Академический Документы

Профессиональный Документы

Культура Документы

Biaxial Base Plate2

Загружено:

abdul kareeИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Biaxial Base Plate2

Загружено:

abdul kareeАвторское право:

Доступные форматы

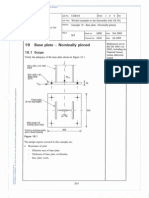

DESIGN OF BASE PLATE AND ANCHOR BOLT FOR BIA AXIAL BENDING MOMENT Pedestal on grid B-21, B-22,

B-25, B-27 (on Node 77, 78, 161, 165) Bolt design Load case Base Plate Design Load Case Design Code = Diameter of bolt Shank diameter factor Shank Area of the bolt No of bolts in x dir = nx No of bolts in z dir = nz Total no of bolts = N Type of Bolt = 1015 MIN GRAVITY + WIND X + PIPING = 1013 MAX GRAVITY + WIND Z + PIPING IS CODE x1 161 77 Z

39 mm = 0.85 = = 863.09 mm2 4 = Nos X 4 = Nos z1 12 = = Grade 8.8 176 Mpa Allowable Shear Stress ( vf) = 264 Mpa Allowable Tensile Stress (stf) = 1 No of Shear Planes = Shear Capacity of a Bolt = 15.485 ton Tension Check for Bolts Ftfcal => Ftfactual Where Ftf = nominal Tensile capacity of a bolt The nominal tensile capacity of a bolt (Ftf) shall be calculated as follows Ftf = Anet x stf x 0.8 where Anet is the tensile stress area of a bolt 23.23 ton Tensile capacity of a bolt =

r1 X

r2

Tension in the bolt due to bending Bolt to NA distance in z dir r1 = Bolt to NA distance in x dir r2 = spacing of bolt in x dir x1 = spacing of bolt in z dir z1 = Zxx of outer bolt =2nxr2/r Zzz of outer bolt =2nzr2/r = = 1.6 1.6

0.2 0.2

m m m m Zxx inner bolt = Zzz inner bolt = bolt check case 1 total Zxx total Zzz = = 1.600 m 1.600 m

m m

baseplate check case 2

39.13 3.76 6.73 7.71 11.47 0.10 0.64

Vertical force in Y-drn.

Horizontal shear in X-drn.

Horizontal shear in Z-drn. Resultant shear

Moment about X-dir Moment about Z-dir Shear per Bolt

1

Fy Fx Fz Fr Mx Mz Fr / N 2

: : : : : : : :

-3.75 2.77 1.53 3.17 3.47 5.00 0.26

ton ton ton ton tonm tonm ton

ton ton ton ton tonm tonm ton

=

tension per bolt

Mx Zxx 3.47

+ +

Mz Zzz 5.00

5.6048 3 Pmin n -3.75

1646.50

= = 5.60 ton < Tensile capacity of Bolt

tension per bolt

1.600

1.600

12

5.60 ton 0.64 ton

< <

Tensile capacity of Bolt Shear Capacity of Bolt

max shear per = bolt The Bolts are Safe in Shear The Bolts are Safe in Tension Interaction Check for Bolts

(

=

Actual Shear Force Permisible Shear Force 0.26 15.48

Actual Tensile Force ( Permisible Tensile Force )

<

1.4

5.60 23.23

0.26

The Bolts are safe in Interaction Check Summary provide 12 Nos of 39 mm dia Grade 8.8 Type Bolts DESIGN OF BASE PLATE

Length of plate Width of plate Pl. thickness (Tprovided)

: : :

0.55 0.55 2.8

m m cm

B z

B B D

= = =

=

0.3025 0.008 0.008

m2 m4 m4

D

x

Ixx = Izz =

x D3 12

x B3 12 Bearing Press.(qc) for Max. Comp.

z =

< 546.58 60.0 T/m2 Kg/cm2

39.13 + 0.303 Hence, Design Bearing Pressure for Plate

11.47 0.10 + 0.028 0.028 54.66 Kg/cm2 =

54.66

Kg/cm2

Hence Safe

Plate is supported on two sides & two sides are free. Refer Book ` Formula for Stress & Strain' By Roark & Young for value of b1 Plate Panel(axb) = 13.7 13.8 cms x Hence b1 Therefore, q x b1 x b2 = = 1850 Kg/cm2 Hence s 2 T 1.754 54.66 x x 190.44 = 9.87 T2 = 1850.0 Trequired = 3.20 cms > Tprovided = 2.8

1.754

For a/b =

0.99

Revise thickness

Вам также может понравиться

- Design of Baseplate and Anchor Bolt - InstrumentationДокумент6 страницDesign of Baseplate and Anchor Bolt - InstrumentationParchuri PraveenОценок пока нет

- Splice ConnectionUC 254X254X73Документ1 страницаSplice ConnectionUC 254X254X73PavanGuptaОценок пока нет

- Base Plate BiaxilДокумент26 страницBase Plate BiaxilvijaystructuralОценок пока нет

- Bolted Fin Plate Connection Design To BS 5950-1: 2000: Description Applied Capacity % of Cap. StatusДокумент14 страницBolted Fin Plate Connection Design To BS 5950-1: 2000: Description Applied Capacity % of Cap. StatusAlma M. LaraОценок пока нет

- Rafter To Column Top Connection Design Given DataДокумент10 страницRafter To Column Top Connection Design Given DataSafi Zabihullah SafiОценок пока нет

- Baseplate Biaxial MZДокумент26 страницBaseplate Biaxial MZD SRINIVAS100% (1)

- Anchor Bolt Design For Portal and Connecting BridgeДокумент2 страницыAnchor Bolt Design For Portal and Connecting BridgeAbhinav YadavОценок пока нет

- Base Plate Design Per EURO CODEДокумент14 страницBase Plate Design Per EURO CODEbutca1Оценок пока нет

- Wcr= (h-x) 3 a ϵ 1+2 (a C) : Crack Width Calculation for ColumnДокумент3 страницыWcr= (h-x) 3 a ϵ 1+2 (a C) : Crack Width Calculation for ColumnAnil kumar RОценок пока нет

- Beam To Column End Plate ConnectionДокумент10 страницBeam To Column End Plate ConnectionParchuri PraveenОценок пока нет

- Anchor Bolt - AISC ASDДокумент7 страницAnchor Bolt - AISC ASDameyyammaiОценок пока нет

- PEB Tender R1Документ54 страницыPEB Tender R1sri projectssОценок пока нет

- Calculation Sheet: Design PhilosophyДокумент36 страницCalculation Sheet: Design Philosophyrammohan100% (1)

- Calculation Sheet: Design of Splice For BeamДокумент6 страницCalculation Sheet: Design of Splice For BeamTOM YEEОценок пока нет

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateДокумент10 страницR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkОценок пока нет

- Larsen & Toubro Ltd. Rev Ltem Structural Design Calculations of Radiant SectionДокумент24 страницыLarsen & Toubro Ltd. Rev Ltem Structural Design Calculations of Radiant SectionAkshay Patil100% (1)

- Base Plate DesignДокумент4 страницыBase Plate DesignAnonymous 1HFV185Sl4Оценок пока нет

- Warn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1Документ11 страницWarn OK OK OK: ACI 318M-14 PIP STE05121 AISC Design Guide 1hemantcabhaleОценок пока нет

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearДокумент4 страницыConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearVenu GopalОценок пока нет

- Bolt End Plate Moment ConnectionДокумент50 страницBolt End Plate Moment ConnectionMarkОценок пока нет

- Nagarjuna Construction Company Limited: Iisco Steel Plant, Blast Furnace Complex (Package 07)Документ21 страницаNagarjuna Construction Company Limited: Iisco Steel Plant, Blast Furnace Complex (Package 07)rammohanОценок пока нет

- Base Plate Design As Per IS 800-2007Документ22 страницыBase Plate Design As Per IS 800-2007Armaan Gupta100% (2)

- Base PlateДокумент6 страницBase PlateJigarОценок пока нет

- Design Sheet 1Документ9 страницDesign Sheet 1SatyamОценок пока нет

- Base Plate Design Excel DesignДокумент120 страницBase Plate Design Excel DesignOmPrakash33% (3)

- Anchor Bolt DesignДокумент1 страницаAnchor Bolt DesignpawanОценок пока нет

- Typ Base PlateДокумент19 страницTyp Base PlateHabibur RahmanОценок пока нет

- Base Plate Design ExampleДокумент74 страницыBase Plate Design ExampleNiko NištićОценок пока нет

- Base Plate INDIA CODEДокумент4 страницыBase Plate INDIA CODEbama sankari100% (1)

- Design Data: Design For Base Plate (Fixed)Документ4 страницыDesign Data: Design For Base Plate (Fixed)Wibawa WorksОценок пока нет

- Sample DBR With MonoslopeДокумент27 страницSample DBR With MonoslopeNitish TakalkarОценок пока нет

- Base Plate Design-1 - J BoltДокумент41 страницаBase Plate Design-1 - J BoltGautam PaulОценок пока нет

- Slab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)Документ12 страницSlab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)shiv kumarОценок пока нет

- Anchor Bolt Design Example As Per Indian Code - Google SearchДокумент2 страницыAnchor Bolt Design Example As Per Indian Code - Google Searchjebin_87Оценок пока нет

- Design of Welded Splice Connection (DET.-D-04) : From Staad OutputДокумент10 страницDesign of Welded Splice Connection (DET.-D-04) : From Staad Outputvikas WaghmareОценок пока нет

- Bare Frame (Mbma-02)Документ2 страницыBare Frame (Mbma-02)ansgcekОценок пока нет

- Fresh Air Stack FoundationДокумент66 страницFresh Air Stack FoundationManan MansoorОценок пока нет

- Moment Splice - BackupДокумент74 страницыMoment Splice - BackupKiran AcharyaОценок пока нет

- BeamДокумент42 страницыBeamlavyОценок пока нет

- Indian Codes - Steel Design Per IS 800:2007Документ3 страницыIndian Codes - Steel Design Per IS 800:2007dineshОценок пока нет

- Flust-Extended End Plate ConnectionДокумент8 страницFlust-Extended End Plate ConnectionamachmouchiОценок пока нет

- Evo Design - Structural Design: Calculation SheetДокумент4 страницыEvo Design - Structural Design: Calculation SheetVij Vaibhav VermaОценок пока нет

- IS800 - 2007 - Tube - Detailed Calculation PDFДокумент4 страницыIS800 - 2007 - Tube - Detailed Calculation PDFLandon MitchellОценок пока нет

- Corbel DesignДокумент5 страницCorbel DesignHari prasad GaddamОценок пока нет

- Calculation For Rafter-Column ConnectionДокумент6 страницCalculation For Rafter-Column ConnectionpriantomoОценок пока нет

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesДокумент13 страницBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- Fixed Base Plate Design - ArhДокумент3 страницыFixed Base Plate Design - Arhmaheshbandham100% (1)

- Fixed Normal 575Документ8 страницFixed Normal 575mohanОценок пока нет

- Structural Calcs SHEDДокумент24 страницыStructural Calcs SHEDvtalexОценок пока нет

- End Plate Connection (Both Side Flush) - IS800 - 2007 - 2020.04.22Документ11 страницEnd Plate Connection (Both Side Flush) - IS800 - 2007 - 2020.04.22MANOJОценок пока нет

- Moment End Plate ConnectionДокумент16 страницMoment End Plate ConnectionNiraj ShindeОценок пока нет

- Ring Wall FoundationДокумент6 страницRing Wall Foundationraghav abudhabiОценок пока нет

- b2b SpliceДокумент21 страницаb2b SplicePrasad Dayalamoorthy DОценок пока нет

- Design of Wind Pressure of SiloДокумент1 страницаDesign of Wind Pressure of SilosrinivasОценок пока нет

- Connection Design-VijayДокумент278 страницConnection Design-VijayPrabhumk07Оценок пока нет

- Client: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarДокумент3 страницыClient: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarUday UdmaleОценок пока нет

- Design of Base Plate by EurocodeДокумент13 страницDesign of Base Plate by EurocodeBharati MajlekarОценок пока нет

- Bolted Connection Angle Brace TensionДокумент2 страницыBolted Connection Angle Brace TensionRajib MaharjanОценок пока нет

- Pinned Base Plate (Rs Shear Key)Документ7 страницPinned Base Plate (Rs Shear Key)winlugue3059100% (2)

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionДокумент11 страницRean'S Building 5/24/2002 Angle Plate Design: Framed Beam Connectionmhel_almoОценок пока нет

- EgyptДокумент4 страницыEgyptabdul kareeОценок пока нет

- Staad File Truss-02Документ11 страницStaad File Truss-02abdul kareeОценок пока нет

- Subject: Maintenance Work of Mosque Inside North Camp - Al Shamaal) As Per MWO No. PMU/W3/132/12 (Документ1 страницаSubject: Maintenance Work of Mosque Inside North Camp - Al Shamaal) As Per MWO No. PMU/W3/132/12 (abdul kareeОценок пока нет

- Qup Area of Punching: Fcu N MM CДокумент1 страницаQup Area of Punching: Fcu N MM Cabdul kareeОценок пока нет

- HORDY Design Example ContinuedДокумент6 страницHORDY Design Example Continuedabdul kareeОценок пока нет

- Computation of Soil Springs For Coupling Effect2Документ25 страницComputation of Soil Springs For Coupling Effect2abdul kareeОценок пока нет

- Bolt Capacity2Документ2 страницыBolt Capacity2abdul kareeОценок пока нет

- Beam Column Connection-Design2Документ16 страницBeam Column Connection-Design2abdul kareeОценок пока нет

- Beam Joist2Документ1 страницаBeam Joist2abdul kareeОценок пока нет

- Free Space Radar: Product Selection Guide - Installation and ApplicationДокумент2 страницыFree Space Radar: Product Selection Guide - Installation and ApplicationGabriela JimenezОценок пока нет

- 1 Struktur KristalДокумент65 страниц1 Struktur Kristalmuhammad faturrahmanОценок пока нет

- Aashto T 310 - In-Place Density and Moisture Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Документ6 страницAashto T 310 - In-Place Density and Moisture Content of Soil and Soil-Aggregate by Nuclear Methods (Shallow Depth)Aldrin SantosОценок пока нет

- Unit-2-Automobile EnggДокумент23 страницыUnit-2-Automobile EnggPrashant BhumireddyОценок пока нет

- Physics Informed Neural Network SolutionДокумент23 страницыPhysics Informed Neural Network SolutionAhmed RahmanОценок пока нет

- Chapter 3: Thermodynamics of Fluid Flow: 3.1 Sonic Velocity and Mach NumberДокумент25 страницChapter 3: Thermodynamics of Fluid Flow: 3.1 Sonic Velocity and Mach NumberShrinidhi KОценок пока нет

- MID 039 - CID 1846 - FMI 09: Pantalla AnteriorДокумент6 страницMID 039 - CID 1846 - FMI 09: Pantalla AnteriorWalterОценок пока нет

- Introduction To Piping FabricationДокумент5 страницIntroduction To Piping FabricationSyed IbrahimОценок пока нет

- RG 2018170038Документ14 страницRG 2018170038Lyht TVОценок пока нет

- General Knowledge For PPSC, FPSC, SPSC, KPPSC, NTS, Ots, Pts Tests-Part2Документ25 страницGeneral Knowledge For PPSC, FPSC, SPSC, KPPSC, NTS, Ots, Pts Tests-Part2Muhammad SiddiqueОценок пока нет

- Grounding & Lighting Prot-Grounding BarДокумент2 страницыGrounding & Lighting Prot-Grounding BarAlifia AiniОценок пока нет

- MCQ Nano Science and FEДокумент6 страницMCQ Nano Science and FEJamilur Rahman100% (1)

- 5.2 Method of JointsДокумент37 страниц5.2 Method of Jointsnisa erinaОценок пока нет

- Technical Data Sheet "Infinity 3100": 10 15 20 kVA 3Ph - 1PhДокумент7 страницTechnical Data Sheet "Infinity 3100": 10 15 20 kVA 3Ph - 1PhFlorin MОценок пока нет

- RIC Research Proposal FormatДокумент6 страницRIC Research Proposal FormatDr P Markandeya Raju (MVGR Civil)Оценок пока нет

- Determine The Linear Density (Atoms/nm) For BCC (100), (110), and (111) Directions in Terms of Atomic Radius RДокумент8 страницDetermine The Linear Density (Atoms/nm) For BCC (100), (110), and (111) Directions in Terms of Atomic Radius Rabdo mahmoudОценок пока нет

- Ion-Selective Analyzer Operator's Manual: NormalyteДокумент46 страницIon-Selective Analyzer Operator's Manual: NormalyteDani JuhaszОценок пока нет

- Comparison of the Transformation Sequence From Γ-AlOOH (Boehmite) to Α-Al2O3 (Corundum) Induced by Heating and by Ball MillingДокумент5 страницComparison of the Transformation Sequence From Γ-AlOOH (Boehmite) to Α-Al2O3 (Corundum) Induced by Heating and by Ball Millingsuleyman akpinarОценок пока нет

- Manual em SensorДокумент3 страницыManual em SensorSILVIO PALHA NASCIMENTOОценок пока нет

- Belilios Public School Half-Yearly Examination, 2015-2016 MATHEMATICS Compulsory PartДокумент33 страницыBelilios Public School Half-Yearly Examination, 2015-2016 MATHEMATICS Compulsory PartOlivia LinОценок пока нет

- StrengthДокумент20 страницStrengthCriss DodgeОценок пока нет

- 03 PAES Master Catalog 39th Edition Aeration PDFДокумент66 страниц03 PAES Master Catalog 39th Edition Aeration PDFjcbobedaОценок пока нет

- Cambridge O Level: Physics 5054/11Документ20 страницCambridge O Level: Physics 5054/11iman jamilОценок пока нет

- Research Paper On Laws of MotionДокумент7 страницResearch Paper On Laws of Motionfvfee39d100% (1)

- Physics Muster PDFДокумент36 страницPhysics Muster PDFMarlon FariaОценок пока нет

- Tunneling-Like Wave Transmission in Non-Hermitian Lattices With Mirrored NonreciprocityДокумент6 страницTunneling-Like Wave Transmission in Non-Hermitian Lattices With Mirrored Nonreciprocitydonniedarko817Оценок пока нет

- Mass Transfer Slides - CHE304 - Chapter 27Документ50 страницMass Transfer Slides - CHE304 - Chapter 27RehabОценок пока нет

- Fiber OpticsДокумент28 страницFiber OpticsShebОценок пока нет

- Navodila Za Uporabo Woson-AvtoklavДокумент46 страницNavodila Za Uporabo Woson-AvtoklavIrma MunkasicОценок пока нет

- Updated Standard Operation Manual For Tank Vent Gas Recovery System Feb. 2013Документ3 страницыUpdated Standard Operation Manual For Tank Vent Gas Recovery System Feb. 2013Steve WanОценок пока нет