Академический Документы

Профессиональный Документы

Культура Документы

Plastics Recycling - Cost Benefit Analysis-Austria-1998

Загружено:

ChevronelleИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Plastics Recycling - Cost Benefit Analysis-Austria-1998

Загружено:

ChevronelleАвторское право:

Доступные форматы

Cost-Benefit Analysis of Plastic Recycling Summary

COST-BENEFIT ANALYSIS OF PLASTIC RECYCLING

Macro-economic assessment of mechanical recycling of plastic waste in Austria including ecological effects

SUMMARY

Harald HUTTERER, Harald PILZ

GUA - Corporation for Ecological Waste Management

By order of Federal Environment Agency Austria

Complete version of the study (German): Monographien - Vol. 98, Federal Environment Agency Austria

Vienna, 1998

Umweltbundesamt/Federal Environment Agency Austria

M-098 (1998)

Cost-Benefit Analysis of Plastic Recycling Summary

II

SUMMARY

Survey Objectives

The aim of this work was to determine the potential and limits of mechanical recycling of plastics waste on the basis of the current composition of products and thereby also waste in Austria from ecological, micro and macro economic points of view. It was not yet possible to take into account ecological guidance measures or effects.

Methods

1. Determining the volumes of plastics in use, according to type and sector of application. 2. Determining the volume of plastics waste in fractions, where possible according to plastic type and waste origin. 3. Survey of current amounts recycled and estimation of possible future recycling potential with the present product or material composition. 4. Establishing recycling routes which incorporate the separate collection, sorting, purification and recycling of plastics wastes, whereby not only existing routes but also possible future recycling routes were surveyed. 5. Modelling the remaining system as a whole which included the production and processing of the total volume of plastics in use as well as the collection and disposal of non-recycled volumes of plastics wastes. 6. The compiling of all data for the calculation of material balances, the selected ecological parameters (energy balance, CO2 emissions, TOC emissions and volume of waste going to landfill sites) as well as for the macro- and micro-economic analyses. 7. The setting up of a simulation model which, on the basis of this data, computes the identified assessment parameters for the surveyed recycling routes as well as the resulting changes in the remaining system and compiles them in the macro-economic cost-benefit analysis. The details on future recycling potentials and routes are based on the assumption that no changes occur in the market inputs. Many levels of influence were incorporated as variable input parameters (e.g. the volume of incinerated waste from the system or the efficiency of waste incineration in view of the current and heat generated). A conventional energy conversion process in the form of a gas and steam turbine was added to the system in order to maintain constant current and steam production. For the ecological analysis of the recycling routes in the survey, the following criteria were calculated from the system material balances: the sum of the primary energy sources consumed, the CO2 emissions, the TOC emissions and the volume of waste going to landfill sites. These four criteria can be regarded as the most important ecological parameters for the recycling routes in consideration.1 Neither examination of other studies on mechanical plastics recycling nor intensive discussion in a parallel think tank on the topic yielded concrete grounds for other relevant criteria. This study, however, does not put a value to the ecological consequences of the mechanical recycling of the unsorted domestic collection material (mixed plastics and miscellaneous waste).

1

This conclusion is based on the following fundamental assumptions: a) the prolonged duration of use of polymer additives through mechanical recycling increases the probability that plastics waste including any additives present (assuming the implementation of the ordinance on landfills) will eventually go for incineration instead of landing on a dumping site. b) The potentially negative effects of using secondary products are no greater than those from the corresponding primary products. M-098 (1998)

Umweltbundesamt/Federal Environment Agency Austria

Cost-Benefit Analysis of Plastic Recycling Summary

III

For the micro-economic analysis, the costs for each stage of the recycling routes being surveyed were calculated on the basis of the price situation in 1997/98. These costs were compared to the savings accrued through alternative residual waste collection and treatment. Feasible levels of profit made from the production of secondary raw materials or the electricity and steam generated were also taken into account. The macro-economic evaluation was carried out by means of a macro-economic costbenefit analysis. The benefits of a recycling route, measured in monetary terms, were compared to the cost changes (mostly additional expenses) of the system as a whole with the implementation of the said recycling route. The following benefits were taken into consideration: replacement primary production of plastics, replacement conventional production of electricity and heat, reduction in CO2 emissions, in TOC emissions and in the volume of waste going to landfill disposal sites. The simulation model which was developed is capable of integrating additional recycling routes in the future or else further subdividing routes already included. Moreover, since all the data is inter-linked, a multitude of sensitivity analyses is possible.

Erze ugu Production

Vera rbeiProcessing

Eins Consumpatz

tion

Rest Residual mll-

Waste Coll.

MVA En . Recov., , W. Disposal

Alter Convent. nat.

En. Conv.

Getr Separate ennt

Collection

Sorti Sorting erun

Disassembly

Stoff Mechanical liche

Recycling

Fig. 1: Simplified diagram of the system structure used for the analysis of the mechanical recycling of plastics waste. The dotted arrows represent electricity and heat output. Abbreviations: Residual waste collection (Residual waste coll. ), Energy recovery (En. Recov.), Waste disposal (W. disposal), Conventional energy conversion (Convent. En. Conv.).

Plastics consumption

In 1995 the market input of new plastic products was estimated at some 700,000-760,000 tonnes in Austria i.e. approx. 90 kg per inhabitant and year. Non-plastic applications such as fibres, glues, varnish, paint and laminates as well as rubbers and elastomers are not included in this figure or ensuing figures in this survey. The main reason for ambiguity regarding market input comes from the problems of definition in non-plastic applications, undisclosed production figures, unrecorded processing statistics of small industries as well as import and export goods which are only part plastic. 90% of the plastics in use are thermoplasts. It is possible to categorise around half the total volume into sectors of application where the products are predominantly durable and packaging makes up approximately one third.

Umweltbundesamt/Federal Environment Agency Austria

M-098 (1998)

Cost-Benefit Analysis of Plastic Recycling Summary

IV

Tab. 1:

Consumption by type and sector of application (1000 t/a Austria 1995)

HDPE L/LDPE PP PVC PS EPS PET ABS Other thermoplasts PUR Other thermosets Total

Automotive 2 0 20 8 1 0 2 7 12 10 4 66

Electrical 2 6 11 15 15 0 3 10 12 4 10 86

Packaging 54 106 36 3 24 5 10 0 1 1 0 241

Building 15 6 6 113 1 11 0 0 3 12 4 171

Other 18 32 28 12 18 1 2 6 11 25 14 165

Total 91 149 102 150 58 17 16 23 40 53 31 730

Plastics waste

The volume of post-consumer plastics waste in Austria was estimated to have amounted to some 470,000 t. Whereby this figure also includes moisture and impregnated dirt on top of the plastics waste itself. These impurities make up a total of approximately 70,000 t. Therefore the volume of pure plastics waste comes to 400,000 t/a or 50 kg per inhabitant and year. Some further 50,000 t of production waste accumulates from the production and processing of the plastics used in Austria. The most prominent data ambiguity occurs in areas of commercial waste, building site waste and bulky refuse.

Post-consumer plastics waste in Austria 1995 (without impurities) Plastics waste from ...

... Mechanically recycled fraction ... Energy recovery fraction ... Separated electronic scrap ... Used cars ... Hospital waste ... Other commercial waste ... Building site refuse ... Bulky refuse ... Municipial solid waste ... Hazardous waste 0 20.000 40.000 60.000 80.000 100.000 120.000 140.000 Packaging (55 %)

Non-packaging (45 %)

t/a

Post-consumer plastics waste: 400,000 t, of which 220,000 t are packaging.

Additional 50,000 t of production waste, of which 38,000 t mechanically recycled.

Fig. 2: Distribution and make up of post-consumer plastics waste in Austria

Umweltbundesamt/Federal Environment Agency Austria

M-098 (1998)

Cost-Benefit Analysis of Plastic Recycling Summary

From the total 450,000 t of plastics waste, 82,000 t were mechanically and 31,000 t energetically recovered in 1995. From the waste not recycled, 17% went to incineration plants and 83% to disposal sites.

The status quo of mechanical recycling from plastics waste

In 1995 approximately 38,400 t of production waste and 2,500 t of non-packaging plastics waste were mechanically recycled. The latter originated mostly from the auto, agricultural and building sectors. The volumes from 1996 were used for the recycling of plastic packaging in order to portray the most up-to-date status possible. 44,200 t of plastic packaging (excluding impurities) were mechanically recycled in 1996. 19,100 t originated from domestic collection and the rest came from the commercial sector. The total amount of waste from plastic packaging in 1996 was estimated at 227,000 t. Thus in 1995 and 1996, 46,600 t (or 11.5%) of the post-consumer plastics waste and 85,000 t (or 19%) of the total volume of plastics waste (including production waste) were mechanically recycled.

Commercial packaging 30%

Domestic packaging 22% Non-packaging 3%

Production waste 45%

Fig. 3: Volumes of plastics waste recycled by origin

Definition of future recycling routes

Similarly to before, the details on future recycling routes are based on the assumption that no changes occur in the market input. The following new recycling routes were studied within the framework of this study: The feasibility of recycling a further 25,000 t/a (incl. impurities) in the sector of commercial packaging was tested. This corresponds to a third of the amount still contained in commercial waste and refuse from building sites ("commercial packaging plus"). The ensuing analysis and evaluation of the mechanical recycling process showed that the useful potential in the sector of commercial packaging would thus be exploited to its maximum. The implementation of this recycling route would mean that the separate collection of plastic packaging in the commercial sector would increase by 73% and the amount mechanically recycled by 85%.

Umweltbundesamt/Federal Environment Agency Austria

M-098 (1998)

Cost-Benefit Analysis of Plastic Recycling Summary

VI

The macro-economic analysis in this study showed that the mechanical recycling of domestic packaging at its present volume is not viable. Therefore an improved situation was modelled for the domestic sector in which only the packaging would be collected which, to the main extent, lends itself to mechanical recycling after a largely automated sorting process ("domestic packaging NEW"). A collection of this type would concentrate mainly on blowmoulded parts and plastic films. With such a "new" domestic collection the volume collected is expected to amount to some 34,000 t/a (incl. impurities) of which 23,000 t/a would be mechanically recycled. Although this would mean a 40% drop in the amount collected it would still mean a slight increase in the amount mechanically recycled. In the sector non-packaging, the assessments of possible recycling potentials are based on a recent survey of the Federal Environment Agency in Berlin in which the volumes of plastics waste are calculated in various waste fractions according to type and product group. The result in this sector was a further recycling potential of approx. 27,600 t/a (films used in agriculture and construction, PVC profiles and sheets, polyurethane flexible foam, large moulded parts from used electrical appliances and cars etc.). The potential increase in recycling of production waste was estimated at 6,400 t/a. The combination of existing and further potential recycling routes and the replacement of existing domestic waste collection with the "new" domestic collection would give a total mechanical recycling volume of 138,000 t/a of 'clean' plastics waste which is 30% of the total volume of plastics waste.

Tab. 2: Overview of waste amounts (excluding impurities) in separated collections and mechanically recycled in actual and target status quo's. To achieve the state of "domestic packaging - target", the recycling route "domestic packaging actual" is replaced by the recycling route "domestic packaging new". The other target states result from an expansion of the actual state.

'Clean' Plastics waste [t/a]

Commercial packaging - actual Commercial packaging - target Domestic packaging - actual Domestic packaging - target Non-packaging - actual Non-packaging - target Total post-consumer waste - actual Total post-consumer waste - target Production waste - actual Production waste - target Total of all plastics wastes - actual Total of all plastics wastes - target

1)

waste total 102.000

separate1) collection 26.600 49.500 49.200 30.400 2.400 28.600 78.200 108.500 38.400 44.800 116.600 153.300

material recovery 25.200 43.600 19.100 20.700 2.400 28.600 46.700 92.900 38.400 44.800 85.100 137.700

Material Rec. quota 24,7% 42,7% 15,3% 16,6% 1,3% 15,9% 11,5% 26,7% 76,8% 89,6% 18,6% 30,1%

125.000

180.000

407.000

50.000

457.000

in the case of packaging waste includes non-packaging mixed in the collection

Results

Umweltbundesamt/Federal Environment Agency Austria

M-098 (1998)

Cost-Benefit Analysis of Plastic Recycling Summary

VII

The evaluation of the recycling routes studied using the model described led to the following results under the current waste management frame conditions: Ecological parameter All the recycling routes for the criteria energy, CO2, TOC and disposal site content have positive effects on the system as a whole. Thus, for example, the primary energy balance per tonne of plastic can be improved using mechanical recycling instead of the alternative disposal method by 35% to 90%. Notably, the sum of all recycling routes ("domesticnew" instead of "domestic-actual") lowers the primary energy input of the system as a whole by only 15%. Waste management net cost analysis In the sector of production waste and non-packaging, the current costs for separate collection, purification and recycling of plastic waste are lower than the costs of the alternative residual waste collection and disposal. On the other hand, collection and recycling costs more for the commercial packaging sector and considerably more in the domestic packaging sector than the alternative residual waste collection and disposal.

Macro-economic cost-benefit analysis The question of whether the identified ecological advantages justified the addition microeconomic costs of recycling was examined with the aid of a cost-benefit analysis. The result of such a cost-benefit analysis is composed of the following factors:

Cost-benefit analysis factors for the processes of mechanical recycling Costs of separate collection and sorting Net costs of mechanical recycling and energy recovery + Savings on costs of residual waste collection + Savings on net costs of residual waste treatment = Result of the waste management net cost analysis

+ Savings on costs of primary production and conventional energy conversion + Savings on costs of emission avoidance and landfill site cleaning = Result of the macro-economic cost-benefit analysis

The cost-benefit analysis of the current mechanical recycling improved the already positive balance of the waste management net cost analysis in the areas of production waste and

Umweltbundesamt/Federal Environment Agency Austria M-098 (1998)

Cost-Benefit Analysis of Plastic Recycling Summary

VIII

non-packaging waste. The macro-economic advantage of additional recycling instead of disposal of non-packaging waste amounted to a total of ATS 220 Million p.a. The cost-benefit analysis of packaging recycling showed that, for the status quo, the benefits outweigh the additional costs in the commercial sector (positive cost-benefit balance). The mechanical recycling of plastic packaging from the commercial sector can therefore be seen as macro-economically viable.

Umweltbundesamt/Federal Environment Agency Austria

M-098 (1998)

Cost-Benefit Analysis of Plastic Recycling Summary

IX

Factors for the cost-benefit analysis on recycling route 'Domestic Packaging - Actual'

5,00

3,90

Costs (-) and saved costs (+) [ATS/kg of plastic waste collected]

2,00

2,10

2,30

Waste management net cost balance

Savings in primary production & conventional energy conversion

-2,50

Mechanical recycling and energy recovery

-5,00

Savings on residual waste collection

Savings on residual waste treatment

Savings on emission avoidance & disposal site cleaning

-9,80

-10,00

-13,20

Discrepancy margin due to erroneous collation

-15,00

Fig. 4: Sub total values of the waste management net cost balance and the resulting cost-benefit analysis on the example of mechanical recycling of plastic packaging from households, actual status 1996. All the given costs are uniformly based on the volume of plastic waste from separate collection.

Umweltbundesamt/Federal Environment Agency Austria M-098 (1998)

Macro-economic cost-benefit balance

-5,40

Separate collection and sorting

0,00

Cost-Benefit Analysis of Plastic Recycling Summary

Cost-benefit analysis for the maximum condition of material recovery

15.000

12.000

Positive net benefit In ATS/t of collected plastics waste

9.000

6.000

Production waste - actual Production waste - plus Commercial pack. - actual Commerial pack. - plus Domestic pack. - actual Domestic pack. - new Non-packaging - actual Non-packaging - plus

3.000

0 0 -3.000 50.000 100.000 150.000

-6.000

Results for the condition: 20% Waste Incineration, 80% Landfill

"Domestic packaging actual" is replaced by "domestic packaging new"

Collected plastics waste in t/a

Fig. 5: The macro-economic cost-benefit analysis of mechanical recycling of plastics revealed that, in its actual status, the recycling of production waste is connected with a significant macroeconomic benefit and the recycling of domestic packaging with a negative cost-benefit balance. The most important measures for the further development of plastics recycling should be the optimisation of domestic waste collection and the expansion of the recycling of nonpackaging materials. The width of the bars in the diagram represents the collection volume of each recycling route. Their height shows the cost benefit balance per tonne of plastics waste separately collected. Thus the area of each bar corresponds to the total macro-economic effect of a recycling route. By varying different basis data within its tolerance margins the cost-benefit balance for "commercial packaging plus" can give results between1,- and +1,- ATS/kg.

On the other hand the benefits of further lucrative potentials in the commercial sector only marginally outweigh the drawbacks. Nevertheless it should be noted that this further potential is made up of a mixture of viable additions (with partly new solutions for collection) and existing parts which are non-viable (similar to domestic levels of collection). At this juncture it must be emphasised that the cost-benefit balances for all the recycling routes are dependant on a series of parameters which may either change due to future developments in waste management policy (e.g. percentage actually incinerated during treatment of residual waste) or are subject to a certain tolerance margin due to loopholes in the quality of data (e.g. the conversion to monetary units of the external benefits from the avoidance of emissions and disposal site content). Generally, in the case of a variation of the values, the magnitude of the results will nevertheless remain within the acceptable range. These tolerance margins are particularly important regarding additional collection of plastic packaging in the commercial sector since relatively small alterations in the values used can make the cost-benefit analysis turn out positive or negative. The cost-benefit analysis revealed a negative result (5,- to 6,- ATS per kg of plastics waste collected separately) for the actual status of mechanical recycling of packaging from the domestic sector. This means that the benefits of the mechanical recycling do not outweigh

Umweltbundesamt/Federal Environment Agency Austria M-098 (1998)

Cost-Benefit Analysis of Plastic Recycling Summary

XI

the additional costs. Put another way round it also means that other methods which are less expensive have to be employed in order to achieve the benefits of mechanical recycling (e.g. via efficient production of heat and electricity, remediation of contaminated sites and the primary production of plastics). The cost-benefit balance improved considerably in the case of the optimised household collection domestic new (blow-moulded parts and large films), although it still remained slightly below zero (0,- to 1,- ATS/kg of plastic waste collected separately). However one can assume that a detailed examination of the possibilities for a restructuring of the domestic scheme on the basis of knowledge gleaned in practice would yield solutions with an even better cost-benefit ratio. Moreover the framework of this study was not able to take into consideration all the benefits of a separated plastic waste collection and the potential negative effects on systems collecting other wastes separately if domestic collection of plastic waste were completely abandoned. The consequences of increases in prices of energy and raw materials should also be examined as additional important factors influencing future decisions. On a macro-economic scale, the profit from the improvements in domestic waste collection amounts to some ATS 280 Million p.a. under present frame conditions. The following table shows the upper limits calculated for recycling potentials of plastic packaging waste in Austria which are feasible on a macro-economic scale. The combination given meets the minimum quota of 20% for mechanical recycling of plastic packaging waste as proposed in the ordinance on the definition of goals for packaging waste.

Tab. 3: Upper limit of macro-economically viable recycling potentials for plastic packaging waste in Austria

Packaging waste

1996

Macro-economically viable recovery potentials

Volume without impurities Household & Small enterprises

Collection Volume [1000 t] 30,4 49,5 79,9 Quota % 24% 49% 35%

Material recovery Volume [1000 t] 20,7 43,6 64,3 Quota % 17% 43% 28%

(large) Business and Industry Total

[1000 t] 125 102 227

"Clean"

"Clean" = without moisture or impregnated dirt!

Comments on the collection figures: They include non-packaging which was mixed in with the collection Equally the maximum useful volume given for the domestic sector can increase with rises in oil prices. Industry including present amounts recycled.

Conclusions and recommendations

In order to carry out the demands of waste management legislation for a macro-economically viable or purpose built recycling system requires the further development of the present waste management scheme. Similarly, guidance measures must also receive attention in order to achieve the goals of minimising harmful substances as well as keeping the use of energy, raw materials and waste disposal sites as low as possible. This study has shown that the methodology of a macro-economic cost-benefit analysis is an excellent tool for ascertaining useful recycling quotients and, in general, for the evaluation of the macro-economic expedience of waste management measures. With the help of cost-benefit analyses, it was possible to bring together all the relevant economic impacts and the most important ecological effects of various routes of separated colUmweltbundesamt/Federal Environment Agency Austria M-098 (1998)

Cost-Benefit Analysis of Plastic Recycling Summary

XII

lection and recycling of plastic waste into a single measurement parameter. Clearly positive or negative cost-benefit balances (macro-economic advantages or disadvantages) from a particular recycling route or waste management measure enable clear recommendations for action which take into account both ecological and economic impacts. Although small in terms of volume, an economically important percentage of the total used product recycling quota was investigated with the setting up of cost-benefit analyses for plastics recycling. Therefore for the optimisation of the system of separation, collection and recycling of used substances as a whole, an analogue analysis of mechanical recycling of other used substances would be beneficial. The following priorities of action were deduced from the results of the macro-economic evaluation of mechanical recycling from plastics waste in Austria purely from the point of view of waste, without taking into account guidance measures or effects on the market input: 1. The improvement of the collection of packaging from households From a macro-economic point of view it is urgently necessary to optimise the collection of plastics packaging from households. This optimisation entails, from now on, only collecting plastics packaging separately which lends itself to cost-effective (automated) sorting and ensuing mechanical recycling by individual resin. On the whole these are blowmoulded parts and large films. The main objective should be to reduce the expenditure (volume, collection systems, etc.) for domestic collection in general and in particular where residual waste is destined for incineration and, at the same time, to aim at a more discerning collection so that the collection product, on the whole, can be recovered to a greater extent mechanically. 2. Recycling of non-packaging plastics waste By expanding the mechanical recycling of non-packaging plastics waste, todays volume of mechanical recycling from post-consumer plastics waste could be increased by 56%. However, in order to actually put the necessary separated collection and mechanical recycling schemes into practice, appropriate concrete measures must first be developed. These measures range from the choice of the best type of separate collection through the development of the market for secondary products to guidance measures set up by legislation or the voluntary engagement of the business world. It should be possible to cover the majority of this additional potential via collection in the commercial sector. Whether certain non-packaging waste materials from households should be collected with the plastics packaging or separately still has to be investigated. 3. Expansion of production waste recycling In terms of volume, the estimated potential of 6,400 t/a for additional mechanical recycling of waste from the processing sector is relatively insignificant. Nevertheless the macroeconomic advantage of some ATS 87 Million p.a. derived from the very positive specific cost-benefit balance is considerable. 4. Expansion of the collection of commercial packaging Any increase in the quota of mechanical recycling from plastics packaging waste will almost exclusively be attained from additional amounts collected from the commercial sector. Albeit to a limited extent, the expansion of separate collection of plastics packaging from the commercial sector is macro-economically expedient under the current conditions of waste management. The upper limit depends, amongst other things, on waste management frame conditions such as the percentage of residual waste which is incinerated as well as the monetary value of external benefits. In the current situation the useful potential for expansion amounts to a maximum of 25,000 t/a which corresponds to approximately 75% of todays collection volume. However, the recycling potential which is viable on a macro-economic scale will drop with an increase in the amounts of residual waste taken to the incinerator.

Umweltbundesamt/Federal Environment Agency Austria M-098 (1998)

Cost-Benefit Analysis of Plastic Recycling Summary

XIII

In the first instance an expansion of the collection of commercial plastics packaging would concern small to medium sized collection points. Therefore new methods of collection should be employed which basically aim at condensing numbers of small collection points, compressing the material at the collection points and providing as direct a transport system as possible between the collection point and the recycling agent. For the evaluations within the framework of this study such new methods were established as models and used as the basis for calculations. The expected macro-economic profit to be gained over the status quo from the optimisation of waste collection of household packaging together with the additional recycling of non-packaging plastics waste comes to a total of some ATS 500 Million p.a. The results at hand show that for mechanical recycling of plastics, it is above all the difficulties in feasible coverage of separate collection and the macro-economic viability which are the limiting factors. The limits for these factors of what is possible and/or sensible are reached far sooner than the ecological limits or the limits of market receptivity to secondary raw materials. Under the proviso of a positive cost benefit ratio a maximum of 30% of all plastics waste (including production waste) can, at any rate, be mechanically recycled. In this maximum case the volume of recyclate in use would make up 16% of the total amount of processed plastic. The improvement of the cost benefit balance from increases in the price of energy and raw materials is one aspect for long-term consideration which was not dealt with in this study. This could lead to alterations in the reasons dictating decisions, especially for recycling routes with bad cost-benefit balances (domestic process, parts of the commercial collecting system, individual non-packaging substances). In medium-term, the most important tasks for the management of plastics waste consist of the following: Developing basis for calculations and simulation models in order to quantify the waste management impacts of product formation and choice of material and enable the corresponding macro-economic cost-benefit analyses. Step-by-step optimisation of the conversion to practice of the ordinance on packaging. Introduction of a comprehensive material management for all plastics waste. This means that efforts towards mechanical recycling should also incorporate non-packaging plastics and should channel plastics waste which is not mechanically recyclable towards an appropriate thermal treatment or recycling process.

Umweltbundesamt/Federal Environment Agency Austria

M-098 (1998)

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Pipewall Thickness Gauges Accessories: KatflowДокумент1 страницаPipewall Thickness Gauges Accessories: KatflowChevronelleОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Data Sheet Sonocontrol 11 Kat V10 E0698Документ2 страницыData Sheet Sonocontrol 11 Kat V10 E0698ChevronelleОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Bombas Savino Barbera - Europump Atex GuidelineДокумент22 страницыBombas Savino Barbera - Europump Atex GuidelineChevronelleОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Instituto Superior T Ecnico Departamento de Matem Atica Sec C Aode Algebra e An AliseДокумент2 страницыInstituto Superior T Ecnico Departamento de Matem Atica Sec C Aode Algebra e An AliseChevronelleОценок пока нет

- Data Sheet Sonometer 30 Kat V10 E0698Документ2 страницыData Sheet Sonometer 30 Kat V10 E0698ChevronelleОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Ultrasonic Flowmeter: Katflow 160Документ4 страницыUltrasonic Flowmeter: Katflow 160ChevronelleОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Coin Meter Work Sheet: 3 Stack Rotary SwitchДокумент1 страницаCoin Meter Work Sheet: 3 Stack Rotary SwitchChevronelleОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Coin Meter Work Sheet: 3 Stack Rotary Switch OFFДокумент1 страницаCoin Meter Work Sheet: 3 Stack Rotary Switch OFFChevronelleОценок пока нет

- Data Sheet KATflow 110 V10 E0803Документ4 страницыData Sheet KATflow 110 V10 E0803Chevronelle100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Pressure-Based Sprayer Plumbing DiagramsДокумент1 страницаPressure-Based Sprayer Plumbing DiagramsChevronelleОценок пока нет

- Dosatron DI1500Документ3 страницыDosatron DI1500ChevronelleОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Dultmeier Sales: Pipe and Tubing Size ChartДокумент1 страницаDultmeier Sales: Pipe and Tubing Size ChartChevronelleОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

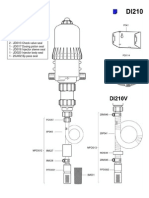

- Dosatron DI210pxДокумент4 страницыDosatron DI210pxChevronelleОценок пока нет

- Chemical Resistance ChartДокумент3 страницыChemical Resistance ChartChevronelleОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Pump Types: CentrifugalДокумент1 страницаPump Types: CentrifugalChevronelleОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Flowmeter Based Sprayer Plumbing Diagrams: Console Should Be Ground Speed OrientedДокумент1 страницаFlowmeter Based Sprayer Plumbing Diagrams: Console Should Be Ground Speed OrientedChevronelleОценок пока нет

- Dultmeier Sales: Pulley Selection Guide (1725 RPM Motor)Документ1 страницаDultmeier Sales: Pulley Selection Guide (1725 RPM Motor)ChevronelleОценок пока нет

- Dultmeier Sales: Electric Motor Horsepower Required To Drive Pressure PumpsДокумент1 страницаDultmeier Sales: Electric Motor Horsepower Required To Drive Pressure PumpsChevronelleОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Liquid Pump TerminologyДокумент1 страницаLiquid Pump TerminologyChevronelleОценок пока нет

- Brine Production System - Convert Rock Salt To Salt BrineДокумент4 страницыBrine Production System - Convert Rock Salt To Salt BrineChevronelleОценок пока нет

- Marketing Environment 1Документ23 страницыMarketing Environment 1vishal111089Оценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Blanchard IM 7e FMДокумент2 страницыBlanchard IM 7e FMJosep GuardiolaОценок пока нет

- SHAIKH, A. (2008) - Competition and Industrial Rates of ReturnДокумент18 страницSHAIKH, A. (2008) - Competition and Industrial Rates of Returncarlos rodriguesОценок пока нет

- 2022 October MS OriginalДокумент24 страницы2022 October MS OriginalKarama OmarОценок пока нет

- Economics Paper-I 1. Advanced Micro EconomicsДокумент3 страницыEconomics Paper-I 1. Advanced Micro EconomicsMr. Kk NayakОценок пока нет

- ER Ch06 Solution ManualДокумент16 страницER Ch06 Solution ManualAbhay Singh ChandelОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- (Intl Investment) Chapter 1 - InvestmentДокумент49 страниц(Intl Investment) Chapter 1 - InvestmentJane VickyОценок пока нет

- FY2014 Analysis of Revenue and ExpenditureДокумент28 страницFY2014 Analysis of Revenue and ExpenditureAzman JantanОценок пока нет

- Annual Report 2015: The Way ForwardДокумент316 страницAnnual Report 2015: The Way ForwardAsif RafiОценок пока нет

- University of Mauritius: Instructions To CandidatesДокумент8 страницUniversity of Mauritius: Instructions To Candidates80tekОценок пока нет

- Panic of 1819Документ5 страницPanic of 1819Ian MutukuОценок пока нет

- International Parity Conditions: Multinational Business Finance (2 Edition)Документ61 страницаInternational Parity Conditions: Multinational Business Finance (2 Edition)Cong Chinh NguyenОценок пока нет

- 10th Social Science Assertion & ReasonДокумент24 страницы10th Social Science Assertion & ReasonAmandeepОценок пока нет

- Graphic OrganizerДокумент16 страницGraphic Organizerteodoro labangcoОценок пока нет

- Investment Opportunities in Somali Regional State Putting The Pastoralists Political Economy in PerspectiveДокумент7 страницInvestment Opportunities in Somali Regional State Putting The Pastoralists Political Economy in PerspectiveInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Unit 3 Review Practice Set (Modules 16-21)Документ9 страницUnit 3 Review Practice Set (Modules 16-21)Samuel JayОценок пока нет

- Quiz 544Документ4 страницыQuiz 544Haris NoonОценок пока нет

- 06Документ9 страниц06Shubham RawatОценок пока нет

- Quantity Theory of MoneyДокумент4 страницыQuantity Theory of MoneyNazmun BegamОценок пока нет

- Solow ModelДокумент61 страницаSolow ModelJs KОценок пока нет

- C1,2,3,4 (Updated)Документ59 страницC1,2,3,4 (Updated)Châu Nguyễn Hoài ThùyОценок пока нет

- National Bank of Ethiopia 2017-18 Annual ReportДокумент106 страницNational Bank of Ethiopia 2017-18 Annual Reportsamuel seifu100% (1)

- Aggregate Demand I: Building The - Model: IS LMДокумент40 страницAggregate Demand I: Building The - Model: IS LMaditya prudhviОценок пока нет

- Group Work Project: Mscfe 660 Case Studies in Risk ManagementДокумент7 страницGroup Work Project: Mscfe 660 Case Studies in Risk ManagementHo Thanh Quyen100% (1)

- Macroeconomics Homework 5Документ5 страницMacroeconomics Homework 5hanguyenhihiОценок пока нет

- ECONOMICS Passing PackageДокумент10 страницECONOMICS Passing PackageNikitha Jyothi Kumar100% (7)

- LL b2020-21 pdf202106055205Документ206 страницLL b2020-21 pdf202106055205dishu kumar100% (1)

- Chapter 25 Workbook AnswersДокумент2 страницыChapter 25 Workbook AnswersalexОценок пока нет

- Hci h1 Econs Case AnswersДокумент8 страницHci h1 Econs Case AnswersStoneHereОценок пока нет

- Correction Blend 2Документ20 страницCorrection Blend 2Trần Đức TàiОценок пока нет

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionОт EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionРейтинг: 3 из 5 звезд3/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretОт EverandWaste: One Woman’s Fight Against America’s Dirty SecretРейтинг: 5 из 5 звезд5/5 (1)