Академический Документы

Профессиональный Документы

Культура Документы

Minimum Pipe Thickness - B31.1 - PG1

Загружено:

ravivarmadatla2011Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Minimum Pipe Thickness - B31.1 - PG1

Загружено:

ravivarmadatla2011Авторское право:

Доступные форматы

ASME B31.

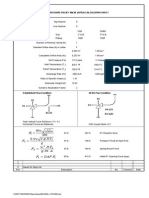

1- Power Piping Minimum Thickness Calculation Pressure Piping Size 10" Pipe Standards SCh 40 Material Material phase Corrosion allowance (A) Material External Diameter (D) Internal Diameter (d) Thickness Stress Value (SE) Quality factor (E) Longitudinal Weld Strength (W) Values of Coefficient (Y) = = = = = = = = = = = = = 0.6 273 9.3 Carbon Steel Ferretic Steels 1 A53 Grade B 273 mm 254.4 mm 9.3 mm 117.9 Mpa 1 1 0.4 Mpa mm

mm

Using Equation 7 from B31.1 104.1.2 t = PD/2(SE + PY) +A = 1.693245 mm With Mill Tolerance of 12.5% = 1.904901 mm XS / S80

Using Equation 8 from B31.1 104.1.2 t = (Pd + 2SEA + 2yPA)/2(SE-Py-P) = 1.047232 mm With Mill Tolerance of 12.5% = 1.178136 mm XS / S80

ASME B31.1- Power Piping Minimum Thickness Calculation Pressure Piping Size 6" Pipe Standards SCh 40 Material Material phase Corrosion allowance (A) Material External Diameter (D) Internal Diameter (d) Thickness Stress Value (SE) Quality factor (E) Longitudinal Weld Strength (W) Values of Coefficient (Y) = = = = = = = = = = = = = 0.6 168.3 7.1 Carbon Steel Ferretic Steels 1 A53 Grade B 168.3 mm 154.1 mm 7.1 mm 117.9 Mpa 1 1 0.4 Mpa mm

mm

Using Equation 7 from B31.1 104.1.2 t = PD/2(SE + PY) +A Using Equation 8 from B31.1 104.1.2 t = (Pd + 2SEA + 2yPA)/2(SE-Py-P) = 0.792534 mm With Mill Tolerance of 12.5% = 0.891601 mm XS / S80 = 1.427374 mm With Mill Tolerance of 12.5% = 1.605796 mm XS / S80

ASME B31.1- Power Piping Minimum Thickness Calculation Pressure Piping Size 1.5" Pipe Standards SCh 80 Material Material phase Corrosion allowance (A) Material External Diameter (D) Internal Diameter (d) Thickness Stress Value (SE) Quality factor (E) Longitudinal Weld Strength (W) Values of Coefficient (Y) = = = = = = = = = = = = = 1.3 48.3 5.1 Carbon Steel Ferretic Steels 1 A53 Grade B 48.3 mm 38.1 mm 5.1 mm 117.9 Mpa 1 1 0.4 Mpa mm

mm

Using Equation 7 from B31.1 104.1.2 t = PD/2(SE + PY) +A Using Equation 8 from B31.1 104.1.2 t = (Pd + 2SEA + 2yPA)/2(SE-Py-P) = 0.611763 mm With Mill Tolerance of 12.5% = 0.688234 mm XS / S80 = 1.265116 mm With Mill Tolerance of 12.5% = 1.423255 mm XS / S80

ASME B31.1- Power Piping Minimum Thickness Calculation Pressure Piping Size 3" Pipe Standards SCh 40 Material Material phase Corrosion allowance (A) Material External Diameter (D) Internal Diameter (d) Thickness Stress Value (SE) Quality factor (E) Longitudinal Weld Strength (W) Values of Coefficient (Y) = = = = = = = = = = = = = 0.6 88.9 5.5 Carbon Steel Ferretic Steels 1 A53 Grade B 88.9 mm 77.9 mm 5.5 mm 117.9 Mpa 1 1 0.4 Mpa mm

mm

Using Equation 7 from B31.1 104.1.2 t = PD/2(SE + PY) +A Using Equation 8 from B31.1 104.1.2 t = (Pd + 2SEA + 2yPA)/2(SE-Py-P) = 0.599035 mm With Mill Tolerance of 12.5% = 0.673914 mm XS / S80 = 1.225749 mm With Mill Tolerance of 12.5% = 1.378968 mm XS / S80

ASME B31.1- Power Piping Minimum Thickness Calculation Pressure Piping Size 2" Pipe Standards SCh 80 Material Material phase Corrosion allowance (A) Material External Diameter (D) Internal Diameter (d) Thickness Stress Value (SE) Quality factor (E) Longitudinal Weld Strength (W) Values of Coefficient (Y) = = = = = = = = = = = = = 0.6 60.3 5.5 Carbon Steel Ferretic Steels 1 A53 Grade B 60.3 mm 49.3 mm 5.5 mm 117.9 Mpa 1 1 0.4 Mpa mm

mm

Using Equation 7 from B31.1 104.1.2 t = PD/2(SE + PY) +A Using Equation 8 from B31.1 104.1.2 t = (Pd + 2SEA + 2yPA)/2(SE-Py-P) = 0.526409 mm With Mill Tolerance of 12.5% = 0.592211 mm XS / S80 = 1.153123 mm With Mill Tolerance of 12.5% = 1.297264 mm XS / S80

ASME B31.1- Power Piping Minimum Thickness Calculation Pressure Piping Size 1.5" Pipe Standards SCh 80 Material Material phase Corrosion allowance (A) Material External Diameter (D) Internal Diameter (d) Thickness Stress Value (SE) Quality factor (E) Longitudinal Weld Strength (W) Values of Coefficient (Y) = = = = = = = = = = = = = 0.6 48.3 5.1 Carbon Steel Ferretic Steels 1 A53 Grade B 48.3 mm 38.1 mm 5.1 mm 117.9 Mpa 1 1 0.4 Mpa mm

mm

Using Equation 7 from B31.1 104.1.2 t = PD/2(SE + PY) +A Using Equation 8 from B31.1 104.1.2 t = (Pd + 2SEA + 2yPA)/2(SE-Py-P) = 0.497969 mm With Mill Tolerance of 12.5% = 0.560215 mm XS / S80 = 1.122651 mm With Mill Tolerance of 12.5% = 1.262982 mm XS / S80

ASME B31.1- Power Piping Minimum Thickness Calculation Pressure Piping Size 1" Pipe Standards SCh 80 Material Material phase Corrosion allowance (A) Material External Diameter (D) Internal Diameter (d) Thickness Stress Value (SE) Quality factor (E) Longitudinal Weld Strength (W) Values of Coefficient (Y) = = = = = = = = = = = = = 0.6 33.4 4.5 Carbon Steel Ferretic Steels 1 A53 Grade B 33.4 mm 24.4 mm 4.5 mm 117.9 Mpa 1 1 0.4 Mpa mm

mm

Using Equation 7 from B31.1 104.1.2 t = PD/2(SE + PY) +A Using Equation 8 from B31.1 104.1.2 t = (Pd + 2SEA + 2yPA)/2(SE-Py-P) = 0.463179 mm With Mill Tolerance of 12.5% = 0.521077 mm XS / S80 = 1.084815 mm With Mill Tolerance of 12.5% = 1.220416 mm XS / S80

ASME B31.1- Power Piping Minimum Thickness Calculation Pressure Piping Size 1" Pipe Standards SCh 80 Material Material phase Corrosion allowance (A) Material External Diameter (D) Internal Diameter (d) Thickness Stress Value (SE) Quality factor (E) Longitudinal Weld Strength (W) Values of Coefficient (Y) = = = = = = = = = = = = = 0.6 21.3 3.7 Carbon Steel Ferretic Steels 1 A53 Grade B 21.3 mm 13.9 mm 3.7 mm 117.9 Mpa 1 1 0.4 Mpa mm

mm

Using Equation 7 from B31.1 104.1.2 t = PD/2(SE + PY) +A Using Equation 8 from B31.1 104.1.2 t = (Pd + 2SEA + 2yPA)/2(SE-Py-P) = 0.436516 mm With Mill Tolerance of 12.5% = 0.49108 mm XS / S80 = 1.054088 mm With Mill Tolerance of 12.5% = 1.185849 mm XS / S80

ASME B31.1- Power Piping Minimum Thickness Calculation Pressure Piping Size 3" Pipe Standards SCh 40 Material Material phase Corrosion allowance (A) Material External Diameter (D) Internal Diameter (d) Thickness Stress Value (SE) Quality factor (E) Longitudinal Weld Strength (W) Values of Coefficient (Y) = = = = = = = = = = = = = 1.3 88.9 5.5 Carbon Steel Ferretic Steels 1 A53 Grade B 88.9 mm 77.9 mm 5.5 mm 117.9 Mpa 1 1 0.4 Mpa mm

mm

Using Equation 7 from B31.1 104.1.2 t = PD/2(SE + PY) +A Using Equation 8 from B31.1 104.1.2 t = (Pd + 2SEA + 2yPA)/2(SE-Py-P) = 0.830223 mm With Mill Tolerance of 12.5% = 0.934001 mm XS / S80 = 1.487967 mm With Mill Tolerance of 12.5% = 1.673962 mm XS / S80

ASME B31.1- Power Piping Minimum Thickness Calculation Pressure Piping Size 2.5" Pipe Standards SCh 40 Material Material phase Corrosion allowance (A) Material External Diameter (D) Internal Diameter (d) Thickness Stress Value (SE) Quality factor (E) Longitudinal Weld Strength (W) Values of Coefficient (Y) = = = = = = = = = = = = = 1.3 73 5.2 Carbon Steel Ferretic Steels 1 A53 Grade B 73 mm 62.6 mm 5.2 mm 117.9 Mpa 1 1 0.4 Mpa mm

mm

Using Equation 7 from B31.1 104.1.2 t = PD/2(SE + PY) +A Using Equation 8 from B31.1 104.1.2 t = (Pd + 2SEA + 2yPA)/2(SE-Py-P) = 0.746242 mm With Mill Tolerance of 12.5% = 0.839522 mm XS / S80 = 1.400692 mm With Mill Tolerance of 12.5% = 1.575779 mm XS / S80

Вам также может понравиться

- RC Tie Beam DesignДокумент10 страницRC Tie Beam DesignSujay Santra67% (3)

- Ultimate GuideДокумент33 страницыUltimate GuidemrosamusicОценок пока нет

- RPS Support CatalogueДокумент49 страницRPS Support Catalogueravivarmadatla2011Оценок пока нет

- RC Roof Beam DesignДокумент5 страницRC Roof Beam DesignSujay SantraОценок пока нет

- Pipe Under Clamping ForceДокумент6 страницPipe Under Clamping ForceJaya DiОценок пока нет

- Wall Thickness Calculation - ASME B31.8 2007 (Template)Документ1 страницаWall Thickness Calculation - ASME B31.8 2007 (Template)Hendra Yudistira100% (1)

- Thickness Calc.-30 Inch-PV-21019Документ25 страницThickness Calc.-30 Inch-PV-21019RajeshvbОценок пока нет

- Asme B31.8Документ14 страницAsme B31.8omar equihua100% (1)

- BAR FlatДокумент2 страницыBAR Flatravivarmadatla201150% (2)

- BAR FlatДокумент2 страницыBAR Flatravivarmadatla201150% (2)

- Pipe Wall Thickness CalculationДокумент8 страницPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- Standard Pipe SupportsДокумент73 страницыStandard Pipe SupportsSaad Ahmad Siddiqui100% (1)

- TeluguXXX PinniniДокумент14 страницTeluguXXX Pinniniaruna11651% (80)

- ASME B31.3 Wall Thickness CalculationДокумент27 страницASME B31.3 Wall Thickness CalculationJesus Magallanes SОценок пока нет

- ASME B31.8 Riser CalcДокумент12 страницASME B31.8 Riser CalcSalz EngineeringОценок пока нет

- Retirement ThicknessДокумент7 страницRetirement ThicknessKamal UddinОценок пока нет

- Storage Tank Design CalculationДокумент12 страницStorage Tank Design Calculationhtutswe80% (15)

- Wall Thickness Pipeline (Gas) B31Документ25 страницWall Thickness Pipeline (Gas) B31Rais Brian Abdurahman100% (6)

- SPAN Calc.Документ48 страницSPAN Calc.yoi_123Оценок пока нет

- YoussefДокумент1 страницаYoussefhhgjdfОценок пока нет

- Pipe Is Under Clamping ForceДокумент7 страницPipe Is Under Clamping Forcejosediaz141Оценок пока нет

- ASME B31 4 Calculator V1 1Документ11 страницASME B31 4 Calculator V1 1vazzoleralex6884100% (1)

- Wall THK Calculation Asme b31.4Документ7 страницWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- ASME 31 - 8mДокумент1 страницаASME 31 - 8mMarcoAlbaОценок пока нет

- Thickness Analysis ReportДокумент9 страницThickness Analysis ReportEhtisham AndrAbiОценок пока нет

- ASME B31.8 Riser CalcДокумент23 страницыASME B31.8 Riser Calcisrar khan100% (2)

- Above Ground Piping Wall Thickness CalculationsДокумент7 страницAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- Pipe Maximum Alowable Pressures For A53 A106 and API 5LДокумент8 страницPipe Maximum Alowable Pressures For A53 A106 and API 5Llinhcdt3100% (1)

- Pipe Wall Thickness (Complete)Документ40 страницPipe Wall Thickness (Complete)Andri PutraОценок пока нет

- Calculation BS 31.3Документ1 страницаCalculation BS 31.3prabhjot123Оценок пока нет

- Syntorial NotesДокумент13 страницSyntorial NotesdanОценок пока нет

- ASME B31 8 Riser CalcДокумент12 страницASME B31 8 Riser CalcEmmanuel LawrenceОценок пока нет

- EB-300 310 Service ManualДокумент32 страницыEB-300 310 Service ManualVictor ArizagaОценок пока нет

- Calculation of Wall Thickness MAWP API 5l x52 (Rev-2)Документ21 страницаCalculation of Wall Thickness MAWP API 5l x52 (Rev-2)YusepSúarðiОценок пока нет

- S.V. Kulkarni, S.A. Khaparde Transformer and Inductor Design Handbook 2004Документ532 страницыS.V. Kulkarni, S.A. Khaparde Transformer and Inductor Design Handbook 2004Gianpiero Boccato0% (1)

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetДокумент1 страницаPY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540Оценок пока нет

- General Anaesthesia MCQsДокумент5 страницGeneral Anaesthesia MCQsWasi Khan100% (3)

- ... Go To Air Volume Calculation Prepared by MD - Zafar ... Go To Strength & Leak TestДокумент5 страниц... Go To Air Volume Calculation Prepared by MD - Zafar ... Go To Strength & Leak Testmahesh100% (1)

- Wall Thickness Calculation - ASME B31.8 2007 (Template)Документ1 страницаWall Thickness Calculation - ASME B31.8 2007 (Template)LU1228100% (3)

- Area Reinforcement CalculatorДокумент5 страницArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Pressure Relief Valve (Open) Calculation Sheet: G T R G W F T R W FДокумент1 страницаPressure Relief Valve (Open) Calculation Sheet: G T R G W F T R W Fdj.4t67395Оценок пока нет

- Wall THK Calculation Asme b31.4Документ5 страницWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Pipe Thickness Calculation AS Per ASME 31.3Документ11 страницPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRОценок пока нет

- ASME B31.3.4.8 Wall Thickness CalculatorДокумент26 страницASME B31.3.4.8 Wall Thickness Calculatoreko123100% (1)

- Hydrostatic Test Pressure Calculation: Pipe DataДокумент2 страницыHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadОценок пока нет

- Calculation For Reinforced PadДокумент4 страницыCalculation For Reinforced Padjsridhar_34750% (2)

- Wall Thickness Calculation ASME B31!8!2007Документ1 страницаWall Thickness Calculation ASME B31!8!2007shafeeqm3086Оценок пока нет

- Wall THK Calculation Asme B31.4Документ7 страницWall THK Calculation Asme B31.4ISRAEL PORTILLOОценок пока нет

- Max Allowable Pressure of Pipes and Pipellines CER 04022013Документ89 страницMax Allowable Pressure of Pipes and Pipellines CER 04022013Castro Quinteros WinstonОценок пока нет

- ASME 31 - 4 CalcДокумент1 страницаASME 31 - 4 CalcMarcoAlbaОценок пока нет

- HOT TAP Calculation ThicknessДокумент4 страницыHOT TAP Calculation Thicknesscecepsmuhlis67% (3)

- Calc Hoop StressДокумент11 страницCalc Hoop StressApril Trevino100% (1)

- Bends (Elbows) (ASME B31.3-2012 Para. 304.2.1) : Design ConditionsДокумент1 страницаBends (Elbows) (ASME B31.3-2012 Para. 304.2.1) : Design ConditionsabhisheknharanghatОценок пока нет

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantДокумент49 страницDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Оценок пока нет

- Wall Thickness Calculations As Per ASME B31 3 PDFДокумент2 страницыWall Thickness Calculations As Per ASME B31 3 PDFAnonymous cyKuQKОценок пока нет

- Tech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPДокумент39 страницTech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPEl Mundo De Yosed100% (1)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Документ1 страницаPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadОценок пока нет

- AS4041 ASME B31 - 3 Pipe Wall ThicknessДокумент8 страницAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- ASME B31.3 Area ReplacementДокумент2 страницыASME B31.3 Area ReplacementJahsbuck100% (1)

- Pipe Wall Thickness Calculation According ASME B31 3Документ93 страницыPipe Wall Thickness Calculation According ASME B31 3linhcdt3100% (1)

- ASME B31.4 Riser CalcДокумент14 страницASME B31.4 Riser CalcCastorNoroñoОценок пока нет

- Taper Lock BushesДокумент4 страницыTaper Lock BushesGopi NathОценок пока нет

- Pipe Thickness Calculations - : ClassДокумент1 страницаPipe Thickness Calculations - : ClassOluwachidiОценок пока нет

- Pipe Wall Thickness Calculation ASME B31.3 Straight PipeДокумент5 страницPipe Wall Thickness Calculation ASME B31.3 Straight Pipeaike_5Оценок пока нет

- Branch Reinforcement Per Asme B31.4 PipelineДокумент1 страницаBranch Reinforcement Per Asme B31.4 PipelinegateauxboyОценок пока нет

- Asme Pipe Wall ThicknessДокумент3 страницыAsme Pipe Wall ThicknessYoke ShuОценок пока нет

- Thickness Calculation For PipeДокумент7 страницThickness Calculation For PipeNAYEEM100% (5)

- b31.8 Steel Piping Design FormulaДокумент19 страницb31.8 Steel Piping Design FormulaTim Bagwell100% (1)

- A11Документ1 страницаA11liviu_dovaОценок пока нет

- 316 316l Data SheetДокумент2 страницы316 316l Data SheetDiman Aditya KardiОценок пока нет

- DOT Pipeline SpecificationsДокумент20 страницDOT Pipeline Specificationssect349Оценок пока нет

- 150# Cs Ball Valve Datasheet: GeneralДокумент3 страницы150# Cs Ball Valve Datasheet: GeneralVijay GaikwadОценок пока нет

- Pipe Design Thikness For PipingДокумент1 страницаPipe Design Thikness For PipingKanit ChobОценок пока нет

- NDT Calculation: Test Package No: PA-SS08-03 Project: Mead Johnson Nutritional CE370-12Документ7 страницNDT Calculation: Test Package No: PA-SS08-03 Project: Mead Johnson Nutritional CE370-12ravivarmadatla2011Оценок пока нет

- C2 - G1.2 - PipeworkДокумент58 страницC2 - G1.2 - Pipeworkravivarmadatla2011Оценок пока нет

- (045kva) Generator Denyo DCA455ESIДокумент1 страница(045kva) Generator Denyo DCA455ESIravivarmadatla2011Оценок пока нет

- 2.BOM Page 29,33Документ3 страницы2.BOM Page 29,33ravivarmadatla2011Оценок пока нет

- C2 - G1.2 - PipeworkДокумент58 страницC2 - G1.2 - Pipeworkravivarmadatla2011Оценок пока нет

- C2 - G1.2 - PipeworkДокумент58 страницC2 - G1.2 - Pipeworkravivarmadatla2011Оценок пока нет

- C2 - P2.6 - Documentation For The WorksДокумент22 страницыC2 - P2.6 - Documentation For The Worksravivarmadatla2011Оценок пока нет

- PPC - Takasago - Plans6 (Steel Platform) (17.01.2013) - ModelДокумент1 страницаPPC - Takasago - Plans6 (Steel Platform) (17.01.2013) - Modelravivarmadatla2011Оценок пока нет

- Acknowledgment of ReceiptДокумент1 страницаAcknowledgment of Receiptravivarmadatla2011Оценок пока нет

- Time SheetДокумент1 страницаTime Sheetravivarmadatla2011Оценок пока нет

- Sorting (Seiri) Eliminate All Unnecessary Tools, Parts, and Instructions. Go Through All Tools, MaterialsДокумент1 страницаSorting (Seiri) Eliminate All Unnecessary Tools, Parts, and Instructions. Go Through All Tools, Materialsravivarmadatla2011Оценок пока нет

- Safety HarnessДокумент1 страницаSafety Harnessravivarmadatla2011100% (1)

- PDFДокумент8 страницPDFDocОценок пока нет

- Noxim MANUALДокумент5 страницNoxim MANUALSAI NRUSIMHA DEEPAK BURRA SAI NRUSIMHA DEEPAK BURRAОценок пока нет

- Mathematics For Engineers and Scientists 3 PDFДокумент89 страницMathematics For Engineers and Scientists 3 PDFShailin SequeiraОценок пока нет

- Icpc11 - Thermodynamics and Fluid MechanicsДокумент22 страницыIcpc11 - Thermodynamics and Fluid MechanicsAPARNAОценок пока нет

- K&J Magnetics - Demagnetization CurvesДокумент4 страницыK&J Magnetics - Demagnetization CurvessubbannachrsОценок пока нет

- Wjec Biology SpectificaionДокумент93 страницыWjec Biology SpectificaionLucy EvrettОценок пока нет

- CFD - Basement Car ParkДокумент43 страницыCFD - Basement Car ParkTanveer HasanОценок пока нет

- PalmistryДокумент116 страницPalmistrymarinoyogaОценок пока нет

- Monthly Exam Part I Aurora English Course 1 (KD 1, KD2, PKD3)Документ20 страницMonthly Exam Part I Aurora English Course 1 (KD 1, KD2, PKD3)winda septiaraОценок пока нет

- ScilabДокумент4 страницыScilabAngeloLorenzoSalvadorTamayoОценок пока нет

- Data Sheet: W-Series WSI 6/LD 10-36V DC/ACДокумент12 страницData Sheet: W-Series WSI 6/LD 10-36V DC/ACLUIS FELIPE LIZCANO MARINОценок пока нет

- Chapter 2Документ82 страницыChapter 2Kavitha Selvaraj50% (2)

- Monk - Way of The Elements RevisedДокумент3 страницыMonk - Way of The Elements Revisedluigipokeboy0% (1)

- Non-Pen MountДокумент17 страницNon-Pen MountT BagОценок пока нет

- Neuromuscular Diseases. ALSДокумент7 страницNeuromuscular Diseases. ALSjalan_zОценок пока нет

- RA9275Документ49 страницRA9275znarf_ryanОценок пока нет

- Food Poisoning: VocabularyДокумент9 страницFood Poisoning: VocabularyHANG WEI MENG MoeОценок пока нет

- Tank Gauging TankvisionДокумент31 страницаTank Gauging Tankvisionkhangduongda3Оценок пока нет

- Study of Mosquito Larvicidal Effects of (Bitter Gourd) Extracts As NanopowderДокумент3 страницыStudy of Mosquito Larvicidal Effects of (Bitter Gourd) Extracts As NanopowderAnonymous AkoОценок пока нет

- Flash Memoir RevisedДокумент3 страницыFlash Memoir Revisedapi-511179803Оценок пока нет

- Visedo FPC-2016Документ13 страницVisedo FPC-2016Probonogoya Erawan SastroredjoОценок пока нет

- Class 28: Outline: Hour 1: Displacement Current Maxwell's Equations Hour 2: Electromagnetic WavesДокумент33 страницыClass 28: Outline: Hour 1: Displacement Current Maxwell's Equations Hour 2: Electromagnetic Wavesakirank1Оценок пока нет

- JCHT35K9 EngДокумент5 страницJCHT35K9 EngRodica PuscauОценок пока нет