Академический Документы

Профессиональный Документы

Культура Документы

Separador Magnetico

Загружено:

Orlando MelipillanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Separador Magnetico

Загружено:

Orlando MelipillanАвторское право:

Доступные форматы

Magnetic Solutions Since 1896

Magnets for Benefication and Tramp Iron Removal

SUSPENDED SEPARATION EQUIPMENT

ELECTROMAGNETIC SUSPENDED SEPARATORS

SELF-CLEANING AND MANUAL

in coil design, allow Walkers Electromagnetic Suspended Separators to remove both Deep penetrating electromagnets, incorporating all of the latest innovations

The separators are designed for continuous operation at peak performance. Electromagnetic Suspended Separators are available in manual and self-

large and small tramp metal from deep burdens on fast-moving conveyors.

cleaning designs. Manually cleaned magnets are discharged electrically. remove the ferrous materials over the side of the conveyor.

Self-cleaning magnets can be mounted in line with the material flow or transverse to

Standard Magnet Features:

115 or 230 VDC aluminum coils Class R (220C) insulation 100% duty cycle, oil cooled Space wound for rapid heat dissipation Internal oil expansion chamber with pressure release valve and drain plugs Heavy wear-resistant non-magnetic steel bottom plate

Standard Self-Cleaning Magnet Features:

DYNAFORCE SUSPENDED SEPARATOR

2 & 4 PULLEY CONSTRUCTION - BELT SPEEDS UP TO 700 FPM IDEAL FOR TRAMP IRON REMOVAL

Walker Magnetics provides the best in experienced staff of design engineers. suspended Magnet and Separator design with its Over 50 years of field expertise has shown us

Heavy-duty self-aligning sealed bearings Rugged structural steel frame TEFC motor Single head and tail pulleys on smaller units, compact four-pulley design on larger units Heavy cleated rubber belt with take-up adjustment Four-point suspension

2 or 4 Pulley Construction Shaft mounted reducers Mounting flexibility Cool operating coils

5 4 7

2 or 4 Pulley Construction Shaft mounted reducers Mounting flexibility Cool operating coils

1

best available for consistent and proven

what is required to make these separators the

performance. We have incorporated a 2 or 4

pulley design for most sizes for ease of tracking and longer belt life. Large shaft diameters are

3 8 2

used for additional bearing life. Heavy-duty operation.

bearings provide virtually maintenance free

most economical unit for your application.

provide the proper selection of the best and

Walker Magnetics application engineers will

1. Heavy-duty shaft mount motor reducer 2. Heavy-duty flange bearings 3. Heavy-duty take-up bearings 4. Liquid dielectric gap wound coil

5. Heavy-duty 2 or 4 pulley construction on most sizes 6. Heavy-duty belt with stainless steel or vulcanized rubber cleats 7. Internal expansion chamber 8. Heavy-duty frame for suspended or base mounting

PERMANENT MAGNET SUSPENDED SEPARATORS

SELF-CLEANING AND MANUAL

increased efficiency in the separation of ferrous materials. The permanent magnet design has a lower installation cost than the electromagnet type, because no DC rectifier is required, and operating costs are also lower, since the magnets consume no power. Suspension heights up to 10 - 12 are available. These separators are available in manual and self-cleaning designs. Manually cleaned Walkers Permanent-Magnet Suspended Separators use powerful Cermax magnets for

magnets remove the ferrous materials over the side of the conveyor.

Parallel self-cleaning magnets are mounted in line with the material flow, while transverse self-cleaning

magnets can be supplied with a stripper mechanism. The self-cleaning type uses a two-pulley design.

Standard Magnet Features:

High-powered Ceramax magnetic circuit for deeper field penetration Heavy-duty welded construction for years of service No power consumption, virtually maintenance-free Extra thick bottom plate for wear resistance Shaft mounted speed reducer TEFC motor Belt take-up adjustment Heavy cleated rubber belt Self-aligning sealed bearings Four point suspension Rugged structural steel frame

Standard Self-Cleaning Magnet Features:

TYPICAL APPLICATIONS PERMANENT AND ELECTROMAGNETIC

Manual Cleaning

In-Line Self-Cleaning

Transverse Self-Cleaning

Name: Company: Address: Telephone:

SUSPENDED SEPARATOR APPLICATION QUESTIONNAIRE

Title: Date: City: Fax: Email: State: Zip:

Application:

Bulk Material: Product: Tons/Hour: Lump Size: Maximum: Equipment to be protected: Hours of operation per day:

Density: Medium:

Cu. Ft./Hour:

Transportation Method - Belt Conveyor: Width: Speed: FPM Max. Burden Depth: Head Pulley Dia. Conv. Incline: Suspension Height Req. Other Transportation Methods: Vibratory Feed: Oscillatory Feed: A. Width: A. Width:

Trough Idlers:

Self Cleaning:

Tramp Iron: Min. Size: Tramp Shape: Hex Nut Cube Rod Max. Length of Tramp Iron to be Extracted: Site Conditions: Ambient Temp: Indoor: Outdoor: A.C. Input: Volts: Phase: NEMA Type Enclosure: If D.C. Voltage Available Specify: Voltage:

Worcester, MA (508) 853-3232 FAX (508) 852-8649 1-800-W-MAGNET Email: sales@walkermagnet.com

Magnet Type:

Manual Cleaning:

A. Cross-Belt Permanent: A. Over-Belt:

B. In-Line: Electro:

B. Side Height: B. Side Height:

B. Over Head Pulley:

Max. Size: Plate Max: Hertz: KW: Min:

Sphere

www.walkermagnet.com

Magnetic Solutions Since 1896

Walker Magnetics National Stoney Creek, Ontario Canada (905) 643-3338 In Canada: 1-800-267-4678 FAX (905) 643-6111 Email: walkermagnet@look.ca

Walker National Columbus, OH (614) 481-0007 FAX (614) 481-0040 Email: columbus@walkermagnet.com

WM10/07-1

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- C2.2 Parts BookДокумент263 страницыC2.2 Parts BookOrlando Melipillan100% (5)

- TS4065 McCloskeyДокумент61 страницаTS4065 McCloskeyOrlando Melipillan100% (1)

- Trio 44x32 Twin FMW Operating ManualДокумент33 страницыTrio 44x32 Twin FMW Operating ManualOrlando Melipillan100% (2)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Part 11 Metal Detector Manual PDFДокумент24 страницыPart 11 Metal Detector Manual PDFOrlando Melipillan100% (1)

- TechnicalErrors 98Документ242 страницыTechnicalErrors 98李侑宗Оценок пока нет

- Strickland Parts ManualДокумент27 страницStrickland Parts ManualOrlando Melipillan100% (1)

- Ts4065 Parts Rev4Документ30 страницTs4065 Parts Rev4Orlando MelipillanОценок пока нет

- AC Current TransducerДокумент5 страницAC Current TransducerOrlando MelipillanОценок пока нет

- Lam 090713 Din Rail Engl Fin WebДокумент8 страницLam 090713 Din Rail Engl Fin WebOrlando MelipillanОценок пока нет

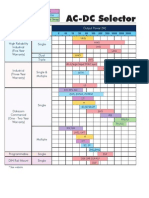

- AC-DC Selector: Output Power (W)Документ3 страницыAC-DC Selector: Output Power (W)Orlando MelipillanОценок пока нет

- Acoples PDFДокумент1 страницаAcoples PDFOrlando MelipillanОценок пока нет

- C38Документ1 страницаC38Orlando MelipillanОценок пока нет

- Jaw Crusher BrochureДокумент2 страницыJaw Crusher BrochureAnthony FuОценок пока нет

- PPI CorpBroДокумент0 страницPPI CorpBroOrlando MelipillanОценок пока нет

- Engineering Data To Design A Conveyor Pulley, Shaft & BearingДокумент0 страницEngineering Data To Design A Conveyor Pulley, Shaft & BearingOrlando MelipillanОценок пока нет

- Agriculture SolutionsДокумент2 страницыAgriculture SolutionsOrlando MelipillanОценок пока нет

- Idler EngrDimДокумент64 страницыIdler EngrDimOrlando MelipillanОценок пока нет

- PPI ProfileДокумент0 страницPPI ProfileOrlando MelipillanОценок пока нет

- Benefits of Masaba: (877) MASABAO Strength You Can Depend OnДокумент2 страницыBenefits of Masaba: (877) MASABAO Strength You Can Depend OnOrlando MelipillanОценок пока нет

- Lift Brochure 8 06-2Документ8 страницLift Brochure 8 06-2Orlando MelipillanОценок пока нет

- PPI TermsДокумент0 страницPPI TermsOrlando MelipillanОценок пока нет

- Benefits of Masaba: (877) MASABAO Strength You Can Depend OnДокумент2 страницыBenefits of Masaba: (877) MASABAO Strength You Can Depend OnOrlando MelipillanОценок пока нет

- MASABAO Strength You Can Depend OnДокумент2 страницыMASABAO Strength You Can Depend OnOrlando MelipillanОценок пока нет

- Cone Crusher SBMДокумент3 страницыCone Crusher SBMOrlando Melipillan100% (1)

- Fine Material Screw Washers: Other Size Options AvailableДокумент2 страницыFine Material Screw Washers: Other Size Options AvailableOrlando MelipillanОценок пока нет

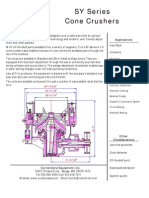

- SY Series Cone CrushersДокумент2 страницыSY Series Cone CrushersOrlando MelipillanОценок пока нет

- 2015 Macbook Air A1466 ALL - SYS - PWRGDДокумент1 страница2015 Macbook Air A1466 ALL - SYS - PWRGDVivek VarshneyОценок пока нет

- Review - Panasonic AG-HPX370Документ56 страницReview - Panasonic AG-HPX370arthur_8Оценок пока нет

- FACTS Stability DIgSILENTДокумент6 страницFACTS Stability DIgSILENTAlberto JimenezОценок пока нет

- TVT Pricelist 2019 DistДокумент31 страницаTVT Pricelist 2019 DistVinodh MОценок пока нет

- Current Balancing Technique in Symmetrical Configuration of Quad-Active-Bridge Converter Using Integrated Magnetic Current Balancing CellsДокумент6 страницCurrent Balancing Technique in Symmetrical Configuration of Quad-Active-Bridge Converter Using Integrated Magnetic Current Balancing CellsSh M AaqibОценок пока нет

- Ai-719 Artificial Intelligence Industrial ControllerДокумент46 страницAi-719 Artificial Intelligence Industrial ControllerFabio SilvaОценок пока нет

- Tiger T650 FULLДокумент44 страницыTiger T650 FULLSolomon TekalignОценок пока нет

- Мануал L33 - new - MS50199 - 01EДокумент16 страницМануал L33 - new - MS50199 - 01EAleksey100% (1)

- Tarea Transmission MediaДокумент5 страницTarea Transmission Mediabrian barretusОценок пока нет

- F1000 User ManualДокумент86 страницF1000 User Manualcasket666@hotmail.com0% (1)

- Lab Test Report: Kyocera FS-4020DNДокумент19 страницLab Test Report: Kyocera FS-4020DNdatajerzyОценок пока нет

- Digital TriaxДокумент2 страницыDigital TriaxLaurentiu IacobОценок пока нет

- Renault Zoe - CARSHARING MODULEДокумент7 страницRenault Zoe - CARSHARING MODULERui PeixeiroОценок пока нет

- Parrot CK3X00 Wiring Reference Revision AДокумент3 страницыParrot CK3X00 Wiring Reference Revision ASandu PalantinОценок пока нет

- NOTE - Final Revision SPM 2020 (Part 2)Документ65 страницNOTE - Final Revision SPM 2020 (Part 2)Lee Li JieОценок пока нет

- Analog Tape RestorationДокумент5 страницAnalog Tape RestorationBrandy ThomasОценок пока нет

- CIM Operation V102Документ52 страницыCIM Operation V102Gerard ValdezОценок пока нет

- Understanding The BLE PCB AntennaДокумент13 страницUnderstanding The BLE PCB AntennajackОценок пока нет

- MD600N Pacific PDFДокумент19 страницMD600N Pacific PDFJuan Carlos LetonaОценок пока нет

- Yu Science 334 333 2011Документ30 страницYu Science 334 333 2011ab4azizОценок пока нет

- Ac Servo Motor Trainer: - MechatronicsДокумент1 страницаAc Servo Motor Trainer: - MechatronicsatifОценок пока нет

- Proform 735CSДокумент26 страницProform 735CSjaf323Оценок пока нет

- MAHINDRA SCORPIO CRDeДокумент148 страницMAHINDRA SCORPIO CRDeAlex Checa100% (4)

- (DOM) Kobold FRT12 ManualДокумент12 страниц(DOM) Kobold FRT12 Manualvallolet_sb5185Оценок пока нет

- Key Facts: Volkswagen Golf 1.6 FSI SE 5dr - 2,695Документ3 страницыKey Facts: Volkswagen Golf 1.6 FSI SE 5dr - 2,695neyplayerОценок пока нет

- Construction and Working Principles of Measuring InstrumentsДокумент20 страницConstruction and Working Principles of Measuring Instrumentsmarcelee wheatleОценок пока нет

- My TBS - Micro - V2.0 - E - TBS Micro ManualДокумент13 страницMy TBS - Micro - V2.0 - E - TBS Micro ManualAnkh TharaОценок пока нет

- Pvsyst - Simulation Report: Grid-Connected SystemДокумент9 страницPvsyst - Simulation Report: Grid-Connected Systemvjeusb8151Оценок пока нет

- Pju PDFДокумент450 страницPju PDFPiotr MuszakОценок пока нет