >STD 80 3 II 6.3 >STD 100 4 II 7.1 >STD 150 6 III 8 >STD

-550 40

CLASS ACP3A

Flange facing: 0.8 to 3.2 Ra Type B2 2)

15 1/2 0 5 160 20 3/4 0 5.6 160 25 1 0 5.6 >XS 40 1 I 5 XS 50 2 I 5.6 XS

Notes

SR EN10216-3 grade P275NL1, group 1.1, plain ends DN40, beveled ends DN50 6) or 7) 7) 7) SR EN 10253-2 type B, beveled ends9) , radius = 2D, 3D and 5D10) Grade P265 NL, group 1.1 or Grade P265 NL, group 1.1 [Grade P285 NH, group 8E2 (1.2) forging] Grade P285 NH, group 8E2 (1.2) Grade P285 NH, group 8E2 (1.2) Grade P285 NH, group 8E2 (1.2) SR EN 10222-4 grade P285NH group 8E2 (1.2) 160 160 160 XS XS XS XS XS XS Dimension comply with MSS SP97 The O-let size (DN) comply with Class Class 600 Branch-Chart classes ACP3A 3000 Wall thickness to mach pipe SR EN 1092-1, material SR EN 10222-4 grade P285NH group 8E2 (1.2) PN 40 SR EN 1092-1, material SR EN 10028-3 grade P275NH group 8E2 (1.1) PN 40 Similar to ASME B16.48 15) , material SR EN 10028-3 grade P275NH group 8E2 (1.1) SR EN 1514-1, non metallic flat gasket type IBC, expended graphite with insertion PN 40 Dimensions and fabrication STAS 8121/3-84, Material 42CrMo4 QT SR EN 10269 Dimensions and fabrication STAS 8121/2-84, Material 42CrMo4 QT SR EN 10269 15 20 25 40 50 65 80 100 150 ISO 17292 Flanged ends PN40 Floating ball Trunnion SR EN 1984 Flanged ends PN40 SR EN 13709 Flanged ends PN40 SR EN 14341 Flanged ends PN40

Seamless Seamless

Forging Forging Forging Forging

Forging Forging Forging

Blind flange type 05 Line blanks Gaskets Bolting Bolts type 2.A Nuts type 1 Valve DN Ball valves

16)

Gate valves Globe valves

16)

Full bore Full bore

Check valves

16)

Full bore

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

15 of 25

Notes:

1) 2) 3) 4) 5) Rating for material group 8.E2 (SR EN 1092-1). For all flanges inclusive for valves. Gas, Fluid Group 1 complience with CEN / TR 13480-7. Complies with SR EN 13480-1. The piping category is done by the maximum DN of the components. The pipe wall thickness was calculated at pressure limit and upgraded up the fittings wall thickness. If stress induced by the assembly of the piping on the supports and also by the thermal stress are larger than the stress from pressure limit, the designer shall calculate the new wall thickness. Wall thickness for pipe DN600 = 14.2mm. For piping category 0 and I: pipe test category TC1 (SR EN 10216-3), inspection certificate type 3.1 (SR EN 10204), ordering options comply with Table 3.1 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. For piping category II and III: pipe test category TC2 (SR EN 10216-3), inspection certificate type 3.2 (SR EN 10204), ordering options comply with Table 3.1 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. Inspection certificate SR EN 10204: (piping category 0 type 3.1) and (piping category II and III type 3.2), ordering options comply with Table 7.1 and paragraph 7.2.1 of the EP FA MP 03 TS. Beveled end shall comply with SR EN 1092-1. Preferable use R = 5D, use 3D or 2D only if is not possible to use 5D. (ex: the space for piping is too small). Preferable use concentric reducer. Inspection certificate SR EN 10204: (piping category 0 and I type 3.1) and (piping category II and III type 3.2). Ordering options comply with paragraph 7.2.1 of the EP FA MP 03 TS. The range of the O-let shall match with the outside diameter of the pipe. The threads size shall meci with the instrumentation equipment size see Branch Chart Classes ACP3A. See paragraph 10.1 of the EP FA MP 03 TS. Valves body and bonnet shall have pressure/temperature rating at least as for material group 8E2.

6) 7) 8) 9) 10) 11) 12) 13) 14) 15) 16)

CLASS ACP3A BRANCH CHART instrumentation conection

mm (inch) 50 (2) 65 (2 ) 80 (3) 100 (4) 15 (1/2) SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL 20 (3/4) 25 (1) 40 (1 1/2)

LEGEND SL- Sockolet TL- Thredolet* * Thredolets threads shall match with the instrumentations threads

CLASS ACP3A BRANCH CHART pipe conection

mm (inch) 15 (1/2) 20 (3/4) 25 (1) 40 (1 ) 50 (2) 65 (2 ) 80 (3) 100 (4) 15 (1/2) ET RT RT RT WL WL WL RP WL RP ET RT RT RT WL WL WL RP ET RT RT RT WL WL ET RT RT RT WL ET RT RT RT ET RT RT ET RT LEGEND ET- Buttwelded Equal Tee RT- Buttwelded Reduced Tee WL Weldolet RP - Reinforcing 20 (3/4) 25 (1) 40 (1 ) 50 (2) 65 (2 ) 80 (3)

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

16 of 25

6.3

CLASS HCM3A

6.3. CLASA HCM3A

Material group: carbon steel Rating : 1) PN 16

DN / NPS Category Wall Thickness5) Pipe schedule Piping components Pipe Fittings 8) Elbow 45 Elbow 90 Returns Reducer 11) Straight tee Reducing Tee Cap O-let 12) 13) Weldolet Sockolet, 14) thredolet 9) Flanges Weld-neck flange type 11 Blind flange type 05 Line blanks Gaskets Bolting Bolts type 2.A Nuts type 1 Valve DN 16) Ball valves Gate valves Globe valves Check valves

4)

Service / Fluids: Produced water, treated water, injection water Corrosion Allowance: 3 mm Code Design: SR EN 13480-3 Design temperature C -2960 Flange facing: 0.8 to 3.2 Ra 2) Type B2

15 1/2 0 5 20 3/4 0 5.6 25 1 0 5.6 40 1 0 5 50 2 0 5.6

CLASS HCM3A

Design pressure bar WP, TW, IW 3) P.W.H.T No required

65 2 0 5.6 80 3 0 5.6 100 4 0 6.3 150 6 II 7.1 200 8 II 8

16

Notes

SR EN10216-3 grade P275NL1, group 1.1, plain ends DN40, beveled ends DN50 6) or 7) 6) or 7) 7) SR EN 10253-2 type B, beveled ends9) , radius = 2D, 3D and 5D10) Grade P265 NL, group 1.1 or [Grade P285 NH, group 8E2 (1.2) forging] Grade P285 NH, group 8E2 (1.2) Grade P285 NH, group 8E2 (1.2) Grade P285 NH, group 8E2 (1.2) SR EN 10224-4 grade P285NH group 8E (1.2) Dimension comply with MSS SP97 The O-let size (DN) comply with Branch-Chart classes HCM3A Wall thickness to mach pipe SR EN 1092-1, material SR EN 10222-4 grade P285NH group 8E2 (1.2) PN 40 PN 16 SR EN 1092-1, material SR EN 10028-3 grade P275NH group 8E2 (1.1) PN 40 PN 16 Similar to ASME B16.48 15) , material SR EN 10028-3 grade P275NH group 8E2 (1.1) SR EN 1514-1, non metallic flat gasket type IBC, expended graphite with insertion PN 40 PN 16 Dimensions and fabrication STAS 8121/3-84, Material 42CrMo4 QT SR EN 10269 Dimensions and fabrication STAS 8121/2-84, Material 42CrMo4 QT SR EN 10269 15 20 25 40 50 65 80 100 150 ISO 17292 Flanged ends PN16 Floating ball Trunnion SR EN 1984 Flanged ends PN16 SR EN 13709 Flanged ends PN16 SR EN 14341 Flanged ends PN16

Seamless Seamless

Forging Forging Forging Forging

Forging Forging Forging

Full bore Full bore Full bore

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

17 of 25

Notes:

1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11) 12) 13) 14) 15) 16) Rating for material group 8.E2 (SR EN 1092-1). For all flanges inclusive for valves. Liquid Group 2 complience with CEN / TR 13480-7. Complies with SR EN 13480-1. The piping category is done by the maximum DN of the components. The pipe wall thickness was calculated at pressure limit and upgraded up the fittings wall thickness. If stress induced by the assembly of the piping on the supports and also by the thermal stress are larger than the stress from pressure limit, the designer shall calculate the new wall thickness for pipe DN600 = 12.5mm. For piping category 0 and I: pipe test category TC1 (SR EN 10216-3), inspection certificate type 3.1 (SR EN 10204), ordering options comply with Table 3.1 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. For piping category II and III: pipe test category TC2 (SR EN 10216-3), inspection certificate type 3.2 (SR EN 10204), ordering options comply with Table 3.1 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. Inspection certificate SR EN 10204: (piping category 0 and I type 3.1) and (piping category II and III type 3.2), ordering options comply with Table 7.1 and paragraph 7.2.1 of the EP FA MP 03 TS. Beveled end shall comply with SR EN 1092-1. Preferable use R = 5D, use 3D or 2D only if is not possible to use 5D. (ex: the space for piping is too small). Preferable use concentric reducer. Inspection certificate SR EN 10204: (piping category 0 and I type 3.1) and (piping category II and III type 3.2), ordering options complies with paragraph 7.2.1 of the EP FA MP 03 TS. The range of the O-let shall match with the outside diameter of the pipe. The threads size shall meci with the instrumentation equipment size see Branch Chart Classes HCM3A. See paragraph 10.1 of the EP FA MP 03 TS. Valves body and bonnet shall have pressure/temperature rating at least as for material group 8E2.

CLASS HCM3A BRANCH CHART instrumentation conection

mm (inch) 50 (2) 65 (2 ) 80 (3) 100 (4) 15 (1/2) SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL 20 (3/4) 25 (1) 40 (1 1/2)

LEGEND SL- Sockolet TL- Thredolet* * Thredolets threads shall match with the instrumentations threads

CLASS HCM3A BRANCH CHART pipe conection

mm (inch) 15 (1/2) 20 (3/4) 25 (1) 40 (1 ) 50 (2) 65 (2 ) 80 (3) 100 (4) 15 (1/2) ET RT RT RT WL WL WL WL ET RT RT RT WL WL WL ET RT RT RT WL WL ET RT RT RT RT ET RT RT RT ET RT RT ET RT

LEGEND ET- Buttwelded Equal Tee RT- Buttwelded Reduced Tee WL Weldolet RP - Reinforcing

20 (3/4)

25 (1)

40 (1 )

50 (2)

65 (2 )

80 (3)

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

18 of 25

6.4

CLASS HCN3A

6.4. CLASA HCN3A

Material group: carbon steel Rating : 1) PN 25

DN / NPS Category Wall Thickness5) Pipe schedule Piping components Pipe Fittings Elbow 45 Elbow 90 Returns Reducer 11) Straight tee Reducing Tee Cap O-let 12) 13) Weldolet Sockolet, 14) thredolet 9) Flanges Weld-neck flange type 11 Blind flange type 05 Line blanks Gaskets Bolting Bolts type 2.A Nuts type 1 Valve DN 16) Ball valves Gate valves Globe valves Check valves

8) 4)

Service / Fluids: treated water Corrosion Allowance: 3 mm Code Design: SR EN 13480-3 Design temperature C Design pressure bar Flange facing: 0.8 to 3.2 Ra TW 3) 2) Type B2 P.W.H.T No required

15 1/2 0 5 20 3/4 0 5.6 25 1 0 5.6 40 1 0 5 50 2 0 5.6 65 2 0 5.6 80 3 0 5.6 100 4 II 6.3 150 6

-550 25

CLASS HCN3A

Notes

SR EN10216-3 grade P275NL1, group 1.1, plain ends DN40, beveled ends DN50 6) or 7) 6) or 7) 7) SR EN 10253-2 type B, beveled ends9) , radius = 2D, 3D and 5D10) Grade P265 NL, group 1.1 or [Grade P285 NH, group 8E2 (1.2) forging] Grade P285 NH, group 8E2 (1.2) Grade P285 NH, group 8E2 (1.2) Grade P285 NH, group 8E2 (1.2) SR EN 10224-4 grade P285NH group 8E2 (1.2) 160 XS XS STD Class 6000 Class 3000

Seamless Seamless

Forging Forging Forging Forging XS

Wall thickness to mach pipe SR EN 1092-1, material SR EN 10222-4 grade P285NH group 8E2 (1.2) PN 40 SR EN 1092-1, material SR EN 10028-3 grade P275NH group 8E2 (1.1) PN 40 15) Similar to ASME B16.48 , material SR EN 10028-3 grade P275NH group 8E2 (1.1) SR EN 1514-1 , non metallic flat gasket type IBC, expended graphite with insertion PN 40 Dimensions and fabrication STAS 8121/3-84, Material 42CrMo4 QT SR EN 10269 Dimensions and fabrication STAS 8121/2-84, Material 42CrMo4 QT SR EN 10269 15 20 25 40 50 65 80 100 150 ISO 17292 Flanged ends PN25 Floating ball Trunnion SR EN 1984 Flanged ends PN25 SR EN 13709 Flanged ends PN25 SR EN 14341 Flanged ends PN25 Forging Forging Forging

Full bore Full bore Full bore

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

19 of 25

Notes:

1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11) 12) 13) 14) 15) 16) Rating for material group 8.E2 (SR EN 1092-1). For all flanges inclusive for valves. Liquid Group 2 complience with CEN / TR 13480-7. Complies with SR EN 13480-1. The piping category is done by the maximum DN of the components. The pipe wall thickness was calculated at pressure limit and upgraded up the fittings wall thickness. If stress induced by the assembly of the piping on the supports and also by the thermal stress are larger than the stress from pressure limit, the designer shall calculate the new wall thickness for pipe DN600 = 12.5mm. For piping category 0 and I: pipe test category TC1 (SR EN 10216-3), inspection certificate type 3.1 (SR EN 10204), ordering options comply with Table 3.1 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. For piping category II and III: pipe test category TC2 (SR EN 10216-3), inspection certificate type 3.2 (SR EN 10204), ordering options comply with Table 3.1 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. Inspection certificate SR EN 10204: (piping category 0 and I type 3.1) and (piping category II and III type 3.2), ordering options comply with Table 7.1 and paragraph 7.2.1 of the EP FA MP 03 TS. Beveled end shall comply with SR EN 1092-1. Preferable use R = 5D, use 3D or 2D only if is not possible to use 5D. (ex: the space for piping is too small). Preferable use concentric reducer. Inspection certificate SR EN 10204: (piping category 0 and I type 3.1) and (piping category II and III type 3.2), ordering options complies with paragraph 7.2.1 of the EP FA MP 03 TS. The range of the O-let shall match with the outside diameter of the pipe. The threads size shall meci with the instrumentation equipment size see Branch Chart Classes HCN3A. See paragraph 10.1 of the EP FA MP 03 TS. Valves body and bonnet shall have pressure/temperature rating at least as for material group 8E2.

CLASS HCN3A BRANCH CHART instrumentation conection

mm (inch) 50 (2) 65 (2 ) 80 (3) 100 (4) 15 (1/2) SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL 20 (3/4) 25 (1) 40 (1 1/2)

LEGEND SL- Sockolet TL- Thredolet* * Thredolets threads shall match with the instrumentations threads

CLASS HCN3A BRANCH CHART pipe conection

mm (inch) 15 (1/2) 20 (3/4) 25 (1) 40 (1 ) 50 (2) 65 (2 ) 80 (3) 100 (4) 15 (1/2) ET RT RT RT WL WL RP WL RP WL RP ET RT RT RT WL WL RP WL RP ET RT RT RT WL WL RP ET RT RT RT WL ET RT RT RT ET RT RT ET RT

LEGEND ET- Buttwelded Equal Tee RT- Buttwelded Reduced Tee WL Weldolet RP - Reinforcing

20 (3/4)

25 (1)

40 (1 )

50 (2)

65 (2 )

80 (3)

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

20 of 25

6.5

CLASS HCP3A

6.5. CLASA HCP3A

Material group: carbon steel Rating : PN 40 1)

DN / NPS Category 5) Wall thickness Pipe schedule Piping components Pipe Fittings 8) Elbow 45 Elbow 90 Returns Reducer Straight tee Reducing tee Cap O-let 12) 13) Weldolet Sockolet, thredolet14) Flanges 9), 18)

Weld-neck flange type 11

11) 4)

Service / Fluids: TREATED WATER Corrosion Allowance: 3 mm Code Design: SR EN 13480-3 Design temperature C Design pressure bar Flange facing: 0.8 to 3.2 Ra Type B2 2)

15 1/2 0 5 160 20 3/4 0 5.6 160 25 1 0 5.6 >XS 40 1 0 5 XS 50 2 0 5.6 XS

-550 40

CLASS HCP3A

TW 3) P.W.H.T No required

65 2 II 6.3 >STD 80 3 II 6.3 >STD 100 4 II 7.1 >STD 150 6 II 8 >STD Notes

SR EN10216-3 grade P275NL1, group 1.1, plain ends DN40, beveled ends DN50 6) or 7) 7) 7) SR EN 10253-2 type B, beveled ends9) , radius = 2D, 3D and 5D10) Grade P265 NL, group 1.1 or Grade P265 NL, group 1.1 [Grade P285 NH, group 8E2 (1.2) forging] Grade P285 NH, group 8E2 (1.2) Grade P285 NH, group 8E2 (1.2) Grade P285 NH, group 8E2 (1.2) SR EN 10222-4 grade P285NH group 8E2 (1.2) 160 160 160 XS XS XS XS XS XS Dimension comply with MSS SP97 The O-let size (DN) comply with Class Class 600 Branch-Chart classes HCP3A 3000 Wall thickness to mach pipe SR EN 1092-1, material SR EN 10222-4 grade P285NH group 8E2 (1.2) PN 40 SR EN 1092-1, material SR EN 10028-3 grade P275NH group 8E2 (1.1) PN 40 Similar to ASME B16.48 15) , material SR EN 10028-3 grade P275NH group 8E2 (1.1) SR EN 1514-1, non metallic flat gasket type IBC, expended graphite with insertion PN 40 Dimensions and fabrication STAS 8121/3-84, Material 42CrMo4 QT SR EN 10269 Dimensions and fabrication STAS 8121/2-84, Material 42CrMo4 QT SR EN 10269 15 20 25 40 50 65 80 100 150 ISO 17292 Flanged ends PN40 Floating ball Trunnion SR EN 1984 Flanged ends PN40 SR EN 13709 Flanged ends PN40 SR EN 14341 Flanged ends PN40

Seamless Seamless

Forging Forging Forging Forging

Forging Forging Forging

Blind flange type 05 Line blanks Gaskets Bolting Bolts type 2.A Nuts type 1 Valve DN Ball valves

16)

Gate valves Globe valves

16)

Full bore Full bore

Check valves

16)

Full bore

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

21 of 25

Notes:

1) 2) 3) 4) 5) Rating for material group 8.E2 (SR EN 1092-1). For all flanges inclusive for valves. Liquid Group 2 complience with CEN / TR 13480-7. Complies with SR EN 13480-1. The piping category is done by the maximum DN of the components. The pipe wall thickness was calculated at pressure limit and upgraded up the fittings wall thickness. If stress induced by the assembly of the piping on the supports and also by the thermal stress are larger than the stress from pressure limit, the designer shall calculate the new wall thickness. Wall thickness for pipe DN600 = 14.2mm. For piping category 0 and I: pipe test category TC1 (SR EN 10216-3), inspection certificate type 3.1 (SR EN 10204), ordering options comply with Table 3.1 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. For piping category II and III: pipe test category TC2 (SR EN 10216-3), inspection certificate type 3.2 (SR EN 10204), ordering options comply with Table 3.1 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. Inspection certificate SR EN 10204: (piping category 0 type 3.1) and (piping category II and III type 3.2), ordering options comply with Table 7.1 and paragraph 7.2.1 of the EP FA MP 03 TS. Beveled end shall comply with SR EN 1092-1. Preferable use R = 5D, use 3D or 2D only if is not possible to use 5D. (ex: the space for piping is too small). Preferable use concentric reducer. Inspection certificate SR EN 10204: (piping category 0 and I type 3.1) and (piping category II and III type 3.2). Ordering options comply with paragraph 7.2.1 of the EP FA MP 03 TS. The range of the O-let shall match with the outside diameter of the pipe. The threads size shall meci with the instrumentation equipment size see Branch Chart Classes HCP3A. See paragraph 10.1 of the EP FA MP 03 TS. Valves body and bonnet shall have pressure/temperature rating at least as for material group 8E2.

6) 7) 8) 9) 10) 11) 12) 13) 14) 15) 16)

CLASS HCP3A BRANCH CHART instrumentation conection

mm (inch) 50 (2) 65 (2 ) 80 (3) 100 (4) 15 (1/2) SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL 20 (3/4) 25 (1) 40 (1 1/2)

LEGEND SL- Sockolet TL- Thredolet* * Thredolets threads shall match with the instrumentations threads

CLASS HCP3A BRANCH CHART pipe conection

mm (inch) 15 (1/2) 20 (3/4) 25 (1) 40 (1 ) 50 (2) 65 (2 ) 80 (3) 100 (4) 15 (1/2) ET RT RT RT WL WL RP WL RP WL RP ET RT RT RT WL WL RP WL RP ET RT RT RT WL WL RP ET RT RT RT WL ET RT RT RT ET RT RT ET RT LEGEND ET- Buttwelded Equal Tee RT- Buttwelded Reduced Tee WL Weldolet RP - Reinforcing 20 (3/4) 25 (1) 40 (1 ) 50 (2) 65 (2 ) 80 (3)

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

22 of 25

6.6

CLASS HCR3A

6.6. CLASA HCR3A

Material group: carbon steel Rating : PN 100 1)

DN / NPS Category 5) Wall thickness Pipe schedule Piping components Pipe Fittings 8) Elbow 45 Elbow 90 Returns Reducer 11) Straight tee Reducing tee Cap O-let 12) 13) Weldolet Sockolet, 14) thredolet 9), Flanges

Weld-neck flange type 11

4)

Service / Fluids: GAS AND OIL PRODUCTION PLANTS Corrosion Allowance: 3 mm Code Design: SR EN 13480-3 Design temperature C Design pressure bar Flange facing: 0.8 to 3.2 Ra Type B2 2)

15 1/2 0 5 20 3/4 0 5.6 25 1 0 5.6 40 1 0 6.3 50 2 0 7.1

-550 40

CLASS HCR3A

PO 3) P.W.H.T No required

65 2 II 7.1 80 3 II 8 100 4 II 8.8 Notes

SR EN10216-3 grade P355NL1, group 1.1, plain ends DN40, beveled ends DN50 6) or 7) 7) 7) SR EN 10253-2 type B, beveled ends9) , radius = 2D, 3D and 5D10) Grade P355 NH, group 8E3 (1.2) Grade P355 NH, group 8E3 (1.2) Grade P355 NH, group 8E3 (1.2) Grade P355 NH, group 8E3 (1.2) SR EN 10222-4 grade P355NH group 8E3 (1.2) 160 160 160 160 160 XS XS Dimension comply with MSS SP97 The O-let size (DN) comply with Branch-Chart Class 6000 classes HCR3A Wall thickness to mach pipe SR EN 1092-1, material SR EN 10222-4 grade P355NH group 8E3 (1.2) PN 100 SR EN 1092-1, material SR EN 10022-4 grade P355NH group 8E3 (1.2) PN 100 15) Similar to ASME B16.48 , material SR EN 10022-4 grade P355NH group 8E3 (1.2) SR EN 1514-2 PN100,spiral wound gasket type C/I PN 100 Dimensions and fabrication STAS 8121/3-84, Material 42CrMo4 QT SR EN 10269 Dimensions and fabrication STAS 8121/2-84, Material 42CrMo4 QT SR EN 10269 15 20 25 40 50 65 80 100 150 SR EN 1983 Flanged ends PN100 Floating ball Trunnion SR EN 1984 Flanged ends PN100 SR EN 13709 Flanged ends PN100 SR EN 14341 Flanged ends PN100

Seamless Seamless

Forging Forging Forging Forging

Forging Forging Forging

Blind flange type 05 Line blanks Gaskets Bolting Bolts type 2.A Nuts type 1 Valve DN Ball valves

16)

Gate valves Globe valves

16)

Full bore Full bore

Check valves

16)

Full bore

This document is Company property. OMV-PETROM lawfully reserves all rights. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited. File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

23 of 25

Notes:

1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11) 12) 13) 14) 15) 16) Rating for material group 8.E3 (SR EN 1092-1). For all flanges inclusive for valves. Liquid Group 2 complience with CEN / TR 13480-7. Complies with SR EN 13480-1. The piping category is done by the maximum DN of the components. The pipe wall thickness was calculated at pressure limit and upgraded up the fittings wall thickness. If stress induced by the assembly of the piping on the supports and also by the thermal stress are larger than the stress from pressure limit, the designer shall calculate the new wall thickness. For piping category 0 and I: pipe test category TC1 (SR EN 10216-3), inspection certificate type 3.1 (SR EN 10204), ordering options comply with Table 3.1 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. For piping category II and III: pipe test category TC2 (SR EN 10216-3), inspection certificate type 3.2 (SR EN 10204), ordering options comply with Table 3.1 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. Inspection certificate SR EN 10204: (piping category 0 type 3.1) and (piping category II and III type 3.2), ordering options comply with Table 7.1 and paragraph 7.2.1 of the EP FA MP 03 TS. Beveled end shall comply with SR EN 1092-1. Preferable use R = 5D, use 3D or 2D only if is not possible to use 5D. (ex: the space for piping is too small). Preferable use concentric reducer. Inspection certificate SR EN 10204: (piping category 0 and I type 3.1) and (piping category II and III type 3.2). Ordering options comply with paragraph 7.2.1 of the EP FA MP 03 TS. The range of the O-let shall match with the outside diameter of the pipe. The threads size shall meci with the instrumentation equipment size see Branch Chart Classes HCR3A. See paragraph 10.1 of the EP FA MP 03 TS. Valves body and bonnet shall have pressure/temperature rating at least as for material group 8E2.

CLASS HCR3A BRANCH CHART instrumentation conection

mm (inch) 50 (2) 65 (2 ) 80 (3) 100 (4) 15 (1/2) SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL SL, TL 20 (3/4) 25 (1) 40 (1 1/2)

LEGEND SL- Sockolet TL- Thredolet* * Thredolets threads shall match with the instrumentations threads

CLASS HCR3A BRANCH CHART pipe conection

mm (inch) 15 (1/2) 20 (3/4) 25 (1) 40 (1 ) 50 (2) 65 (2 ) 80 (3) 100 (4) 15 (1/2) ET RT RT RT WL WL WL WL ET RT RT RT WL WL WL ET RT RT RT WL WL ET RT RT RT RT ET RT RT RT ET RT RT ET RT LEGEND ET- Buttwelded Equal Tee RT- Buttwelded Reduced Tee WL Weldolet RP - Reinforcing 20 (3/4) 25 (1) 40 (1 ) 50 (2) 65 (2 ) 80 (3)

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

24 of 25

6.7

CLASS FSM1H

6.7. CLASA FSM1H

Material group: Stainless steel Rating : PN 16 1)

DN / NPS Category Wall 5) Thickness Pipe schedule Piping components Pipe Fittings 7) Elbow 45 Elbow 90 Returns Reducer 10) Straight tee Reducing tee Cap 11) O-let Weldolet Sockolet, thredolet 12) Flanges Weld-neck flange type 11 Blind flange type 05 Line blanks Gaskets Bolting Bolts type 2.A Nuts type 1 Valve DN Ball valves Gate valves Globe valves Check valves

4)

Service / Fluids: CHEMICAL INJECTION Corrosion Allowance: 0 mm Code Design: SR EN 13480-3 Design temperature C Design pressure bar Flange facing: 0.8 to 3.2 Ra Type B2 2)

25 1 0 2.9 Sch 30

-550 16

CLASS FSM1H

XH 3) P.W.H.T No required

Notes

SR EN10216-5 X6CrNiMoTi17-12-2, group 8.1, plain ends DN40, beveled ends DN50 6) SR EN 10253-4 type B, beveled ends8) , radius = 2D, 3D and 5D9) Grade X6CrNiMoTi17-12-2, group 8.1 Grade X6CrNiMoTi17-12-2 15E0(8.1) Grade X6CrNiMoTi17 Grade X6CrNiMoTi17 SR EN 10222-5 Grade X6CrNiMoTi17-12-2 15E0(8.1) Dimension comply with MSS SP97 The O-let size (DN) comply with Branch-Chart classesFSM1H (class 3000) Wall thickness to mach pipe SR EN 1092-1, material SR EN 10222-5 Grade X6CrNiMoTi17-12-2 15E0(8.1) PN 40 SR EN 1092-1, material SR EN 10028-7 Grade X6CrNiMoTi17-12-2 15E0(8.1) PN 40 13) Similar to ASME B16.48 , material SR EN 10028-7 Grade X6CrNiMoTi17-12-2 15E0(8.1) SR EN 1514-1 , non metallic flat gasket type IBC, PN 40 Dimensions and fabrication STAS 8121/3-84, Material 42CrMo4 QT SR EN 10269 Dimensions and fabrication STAS 8121/2-84, Material 42CrMo4 QT SR EN 10269 15 20 25 40 50 65 80 100 150 SR EN 1983 Flanged ends PN16 Floating ball Trunnion SR EN 1984 Flanged ends PN16 SR EN 13709 Flanged ends PN16 SR EN 14341 Flanged ends PN16

Seamless Seamless

Forging Forging Forging Forging

Forging Forging Forging

Full bore Full bore Full bore

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

WATER FLOOD PILOT PROJECT IN TICLENI AREA / PROIECT PILOT DE INJECTIE APA IN ZONA TICLENI PIPING CLASSES SPECIFICATION / SPECIFICATIE CLASE CONDUCTE

Doc. no.: Rev. no.:

PETM-TIC-P00014-MSPE-0001 A01

Petrofac

COMPROIECT-92

Page no.

25 of 25

Notes:

1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11) 12) 13) Rating for material group 15E0 (SR EN 1092-1). For all flanges inclusive for valves. Liquid Group 1 complience with CEN / TR 13480-7. Complies with SR EN 13480-1. The piping category is done by the maximum DN of the components. The pipe wall thickness was calculated at pressure limit and upgraded up the fittings wall thickness. If stress induced by the assembly of the piping on the supports and also by the thermal stress are larger than the stress from pressure limit, the designer shall calculate the new wall thickness. For piping category 0 : pipe test category TC1 (SR EN 10216-2), inspection certificate type 3.1 (SR EN 10204), ordering options comply with Table 3.5 and paragraph 3.4 and 3.5 of the EP FA MP 03 TS. Inspection certificate SR EN 10204: (piping category 0 type 3.1) ordering options comply with Table 7.1 and paragraph 7.2.1 of the EP FA MP 03 TS. Beveled end shall comply with SR EN 1092-1. Preferable use R = 5D, use 3D or 2D only if is not possible to use 5D. (ex: the space for piping is too small). Preferable use concentric reducer. The range of the O-let shall match with the outside diameter of the pipe. The threads size shall meci with the instrumentation equipment size see Branch Chart Classes FSM1H. See paragraph 10.1 of the EP FA MP 03 TS.

CLASS FSM1H BRANCH CHART instrumentation conection

ND/NPS 6 (1/8) 8 (1/4) 10 (3/8) 15 (1/2) 20 (3/4) 25 (1)

1)

6 (1/8) ETS ETST RTS RTST RTS RTST RTBS RTBT SL, TL

8 (1/4)

10 (3/8)

15 (1/2)

20 (3/4)

25 (1)

LEGEND ET- Buttwelded Equal Tee ETS - Sockolet W elded Equal Tee ETST - Sockolet W elded Equal Tee with Threaded Instrument Air ETT - Buttwelded Equal Tee with Threaded Instrument Joint RT Buttwelded Reduced Tee RTS - Sockolet W elded Reduced Tee RTST - Sockolet W elded Reduced Tee with Threaded Instrument Joint RTBS Buttwelded and Sockolet 1) Welded Reduced Tee RTBT - Buttwelded Reduced Tee with Threaded Instrument Joint SL - Sockolet TL- Thredolet* * Thredolets threads shall match with the instrumentations threads

ETS ETST RTS RTST RTBS RTBT SL, TL

ETS ETST RTBS RTBT RTBS RTBT RTBS RTBT

ET ETT RT RTBT RT RTBT

ET ETT RT RTBT ET ETT

SL, TL

SL, TL

Inlet branch (process) buttwelded and outlet branch (instrumentation) Sockolet Welded

CLASS FSM1H BRANCH CHART pipe conection

mm (inch) 6 (1/8) 8 (1/4) 10 (3/8) 15 (1/2) 20 (3/4) 25 (1)

1)

6 (1/8) ETS RTS RTS RTBS SL SL

8 (1/4)

10 (3/8)

15 (1/2)

20 (3/4)

25 (1)

LEGEND ET- Buttwelded Equal Tee ETS - Sockolet Welded Equal Tee RT- Buttwelded Reduced Tee RTS - Sockolet Welded Reduced Tee RTBS Buttwelded and Sockolet Welded Reduced Tee 1) WL Weldolet RP - Reinforcing

ETS RT RTBS SL SL ETS RTBS RTBS RTBS ET RT RT ET RT ET

Inlet branch buttwelded and outlet branch Sockolet Welded

File name: 02_PETM-TIC-P00014-M-SPE-0001.doc

Вам также может понравиться

- Typical Arrangement of Air Cooler PipingДокумент4 страницыTypical Arrangement of Air Cooler Pipingvedadon100% (1)

- Thermal BowingДокумент8 страницThermal BowingA. VenugopalОценок пока нет

- Checklist For Line-By-Line ReviewДокумент3 страницыChecklist For Line-By-Line ReviewSusanna Paul100% (1)

- Guidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) AnalysisДокумент8 страницGuidelines For Acoustic Induced Vibration (AIV), Flow Induced Vibration (FIV) Analysisgpskumar22Оценок пока нет

- Plot Plan Development 19822mon TwuwДокумент9 страницPlot Plan Development 19822mon TwuwTom50% (2)

- How Do You Carry Out Estimation? Ans: 1. Input From BidДокумент21 страницаHow Do You Carry Out Estimation? Ans: 1. Input From BidSunil ShaОценок пока нет

- SPPID Check ListДокумент1 страницаSPPID Check Lists_baishya100% (2)

- SAMSUNG SEM-9471E - Process Design Manual - Health and Design Safety Specification Rev0 2004Документ7 страницSAMSUNG SEM-9471E - Process Design Manual - Health and Design Safety Specification Rev0 2004d_mazieroОценок пока нет

- New Why To Use A Spring SupportДокумент9 страницNew Why To Use A Spring SupportAmarKumarОценок пока нет

- Acceptable Reasons For Model Review ChangesДокумент8 страницAcceptable Reasons For Model Review Changeskad-7Оценок пока нет

- Pipe Stress Analysis Complete Course From PassДокумент2 страницыPipe Stress Analysis Complete Course From Passsleiman shokr100% (1)

- Rack Piping For A Piping Stress EngineerДокумент4 страницыRack Piping For A Piping Stress EngineerFaizal Khan100% (2)

- Plot Plan and Equipment LayoutДокумент23 страницыPlot Plan and Equipment Layoutravirawat15100% (1)

- Petronastechnicalstandards: Pipe SupportsДокумент41 страницаPetronastechnicalstandards: Pipe SupportsEric TingОценок пока нет

- Cross Country Piping Stress AnalysisДокумент8 страницCross Country Piping Stress Analysisprabu2001Оценок пока нет

- Zinq - AnalysisДокумент116 страницZinq - AnalysisAimiОценок пока нет

- Column Piping - Study Layout, Nozzle Orientation & Platforms RequirementsДокумент37 страницColumn Piping - Study Layout, Nozzle Orientation & Platforms RequirementsvasuОценок пока нет

- Piping Fundamentals - For Fresher Engineers: Piping System - What Is That?Документ29 страницPiping Fundamentals - For Fresher Engineers: Piping System - What Is That?Venkatesan Arunachalam100% (1)

- Pipe RoutДокумент10 страницPipe Routghkashyap1100% (1)

- DGS 1300 160 Bolt TorquingДокумент12 страницDGS 1300 160 Bolt TorquingMcmiltondmordom100% (1)

- Procedure To Model API 650 Nozzle1Документ4 страницыProcedure To Model API 650 Nozzle1Vishal KandОценок пока нет

- 3PS PL 006Документ22 страницы3PS PL 006ravi00098Оценок пока нет

- Dhamra LNG Terminal Pvt. Ltd. (DLTPL)Документ11 страницDhamra LNG Terminal Pvt. Ltd. (DLTPL)balajikrishnanОценок пока нет

- Line SizingДокумент14 страницLine SizingSaif MujawarОценок пока нет

- Procurement of Piping SP Item PDFДокумент1 страницаProcurement of Piping SP Item PDFDinda Putri AmaliaОценок пока нет

- Column Piping: Study Layout, Nozzle Orientation & Platforms RequirementsДокумент23 страницыColumn Piping: Study Layout, Nozzle Orientation & Platforms Requirementsreach_arindomОценок пока нет

- Petrofac International LTD.: Document TransmittalДокумент2 страницыPetrofac International LTD.: Document TransmittalbelhaskaОценок пока нет

- 2G Ethanol Biorefinery Project: 500050-00-000-PP01DB-003 Design Basis For Stress AnalysisДокумент23 страницы2G Ethanol Biorefinery Project: 500050-00-000-PP01DB-003 Design Basis For Stress AnalysisSachin ShindeОценок пока нет

- D 000 PIP 001 Piping Design Guide OverallДокумент181 страницаD 000 PIP 001 Piping Design Guide OverallAde FaruroziОценок пока нет

- S-00-1360-001 Rev.0 - FC (General Specification For Piping)Документ11 страницS-00-1360-001 Rev.0 - FC (General Specification For Piping)ajmainОценок пока нет

- 0000 A0 060 Cal 0001Документ418 страниц0000 A0 060 Cal 0001vignesh558855Оценок пока нет

- Underground Piping Stress Analysis Procedure Using Caesar IIДокумент7 страницUnderground Piping Stress Analysis Procedure Using Caesar IIFandy SipataОценок пока нет

- Flare Piping Stress NalysisДокумент7 страницFlare Piping Stress Nalysisgpskumar22100% (1)

- Caesar GuidelineДокумент152 страницыCaesar Guidelineraghib_afzal0% (1)

- Presentation On Piping Stress AnalysisДокумент17 страницPresentation On Piping Stress AnalysisTasawwur Tahir100% (1)

- Piping Support Ofon NG 018 XX PNL 405102 00Документ136 страницPiping Support Ofon NG 018 XX PNL 405102 00CHUKUDIОценок пока нет

- (D-103) Fractionating Trays - Rev1 PDFДокумент10 страниц(D-103) Fractionating Trays - Rev1 PDFmihir_jha2Оценок пока нет

- Checklist For Nozzle OrientationДокумент4 страницыChecklist For Nozzle OrientationDayo IdowuОценок пока нет

- Ssg-Ng01017365-Gen-Mp-7303-00002 - D01 - MR For FlangesДокумент8 страницSsg-Ng01017365-Gen-Mp-7303-00002 - D01 - MR For FlangesDaniel DamboОценок пока нет

- Plot Plan Design Criteria For Process UnitsДокумент11 страницPlot Plan Design Criteria For Process UnitsEddie SantillánОценок пока нет

- Pipeline Risk Management Basic ManualДокумент6 страницPipeline Risk Management Basic ManualhemnОценок пока нет

- Training Manual-Piping: Piping Study Underground PipingДокумент30 страницTraining Manual-Piping: Piping Study Underground Pipingrams789100% (2)

- Reviewed: by Nadiera at 11:45 Am, 5/17/22Документ16 страницReviewed: by Nadiera at 11:45 Am, 5/17/22carlos farinaОценок пока нет

- Piping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFДокумент5 страницPiping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDhiren PatelОценок пока нет

- Models For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationДокумент11 страницModels For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationElias TascaОценок пока нет

- Drain Philosophy Rev BДокумент26 страницDrain Philosophy Rev BAnonymous nxWj29Оценок пока нет

- Piping Typical Installation DrawingsДокумент51 страницаPiping Typical Installation DrawingsNguyen Anh Tung100% (3)

- Check List For Piping Material Take-Off (MTO)Документ7 страницCheck List For Piping Material Take-Off (MTO)MohamedОценок пока нет

- Piping Stress Analysis Design Basis PDFДокумент38 страницPiping Stress Analysis Design Basis PDFSaima SaimaОценок пока нет

- Piping Design Guide: Reliance Engineering Associates Private LimitedДокумент11 страницPiping Design Guide: Reliance Engineering Associates Private Limitedrishit_aОценок пока нет