Академический Документы

Профессиональный Документы

Культура Документы

Hardwear Brochure

Загружено:

metalebrioxD0 оценок0% нашли этот документ полезным (0 голосов)

50 просмотров0 страницHARDWEAR steels are used in the original fabrication and repair of heavy equipment subject to severe abrasion wear. Grades are available in thicknesses from 1 / 8 to 3 inches (3 mm to 76 mm)

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документHARDWEAR steels are used in the original fabrication and repair of heavy equipment subject to severe abrasion wear. Grades are available in thicknesses from 1 / 8 to 3 inches (3 mm to 76 mm)

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

50 просмотров0 страницHardwear Brochure

Загружено:

metalebrioxDHARDWEAR steels are used in the original fabrication and repair of heavy equipment subject to severe abrasion wear. Grades are available in thicknesses from 1 / 8 to 3 inches (3 mm to 76 mm)

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 0

ArcelorMittal USA

Plate

HARDWEAR

Plate: Premium abrasion-resistant steels

Introduction

HARDWEAR, a line of premium abrasion-resistant plate steels, is

available in four grades HARDWEAR 400F, HARDWEAR 425F,

HARDWEAR 450F and HARDWEAR 500F with nominal Brinell

hardness of the number in the grade title. These grades are all pro-

duced at facilities in Coatesville and Conshohocken, PA. HARDWEAR

400F is also produced at Burns Harbor, IN.

Each grade exhibits an excellent combination of hardness, abrasion

resistance, formability, weldability, toughness and atness to meet

fabrication needs and end-use requirements. HARDWEAR steels are

designed for through-thickness hardness while maintaining minimum

carbon, alloy and carbon equivalent contents to improve weldability.

All HARDWEAR grades are heat treated. Thicker HARDWEAR 400F

and all other HARDWEAR grades are quenched and tempered. Thin-

ner HARDWEAR 400F plates may be untempered.

The sulfur content is reduced to a maximum of 0.005% and the

steels are calcium treated for inclusion shape control. These factors

enhance the cold forming characteristics of the steels and thus the

F in the grade names, for formable.

HARDWEAR grades are available in thicknesses from 1/8 to 3

inches (3 mm to 76 mm) and produced to one-half of the ASTM

A6 atness tolerance. The availability of HARDWEAR grades to 1/8

(3 mm) thickness is a recent capability enhancement. Inquire with

ArcelorMittal USA Plate ofces for availability.

Applications

HARDWEAR plate steels are used in the original fabrication and repair

of heavy equipment subject to severe abrasive wear. Their use is

especially effective where formed transitions are preferred over

welded joints for owability in material handling equipment used in

the mining, aggregate, pulp and paper, and construction industries.

HARDWEARs improved weldability enhances its attractiveness

where eld welding is often performed.

Most common applications are in the mining and construction

markets with uses as liners for truck beds, buckets, hoppers, chutes,

crushers and conveyor troughs. Concrete mixer drums, trash truck

bottoms, bucket lips, street sweepers and dump trailers are among

other applications.

Composition

HARDWEAR steels are designed with as low a carbon equivalent as

possible, consistent with meeting surface and through-thickness

hardness requirements. The chemistry range for each HARDWEAR

grade is shown in Table 1. Figures 1 and 2 show the carbon equiva-

lent results for a representative number of heats of steel produced

for plates to 1 inch (25.4 mm) thick in grades 400F and 500F. More

restrictive carbon equivalent levels are available for thinner plates.

Because of ArcelorMittal USA Plate mills ladle rening practices, very

precise and reproducible chemistries can be expected from these

steels. The low sulfur and phosphorus levels for HARDWEAR plate

steels are shown in the distributions in Figures 4 and 5. Lower sulfur

and phosphorus specication levels are available when specied.

ArcelorMittal USA HARDWEAR Steels (1/8 to 3 thick)

Table 1: Chemistry (maximum unless range is shown)

Grade C Mn P S* Si Ni Mo Cr B

400F .12/.16 1.55 .025 .005 .35/.55 1.00 .55 .55 .0005/.005

425F .17/.21 1.55 .025 .005 .35/.55 1.00 .55 .55 .0005/.005

450F .20/.25 1.35 .025 .005 .35/.55 1.00 .65 .55 .0005/.005

500F .25/.31 0.95 .025 .005 .35/.55 1.00 .65 .75 .0005/.005

* with calcium treatment for inclusion shape control, Fineline Double-O-Five

HARDWEAR Page 2

3/4 inch thick HARDWEAR 500F plates formed for truck bed liners being prepared for

shipment from a service center.

Figure 3:

3/8 thick ArcelorMittal USA HARD-

WEAR 450F formed with 3T bend

radius parallel to the rolling direction

Figure 1: ArcelorMittal USA HARDWEAR 400F Heat

Chemistry Distribution

Carbon Equivalent Distribution for Thickness to 1 in. (25.4 mm)

Figure 5: ArcelorMittal USA HARDWEAR 400F Plate

Phosphorus Levels for 336 Heats

Figure 2: ArcelorMittal USA HARDWEAR 500F Heat

Chemistry Distribution

Carbon Equivalent Distribution for Thickness to 1 in. (25.4 mm)

Figure 4: ArcelorMittal USA HARDWEAR 400F Plate

Sulfur Levels for 336 Heats

F

r

e

q

u

e

n

c

y

F

r

e

q

u

e

n

c

y

F

r

e

q

u

e

n

c

y

F

r

e

q

u

e

n

c

y

70

60

50

40

30

20

10

0

100

80

60

40

20

0

30

25

20

15

10

2

0

200

160

120

80

40

0

0.43 0.44 0.45 0.46 0.47 0.48 0.49 0.50 0.51

.006 .007 .008 .009 .010 .011 .012 .013 .014

0.52 0.53 0.54 0.55 0.56 0.57 0.58 0.59

.001 .002 .003 .004 .005

C.E. = C + Mn/6 + (Cr + Mo + V)/5 + (Cu + Ni)/15

Total Observations = 147

Mean = 0.47

C.E. = C + Mn/6 + (Cr + Mo + V)/5 + (Cu + Ni)/15

Total Observations = 40

Mean = 0.56

HARDWEAR Page 3

Hardness

The primary ordering requirement for HARDWEAR steels is mini-

mum surface hardness. The hardness distributions of almost 60,000

HARDWEAR 400F plates and approximately 8,000 HARDWEAR

500F plates are shown in Figures 6 and 7. The Brinell hardness (HB)

ranges of the HARDWEAR grades are:

Pin Abrasion

The Pin Abrasion test is used to compare abrasion resistant steels. A

standard test pin, machined from the steel to be tested, is abraded

by a 150-mesh garnet abrasive cloth under specied laboratory

conditions and the pins weight loss, in milligrams, is measured. The

results of testing conducted by ArcelorMittal USA Plate metallurgists,

comparing the pin weight loss with corresponding hardness of the

HARDWEAR grades, are shown in Figure 8.

HARDWEAR Grade Hardness Range (HB) *

400F 360-444

425F 401-477

450F 429-495

500F 460-544

* Inquire with ArcelorMittal USA Plate ofces if more restrictive hardness levels are

required.

Figure 6: ArcelorMittal USA HARDWEAR 400F Plate

Hardness Distribution

To 3/4 (19 mm) Thickness

Figure 7: ArcelorMittal USA HARDWEAR 500F Plate

Hardness Distribution

To 3/4 (19 mm) Thickness

Surface Hardness, HB

Brinell Hardness

400F

500F

Other

Steels

Surface Hardness, HB

20,000

15,000

10,000

5,000

0

2,000

1,600

1,200

800

400

0

360 370 380 390 400 410 420 430 440

460 470 480 490 500 510 520 530 540 550

Total Observations = 59,400

Mean = 388

Total Observations = 8,000

Mean = 495

F

r

e

q

u

e

n

c

y

F

r

e

q

u

e

n

c

y

Figure 8: ArcelorMittal USA HARDWEAR F Series Plate

Pin Abrasion Test vs. Hardness

P

i

n

W

e

i

g

h

t

L

o

s

s

(

m

g

)

130

125

120

115

110

105

100

95

90

85

80

350 375 400 425 450 475 500 525 550

HARDWEAR Page 4

Charpy V-Notch Impact Toughness

The results of extensive Charpy V-Notch impact testing are

summarized in Figures 11 and 12. ArcelorMittal USA Plate facilities

can guarantee impact properties of any HARDWEAR grade when

specied.

Figure 10: ArcelorMittal USA

HARDWEAR 500F Plate - Tensile Strength

S

t

r

e

n

g

t

h

(

k

s

i

)

Thickness, inches

Ultimate Tensile Strength

Yield Strength

300

275

250

225

200

175

150

125

100

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00

Averages for all thickness:

Transverse Orientation

Y.S. 187.2 % RA 44.0

U.T.S. 247.7 % Elong. 11.1

Temperature (F)

Temperature (F)

Figure 11: ArcelorMittal USA HARDWEAR 400F Plate

Transverse CVN Toughness, 7/16 - 2 Thick Plates

Figure 12: ArcelorMittal USA HARDWEAR 500F Plate

Transverse CVN Toughness, 7/16 - 2 Thick Plates

C

N

V

E

n

e

r

g

y

A

b

s

o

r

b

e

d

(

f

t

-

l

b

s

)

C

N

V

E

n

e

r

g

y

A

b

s

o

r

b

e

d

(

f

t

-

l

b

s

)

110

100

90

80

70

60

50

40

30

20

10

0

110

100

90

80

70

60

50

40

30

20

10

0

-100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160 180 200 220

-100 -80 -60 -40 -20 0 20 40 60 80 100 120 140 160 180 200 220

Mechanical Properties

While HARDWEAR steels are normally specied by Brinell hardness, it

is of interest to know other mechanical properties of these steels.

Tensile Strength

ArcelorMittal USA Plate facilities does not guarantee tensile properties

of HARDWEAR grades. However, for information purposes, Figures

9 and 10 show typical yield and tensile strength behavior of grades

400F and 500F as a function of thickness. The transverse values

shown approximate those in the longitudinal direction. Furthermore,

both steels exhibit fairly consistent strength, independent of thickness.

Please note the tensile specimens used for this study had a 1 inch

gauge length. The reported elongation values are greater than those

obtained with longer gauge lengths.

Figure 9: ArcelorMittal USA

HARDWEAR 400F Plate - Tensile Strength

S

t

r

e

n

g

t

h

(

k

s

i

)

Thickness, inches

Ultimate Tensile Strength

Yield Strength

300

275

250

225

200

175

150

125

100

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00

Averages for all thickness:

Transverse Orientation

Y.S. 140.3 % RA 65.2

U.T.S. 180.3 % Elong. 14.8

HARDWEAR Page 5

Fabrication Guidelines for HARDWEAR

General information on fabrication with plate steels is given in

Guidelines for Fabricating and Processing Plate Steel book. For

guidelines specic to HARDWEAR grades, the following information

is provided.

Bend Formability

HARDWEAR steels were specically designed for improved formabil-

ity. ArcelorMittal USA Plate metallurgists plane strain bend testing of

HARDWEAR 400F, HARDWEAR 450F and HARDWEAR 500F led to

the forming guidelines presented in Table 2. Plate in the thinner part

of the thickness range may allow tighter bends (see Figure 3).

These guidelines are based on forming at typical shop temperatures

over +60F*. We caution that bend forming of these hard steels

should be carried out using shop practices which include, but are not

limited to, using hardened V-dies with a liberal radius (See Table 2).

It is recommended that adequate lubrication, grinding of thermal

cut or sheared plate edges and applying the load in a smooth, steady

manner be utilized. Particular caution should be used in applying the

bump and move technique to control the depth and number of

bends.

HARDWEAR steels are not intended for hot forming applications, un-

less reheat treatment of the part is included. Consult ArcelorMittal

USA Plate ofces for heat treatment guidelines.

Machinability

Due to their high hardness levels, HARDWEAR steels, as are all abra-

sion resistant grades, are inherently more difcult to machine when

compared to normal structural steels. Also, the cleanliness, low sulfur

and inclusion levels of HARDWEAR steels inuence chip breakage

behavior. Therefore, machining these steels requires the use of

cobalt-alloyed, high speed steel (HSS) tools or carbide tips, using a

generous supply of cutting uid. In milling operations, the 400F and

500F grades require cutting speeds of 45% and 35%, respectively, of

the speeds for milling A572-50. The following parameters have been

found effective in the drilling of HARDWEAR steels (See Table 3).

Thermal Cutting

ArcelorMittal USA HARDWEAR 400F, 425F, 450F and 500F plates

can be thermally cut with conventional oxygen-fuel and plasma-

cutting techniques. The minimum plate temperature prior to thermal

cutting should be +60F for all grades. It is further recommended

that HARDWEAR 425F and 450F plates greater than 2 in (51 mm)

thick and HARDWEAR 500F plates greater than 1 inch (25.4 mm)

thick be preheated to 300F to prevent edge cracking. Use of re-

duced cutting speeds with other proper cutting parameters may also

be used for thicker plates.

Table 2: ArcelorMittal USA

HARDWEAR 400F, 450F and 500F Plate *

Severity Ratios for Single Stroke Bend to 90

Grade Thickness Range

**

Bend Transverse to

Rolling Direction

Bend Parallel to

Rolling Direction

Inches (mm) R/t W/t R/t W/t

400F 1/8 3/4 (3 19) 3 13.5 4 14.5

450F 1/8 3/4 (3 19) 4 14 5 15

500F 1/8 1/2 (3 13) 6 16 6 16

* Use 450F guidelines for 425F

** Consult ArcelorMittal USA Plate ofces for greater thicknesses

Table 3: ArcelorMittal USA

HARDWEAR 400F, 425F, 450F and 500F Plate **

Grade Drill Speed, rpm

Cutting Speed, In./Min. 0.4 Inch. Dia.* 0.8 Inch Dia.* 1.2 Inch.

Dia. *

400F 250-450 300 150 100

450F 200-300 215 110 70

500F 150-250 130 65 40

* Feed rate In./Rev. .004, .008, .012, respectively

** Use the machining guides for grade 450F for 425F

Bend Load Requirement Formulas (for nominal strength levels) *

P = estimated press load, tons

L = length of plate to bend, inches

400F

P = (150 x t

2

x L)/W

500F

P = (200 x t

2

x L)/W

Example: 400F plate 0.5-inch thick by

48-inches wide with a die W of 7 inches

P = (150 x 0.52 x 48)/7 = 257 tons needed for forming

* loads for 425F and 450F are between these shown

Punch Bend Forming

Severity Ratio R/t

Punch Bend Forming

Severity Ratio W/t

Cylindrical sections of top hat crusher

liners formed from 3/4 inch thick

HARDWEAR 500F

The welded conical portion of this

reducing hopper formed from 3/8 inch

thick HARDWEAR 400F

ArcelorMittal USA

Corporate Ofce

1 South Dearborn Street

18th Floor

Chicago, IL 60603-9888

USA

T +1 800 422 9422

www.arcelormittal.com

ArcelorMittal USA

Plate

ARC Building

139 Modena Road

Coatesville, PA 19320-0911

USA

T +1 800 966 5352

www.arcelormittal.com

ArcelorMittal USA

Plate

250 West U.S. Highway 12

Burns Harbor, IN 46304-9745

USA

T +1 800 422 9422

www.arcelormittal.com

December 2010

All information in this brochure is for the purpose of information only. ArcelorMittal USA reserves the right to change its product range at any time without prior notice.

Technical Information

Contact John Babich at +1 610 383 3244, or john.babich@arcelormittal.com

Continuing updates of this information can be found on our website at: http://www.arcelormittal.com

Weldability

ArcelorMittal USA Plate mills HARDWEAR steels may be welded by

any of the conventional welding processes such as SMAW, GMAW

and SAW, provided proper precautions and low-hydrogen welding

practices are employed. ArcelorMittal USA Plate facilities welding

guidelines for HARDWEAR 400F, 450F and 500F are summarized in

the Table 4 shown below. The guidelines were developed using the

Y groove weldability test specimen. For joints under less restrained

conditions, some fabricators have found lower preheat temperatures

may be used. If the humidity level in the work area is high and/or the

weldment is highly restricted, higher preheat temperatures may be

required. Postweld heat treatment above 400F should not be ap-

plied to the steels if the original hardness levels are to be maintained.

Welding guidelines for HARDWEAR 425F should use those of 450F.

Table 4: Welding Preheat Guide for ArcelorMittal USA

HARDWEAR Plate Recommended Minimum Preheat (F)6

Combined Plate

Thicknesses

HARDWEAR 400F

Heat Input (KJ/Inch)

HARDWEAR 450F

Heat Input (KJ/Inch)

HARDWEAR 500F

Heat Input (KJ/Inch)

T1 + T2 + T3 30 35 40 45 >45 30 35 40 45 30 35 40 45

3/4 Inch 60 60 60 60 60 60 60 60 60 200 200 200 200

1 60 60 60 60 60 60 60 60 60 250 200 200 200

1-1/4 60 60 60 60 60 60 60 60 60 300 250 200 200

1-1/2 60 60 60 60 60 200 200 60 60 350 300 250 200

2 60 60 60 60 60 250 250 200 200 400 350 300 300

2-1/2 60 60 60 60 60 300 300 250 250 400 350 300 300

3 200 200 200 60 60 350 350 300 300 400 400 350 350

4 250 250 250 200 200 400 400 350 350 400 400 400 400

Notes:

Preheat temperature is based on SMAW process and E7018 electrode.

E7018 electrodes must be stored in an oven at 250F +25F. Maximum exposure

four hours out of the can or out of the oven.

Preheat minimum temperature may be reduced by 50F (but not less than 50F)

using GMAW process, ER705-3 electrode and AR-Co

2

gas.

Maximum preheat and interpass temperatures should be 400F to retain hardness

properties.

35 KJ/inch represents approximately a 1/4 inch llet weld (SMAW).

T1 T1

T1

T3 T3 T2 T2 T2

L L L

If L is Less Than or Equat to 1/2 T2, Consider T2 = 0

T3

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Rotary Valve Functions BookletДокумент17 страницRotary Valve Functions Bookletamahmoud3Оценок пока нет

- 1400 CFM TДокумент3 страницы1400 CFM TmahmadwasiОценок пока нет

- Review Problems Chapter 4 Solutions PDFДокумент4 страницыReview Problems Chapter 4 Solutions PDFAntoninoОценок пока нет

- Budget of Work Sci5Документ1 страницаBudget of Work Sci5Jhoy Angeles PinlacОценок пока нет

- Workshop 2 Electrical Installations Single PhaseДокумент3 страницыWorkshop 2 Electrical Installations Single PhaseDIAN NUR AIN BINTI ABD RAHIM A20MJ0019Оценок пока нет

- EXP.2 Enzyme Extraction From BacteriaДокумент3 страницыEXP.2 Enzyme Extraction From BacteriaLinhNguyeОценок пока нет

- Chem 1211 Lab ReportДокумент9 страницChem 1211 Lab Reportansleybarfield0% (1)

- Solution Manual For Introductory Statistics 9th Edition by Mann Chapters 1 13 PDFДокумент10 страницSolution Manual For Introductory Statistics 9th Edition by Mann Chapters 1 13 PDFa40095824643% (14)

- VT300 User ManualДокумент21 страницаVT300 User ManualLuvОценок пока нет

- 6 Jazz Reading Exercise PDFДокумент5 страниц6 Jazz Reading Exercise PDFQuốc LiêmОценок пока нет

- Epson WorkForce Pro WF-C878-879RДокумент8 страницEpson WorkForce Pro WF-C878-879Rsales2 HARMONYSISTEMОценок пока нет

- Ex450-5 Technical DrawingДокумент12 страницEx450-5 Technical DrawingTuan Pham AnhОценок пока нет

- ADO NET Tutorial - 16Документ18 страницADO NET Tutorial - 16Fenil Desai100% (1)

- P 130881757895329843Документ44 страницыP 130881757895329843Vijay MohanОценок пока нет

- Quarter 4 Summative Test No. 1 Mga Layunin Code Bahagda N Bilang NG Aytem Kinalalagyan NG BilangДокумент4 страницыQuarter 4 Summative Test No. 1 Mga Layunin Code Bahagda N Bilang NG Aytem Kinalalagyan NG Bilangmichelle milleondagaОценок пока нет

- Atmel 2565 Using The Twi Module As I2c Slave - Applicationnote - Avr311Документ14 страницAtmel 2565 Using The Twi Module As I2c Slave - Applicationnote - Avr311m3y54mОценок пока нет

- Varargout Tugas - GUI (Varargin) : FunctionДокумент7 страницVarargout Tugas - GUI (Varargin) : FunctionDwi Lestari dwi375ft.2019Оценок пока нет

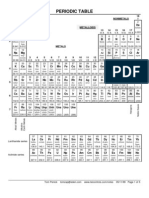

- Periodic Table and AtomsДокумент5 страницPeriodic Table and AtomsShoroff AliОценок пока нет

- A Simulation-Based Process Model For Managing Complex Design ProcessДокумент13 страницA Simulation-Based Process Model For Managing Complex Design ProcessMetehan AgacaОценок пока нет

- Fib Lucas StaДокумент5 страницFib Lucas StafabriziomaccalliniОценок пока нет

- DA Savitz - Interpreting Epidemiologic Evidence - Strategies For Study Design and Analysis 2003 PDFДокумент329 страницDA Savitz - Interpreting Epidemiologic Evidence - Strategies For Study Design and Analysis 2003 PDFrindy_bilhaniОценок пока нет

- TOEC8431120DДокумент522 страницыTOEC8431120Dvuitinhnhd9817Оценок пока нет

- CHM170L Exp3 Surface TensionДокумент5 страницCHM170L Exp3 Surface TensionKaiser SaltoОценок пока нет

- Sap SCM TrainingДокумент5 страницSap SCM TrainingGLOBAL TEQОценок пока нет

- IK Gujral Punjab Technical University: 1. Electric ChargeДокумент12 страницIK Gujral Punjab Technical University: 1. Electric ChargeJashandeep KaurОценок пока нет

- ADA Practical File: Kartik KatariaДокумент34 страницыADA Practical File: Kartik KatariaKilari TejaОценок пока нет

- Lab 3.1 - Configuring and Verifying Standard ACLsДокумент9 страницLab 3.1 - Configuring and Verifying Standard ACLsRas Abel BekeleОценок пока нет

- 02 WholeДокумент344 страницы02 WholeedithgclemonsОценок пока нет

- Which Is The Best Solid Modelling - Dhyan AcademyДокумент3 страницыWhich Is The Best Solid Modelling - Dhyan Academydhyanacademy engineersОценок пока нет