Академический Документы

Профессиональный Документы

Культура Документы

EO Purifier - My Report

Загружено:

apiskaiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

EO Purifier - My Report

Загружено:

apiskaiАвторское право:

Доступные форматы

Plant Design Project II

FINAL YEAR DESIGN PRO1ECT

DESIGN OF 202,000 TONES PER ANNUM

ETH!ENE O"IDE P!ANT

GROUP NO #$

SHEET %&'#

(O) *ODE

DESIGNER

+UMARAGURU

A&!

GUNASEGARAN,

GURU-

DETAILED DESIGN OF

MA1OR EQUIPMENT

ETHYLENE OXIDE PURIFIER COLUMN

C-702

PREPARED ). +UMARAGURU A&! GUNASEGARAN

DO*

NO

DES*RIPTION PREPARED )

RE/IE0ED

)

DATE

0% INTRODU*TION GURU 2#&0$&01

02 PRO*ESS DESIGN GURU 2#&0$&01

0# ME*HANI*A! DESIGN GURU 2#&0$&01

0$

SPE*IFI*ATION SHEET 2 DETAI!ED

DRA0ING

GURU 2#&0$&01

03 *OSTING GURU 2#&0$&01

04

OPERATING MANUA! ,START

UP&SHUTDO0N-

GURU 2#&0$&01

0' REFEREN*ES GURU 2#&0$&01

TABLE OF CONTENT

1 GENERAL DESCRIPTION

%

Plant Design Project II

%5% Process Descri6tion775755555555555555555555555555555555555555555555555555555555555553

%52 Selection *riteria 8or P9ri8ier *ol9:n7775777777774

%5# Design Met;o<olog=755555555555555555555555555555555555555555555555555555555555555555555'

2 PROCESS DESIGN OF ETHYLENE OXIDE PURIFIER COLUMN

25% M9lti>co:6onent Distillation 77777777777777551

252 Si?ing o8 *ol9:n Internals77777777777575777%'

3 MECHANICAL DESIGN

#5% Selection o8 Material o8 *onstr9ction 77777777777#'

#52 *o:@ine< !oa<ing on /essel 777757777777777$0

#5# 0in< !oa<ing7777777777777557577775755$#

#5$ Anal=sis o8 Stresses 777777777777777777$#

#53 /essel SAirts an< S966ort757777777777777755$3

#54 Design o8 Flanges7777777777777777557755$B

#5' Flange 8or Man;oles777777777777777775555$1

#5B Design o8 No??les7777777777777777575753$

4 SPECIFICATION SHEET AND DRAWING(S)

$5% S6eci8ication S;eet 7777777777777777755 4%

$52 Tec;nical Engineering DraCing 77777777777754#

5 COSTING 77777777557777777777777777775554$

6 OPERATING MANUAL (START UP/SHUTDOWN)77777777754B

7 REFERENCES777777777777777777757775575755'2

8 APPENDIX777777777777777777777755577755555'#

LIST OF TABLES

2

Plant Design Project II

Ta@le %. Distri@9tion o8 *o:6onent

Ta@le 2. Antoine Para:eters

Ta@le #. DeC Point *alc9lation ,Distillate--

Ta@le $. )9@@le Point *alc9lation ,)otto:-

Ta@le 3. )9@@le Point *alc9lation ,Fee<-

Ta@le 4. Tra= Pro8ile In8or:ation 8ro: i*ON

Ta@le '. S9r8ace Tension 8or eac; *o:6onent

Ta@le B. )olt Si?e

Ta@le 1. )olt Si?e

Ta@le %0. )olt Si?e

Ta@le %%. )olt Si?e

LIST OF FIGURES

#

Plant Design Project II

Fig9re %. Design Met;o<olog= 8or P9ri8ier *ol9:n *>'02

Fig9re 2. E@@ar Ma<<oD *orrelation

Fig9re #. Floo<ing Eelocit= ,R. K. Sinnott, 1993-

Fig9re $. Selection o8 !iF9i< FloC Arrange:ent ,RK Sinnott, 1993-

Fig9re 3. 0eir lengt; correlation ,RK Sinnott, 1993-

Fig9re 4. 0ee6 Point *orrelations

Fig9re '. Disc;arge *oe88icient SieEe Plates

Fig9re B. Entrain:ent *orrelation 8or SieEe Plates

Fig9re 1. Relation @etCeen Angle S9@ten<e< @= *;or<, *;or< Heig;t an< *;or< !engt;

Fig9re %0. Trial !a=o9t

Fig9re %%. DoCnco:er )acA96

Fig9re %2. Met;o<olog= 8or Mec;anical Designs

Fig9re %#. Toris6;erical Diagra:

Fig9re %$. Elli6soi<al Diagra:

Fig9re %3. P9rc;asing *ost o8 /ertical *ol9:ns

Fig9re %4. P9rc;ase< *ost o8 Tra=s in Tra= *ol9:n

Fig9re %'. Installe< *ost o8 /ario9s In<9strial Ins9lations 8or *ol9:ns, ToCers an< TanAs5

$

Plant Design Project II

1.0 INTRODUCTION

1.1 General Description

Et;=lene ODi<e P9ri8ier *ol9:n, *>'02 ;aEe @een selecte< in t;is <etaile< <esign

since it is t;e 8inal :ajor 9nit o6erations 9se< in t;e Et;=lene ODi<e 6ro<9ction 6lant5

)asicall=, t;e 89nction o8 t;is <istillation col9:n, *>'02 is to recoEer Et;=lene ODi<e 8ro:

Cater5

T;e entire @otto: 6ro<9ct 8ro: *>'02, C;ere t;e :ajor co:6onent is Cater, Cill @e

sent to t;e Caste Cater treat:ent5 T;e to6 6ro<9ct C;ic; is Et;=lene ODi<e is recoEere< an<

sent to storage tanA

SieEe tra= :et;o< ;as @een selecte< to <esign t;e <istillation col9:n5 )ase< on t;e

calc9lations res9ltsG t;ere are 20 tra=s in t;e col9:n to ac;ieEe< t;e <esire< 6ro<9ct F9alit=

Cit; t;e ass9:6tions o8 $1 H tra=s e88icienc=5 T;e ;eig;t o8 col9:n is %353 : Cit; inner

<ia:eter o8 05B4 :5 Stainless steel is c;osen as t;e <esign an< tra= :aterial as t;e :ost cost>

saEing :aterial co:6are< to ot;er :aterial5

3

Plant Design Project II

1.2 Selection Criteria

)e8ore t;e 6roject is carrie< o9t, st9<ies an< researc;es ;aEe @een con<9cte< in

consi<ering a 8eC alternatiEes s9c; as t;e se6aration :et;o< an< ot;er 6ossi@le alternatiEes5

T;e j9sti8ications o8 eac; selection are state< in t;is c;a6ter5

1.2.1 Separation Method Selection

Distillation :et;o< is c;osen <9e to it a@ilit= to 6ro<9ce a 6ro<9ct Cit; ;ig; 69rit=

as state< in o9r clientIs reF9ire:ent5 Distillation 6rocess can also ;an<le a Ci<e

range o8 t;ro9g;69t, C;ereas :an= ot;er alternatiEes can ;an<le onl= loC

t;ro9g;69t5 T;e a@ilit= o8 <istillation 6rocess to ;an<le a Ci<e range o8 8ee<

concentrations is also a 6l9s 6oint since o9r 8ee< consists o8 :9lti>co:6onent

:iDt9re5

1.2.2 Justification for Tray Column

Accor<ing to *o9lson an< Ric;ar<sonIs j9sti8ications, tra= col9:ns generall=

6roEi<e satis8actor= o6eration oEer a Ci<e range o8 liF9i< an< Ea6or loa<ings5 T;e

Ea6or an< liF9i< rates can Ear= in<e6en<entl= oEer a @roa< range an< t;e col9:n can

o6erate satis8actoril=5 T;9s, it is c;osen 8or o9r <istillation col9:n eF9i6:ent5

1.2.3 Justification of Sieve Tray

SieEe tra= ;as t;e a<Eantages o8 loCest relatiEe cost ,si:6lest constr9ction-, loCest

6ress9re <ro6, an< increase< ca6acit= 8or a giEen toCer <ia:eter5 Alt;o9g; t;e sieEe

tra= generall= ;as ;ig;er ca6acit=, its :ain <isa<Eantage is t;at it is s9sce6ti@le to

Cee6ing or <9:6ing o8 liF9i< t;ro9g; t;e ;oles at loC Ea6or 8loC rate an< its

t9rn<oCn ca6acit= is li:ite<5

Deter:ination o8 o6ti:9: o6erating region, i5e5 :aDi:9: an< :ini:9: Ea6or an<

liF9i< loa< is cr9cial to ens9re sa8e col9:n o6eration an< aEoi< con<ition s9c; as

8loo<ing, Cee6ing an< entrain:ent5

4

Plant Design Project II

1.2.4 Reboiler Selection

+ettle re@oiler is a<o6te< 8or a66lication <9e to t;e ease o8 control an< no tCo 6;ase

8loC or circ9lation o8 liF9i< t;ro9g; t;e eDc;anger is reF9ire<5 !iF9i< 8ro: t;e

@otto: tra= is graEit= 8e< to t;e re@oiler 8ro: a <raC o88 on t;e @otto: o8 t;e tra=5 A

Ceir :aintains t;e liF9i< leEel in t;e re@oiler s9c; t;at t;e t9@e @9n<le is alCa=s

s9@:erge<5 T;e Ea6or is 6i6e< @acA to t;e col9:n to 6roEi<e stri66ing Ea6or 8or t;e

@otto: tra=5 D9e to t;e Ea6or <isengage:ent reF9ire:ent, Aettles are constr9cte<

Cit; as eD6an<e< s;ell5

1.2. Condenser Selection

T;e selection o8 a 6artial or total con<enser is 8iDe< @= t;e reF9ire:ent o8 t;e

oEer;ea< 6ro<9ct5 A total con<enser is 9se< 8or a liF9i< 6ro<9ct an< a 6artial

con<enser 8or a Ea6or 6ro<9ct5 HoCeEer, t;e liF9i< 6ro<9ct can @e 6ro<9ce< as a

Ea6or an< s9@seF9entl= coole< to 6ro<9ce a liF9i< 6ro<9ct5 In t;e <esign o8 t;e

Et;=lene ODi<e 69ri8ier col9:n ,*>'02-, t;e total con<enser is a<o6te< as it is

econo:icall= attractiEe, as t;e cost o8 6artial con<enser relatiEel= :ore eD6ensiEe

since it Cill ;aEe to @e co:6ensate< against t;e cost o8 a<<itional <oCnstrea:

eF9i6:ent s9c; as a<<itional cooler5

'

Plant Design Project II

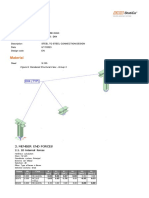

1.3 Design Methodology

In <esigning t;e Et;=lene ODi<e 69ri8ier col9:n ,*>'02-, C;ic; is a @inar=

<istillation col9:n, a s=ste:atic 6roce<9re Cas i:6le:ente<5 Fig9re % @eloC s9::ari?es

t;e :et;o<olog= in <esigning t;e <istillation col9:n5

Figure 1: Design Methodology for Purifier Column C-!"

Step 1

Pre6aring i*ON si:9lation o8 t;e oEerall 6lant 6rocess

Step 2

Select t=6es o8 <istillation col9:n, re@oiler an< con<enser to @e 9se<5

Step 3

*alc9late t;e col9:n o6erating con<ition J @otto: @9@@le 6oint, oEer;ea<

<eC 6oint an< 8ee< @9@@le 6oint

Step 4

Pre6are a 6reli:inar= 6rocess <esign to <eter:ine Re8l9D Ratio an<

N9:@er o8 Tra=

Step

*alc9late t;e col9:n o6erating region @= 9sing Stic;l:air an< Fair

:et;o< to 6reEent 96set insi<e col9:n s9c; as 8loo<ing an< ot;ers

Step !

*alc9late t;e <i:ension o8 t;e *>'02 <istillation col9:n

Step "

Pre6are t;e tec;nical engineering <raCing,s- an< tra= col9:n

s6eci8ication s;eet

Step #

Per8or: start 96 an< s;9t <oCn 6roce<9res 8or *>'02

B

Plant Design Project II

T;is section 6resente< <etaile< 6rocess <esign o8 Et;=lene ODi<e 69ri8ier col9:n C;ic;

incl9<es <eter:ination o8 col9:n o6erating 6ara:eters an< si?ing o8 col9:n internals5

2.0 PROCESS DESIGN OF ETHYLENE OXIDE PURIFIER COLUMN

(C-702)

2.1 MULTI-COMPONENT DISTILLATION

2.1.1 Determination of Column Operating Condition

To esti:ate t;e <eC an< @9@@le 6oints, it is ass9:e t;at not;ing ;eaEier t;an ;eaE= Ae=

a66ears at <istillate an< not;ing lig;ter t;an lig;t Ae= in @otto:5 T;e s9::ar= o8

co:6onent <istri@9tion is as @eloC.

Ta@le %. Distri@9tion o8 *o:6onent

Component Feed Mole

fraction

Distillate

flow

(kmol/h)

Mole

fraction

Bottom

flow

(kmol/h)

Bottom

Et;=lene Gl=col 135B3B3 050'31 05%#$B4 050022 135'2#4$ 05114##

0ater 05B'2B %500E>%00 05B'2'1 %500E>%00 254%E>04 25'2E>0B

Generall=, <eC an< @9@@le 6oints are esti:ate< 9sing t;e 8olloCing eF9ations.

)9@@le Point .

0 5 %

i i i

# K y

77777775,EF5F>%-

DeC Point .

0 5 % &

i i i

K y #

777777555,EF5F>2-

K

i

is t;e Ea6or>liF9i< eF9ili@ri9: constant or <istri@9tion coe88icient 8or co:6onent i5 T;e

eF9ili@ri9: <ata are o8ten re6resente< @=,

P P K

i i

&

C;ere P

i

is 6artial 6ress9re o8 eac;

co:6onent <eter:ine< @= Antoine EF9ation an< P is col9:n o6erating 6ress9re5

Antoine EF9ation.

C K $

%

& P

+

- ,

log

7777555 ,EF5F>#-

0;ere,

A, ), * K Antoine 6ara:eters

T K Strea: te:6erat9re in +elEin

1

Plant Design Project II

Ta@le 2. Antoine Para:eters

No5 *o:6onent Antoine *oe88icients

A ) *

% Et;=lene Gl=col B5410%4 20035'B ##$5''

2 0ater '5144B% %44B52% 22B500

T;ere are onl= tCo signi8icant co:6onents 8e< to EO 69ri8ier C;ic; are Et;=lene ODi<e an<

0ater5 Ot;er co:6onents are negligi@le an< can @e ignore<5 *ol9:n 6ress9re is taAen as

%%30 APa ,at re@oiler-5T;e <eter:ination o8 @9@@le 6oint at @otto: an< 8ee< ,sat9rate<

liF9i<- an< <eC 6oint o8 <istillate ,sat9rate< Ea6or- is @= trial an< error to satis8= EF9ation %

an< 25

Table 3: Bubble Point Calculation (Feed)

8ee< te:6erat9re,L*- B453

8ee< 6ress9re,APa- %0B0

Component log P`

P`(mmhg

) P`(KPa) Ki

Composition(Xi

) KiXi oi,HK

Et;=lene ODi<e

#512B

B B$BB5403B

%%#%5'2%

0

%50$'

1 0512#$

05041

' %B5$43%

0ater

25442

3 $315'%%B 4%52B11

05034

' 050'31

05032

1 %50000

Table 4: Dew Point Calculation (Distillate)

<istillate te:6erat9re,L*- B25B

%0

Plant Design Project II

<istillate 6ress9re,APa- %030

Component log P`

P`(mmhg

) P`(KPa) Ki Composition(yi) Yi/Ki oi,HK

Et;=lene ODi<e

#5BB4

4 ''025'4'2

%024513%

2

051'B

0 0511B2

%50%1

1 '5342$

0ater

25311

# #1'530%' 3251131

05030

3 050022

050$#

4 %50000

Table 5: Bubble Point Calculation (Bottom)

@otto: te:6erat9re,L*- %B%5#

@otto: 6ress9re,APa- %%00

Component log P` P`(mmhg) P`(KPa) Ki

Composition(Xi

) KiXi oi,HK

Et;=lene ODi<e

$5B0#

3

4#40#5$1'

#

B$'15'4B

1

'5'0B

1 0500#4

0502'

B %5%3B'

0ater

#5B1%

0 ''B%5%1B4

%0#'5$0'

B

051$#

% 05114$

051#1

' %50000

2.1.2 Minimum Number of Stages (Fenske Equation)

FensAe eF9ation is 9se< to esti:ate t;e :ini:9: stages reF9ire< at total re8l9D5 T;e relatiEe

Eolatilities are esti:ate< at t;e 8ee< @9@@le 6oint, C;ic; giEes a ro9g; in<ication o8 t;e

aEerage col9:n te:6erat9re5 T;e FensAe eF9ation is re6resente< as.

'K

(

'K

)K

d

)K

'K

#

#

#

#

*

log

log

:in

1

]

1

1

]

1

'K

(

'K

)K

d

)K

'K

#

#

#

#

*

log

log

:in

1

]

1

1

]

1

7777775 ,EF5F>$-

1 B 5 B

:in

*

%%

Plant Design Project II

0;ere,

N

:in

K :ini:9: n9:@er o8 stages at total re8l9D

M

!+

K aEerage relatiEe Eolatilit= o8 t;e lig;t Ae= Cit; res6ect to t;e ;eaE= Ae=

K ,M

to6

M

@otto:

-

%&2

K 251402

D

!+,

D

H+

K lig;t an< ;eaE= Ae= concentrations

2.1.3 To Estimate the Minimum Reflux Ratio, R

min

T;e :ini:9: re8l9D ratio is a g9i<e in c;oosing a reasona@le re8l9D ratio 8or an

o6erating col9:n an< in esti:ating t;e n9:@er o8 6lates nee<e< 8or a giEen se6aration at

certain Eal9es o8 t;e re8l9D ratio5 Accor<ing to M+C,(e, Smith ,nd ),rriott -"!!1., t;e

<esire< se6aration 9s9all= re8ers to t;e a:o9nt o8 lig;t Ae= recoEere< in t;e <istillate an<

t;e a:o9nt o8 ;eaE= Ae= recoEere< in t;e @otto:s5 Ass9:ing 11 H lig;t Ae= recoEere<

in t;e <istillate an< 11 H ;eaE= Ae= recoEere< in t;e @otto:s5

R

min

J T;e :ini:9: re8l9D ratio

/ /al9e 8or Eario9s 8ee< con<itions.

!iF9i< @eloC @oiling 6oint ,/ N %-

!iF9i< at @oiling 6oint ,/ K %-

!iF9i< O Ea6or ,0 P / P %-

Sat9rate< Ea6or ,/ K 0-

Since 8ee< is Ea6or at @oiling 6oint, t;ere8ore / K05

For sat9rate< Ea6or, 9n<erCoo<Is eF9ation 8or t;e :ini:9: re8l9D ratio is.>

( ) ( ) %

%

%

% & %

:in

1

1

]

1

,

_

f

D

f

D

y

#

y

#

R

7777775 ,EF5F>3-

( ) ( ) %

0512#$ %

0511B2 %

0512#$

0511B2 1402 5 2

% 1402 5 2 & %

:in

1

]

1

,

_

R

R

min

K 05'3%1

%2

Plant Design Project II

2.1.4 To Estimate the Optimum Reflux Ratio,R and the Ideal Number of

Stages,$

An i:6ortant s;ortc9t :et;o< to <eter:ine t;e t;eoretical n9:@er o8 stages reF9ire<

8or an o6erating re8l9D ratio, R is t;e e:6irical correlation o8 0r(,r ,nd M,ddo#

giEen in Fig9re %5 In Fig9re %, t;e o6erating re8l9D ratio R is correlate< Cit; t;e

:ini:9: R

min

o@taine< 9sing 1nder2ood :et;o<, t;e :ini:9: n9:@er o8 stages

*

min

o@taine< @= t;e Fens3e :et;o<5

Re8erring to Fig9re %, Er@ar>Ma<<oD correlation ,Er@ar an< Ma<<oD, %14%-, to o@tain Eal9e

o8 *

min

4*5

Fig9re 2. Er@ar>Ma<<oD correlation ,0r(,r ,nd M,ddo#, 1951.

%#

Plant Design Project II

It ;as @een s;oCn 8or :an= cases t;at t;e o6ti:9: re8l9D ratio is @etCeen %52Rmin to %53Rmin5

T;ere8ore taAe R K %53QRmin

R K %53Q05'3%1

R K %5%2'1

R &,RO%- K053#0

R min& ,RminO%- K05$21

N:&N K 05$3 ,8ro: t;e gra6;-

* K 20 stages ,in+luding re(oiler.

2.1.5 To Estimate Feed-Point Location

1

1

]

1

,

_

,

_

,

_

,

_

2

,

,

,

5

log 204 5 0 log

)K d

'K (

'K f

)K f

s

r

#

#

#

#

D

%

*

*

777777557557 ,EF5F>4-

*r > N9:@er o8 stages a@oEe t;e 8ee<

*s > N9:@er o8 stage @eloC t;e 8ee<

% > Molar 8loC @otto: 6ro<9ct ,8ro: Ta@le F>3-

D > Molar 8loC to6 6ro<9ct ,8ro: Ta@le F>3-

#

f,)K

> *oncentration o8 t;e ;eaE= Ae= at 8ee< ,8ro: Ta@le F>3-

D

f,'K

> *oncentration o8 t;e lig;t Ae= at 8ee< ,8ro: Ta@le F>3-

#

d,)K

> *oncentration o8 t;e ;eaE= Ae= in t;e to6 6ro<9ct ,8ro: Ta@le F>3-

D

(,'K

> *oncentration o8 t;e lig;t Ae= in t;e @otto: 6ro<9ct ,8ro: Ta@le F>3-

Since 8ro: t;e calc9late< Eal9esG

R K %5%2'1

* K 20 stages

% K 14540 Ag:ole&;r

D K 3B25#0 Ag:ole&;r

#

f,)K

K 050'31

D

f,'K

K 0512#$

%$

Plant Design Project II

#

d,)K

K 050022

D

(,'K

K 0500#4

S9@stit9te all t;e Eal9es o@taine< into EF5F>4.

1

1

]

1

,

_

,

_

,

_

,

_

2

0022 5 0

00#4 5 0

12#$ 5 0

0'31 5 0

#0 5 3B2

40 5 14

log 204 5 0 log

s

r

*

*

[ ] 0#43%# 5 0 log 204 5 0 log

,

_

s

r

*

*

214 5 0 log

,

_

s

r

*

*

303B 5 0

,

_

s

r

*

*

*

r

O *

s

K %1 ,eDcl9<ing re@oiler-

*

s

K %254%B

Fee< tra= location K %#

t;

tra=

%3

Plant Design Project II

2.2 PLATE HYDRAULIC DESIGN

2.2.1 Operating Range

Satis8actor= o6eration Cill onl= @e ac;ieEe< oEer a li:ite< range o8 Ea6or an< liF9i<

8loC rates5 *are89l col9:n <i:ensioning reF9ires <eter:ination o8 t;e entire o6erating

region an< t;e 6ro6er selection o8 t;e o6erating 6ara:eters so t;at a sa8et= :argin can

@e :aintaine< Cit; res6ect to t;is li:it 8or liF9i< an< gas loa<s5

2.2.2 Plate Design Procedure

A trial an< error a66roac; ;as @een 9se< in 6late <esign. starting Cit; a ro9g; 6late

la=o9t, c;ecAing Ae= 6er8or:ance 8actors an< reEising t;e <esign, as necessar=, 9ntil a

satis8actor= <esign is ac;ieEe<5

a) To Estimate the Column Diameter, %c

T;e 6rinci6al 8actor t;at <eter:ines t;e col9:n <ia:eter is t;e Ea6or 8loC>rate5

)ase< on 8loo<ing consi<erationsG t;e col9:n <ia:eter is esti:ate<5 T;e 8loo<ing

con<ition 8iDes t;e 966er li:it o8 Ea6or Eelocit=5 T;e Eelocit= Cill nor:all= @e

@etCeen '0 to 10 6er cent o8 t;at C;ic; Co9l< ca9se 8loo<ing5 For <esign, a Eal9e o8

6! to 67 6er cent o8 t;e 8loo<ing Eelocit= s;o9l< @e 9se<5

M,#imum flo2:

MaDi:9: liF9i< :ass 8loCrate, '

2, m,#

K %$54#2' Ag&s

MaDi:9: Ea6o9r :ass 8loCrate, 8

2, m,#

K %353'3$ Ag&s

Minimum flo2:

Mini:9: liF9i< :ass 8loCrate, '

2, min

K %5#'%3 Ag&s

Mini:9: Ea6o9r :ass 8loCrate, 8

2, min

K 05#4B$ Ag&s

%4

Plant Design Project II

Ta@le 4. Tra= Pro8ile In8or:ation 8ro: i*ON

Stage

T P Liquid Flow Liquid flow Vapour Flow Vapor flow

C kPa kgmole/h (kg/h) kgmole/h (kg/h)

1 (code!er) "#$#%&' 1'&%$&''' "&1$#('' 1&)(*$*&1) '$"%%( )*$'+1)

% +%$*&'' 1'&&$'''' "&1$**'' 1&)(&$%'++ 1%##$*''' &*'#1$)'""

) +#$&#&' 1'&#$&''' "&'$&&'' 1&)%&$%'++ 1%##$&''' &*'**$+%''

( 1'%$&''' 1'*'$'''' "(#$&)'' 1&%#'$#+&& 1%#*$(''' &*'1"$*()%

& 1'#$(%&' 1'*%$&''' "('$&#'' 1&1(&$)+') 1%#)$(''' &&""*$+#+%

* 11%$)&'' 1'*&$'''' "%($()'' 1("&($&#+# 1%**$(''' &&&#+$#*)%

# 11#$%#&' 1'*#$&''' #(+$"*'' 1)&1'$+##& 1%&'$)''' &("#)$1**(

" 1%%$%''' 1'#'$'''' (%'$%%'' #$&%(' 11#&$#''' &1&++$1%1*

+ 1%#$1%&' 1'#%$&''' (&($1''' "1"1$+#)" "(*$'+'' )#1))$1+#+

1' 1)%$'&'' 1'#&$'''' (&&$)('' "%'($)1*1 "#+$+#'' )"*%'$1%)(

11 1)*$+#&' 1'##$&''' (&&$(*'' "%'*$(#") ""1$%1'' )"*#($&((&

1% 1(1$+''' 1'"'$'''' (&&$&&'' "%'"$'+++ ""1$))'' )"*#+$"11'

1) 1(*$"%&' 1'"%$&''' (&&$*)'' "%'+$&(1) ""1$(%'' )"*")$#*1'

1( 1&1$#&'' 1'"&$'''' (&&$#%'' "%11$1*)' ""1$&''' )"*"#$%#%'

1& 1&*$*#&' 1'"#$&''' (&&$"''' "%1%$*'(( ""1$&+'' )"*+1$%%1+

1* 1*1$*''' 1'+'$'''' (&&$"+'' "%1($%%*' ""1$*#'' )"*+($#))'

1# 1**$&%&' 1'+%$&''' (&&$+"'' "%1&$"(#* ""1$#*'' )"*+"$*"%+

1" 1#1$(&'' 1'+&$'''' (&*$'*'' "%1#$%"+1 ""1$"&'' )"#'%$*)%"

1+ 1#*$)#&' 1'+#$&''' (%%$'1'' #*')$##*% ""1$+('' )"#'*$&"%#

%' (re,oiler) 1"1$)''' 11''$'''' %#($')'' (+)#$(#%& 1(#$+"'' *(+($&(*%

%'

Plant Design Project II

)otto:s liF9i< <ensit=,

', (ottom

K BB%52%21 Ag&:

#

)otto:s Ea6o9r <ensit=,

8, (ottom

K %%532B$ Ag&:

#

To6 liF9i< <ensit=,

', to9

K '%B5'1BB Ag&:

#

To6 Ea6o9r <ensit=,

8, to9

K %#5342$ Ag&:

#

'

:

;

;

'8

8

'

F

77777777557557 ,EF5F>'-

C;ere '

2

J liF9i< :ass 8loC>rate, Ag&s

8

2

J Ea6o9r :ass 8loC>rate, Ag&s

S9@stit9te all t;e Eal9es into EF5F>'.

F

!/, :aD, @otto:s

2%21 5 BB%

32B$ 5 %%

3'3$ 5 %3

4#2' 5 %$

K 05%0'3

F

!/, :in, @otto:s

<

2%21 5 BB%

32B$ 5 %%

#4B$ 5 0

#'%3 5 %

K 05$23B

F

!/, :aD, to6

K

'1BB 5 '%B

342$ 5 %#

3'3$ 5 %3

4#2' 5 %$

K 05%210

F

!/, :in, to6

K

'1BB 5 '%B

342$ 5 %#

#4B$ 5 0

#'%3 5 %

K 053%%$

T;e ;ig;er Eal9e o8 F

'8, m,#

an< F

'8, min

is taAenG

F

'8, m,#

K 05%210 an< F

'8, min

K 05$23B

T;e o6erating Eal9e o8 F

'8

s;o9l< lie @etCeen F

'8, min

an< F

'8, m,#

5

05%210P F

'8

P05$23B

TaAe t;e F

'8, o9

K 052'B

TaAe tra= s6acing as 0534 :

%B

Plant Design Project II

Accor<ing to ,R. K Sinnott, 1993., Plate s6acing 8ro: 05%3: to %: are nor:all=

9se<5

2.2.3 Surface tension calculation:-

Ta@le '. S9r8ace Tension an< :ole 8raction 8or eac; co:6onent

R

:

KR

%

D

%

OR

2

D

2

O75

R

:

K s9r8ace tension :iDt9re

R

%

K s9r8ace tension co:6onent %

D

%

K :ole 8raction co:6onent %

S9r8ace tension K 31.2769 dyne/cm

Compoet Surface te!io (d-e/cm) .ole fractio

/th-lee 01ide )1$% '$++"%

2ater *'$& '$''%%

%1

Plant Design Project II

Fig9re #. Floo<ing Eelocit= ,R. K. Sinnott, 1993-

Fro: Fig9re F>2. Floo<ing Eelocit=, sieEe 6lates

K

1,o9

K 050B

*orrection 8or s9r8ace tension is calc9late< 9sing EF5F>BG

K

1,o9

0'3% 5 0 0B 5 0

02 5 0

0%$31 5 0

2 5 0

,

_

777777775575 ,EF5F>

B-

T;e :aDi:9: 8loo<ing Eelocit= can @e esti:ate< 8ro: t;e correlation giEen @= F,ir

-1951..

:

: '

o9 f

K u

, % :aD ,

77777777757557 ,EF5F>1-

20

Plant Design Project II

s m u

f

& 432 5 0

32B$ 5 %%

32B$ 5 %% 2%21 5 BB%

0'3% 5 0

:aD ,

FairIs 8loo<ing correlation state< t;at B0 to B3H o8 8loo<ing Eal9e <esign s;o9l< @e

9se< an< 8or t;is <esign B0 6ercent 8loo<ing at :aDi:9: 8loC rate is ass9:e<G

:aD ,

S

f :

u flooding 9er+ent,ge u

77777755 ,EF5F>%0-

s m u

:

& 32%4 5 0 B0 5 0 432 5 0

MaDi:9: Eol9:etric 8loC>rateG

At Tra= 2 ,8ro: i*ON, re8er to Ta@le 4-G

MaDi:9: Ea6o9r ,:olar 8loC- K %2''540 Ag:ole&;

Molec9lar Ceig;t K $#5BBB

Densit=,

E

K %%532B$ Ag&:

#

MaDi:9: Ea6o9r 8loC>rate K

s m & #3% 5 %

#400 32B$ 5 %%

BBB 5 $# 40 5 %2''

#

Net area reF9ire< K

:

u

r,te flo2 :,9our M,#imum S S

7777777557 ,EF5F>%%-

Net area K

2

310% 5 2

32%4 5 0

#3% 5 %

m

: :

2

+

u

8

D

$

777777775577557 ,EF5F>%2-

S9@stit9ting t;e Eal9es into EF5F>%2, t;e <ia:eter is o@taine<5

m D

+

B%40 5 %

310% 5 2 $

D

+

K %5B%40 :

Use sa:e <ia:eter a@oEe an< @eloC 8ee<, re<9cing t;e 6er8orate< area 8or 6lates

a@oEe t;e 8ee<5

2%

Plant Design Project II

b) To Decide on The Liquid Flow Arrangement

At Tra= 2 ,8ro: i*ON, re8er to Ta@le 1-G

MaDi:9: liF9i< ,:olar 8loC- K %2''540 Ag:ole&;

Molec9lar Ceig;t K$#5BBB

Densit=,

!

K BB%52%21 Ag&:

#

MaDi:9: liF9i< 8loC>rate K

s m & 0%'4' 5 0

#400 2%21 5 BB%

BBB 5 $# 40 5 %2''

#

For :aDi:9: liF9i<>8loC rate K 050%'4' :

#

&s

D

+

K %5B%40 :

Using Fig9re F>$. Selection o8 liF9i< 8loC arrange:ent

T;e 6late <ia:eter is insi<e t;e range o8 Fig9re #, it is clear t;at t;e 6late to @e 9se<

is cross 8loC ,single 6ass- 6late5 *ross 8loC 6late t;e liF9i< 8loCs across t;e 6late

an< Ea6or 96 t;ro9g; t;e 6late5

Fig9re $. Selection o8 !iF9i< FloC Arrange:ent ,RK Sinnott, 1993-

22

Plant Design Project II

c) To Determine the Trial Layout (To estimate the downcomer area, active area,

hole area, hole size, weir height)

Fro: a- *ol9:n <ia:eter, D

+

K %5B%40 : an< *ol9:n area, &

+

K 25310%:

2

T;e <oCnco:er area an< 6late s6acing :9st @e s9c; t;at leEel o8 t;e liF9i< an< 8rot;

in t;e <oCnco:er is Cell @eloC t;e to6 o8 t;e o9tlet Ceir on t;e 6late a@oEe5 T;e

@acA>96 o8 liF9i< in t;e <oCnco:er is ca9se< @= t;e 6ress9re <ro6 oEer t;e 6late an<

t;e resistance to 8loC in t;e <oCnco:er itsel85

i5 To esti:ate <oCnco:er area, &

d

Initial esti:ate, taAe &

d

as %2 6er cent &

+

&

d

K 05#%0B :

2

ii5 To esti:ate net area, &

n

&

n

K &

+

J &

d

&

n

K 25310% > 05#%0B

K 252'1# :

2

iii5 To esti:ate actiEe area, &

,

&

,

K &

+

J 2&

d

&

,

K 25310%J 2,05#%0B-

K %514B3 :

2

iE5 To esti:ate ;ole area, &

h

Initial esti:ate, taAe &

h

as 4 6er cent &

,

&

h

K 05%%B% :

2

Using Fig9re $. Relation @etCeen <oCnco:er area an< Ceir lengt;G

H 00 5 %2 %00

+

d

&

&

'30 5 0

+

2

D

l

777777775577557 ,EF5F>%#-

m l

2

#42 5 %

Initial esti:ationG

0eir ;eig;t, h

2

K 30::

Hole <ia:eter, d

h

K %0::

Plate t;icAness K 3::

2#

Plant Design Project II

Fig9re 3. 0eir lengt; correlation ,RK Sinnott, 1993-

d) To Check for Weeping Rate

T;e loCer li:it o8 t;e o6erating range occ9rs C;en liF9i< leaAage t;ro9g; t;e 6late

;oles @eco:es eDcessiEe5 T;is is AnoCn as Cee6 6oint5 T;e Ea6or Eelocit= at t;e

Cee6 6oint is t;e :ini:9: Eal9e 8or sta@le o6eration5

i5 To esti:ate :aDi:9: liF9i< rate

MaDi:9: liF9i< ,:olar 8loC- K %2''540 Ag:ole&;

Molec9lar Ceig;t K $#5BBB

MaDi:9: liF9i< rate, '

2,m,#

K

s m & 3'3 5 %3

#400

BBB 5 $# 40 5 %2''

#

,

_

ii5 To esti:ate :ini:9: liF9i< rate

TaAe :ini:9: liF9i< rate at B0 6er cent t9rn><oCn

Mini:9: liF9i< rate, '

2,min

K 05B0,%353'3- K %25$4 :

#

&s

2$

Plant Design Project II

iii5 To esti:ate :aDi:9: an< :ini:9: Ceir liF9i< crest, h

o2

T;e ;eig;t o8 t;e liF9i< crest oEer t;e Ceir can @e esti:ate< 9sing t;e

Fr,n+is 2eir 8or:9la state< @eloC5 For a seg:ental <oCn co:er t;e eF9ation

can @e Critten as.

# & 2

'30

1

]

1

2 '

2

o2

l

'

h

7777777557 ,EF5F>%$-

C;ere l

2

J Ceir lengt;, :

h

o2

J Ceir crest, :: liF9i<

'

2

J :in liF9i< 8loC rate, :

#

&s

0it; seg:ental <oCnco:ers t;e col9:n Call constricts t;e liF9i< 8loC, an<

t;e Ceir crest Cill @e ;ig;er t;an t;at 6re<icte< @= t;e Francis 8or:9la 8or

8loC oEer an o6en Ceir5

At :aDi:9: liF9i< 8loCG 8ro: 6art a-

!

K 2#405# Ag&:

#

Fro: 6art c-

m l

2

#42 5 %

li/uid mm h

o2

S B4 5 2'

#42 5 % 40 5 %2''

$40 5 %2

'30

# & 2

:in ,

1

]

1

li/uid mm h

o2

S ## 5 #2

#42 5 % 40 5 %2''

3'3 5 %3

'30

# & 2

:aD ,

1

]

1

Fro: 6art c- 0eir ;eig;t, h

2

K 30::G

T;ere8ore at :ini:9: rate h

2

O h

o2

K 30 O2'5B4K ''5B4 ::

iE5 To <eter:ine t;e :ini:9: Ea6or Eelocit= t;ro9g; t;e ;oles,

:in , h u

( ) [ ]

( )

2 & %

2

:in ,

$ 5 23 10 5 0

:

h

h

d K

u

777777755 ,EF5F>%3-

C;ere

:in , h u

> :ini:9: Ea6or Eelocit= t;ro9g; t;e ;oles ,@ase< on ;ole

area-, :&s

d

h

J ;ole <ia:eter, :: K %0::

8

J %%532B$ Ag&:

#

at :aDi:9: Ea6or 8loC, 8ro: 6art a-

K

"

J a constant o@taine< 8ro: Fig9re 3. 0ee6>6oint correlation ,0dul=ee,

1979- K#05'

23

Plant Design Project II

24

Plant Design Project II

Fig9re 4. 0ee6>6oint *orrelation ,0dul=ee, 1979-

( ) [ ]

s m uh & 1B1 5 $

- 32B$ 5 %% ,

%0 $ 5 23 10 5 0 B 5 #0

2 & %

:in ,

Mini:9: Ea6or 8loC rate K 05B0,#530%B- K 25B0%$:

#

&s

Fro: 6art c- &

h

K 05%%B%:

2

Act9al :ini:9: Ea6or Eelocit=, u

n

K 25B0%$&05%%B% K 2#5'204 :&s

e) To Estimate Plate Pressure Drop, h

t

T;e 6ress9re <ro6 oEer t;e 6lates is an i:6ortant <esign consi<eration5 T;ere are tCo

:ain so9rces o8 6ress9re lossG t;at <9e to Ea6or 8loC t;ro9g; t;e ;oles ,an ori8ice

loss-, an< t;at <9e to t;e static ;ea< o8 liF9i< on t;e 6late5

( )

r o2 2 d t

h h h h h + + +

77777757 ,EF5F>%4-

i5 To esti:ate <r= 6late 6ress9re <ro6, h

d

T;e 6ress9re <ro6 t;ro9g; t;e <r= 6late can @e esti:ate< 9sing eD6ressions

<eriEe< t;ro9g; ori8icesG

'

:

o

h

d

C

u

h

2

:aD ,

3%

1

1

1

]

1

7777777557 ,EF5F>%'-

C;ere C

o

J 89nction o8 6late t;icAness, ;ole <ia:eter an< t;e ;ole to

6er8orate< area ratio5

u

h,m,#

J Eelocit= t;ro9g; t;e ;oles, :&s

Fro: 6art a- :aDi:9: Ea6or 8loC>rate K %5#3% :

#

&s

Fro: 6art c- &

n

K 252'1# :

2

s m uh & 312' 5 0

2'1# 5 2

#3% 5 %

:aD ,

Fro: 6art c- &

h

K 05%%B% :

2,

&

,

K %514B3 :

2,

6late t;icAness K 3:: an< ;ole

<ia:eter, d

h

K %0::

,

h

9

h

&

&

&

&

777777775557 ,EF5F>%B-

2'

Plant Design Project II

H 00 5 4 %00

9

h

&

&

3 5 0

%0

3 S

h

d

thi+3ness Pl,te

Using Fig9re 4. Disc;arge coe88icient, sieEe 6lates ,'ie(son et ,l., 197-

C

o

K 0541

2B

Plant Design Project II

Fig9re '. Disc;arge coe88icient, sieEe 6lates ,'ie(son et ,l., 197-

Fro: 6art a- !iF9i< <ensit=,

',m,# flo2

K BB%52%21 Ag&:

#

an< Ea6or <ensit=,

8,m,# flo2

K %%532B$ Ag&:

#

li/uid mm h

d

S $12# 5 0

2%21 5 BB%

32B$ 5 %%

41 5 0

312' 5 0

3%

2

1

]

1

ii5 To esti:ate t;e resi<9al ;ea<, h

r

T;e si:6le eF9ation 6ro6ose< @= )unt et ,l. -1977. can @e 9se<.

'

r

h

#

%0 3 5 %2

777777777555 ,EF5F%1-

0;ere t;e resi<9al <ro6 as 8iDe< Eal9e o8 %253 :: o8 Cater ,%&2 in5-

21

Plant Design Project II

Fro: a- !iF9i< <ensit=,

',m,# flo2

K BB%52%21 Ag&:

#

li/uid mm h

r

S %B3 5 %$

2%21 5 BB%

%0 3 5 %2

#

iii5 To esti:ate t;e total 6late 6ress9re <ro6, h

t

re8er to EF5F>%4

( )

r o2 2 d t

h h h h h + + +

li/uid mm h

d

S $12# 5 0

h

2

O h

o2

K ''5B4 mm>li/uid

li/uid mm h

r

S %B3 5 %$

li/uid mm h

t

S 3#' 5 12 %B3 5 %$ B4 5 '' $12# 5 0 + +

*ol9:n 6ress9re <ro6 K 30000 Pa ,30 APa-

f) To Estimate Downcomer Back-up, h

b

T;e :ain resistance to 8loC Cill @e ca9se< @= t;e constriction at t;e <oCnco:er

o9tlet, an< t;e ;ea< loss in t;e <oCnco:er can @e esti:ate< 9sing t;e eF9ation giEen

@= Ci+,lese et ,l. -19?.5

i5 To esti:ate t;e <oCnco:er 6ress9re loss, h

d+

2

%44

1

]

1

m '

2d

d+

&

'

h

777777777 ,EF5F20-

0;ere '

2

J liF9i< 8loC rate, Ag&s

&

m

J eit;er t;e <oCnco:er area &

d

or t;e clearance area 9n<er t;e

<oCnco:er &

,9

, C;ic;eEer s:aller, :

2

Fro: 6art <- '

2d

K %353'3 :

#

&s

Fro: a- !iF9i< <ensit=,

',m,# flo2

K BB%52%21 Ag&:

#

T;e clearance area 9n<er t;e <oCnco:er is giEen @=.

2 ,9 ,9

l h &

7777777775 ,EF5F>2%-

C;ere h

,9

J ;eig;t o8 t;e @otto: e<ge i8 t;e a6ron a@oEe t;e 6late5

Accor<ing to RK Sinnot -1993. since t;is ;eig;t is nor:all= set at 3 to %0

:: @eloC t;e o9tlet Ceir ;eig;t.

- %0 S S 3 , mm to h h

2 ,9

Since Ceir ;eig;t, h

2

K 30::

TaAe %0::

h

,9

K $0::

#0

Plant Design Project II

Fro: 6art c-

m l

2

#42 5 %

)= s9@stit9ting all t;e Eal9es into EF5F>2%.

2

03$3 5 0 #42 5 %

%000

$0

m &

,9

Fro: 6art c- &

d

K 05##1:

2

&

m

< &

d

K 05#%0B :

2

, s9@stit9te t;e Eal9es into EF5F>20.

mm h

d+

4B 5 3#

#%0B 5 0 2%21 5 BB%

3'3 5 %3

%44

2

1

]

1

ii5 To esti:ate t;e @acA>96 in <oCnco:er, h

(

In ter:s o8 clear liF9i< t;e <oCnco:er @acA96 is giEen @=.

( )

d+ t o2 2 (

h h h h h + + +

7777755575 ,EF5F>22-

C;ere h

(

J <oCnco:er @acA>96, :eas9re< 8ro: 6late s9r8ace, ::

h

d+

J ;ea< loss in t;e <oCnco:er, ::

h

2

O h

o2

K ''5B4mm>li/uid

li/uid mm h

t

S 3#' 5 12

mm h

d+

4B 5 3#

li/uid mm h

(

S 0'' 5 22$ 4B 5 3# 3#' 5 12 B4 5 '' + +

h

(

K 0522$% :

For sa8e <esign t;e clear liF9i< @acA>96, t;e calc9late< h

(

8ro: EF5F>22

s;o9l< not eDcee< ;al8 t;e 6late s6acing, l

t

to aEoi< 8loo<ing5 AlloCing 8or

t;e Ceir ;eig;t.

( )

2 t (

h l h + <

2

%

777775775 ,EF5F>2#-

Fro: 6art c- 0eir ;eig;t, h

2

K 30:: an< 6late s6acing, l

t

K 053:

( ) m h l

2 t

2'3 5 0 3 5 0 +

0522$%: P 052'3:

iii5 To esti:ate t;e <oCnco:er resi<ence ti:e

S988icient resi<ence ti:e :9st @e alloCe< in t;e <oCnco:er 8or t;e

entraine< Ea6or to <isengage 8ro: t;e liF9i< strea:G to 6reEent ;eaEil=

Taerate<U liF9i< @eing carrie< 9n<er t;e <oCnco:er5 A ti:e o8 at least #

secon<s is reco::en<e< @= RK Sinnot -1993..

2d

' (+ d

r

'

h &

t

777757555775 ,EF5F>2$-

#%

Plant Design Project II

C;ere t

r

J resi<ence ti:e, s

h

(+

J clear liF9i< @acA>96, :

Fro: 6art c- &

d

K 05#%0B :

2

Fro: 6art 8- h

(

K h

(+

K 0522$% :

Fro: 6art <- '

2d

K %353'3 :

#

&s

Fro: 6art a- !iF9i< <ensit=,

',m,# flo2

K BB%52%21 Ag&:

#

s t

r

1$0' 5 #

3'3 5 %3

2%21 5 BB% 22$% 5 0 #%0B 5 0

t

r

#s is reco::en<e<

g) To Check for Entrainment,

Entrain:ent can @e esti:ate< 8ro: t;e correlation giEen @= Fair ,%14%-, Fig9re '

C;ic; giEes t;e 8ractional entrain:ent ,Ag&Ag gross liF9i< 8loC- as a 89nction o8

t;e liF9i< Ea6or 8actor, F

'8

Cit; is t;e 6ercentage a66roac; to a 8loo<ing 6ara:eter5

:aD ,

S

h

n

u

u

flooding Per+ent,ge

7777777775 ,EF5F>23-

Fro: 6art a-

s m u

f

& 312' 5 0

:aD ,

Fro: 6art e-

s m uh & 432 5 0 :aD ,

H 1% 101 5 0

432 5 0

312' 5 0

S flooding Per+ent,ge

Using Fig9re *>B. Entrain:ent correlation 8or sieEe 6lates ,F,ir, 1951-

Fro: 6art a- TaAe t;e F

'8, o9

K 052'B

As a ro9g; g9i<ance t;e 966er li:it o8 can @e taAen as 05#, @eloC t;is Eal9e

e88ect on e88icienc= Cill @e s:all5

K 0502P 052'B ,E88icienc= Cill @e s:all-

#2

Plant Design Project II

Fig9re B. Entrain:ent correlation 8or sieEe 6lates ,Fair, %14%-

##

Plant Design Project II

h) Trial Layout

i5 To esti:ate t;e 6er8orate< area

Fro: 6art a- D

+

K %5B%40:

Fro: 6art c-

m l

2

#42 5 %

'300 5 0

+

2

D

l

Fig9re 1. Relation @etCeen angle s9@ten<e< @= c;or<, c;or< ;eig;t an< c;or< lengt;

!et

+

K 14

AlloC 30:: i:6er8orate< stri6 ro9n< 6late e<geG 30:: Ci<e cla::ing

?ones5

Angle s9@ten<e< at 6late e<ge @= i:6er8orate< stri6 K %B0 J 14 K B$

Mean lengt;, i:6er8orate< e<ge stri6s K ,%5B%40>30%0

>#

-B$&%B0

K 253B1:

Area o8 i:6er8orate< e<ge stri6s K 30%0

>#

253B1 K 05%213 :

2

#$

Plant Design Project II

Mean lengt; o8 cla::ing ?one K ,%5B%40 > 30%0

>#-

sin ,14&2-

K %5#%2$ :

Area o8 cla::ing ?one K 2,%5#%2$ 30%0

>#-

K 05%#%2$:

2

Total area 8or 6er8orations,

&

9

K V&

n

J ,*la::ing area- J ,I:6er8orate< Area-W

&

9

K 252'1# J 05%#%2$ J 05%213 K 250%B4 :

2

Fro: 6art c- &

h

K 05%%B%:

2

&

h

&&

9

K 05%%B%&250%B4K 0503B3%

Fro: Fig9re 1, t;e relation @etCeen ;ole area an< 6itc; are 8o9n<5

l

9

&d

h

K #5'

0Pl

9

&d

h

P $50

ii5 To esti:ate n9:@er o8 ;oles

Fro: 6art a- D

+

K %5B%40:

Area o8 one ;ole K %514$%0

>$

:

2

Fro: 6art c- &

h

K 05%%B%:

2

N9:@er o8 ;oles K 40%

%0 14$ 5 %

%%B% 5 0

$

Fig9re %0. Trial !a=o9t

%5#%2$:

30::

%5B%40:

+

30::

#3

Plant Design Project II

Fig9re %%. DoCnco:er @acA96

i) Plate Specification

Plate No5 % T9rn><oCn B0 6er cent :aD rate

Plate I5D5 %5B%40 : Plate :aterial *ar@on steel

Hole si?e %0 :: DoCnco:er :aterial IS. *ar@on Steel

Hole 6itc; 23 ::

Plate s6acing %50:

Plate t;icAness 3 :: ActiEe ;oles 40%

Plate 6ress9re <ro6 253 +6a

l

t

K053:

h

(

K0522$:

h

,9

K050$:

h

2

K0503:

h

o2

K2'5B4 :: liF9i<

#4

Plant Design Project II

3.0 MECHANICAL DESIGN

T;is s9@c;a6ter Cill coEer <etail :ec;anical <esign 8or Et;=lene ODi<e

69ri8ication col9:n in *>'025 Fig9re %2 @eloC s;oCs t;e :et;o<olog= in

<esigning :ec;anical <esigns

Figure 1": Methodology for Me+h,ni+,l Designs

1. %esi&n pressure and material specification

Set D

i

an< !

Material F

s

, (

O6erating P, T P

<esign

2. Shell thic'ness

3. (ead and Closure

)otto:

To6

)lanA <ia:eter

4. %esi&n of )as'et and *olts

GasAet s6ecs :aterial, :, =, Ci<t;

)olt loa<s

No o8 @olts

. %esi&n of Rin& +lan&e

Flange t;icAness

Flange <ia:eter

!. ,essel sub-ect to combined loadin&

Total Ceig;t K s;ell O 6late O ins9lation

". .ind loadin&

Stress anal=sis at @otto:

Princi6al stresses

*;ecA elasticit=

#. %esi&n of S'irt Support

*;ecA criteria 8or <esign ,tensile an< co:6ressiEe-

SAirt t;icAness

/. $o00le si0in&

Fee< no??le

To6 no??le ,Ea6or o9t an< re8l9D in-

)otto: no??le ,liF9i< o9t an< @oil 96 in-

NO

NO

NO

#'

Plant Design Project II

3.1 The Design of Thin-Walled Vessels under Internal Pressure

3.1.1 Materials of Construction

Selection o8 :aterial to @e 9se< in t;e constr9ction o8 t;e <istillation col9:n is @ase< on

t;e i:6ortant c;aracteristics as @eloC.

i5 Mec;anical Pro6erties

Strengt; J tensile strengt; is a :eas9re o8 t;e @asic strengt; o8 a

:aterial5 It is t;e :aDi:9: stress t;at t;e :aterial Cill Cit;stan<5

Sti88ness J elastic :o<9l9s 89nction o8 t;e :aterial an<

t;e s;a6e o8 cross section o8 t;e :e:@er ,secon< :o:ent o8 area-5 It is

t;e a@ilit= to resist @en<ing an< @9cAling5

To9g;ness J 8ract9re resistance an< cracA 6ro6agation

Har<ness J Cear resistance

Fatig9e resistance J s9@ject to c=cling loa<ing

*ree6 resistance J gra<9al eDtension o8 a :aterial 9n<er

a stea<= tensile stress

ii5 E88ect o8 ;ig; an< loC te:6erat9re on t;e :ec;anical 6ro6erties

Decrease Cit; increasing te:6erat9re

*orrosion resistance

Ease o8 8a@rication

AEaila@ilit= o8 stan<ar< si?es

*ost

In or<er to select t;e correct :aterial o8 constr9ction, t;e 6rocess enEiron:ent to C;ic;

t;e :aterial Cill @e eD6ose< to :9st @e clearl= <e8ine<5 T;e :aterial o8 constr9ction

c;osen is *ar@on Steel5 T;e reason 8or t;is selection is t;at t;e Et;=lene ODi<e is

reactiEe in nat9re5 *ar@on Steels are 9se< 8or corrosion resistance <9e to cost

consi<eration5

#B

Plant Design Project II

3.1.2 Design Pressure

O6erating 6ress9re. %03253 APa

O6erating te:6erat9re. B'5'# *

Material o8 *onstr9ction. Ni>Resist corrosion>resistant cast iron

,ASTM A$#4&$#4 M-

*orrosion AlloCance. 2:: is a<<e<

T;e corrosion alloCance is generall= a<<itional :etal t;icAness a<<e< to alloC

8or :aterial lost @= corrosion, erosion an< scaling5 In t;is 6rocess, t;e 8l9i< is not

corrosiEe t;ere8ore a :ini:al t;icAness is a<<e< on5

Design 6ress9reG is taAen as %0 6er cent a@oEe t;e nor:al o6erating 6ress9re,

Design 6ress9re, P

i

K ,%053# @ar > %- %5%

K %05$B @ar

Press9re tolerance is to aEoi< s69rio9s o6eration <9ring :inor 6rocess 96sets5

3.1.3 Thickness of vessel

T;is is t;e 8or: o8 eF9ation giEen in t;e )ritis; Stan<ar<, )S 3300

i

i i

P @f

D P

t

2

777777777775 ,EF5F>

24-

C;ere D

i

J internal <ia:eter

t J :ini:9: t;icAness reF9ire<

f J <esign stress K %04 N&::

2

,Ta@le 2-

P

i

J internal 6ress9re

@ J joint 8actor K %50 since Cel<s Cill @e 89ll= ra<iogra6;e<

,Ta@le %#5#. MaDi:9: alloCa@le joint e88icienc=-

S9@stit9te t;e Eal9es into EF5F>24

For a c=lin<rical s;ell t;e :ini:9: t;icAness reF9ire< to resist internal 6ress9reG

a) Cylindrical section

#1

Plant Design Project II

0all t;icAness, mm t B1B 5 0

%0$B 5 0 %04 % 2

%0 B%40 5 % %0$B 5 0

#

A<< corrosion alloCance 05B1B O 2K 25B1B ::

Sa= #50 :: 6late5

b) Doomed head

Tr= a stan<ar< <is;e< ;ea< ,toris9here-.

*roCn ra<i9s, R

+

K D

i

K %5B%40 :

+n9cAle ra<i9s K 4 6er cent R

+

K05%010 :

A ;ea< o8 t;is si?e Co9l< @e 8or:e< @= 6ressing. no joints, so (K%

Fig9re %#. Toris6;erical

''0$ 5 %

%010 5 0

B%40 5 %

#

$

%

#

$

%

,

_

,

_

+

3

+

s

R

R

C

7777777777775 ,EF5F>2'-

( ) 2 5 0 2 +

s i

s + i

C P f@

C R P

t

757777777775 ,EF5F>

2B-

( )

mm t 34B2 5 %

2 5 0 ''0$ 5 % B%40 5 % % %04 2

''0$ 5 % %0 B%40 5 % %0$B 5 0

#

Tr= a stan<ar< elli9soid,l ;ea<, ratio :ajor. :inor aDes K 2. %

Fig9re %$. Elli6soi<al

$0

Plant Design Project II

i

i i

P @f

D P

t

2 5 0 2

7775557777775 ,EF5F>

21-

mm t B1'B 5 0

- %0$B 5 0 , 2 5 0 % %04 2

%0 B%4 5 % %0$B 5 0

#

So an elli9soid,l he,d Co9l< 6ro@a@l= @e t;e :ost econo:ical5 TaAe as

sa:e t;icAness as Call #50 :: reF9ire< 8or 6ress9re loa<ing5

A :9c; t;icAer Call Cill @e nee<e< at t;e col9:n @ase to Cit;stan< t;e

Cin< an< <ea< Ceig;t loa<s5

3.2 Combined loading on Vessel

Heig;t @etCeen tangent lines K $:

SAirt s966ort ;eig;t K 05': ,ass9:e-

2 sieEe 6lates, eF9all= s6ace<

Ins9lation :ineral Cool K '3:: t;icA

/essel to @e 89ll= ra<iogra6;e< ,joint 8actor %-

As a 8irst trial <iEi<e t;e col9:n into 8iEe sections ,co9rses-, Cit; t;e t;icAness

increasing @= 2:: 6er section5 Tr= 2, $::5

3.2.1 Dead weight of vessel

( )

#

%0 B 5 0

+ t D ) g D C ;

m : m m : :

77755577777755 ,EF5F>

#0-

C;ere ;

:

J total Ceig;t o8 t;e s;ell, eDcl9<ing internal 8ittings, s9c; as

6lates

C

:

J A 8actor acco9nt 8or t;e Ceig;t o8 no??les, :an Ca=s, internal

s966orts, etc5

)

:

J Heig;t, or lengt;, @etCeen tangent lines ,t;e lengt; o8 t;e c=lin<rical

section-, :

g J GraEitational acceleration, 15B% :&s

2

t J 0all t;icAness, ::

$%

Plant Design Project II

m

J Densit= o8 Eessel :aterial, Ag&:

#

D

m

J :ean <ia:eter o8 Eessel K ,D

i

O t %0

>#

-, :

For a steel Eessel,

( )t D ) D C ;

m : m : :

B 5 0 2$0 +

77755575777775 ,EF5F>

#%-

T;e a@oEe eF9ation onl= a66lies strictl= to Eessels Cit; 9ni8or:

t;icAnessG it can @e 9se< to get a ro9g; esti:ate o8 t;e Ceig;t o8 t;is

Eessel @= 9sing t;e aEerage t;icAness, 4::5

TaAe C

:

K %5%3, Eessel Cit; 6lates

D

m

K %5B%40 O 4 %0

>#

K %5B22 :

)

:

K 20 :

t K 4 ::

;

:

K 2$0 %5%3 %5B22Q,20 O ,05B %5B22--Q4

K 4$5'$# AN

a) Weight of plates

Plate area K &$ %5B%40

2

K 25310% :

2

0eig;t o8 a 6late K %52 25310% K #5%0B AN

20 6lates K 20 #5%0B K 425%4 AN

b) Weight of insulation

Mineral Cool <ensit= K %#0 Ag&:

#

A66roDi:ate Eol9:e o8 ins9lation K %5B%4 20

K %%$5%0# :

#

0eig;t K %%$5%0# %#0 15B% K %$3,3%354 N ,%$353%4 AN-

Do9@le t;is to alloC 8or 8ittings, etc, K 21%50#2 AN

Total Ceig;t.

S;ell 4'5'$# AN

Plates 425%40 AN

$2

Plant Design Project II

Ins9lation 21%50#2 AN

$2051#3 AN

3.3 Wind Loading

TaAe t;e <=na:ic Cin< 6ress9re as %2B0 N&:

2

Mean <ia:eter, incl9<ing ins9lation K %5B22 O %5B22,4 O '3- %0

>#

K %51414 :

!oa<ing ,6er linear :etre- F

2

K %2B0 %51414 K 232%50BB N&:

)en<ing :o:ent at @otto: tangent line.

2

2

2#

M

#

77777555 ,EF5F>#2-

*m M

#

'0$ 5 20%4B $

2

0BB 5 232%

2

3.4 Analysis of Stresses

At @otto: tangent line.

i. Pressure stresses:

t

PD

i

'

$

777555777777775 ,EF5F>##-

2

#

& ''#4 5 $

%0 $

%0 B22 5 % %0$B 5 0

mm *

'

t

PD

i

h

2

7775557777775775 ,EF5F>#$-

2

#

& 3$'# 5 1

%0 2

%0 B22 5 % %0$B 5 0

mm *

h

ii. Dead weight stress:

( )t t D

;

i

:

2

+

777555777777755575 ,EF5F>#3-

( )

2

#

& %2022 5 %

%0 %0 %B22

%0 '$# 5 4$

mm *

2

+

,co:6ressiEe-

$#

Plant Design Project II

iii. Bending stress:

D

o

K %B22 O ,2 %0- K %B$2 ::

A

:

K

( )

$ $

4$

i

D Do

7775557777775575 ,EF5F>#4-

A

:

K

( )

$ %0 $ $

%0 $%$42 5 2 %B22 %B$2

4$

mm

2

%0

#

& B$$$$ 5 0 %0

2

%B22

%0 $%$42 5 2

%0 1 5 22%#B

mm *

(

t

,

_

t

T;e res9ltant longit9<inal stress is.

B

K

'

O

2

t

(

7775557777775775 ,EF5F>#'-

2

is co:6ressiEe an< t;ere8ore negatiEe

B

,96Cin<- K $5''#4 J %5%2022 O 05B$$$$ K O$5$1'B2 N&::

2

B

,<oCnCin<- K $5''#4 J %5%2022 J 05B$$$$ K 25B0B1$ N&::

2

As t;ere is no torsional s;ear stress, t;e 6rinci6al stress Cill @e

B

an<

h

T;e greatest <i88erence @etCeen t;e 6rinci6al stresses Cill @e on t;e <oCn>Cin< si<e

,$5$1'B2 J 25B0B1$- K %54BBBB N&::

2

Cell @eloC t;e :aDi:9: alloCa@le <esign stress5

iv. Check elastic stability (buckling)

*ritical @9cAling stress.

2 $

& %0 2 mm *

D

t

o

+

,

_

77755575575775 ,EF5F>#B-

$5B%2#

$5$1'B2

U6>Cin<

$5B%2#

25B0B1$

DoCn>Cin<

$$

Plant Design Project II

2 $

& 3'B 5 %0B

%B$2

%0

%0 2 mm *

+

,

_

v. Principal stresses

T;e 6rinci6al stresses Cill @e giEen @=.

( )

1

]

1

+ + +

2 2

%

$

2

%

B h B h

7775555555575 ,EF5F>#1-

1

K

h

1

K $5B%2# N&::

2

( )

1

]

1

+ + +

2 2

2

$

2

%

B h B h

755577775 ,EF5F>$0-

"

K

B

or

B

K ,96Cin< or <oCnCin<-

,

1

>

"

-

96Cin<

K ,$5B%2# J $5$1'B2- K 05#%$$B N&::

2

,

1

>

"

-

<oCnCin<

K ,$5B%2#>25B0B1$- K 2500##4 N&::

2

0

#

777555777755777775 ,EF5F>$%-

,

1

>

3

- K ,$5B%2# J 0- K $5B%2# N&::

2

,

"

>

3

- K ,$5$1'B2 J 0- K $5$1'B2 N&::

2

iv. Check for Elastic Stability

stress %ending 2eight De,d

+om9

S S

:aD ,

+

77777775 ,EF5F>$2-

stress %ending 2eight De,d

+om9

S S

:aD ,

777555555775 ,EF5F>$#-

:aD , +om9

%5%2022 O 05B$$$$ K %514$44 N&::

2

:aD , +om9

>%5%2022 J ,05B$$$$- K >%5%14$44 N&::2

+

N

+om9,m,#

Design is satis8actor=

$3

Plant Design Project II

3.5 Vessel Skirts and Supports

T;e :et;o< 9se< to s966ort a Eessel Cill <e6en< on t;e si?e, s;a6e an< Ceig;t o8 t;e

Eessel5 Generall= sAirt s966orts are 9se< 8or tall Eertical col9:n as t;e= <o not

i:6ose concentrate< loa<s on t;e Eessel s;ell5 A sAirt s966ort is t;ere8ore c;osen

s966ort in co:6arison Cit; sa<<le s966orts or racAet s966orts5 A sAirt s966ort

consists o8 a c=lin<rical or conical s;ell Cel<e< to t;e @ase o8 t;e Eessel5 A 8lange at

t;e @otto: o8 t;e sAirt trans:its t;e loa< to t;e 8o9n<ations5 O6enings :9st @e

6roEi<e< 8or t;e connecting 6i6es5

Tr= a straig;t c=lin<rical sAirt ,

s

K 10- o8 6lain car@on steel5

i. To determine skirt thickness

A66roDi:ate Ceig;t K

* '% 5 3%%3$ B% 5 1 %000 2 B22 5 %

$

2

,

_

0eig;t o8 Eessel 8ro: #, K 4$5'$# AN

Total Ceig;t K 3%5%33 O 4$5'$# K %%35B1B AN

0in< loa<ing, 8ro: $ K 250%4B AN&:

)en<ing :o:ent at @ase o8 sAirt K 3*m 1323 5 2#%

2

%3

0%4B 5 2

2

)en<ing stress in t;e sAirt.

( )

s s s s

s

(s

D t t D

M

+

$

7775557557777575 ,EF5F>$$-

C;ere M

s

J :aDi:9: @en<ing :o:ent, eEal9ate< at t;e @ase o8 t;e sAirt ,<9e to

Cin<, seis:ic an< eccentric loa<s

D

s

J insi<e <ia:eter o8 t;e sAirt at t;e @ase

t

s

JsAirt t;icAness

As a 8irst trial, taAe t;e sAirt t;icAness as sa:e as t;at o8 t;e @otto: section o8 t;e

Eessel %0 ::5

( )

2

# #

& B$'B 5 B

%0 %B22 %0 %B22

%0 %0 1323 5 2#% $

mm *

(s

+

$4

Plant Design Project II

( )

s s s

2s

t t D

;

+

77755577777775555 ,EF5F>$3-

( )

2

#

& %2022 5 %

%0 %0 %B22

%0 '$# 5 4$

- , mm * o9er,ting

2s

+

( )

2

& #0'44 5 %

%0 %0 %B22

'324%

- , mm * test

2s

+

MaDi:9:

,co:6ressiEe- K %%524%0 O %5#0'44 K %2534B' N&::

2

MaDi:9:

,tensile- K %%524%0 J %5%2022 K %05%$0B N&::

2

TaAe t;e joint 8actor @ as 05B35

*riteria 8or <esign.

,tensile- N f

s

@ sin

%05%$0B N 05B3 %04 sin 10

%05B#$# N 1352#$

,co:6ressiEe- N 05%23 E

sin

,

_

s

s

D

t

%2534B' N 05%23 200000

10 sin

%B22

%0

,

_

%2534B' N %#'52%2

)ot; criteria are satis8ie<, a<< 2 :: 8or corrosion, an< giEe a <esign t;icAness o8

%2::

ii. To determine base ring and anchor bolts

A66roDi:ate 6itc; circle <ia:eter, sa= %53 :

*irc9:8erence o8 @olt circle K %300

)olt s6acing K mm 32 5 21$

%4

%0 3 5 %

#

1

]

1

;

D

M

f ;

&

(

s

( (

(

$ %

7775557777775 ,EF5F>

$4-

$'

Plant Design Project II

2 #

#

B1B3 5 2'4 %0 '$# 5 4$

3 5 %

%0 1323 5 2#% $

%23 %4

%

mm &

(

1

]

1

Use M#0 @olts ,)S $%10.%14'-G root area K 34%::

2

)olt root <ia:eter K mm ''43 5 %B

$ B1B3 5 2'4

Total co:6ressiEe loa< on t;e @ase ring 6er 9nit lengt;

1

1

]

1

+

s

s

s

(

D

;

D

M

F

2

$

777555777777575 ,EF5F>$'-

m * F

(

& %0 2'$ 5 %00

B22 5 %

%0 '$# 5 4$

B22 5 %

%0 1323 5 2#% $

#

#

2

#

1

]

1

TaAing t;e @earing 6ress9re as 3 N&::

2

,Range #53 to ' N&::

2

-

#

%0

%

+

(

(

f

F

'

77755577577775 ,EF5F>$B-

mm '

(

03$B 5 20

%0

%

3

%0 2'$ 5 %00

#

#

Act9al Ci<t; reF9ire<, !

@

K2!

<

K2,20503$B- K$05%014 ::

!

r

K !

@

Ot

s

O30K$05%014O%2O30K%025%014::

SAirt @ase angle,

s

K tan>%

( )

3 5 B2

2% 5 2 #

2

%

#

Sin B253 K 0511 ,Nor:all= B0 to 10 <egree-

Re8erring to Fig9re %#5#0. Anc;or @olt c;air <esign

Act9al @earing 6ress9re on concrete 8o9n<ation.

2

#

#

& %2# 5 %

%0 33B$ 5 %%2

%0 #14 5 %24

X mm * f

+

7775557775555575 ,EF5F>$1-

mm t

(

'1 5 B

33B$ 5 %%2

%2# 5 % #

3BB$ 5 30

7775557777555775 ,EF5F>30-

Ro9n< o88 to 1::

*;air <i:ensions 8ro: Fig9re %#5#0 8or @olt si?e M#05

$B

Plant Design Project II

3.6 Design of flanges

Flanges are generall= 9se< 8or connecting 6i6es an< instr9:ents to Eessels 8or

eDa:6le in t;is <esign, t;e 6i6es entering an< eDiting as Cell as t;e :an;oles5

So:eti:es 8langes are 9se< on t;e Eessel @o<= to ease o6ening it 96 8or

:aintenance5 T;e 6ro6er <e8inition 8or a :an;ole accor<ing to t;e )S $'0 Co9l<

@e ;oles or o6enings on a str9ct9re t;at 6er:it t;e 6erson entr= an< eDit5 For

clearer :eaning access Co9l< @e <e8ine< as t;e insertion into a Eessel o8 :ore

t;an a 6ersonIs ;ea< an< ar:5

3.7 Flange for manholes

i. To determine the gasket width

Flange :aterial IS.200$>%142 *lass 2

)olting :aterial 3H *r>Mo Steel

GasAet As@estos

S;ell o9tsi<e <ia:eter, % 053:

S;ell t;icAness %0::

AlloCa@le stress o8 8lange :aterial %00 N&::

2

AlloCa@le stress o8 @olting :aterial %#B N&::

2

Ass9:e g

1

K g

!

&05'0'

Ass9:e C

F

K % an< y K %B533

*;oose %54:: t;icAness

: K 25'3

= K 23530

Mini:9: gasAet Ci<t; K %0 ::

2 & %

0

- % ,

,

_

m P y

Pm y

d

d

i

7775557775775 ,EF5F>3%-

002% 5 %

- % '3 5 2 , %0$B 5 0 30 5 23

'3 5 2 %0$B 5 0 30 5 23

2 & %

0

,

_

i

d

d

!et d

i

o8 gasAet K %0 :: larger t;an Eessel o9ter <ia:eter, d

o

d

i

K % O %0::

K 0530 O 050%

K 053% :

d

o

K 053% %5002% K 053%%0' :

$1

Plant Design Project II

GasAet Ci<t;, * K

m

$

%0 #3 5 3

2

3% 5 0 3%%0' 5 0

*;oose an eEen Ci<t;, * K %0::

d

o

K 053%%0' O 0502 K 053#%0' :

)asic gasAet seating Ci<t; (

o

K

mm

*

%0

2

20

2

ii. To determine the diameter at location of gasket;

!ocal reaction, C K d

i

O *

K 053% O 0502 K 053# :

iii. To estimate the bolt loads

!ocal <9e to <esign 6ress9re, ) K P

C

$

2

77777777775 ,EF5F>

32-

) K * B02 5 2#%20 %0$B 5 0

$

- %0 3# 5 0 ,

2 #

!ocal <9e to ;96 joint tig;t 9n<er, )

9

K

mP ( C - 2 ,

77775555 ,EF5F>

3#-

( K %0 3 5 2 K '51

)

9

K * BB 5 '3B% %0$B 5 0 '3 5 2 - 1 5 ' 2 , %0 3# 5 0

#

Total o6erating loa< K ) O )

9

;

o

K 2#%205B02 O '3B%5BB K #0'0254B2 N

!oa< to seat gasAet 9n<er @olting 96 con<itionsG

;

g

K C ( y777555777777777777775775 ,EF5F>3$-

* ;

g

%$ 5 ##3$2# 3 5 23 1 5 ' %0 3# 5 0

#

Since ;

g

N ;

o

, ;

g

is controlling loa< K ##3$2#5%$ N

30

Plant Design Project II

iv. To determine the minimum bolting area

o

g

o m

S

;

& &

77755577757775 ,EF5F>33-

2

40 5 2$#0

%#B

%$ 5 ##3$2#

mm & &

o m

!et 9s consi<er )olt si?e, M%4, M%B, M20 an< M22

Ta@le B. )olt si?e

Bolt size

Root diameter

(mm)

Root area, 1

r

(mm

2

)

1

m

21

r

Actual

number,

M%4 %53 %#5%1 %#454$ %'5'1 20

M%B 2 %$5$B %4$54' %$5'4 %4

M20 2 %45$B 2%#5#% %%5#1 %2

M22 2 %B5$B 24B522 1504 %2

3%

Plant Design Project II

Ta@le 1. )olt si?e

( ) m g

$ $

%

%0 $#04 5 % %0 B03 5 2 3% 5 0

- , 2

%

R g % C + +

777555777777777777775755575 ,EF5F>34-

R m R C 2 30 5 0 - %0 $#04 5 % , 2 3 5 0

$

+ + +

R C 2 %0 30# 5 0

#

+

Fro: ta@le, t;e :ini:9: )*D o@taine< c;oosing M%B D 2 @olts, %4 n9:@ers

)olt circle <ia:eter K 0533$:

N9:@er o8 @olts K %4

Si?e K M%B D 2

R K 0502' :

v. To determine the flange outside diameter

& K C O @olt <ia:eter O 0502:77777777757555775 ,EF5F>3'-

K 0533$ O 050%B O 0502

K 05312 :

& K 054 :

vi. To check gasket width

y

* C

S &

g (

2 <

7775557775775555 ,EF5F>3B-

( ) 30 5 23 2

%0 %0 3# 5 0

%#B - 4' 5 %4$ %4 ,

#

<

0 5 3% B$ 5 2% <

*on<ition satis8ie<

Bolt size

Actual

number,

R (mm) *

s

s

%

C - , 2

%

R g % C + +

M%4 %53 20 23 '3 $''5$4 330

M%B 2

%4 2' '3 #B%51' 33$

M20 2 %2 #0 '3 2B45$B 340

M22 2

%2 ## '3 2B45$B 344

32

Plant Design Project II

vii. To determine flange thickness, t

*

P %

; $# 5 203''

$

%0$B 5 0 %0 30 5 0

$

# 2

%

7777555775 ,EF5F>31-

% 2

; ) ;

K 2#%205B02 J 203''5$#0

K 23$#5#'2 N

;

o

K #0'0254B2 N

) ; ;

o

#

K #0'0254B2 J 2#%205B02

K '3B%5BB N

m

g

R , 02'0'2 5 0

2

%0 $#04 5 %

02' 5 0

2

$

%

%

+ +

77755575575 ,EF5F>40-

m

, g R

, 0#1%$ 5 0

2

0%2 5 0 %0 $#04 5 % 02' 5 0

2

$

# %

2

+ +

+ +

75 ,EF5F>4%-

m

C C

, 0%2 5 0

2

3# 5 0 33$ 5 0

2

#

7777777555775 ,EF5F>42-

Mo:ent 9n<er o6erating con<itionsG

# # 2 2 % %

, ; , ; , ; M

o

+ +

777555777775 ,EF5F>

4#-

- 0%2 5 0 , BB 5 '3B% - 0#1%$ 5 0 , #'2 5 23$# - 02'0'2 5 0 , $# 5 203'' + +

o

M

K '$'5402

N:

For @olting 96 con<itionsG

g

( m

S

& &

;

+

2

777555777775 ,EF5F>4$-

2

40 5 2$#0 mm &

m

2

'2 5 24#$ mm &

(

* ; 0B 5 #$130' %#B

2

'2 5 24#$ 40 5 2$#0

+

#

, ; M

g

77755577555775775 ,EF5F>43-

3#

Plant Design Project II

*m M

g

0B 5 $%1$ 0%2 5 0 0B 5 #$130'

M

g

D M

o

Mo:ent 9n<er o6erating con<ition, M

o

is controlling

M K M

o

K #125#$B N:

$

F

%S

y MC

t

2

7775557775777575 ,EF5F>

44-

mm t 34 5 %$3

%00 %0 3 5 0

33 5 %B % %0 #$B 5 #12

#

#

2

t K %2504:: ,050%204:-

)olt 6itc; correcting 8actor, C

F

2 & %

2

,

_

t d

%

C

s

F

77755577755775 ,EF5F>4'-

m %

s

%0B'B 5 0

%4

33$ 5 0

30$3 5 %

0%204 5 0 %0 %B 2

%0B'B 5 0

2 & %

#

,

_

F

C

224' 5 %

F

C

M9lti6l= calc9late< t @=

F

C

t K 050%$'1: ,%$5'1::-

Select 8lange t;icAness %350 ::

3.8 Design of nozzles (similar to design of flanges)

3.8.1 Nozzles for piping

i. To determine the gasket width

Flange :aterial *ar@on Steel ,IS. 200$>%142 *lass 2-

)olting :aterial Hot rolle< car@on steel

GasAet As@estos

Internal <ia:eter o8 6i6e 05%3:

3$

Plant Design Project II

Design 6ress9re %B0APa

*orrosion alloCance 05003:

AlloCa@le stress o8 8lange :aterial B53%0

%

N&::

2

AlloCa@le stress o8 @olting :aterial %5#B%0

2

N&:

2

Ass9:e g

1

K g

!

&05'0'

Ass9:e C

F

K % an< y K %B533

*;oose %54:: t;icAness

: K 25'3

= K 23530

Mini:9: gasAet Ci<t; K %0 ::

+

P @f

D P

t

i

i i

+

2

77777775775 ,EF5F>4B-

0all t;icAness.

m t 022'4 5 0 003 5 0

%B0 5 0 B3 5 0 % 2

%3 5 0 %B0 5 0

+

) K 05022'4 O 05%3: K 05%'2'4 :

2 & %

0

- % ,

,

_

m P y

Pm y

d

d

i

7775557775555775 ,EF5F>3%-

00#2% 5 %

0

i

d

d

!et d

i

o8 gasAet K%0 :: larger t;an Eessel o9ter <ia:eter

d

i

K 0502'3B$ :

d

!

K 0502'4'# :

GasAet Ci<t;, * K

m 0 3 $2'2 5 $

2

02'3B$ 5 0 02'4'# 5 0

*;oose an eEen Ci<t;, * K 2::

)asic gasAet seating Ci<t; (

o

K

mm

*

%

2

2

2

ii. To determine the diameter at location of gasket;

!ocal reaction, C K d

i

O *

K 0502B3B$:

33

Plant Design Project II

iii. To estimate the bolt loads

!ocal <9e to <esign 6ress9re, ) K P

C

$

2

77777777775 ,EF5F>

32-

) K #34B532$

!ocal <9e to ;96 joint tig;t 9n<er, )

9

K

mP ( C - 2 ,

77775555 ,EF5F>

3#-

( K 253 ::

)

9

K $025#4B N

Total o6erating loa< K ) O )

9

;

o

K #34B532$ O $025#4B K #1'05B12 N

!oa< to seat gasAet 9n<er @olting 96 con<itionsG

;

g

K C ( y777555777777777777775775 ,EF5F>3$-

* ;

g

'23 5 314B

Since ;

g

N ;

o

, ;

g

is controlling loa< K 0g is t;e controlling loa<

iv. To determine the minimum bolting area

o

g

o m

S

;

& &

77755577757775 ,EF5F>33-

2

40 5 2$#0

%#B

%$ 5 ##3$2#

mm & &

o m

34

Plant Design Project II

!et 9s consi<er )olt si?e, M%4, M%B, M20 an< M22

Ta@le %0. )olt si?e

Bolt size

Root diameter

(mm)

Root area, 1

r

(mm

2

)

1

m

21

r

Actual

number,

M%2 %53 153$ '5%$1e>3 B502$B %2

M%$ %53 %%5%%1 15'%%e>3 351'0$ B

M%4 %53 %#5%1 %#454$

$5%1B0

B

M%B 2 %$5$B %4$54'

#5$B##

$

M20 2 %45$B 2%#5#%

254B12

$

M22 2 %B5$B 24B522

25%#B4

$

3'

Plant Design Project II

Ta@le %%. )olt si?e

4 $2'3 5 2#

%

0 g

- , 2

%

R g % C + +

777555777777777777775755575 ,EF5F>34-

- - 4 $2'3 5 2# ,, 2 %3 5 0 R 0 C + +

Fro: ta@le, t;e :ini:9: )*D o@taine< c;oosing M%$ D %53 @olts, B n9:@ers

)olt circle <ia:eter K 05%1#4:

N9:@er o8 @olts K

Si?e K M%$ D %53

R K 05022 :

v. To determine the flange outside diameter

& K C O @olt <ia:eter O 05022 :7777777757555775 ,EF5F>3'-

K 05%1#4O 050%B O 05022

K 052##4 :

& K 052##4 :

vi. To check gasket width

y

* C

S &

g (

2 <

7775557775775555 ,EF5F>3B-

$# 5 32 41 5 $3 <

*on<ition satis8ie<

Bolt size

Actual

number,

R (mm) *

s

s

%

C - , 2

%

R g % C + +

M%2 %53

%2 20 '3

2B45$$%B %10

M%$ %53

B 22 '3

%10514%2 %1$

M%4 %53

B 23 '3

%10514%2 200

M%B 2

$ 2' '3

135$B031 20$

M20 2

$ #0 '3

135$B031 2%0

M22 2

$ ## '3

135$B031 2%4

3B

Plant Design Project II

vii. To determine flange thickness, t

* ; 4B3 5 %0$

%

7777777555775 ,EF5F>

31-

% 2

; ) ;

K 2B2'5B4$*

;

o

K #2435$3'

) ; ;

o

#

K ##2510B *

m

g

R , 02#3 5 0

2

%

%

+ 7775557775575 ,EF5F>40-

m

, g R

, 03#$' 5 0

2

# %

2

+ +

777575 ,EF5F>4%-

0B#2$ 5 0

2

#

C C

,

777755555775 ,EF5F>42-

Mo:ent 9n<er o6erating con<itionsG

# # 2 2 % %

, ; , ; , ; M

o

+ +

777555777775 ,EF5F>

4#-

*m M

o

#'' 5 %B%

For @olting 96 con<itionsG

g

( m

S

& &

;

+

2

777555777775 ,EF5F>4$-

* ; %' 5 %4B2#4

#

, ; M

g

77755577555775775 ,EF5F>43-

*m M

g

1B 5 %$00#

M

g

D M

o

Mo:ent 9n<er o6erating con<ition, M

o

is controlling

M K M

o

K %B%5#'' N:

31

Plant Design Project II

$

F

%S

y MC

t

2

7775557775777575 ,EF5F>44-

m t 31 5 %%1%

2

t K 050#$3:

)olt 6itc; correcting 8actor, C

F

2 & %

2

,

_

t d

%

C

s

F

77755577755775 ,EF5F>4'-

0$#3# 5 0

s

%

B#$33 5 0

F

C

1%#3 5 0

F

C

M9lti6l= calc9late< t @=

F

C

t K 050#%32 : ,#%532::-

Select 8lange t;icAness #2 ::

40

Plant Design Project II

4.0 SPECIFICATION SHEETS AND DETAILED DRAWING

4.1 Specification Sheet

Column tray data sheet (C-702)

Tag. No. C-702

Sheet No 1 of 1

Function

To separate Ethylene Oxie

fro! "ater

Operating data

TOWER INI!E !I"#ETER 1#1$ !! TOWER O$TI!E !I"#ETER 1#1% !!

TR"% &"CIN' 1.0 ! ENRIC(IN' TR"% 7 T&'(S

TOT") TR"% IN ECTION 20 T&'(S RECTI*%IN' TR"% 1) T&'(S

Operating +onditions

*EE! TO& ,OTTO#

TE#&ER"T$RE (

O

C) #$.* #2.# 1#1.)

&RE$RE (-&") 10#0 10*0 1100

#O)"R *)OW(-#O).(R) $7#.%# *#2.%0 %$.0#

#" *)OW (-'.(R) 2#+*0.00 2**#2.)2 2#$7.$#

#W (-'.-#O)) +1.%01 +).### 1#.112

!ENIT% (-'.#

/

) 20.$#) 11.*2#+ ##1.212%

0ICOIT% (C&) 1.77%E-0* 1.+#+2E-0+ 1.+$+2E-0+

Te+hni+al . #e+hani+al data

TOWER #"N(O)E !I"#ETER 7*$.)0 !! *)"N'E !I"#ETER %$2.7+ !!

*EE! NO11)E T(IC-NE +.)2 !! ,O)T CIRC)E !I"#ETER 1%).$ !!

0"&OR NO11)E T(IC-NE 2.0) !! ($, !IT"NCE -

RE*)$2 NO11)E T(IC-NE +.10 !! *)"N'E T(IC-NE +*.2) !!

)I3$I! NO11)E T(IC-NE +.27 !! (E)) T(IC-NE 10.00 !!

,OI) $& NO11)E T(IC-NE 2.00 !! #"2 T(IC-NE O* ($, -

CO)$#N INI!E !I"#ETER 1#1$.00 !! '"-ET INI!E !I"#ETER 7#+.)$ !!

CO)$#N O$TI!E !I"#ETER 1#1%.00 !! '"-ET O$TI!E !I"#ETER 7#$.#$ !!

CORROION "))OW"NCE ).00 !!

0EE) #"TERI") C'&,ON STEE-

IE0E TR"% (O)E

!I"#ETER 10 !!

TR"% #"TERI") C'&,ON STEE- WEIR )EN'T( 1)$2 !!

-IRT #"TERI") C'&,ON STEE- WEIR (EI'(T *0.00 !!

TOWER "TT"C(#ENT - (O)E &ITC( -

TR"% *RO# TO& TO ,OTTO# 20 T&'(S !OWNCO#ER "RE" 0.)10# !

2

.ate of en/uiry .ate of orer

Orer No. .&0 No.

1anufacturer

Notes

213 4nternal 5apor an li/ui loaings at the li!iting sections are re/uire to ensure proper tray esign.

.ensities are re/uire at actual insie to"er conitions of te!perature an pressure6 5iscosity is not re/uire unless greater than 0.7 cp

223 Cross out i!ensions units "hich o not apply. Tray supplier to a5ice.

7repare NE' NE'

Chec8e

'ppro5e

.ate Eng6 7rocess &e5 ,y 'ppr. .ate

Ser5ice Ethylene Oxie purification Co!pany 0&O97 )+ CONS9-T'NT

E/uip!ent No. C-702

4%

Plant Design Project II

7ro:ect No.

4.2 Technical Engineering Drawing

42

Plant Design Project II

5.0 COSTING

Costing of Ethylene Oxide Purifier Column (C-702)

Data reF9ire<.>

Dia:eter, DcK%5B%40 :

Heig;t, Hc K20500 :

O6erating Press9re K %03# APa

T=6e o8 Eessel K SieEe tra=

Material o8 constr9ction K *ar@on steel

N9:@er o8 tra=, Nact9al K 20

4#

Plant Design Project II

Ste9 1: Pur+h,se +ost of 8erti+,l Columns

Fig9re %3. P9rc;asing cost o8 Eertical col9:ns

Fro: t;e gra6; a@oEe, t;e 69rc;asing cost o8 col9:n alone Cit;o9t tra= an< internals

Cit; re8erence o8 ;eig;t o8 col9:n <esigne< at 20 :eters, t;e cost <e<9ce< is

a66roDi:atel= YB3,000500 US <ollars5

Ste9 ": Pur+h,se +ost of $r,ys in $r,y Columns

4$

Plant Design Project II

Fig9re %4. P9rc;ase< cost o8 tra=s in tra= col9:ns

T;e gra6; a@oEe <etails t;e 69rc;asing cost o8 tra=s o8 Eario9s t=6es o8 tra= col9:ns

:a<e o8 Cit; :9lti8ario9s t=6es o8 :aterial5 T;e col9:n <esigne< is :a<e o9t o8 car@on

steel an< Cit; sieEe t=6e tra=s5 )ase< on <esigne< <ia:eter o8 %5B%40 :, t;e 69rc;ase<

cost 8or tra=s t;at incl9<es tra= <ecA, risers, <oCnco:ers an< str9ct9ral steel 6arts is YB30

US <ollars 6er tra=5 T;9s, since col9:n consists o8 20 tra=s Cit; a F9antit= 8actor o8 %500

,@ase< on ta@le in gra6; a@oEe-, t;e total cost o8 tra=s 8or Et;=lene ODi<e 69ri8ier col9:n

*>'02 is Y%',000500 US <ollars5

Ste93: Cost of industri,l Ansul,tion

43

Plant Design Project II

Fig9re %'. Installe< cost o8 Eario9s in<9strial ins9lations 8or col9:ns, toCers an< tanAs5

T;e ins9lation selecte< 8or t;e <istillation col9:n is :ineral Cool o8 05% : in t;icAness5

Mineral Cool is alternatiEel= AnoCn as 8i@erglass an< 8ro: gra6; a@oEe, t;e cost to

ins9late col9:n Cit; an al9:in9: jacAet is a66roDi:atel= Y%30 US <ollars 6er sF9are

:eter5 T;e <istillation col9:n <esign is o8 ;eig;t 20 :eter an< <ia:eter %5B%40 :eter5

T;9s area o8 C;ole <istillation col9:n is.

Area o8 col9:n. 20 : " ,#5%$2Q%5B%40 :- K%%$5%%' :

2

T;9s, total cost o8 ins9lation. %%$5%%'Q Y%30 US <ollars K Y%',%%'533 US <ollars

$ot,l Pur+h,se 0/ui9ment +ost -PC0.

T;e total cost o8 69ri8ier col9:n *>'02 is. P9rc;ase cost o8 /ertical *ol9:ns O P9rc;ase

cost o8 Tra=s in Tra= *ol9:ns O *ost o8 in<9strial Ins9lation5

. YB3,000500 US <ollars O Y%',000500 US <ollars O Y%',%%'533 US <ollars K

44

Plant Design Project II

$119,117.55 USD

6.0 OPERATING PROCEDURE

6.1 Pre Start-Up Procedure

No. Procedures Steps Checklist

4'

Plant Design Project II

% /eri8= t;at t;e toCer is rea<= 8or start 965 Ens9re t;at all

:aintenance CorAs ;aEe @een co:6lete<, all @lin<s are re:oEe<

an< 6ro6er gasAets are installe<5

2 *;ecA an< :aAe s9re t;at all 69:6s ;aEe 6ro6er l9@rication

# *o::ission cooling Cater

$ *on<9ct 9rge ,to re:oEe gases 8ro: *>'02- in case t;e col9:n

Cere o6ene< 8or :aintenance5 P9rge 8or #0 :in9tes or 9ntil t;e

leEel o8 oD=gen gas is @eloC 3H5

3 *lose t;e reF9ire< @lee<s an< install 6l9gs or ca6s a8ter 69rging5

4 *;ecA t;e 8olloCing trans:itters are at ?ero.

Stea: to re@oiler an< Ea6or to con<enser

6.2 Start-Up Procedure

No. Procedures Steps Checklist

%

*lose t;e isolation EalEe to isolate col9:n *>'025

2 Fill 96 *>'02 to a@o9t 30 H leEel @= o6ening t;e EalEe5

# *;ecA t;e leEel in t;e sig;t glass to Eeri8= t;e leEel trans:itter in

4B

Plant Design Project II

*>'02

$ 0ar: 96 t;e col9:n @= t;rottling t;e stea: 8loC to t;e re@oiler5

3 *ontrol t;e @otto: leEel at 30 H5

4

Increase t;e stea: to 9ntil t;e @otto: te:6erat9re reac;es t;e

<esire< Eal9e ,or 9ntil t;e stea: 8loC rate reac;es t;e <esire<

Eal9e-5

'

Start t;e re8l9D 8loC to *>'02 an< :aintain t;e re8l9D 8loC o8

stea: on re@oiler5

B

A<j9st t;e re8l9D to @ring t;e te:6erat9re to t;e <esire<

te:6erat9re

1

Note. 0;en re8l9D is co::issione< to t;e col9:n *>'02, t;e

C;ole col9:n te:6erat9re 6ro8ile Cill start to <ro65 I::e<iatel=

increase t;e stea: to re@oiler to co:6ensate Ea6or loa< lost <9e

to t;e cooling e88ect 8ro: t;e re8l9D5 Tr= to increase t;e stea: to

re@oiler to :aintain a goo< col9:n te:6erat9re 6ro8ile ,9se t;e

toCer te:6erat9re as g9i<e-5 Use t;e stea: 8loC incre:ent

8olloCe< @= re8l9D incre:ent 9ntil t;e col9:n is at its <esire<

o6eration5

%0

A<j9st t;e stea: 8loC 9ntil @otto: te:6erat9re reac;es <esire<

te:6erat9re