Академический Документы

Профессиональный Документы

Культура Документы

Interpreting-P N ID Diagram

Загружено:

Anonymous HFIQgANMQАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Interpreting-P N ID Diagram

Загружено:

Anonymous HFIQgANMQАвторское право:

Доступные форматы

Interpreting Piping and Instrumentation Diagrams [Part 1 of 5] Part 1 Introduction

Engineers love to draw. Not necessarily in an artistic sense of t e word! alt oug "eauty is! as t ey say! in t e eye of t e "e older. #s for me! well! I$ve never "een accused of aving a particular gift in t e arts! or p otograp y for t at matter %see "io mug s ot ta&en in my natural a"itat'! "ut I ave done a few process drawings in my (5) years as a process engineer. I guess t at$s earned me my vice! *P of Engineering and +ec nology Development to "e precise.

,i t ere. I$m -o" .oo& and I$m glad to ave you along for my premier entry ere on . Enected.com w ere we e/plore t e interpretation of Piping and Instrumentation Diagrams! or P0IDs for t ose in t e &now. + is is a topic t at can "enefit process! pro1ect and design engineers! "usiness developers! operators! safety! maintenance and even management. 2ow! t at a lot of fol&s3

,owever! consider t is all of t e mem"ers listed a"ove will eit er come across P0IDs intermittently or ave to wor& wit t em as a core aspect of t eir 1o". #nd if I still ave your attention t en! yes! you too s ould ave a solid understanding of ow to read t em3 ,ey you iding t e "ac&4don$t "e "as ful. 5ou say t at you are two! t ree4five years out of sc ool and still not sure you really ave a good andle on P0IDs6 5ou$re not alone. ,aving wor&ed for many companies and provided services to a variety of industries over t e years! I find it curious ow P0IDs are often poorly understood "y t ose w o s ould &now t em "etter. In some cases! t ey e/ude t is aura of intimidating! comple/ documents t at only . E gee&s %and t e li&e' really &now ow to read.

I "elieve t is is simply due to a deart of formal training. 7ol&s are 1ust e/pected to pic& it up 8on t e fly9. :iven t e varia"ility in career direction our "ac&grounds in t e "est engineering field afford us! t is wor&s well for some "ut leaves ot ers playing catc ;up later on. <o even e/perienced engineers and operators may one day discover t eir lac& of &nowledge on t e topic puts t em at a disadvantage. <o let$s 1ust put a stop to all t at "y ta&ing P0IDs apart in t is multi;part series. =egardless of e/perience level! you will find many of t e sym"ols are o"vious. >t ers need a "it more e/planation. In muc t e same way ancient Egyptians used ieroglyp ics t ousands of years ago! we process fol&s %in con1unction wit our peers in t e electrical! controls and ot er departments' 1ust come up wit our own set of sym"ols to represent t e various e?uipment! devices and control concepts t at go into our plants. 2 en you loo& at it t at way! one could argue

t at not muc as c anged in a few t ousand years. I suppose t at$s true. ,ey! if it isn$t "ro&e! w y fi/ it6

Enoug of my "antering! let$s get started already. I loo& forward to a ealt y e/c ange. Part ( will dig into P0IDs + e 7undamentals. I$ll include a few e/ample drawings t at we can use as we venture fort down t at pat of process &nowledge.

If you want to get a ead start! download t em ere. <tay tuned3

Part ( + e 7undamentals

In Part 1 of t is series! I tal&ed a"out w y a solid understanding of P0ID interpretation is important to virtually every discipline involved in a process plant from process engineering and detail design t roug construction! commissioning@start;up! operations and management. I$m glad to see I sold you on t at point and welcome you "ac& to part two of t is saga.

+ ings are starting to eat up and soon we will "e weeding out t e true process engineers from t e causal posers w o would rat er go off and waste time "rowsing reddit or digg %w ic I never do "y t e way'. 2e still ave a "it of t e academic stuff to cover "efore we really dig in "ut it$s important stuff so sit up straig t and pay attention3

Aet$s &ic& t ings off "y defining w at P0IDs are and t e types of information t ey illustrate. #fterwards! we$ll cover some of t eir limitations. It$s important to &now t e limitations of a tool so t at you don$t apply it in t e wrong way.

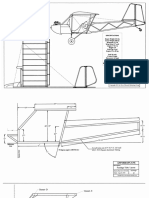

#t t e end of Part 1! I provided a lin& to some e/ample drawings t at I put toget er to elp illustrate some of t e concepts I plan to discuss in t is series. If you aven$t downloaded it yet! please do so now. + e file containsB +wo typical P0ID 8Aead < eets9! and # few e/ample P0ID drawings # 2ord a"out Aead < eets

2e will tal& more a"out t e lead s eets %sometimes referred to as legend s eets' in Part C <ym"ology. If you$ve never encountered lead s eets "efore! for now! 1ust &now t at lead s eets are used to define t e e?uipment and device sym"ols! tags and ot er notations! a""reviations and sometimes esoteric conventions t at companies use to develop P0IDs for any pro1ect t ey e/ecute. If you compare lead s eets from a few doDen companies! you will find t at EFG of t em are pretty muc .opy H Paste. 7or t at last 1FG)! t ere can "e distinct differences and company;specific conventions used t at are not o"vious on P0IDs. + erefore! it is good to &now w ere t e lead s eets are in your company so you can ?uic&ly trac& down t e meaning of t at pipe service la"el or some ot er o"scure sym"ol. + e E/ample P0IDs

+ e last t ree drawings in t e download lin& include some fairly typical P0IDs. I plan to use t ese in some upcoming videos to illustrate ow t e sym"ols from t e lead s eets are applied to a real drawing and t en compare t at drawing to actual pictures of real;world plants. + is will elp forge t e cognitive connection from t e a"stract realm of cu"icle dwellers at .#D stations to t e real world of process plants in action3

Even if you are completely new to P0IDs! I$m sure t ere are some aspects t at are o"vious to you in t ese e/ample drawings t ings li&e t e e?uipment and valve sym"ols! tags! etc. If not! t at$s >I too "ecause we will get into t e details later "ut for now! 1ust loo& t em over and familiariDe yourself wit w at$s t ere. 2 at are P0IDs6

# P0ID %or engineering flow drawing! E7D' is a type of process engineering drawing t at descri"es all process design aspects of a plant. In t is conte/t! 8Process Design9 means all t e stuff t at ma&es up a plant! includingB Ja1or and minor e?uipment t e distinction "etween w at is 8ma1or9 vs. w at is 8minor9 e?uipment is su"1ective *alves! including vents! "leeders! safety relief! sample %all of t em3' Instrumentation! including devices t at are used to continuously measure pressure! flowrate! massrate! temperature or some analyDed parameter suc as p,! concentration! viscosity4t e list goes on. <tand;alone controllers t at may function independently to perform a particular function! li&e a PID controller or relay timer.

-uttons used to control motors and devices! "e t ey pus "utton! toggle! or some ot er type. Jotors and drives many motors are single speed! non;reversing "ut t ere are ot er &inds t at ave varia"le speed drives! and can operate in "ot directions. Aimit and point devices including devices t at only reveal a discrete state! e.g.! if a tan& is at a certain level %point level'! or a valve or actuator is in a particular position %a limit switc ' + at$s it41ust &idding. Piping %of course3'. #ll t e pipes! tu"es and even overflows in t e plant. Not 1ust t e main process pipes in erent to t e particular process! "ut even t e utilities %steam! air! fuel! etc.'. *irtual devices on computer control screens %often as grap ical representations real;world o"1ects' t at are used to interact wit t e plant from t e control room@panel. + is includes t ings li&e 8clic&a"le9 "uttons used to start@stop e?uipment! operate valves! ad1ust controller settings! setpoint sliders and dials! evaluate alarms! etc. .omputer functions and software 8lin&s9 are generally limited "ecause it is difficult to convey complete control meaning using 1ust sym"ols. ,owever! it doesn$t matter if t e process is running on a ome;"rew E/cel *-# pro1ect wit Dic&;and;Kane grap ics or a state;of;t e;art ,oneywell D.< t e sym"ology used to represent t e control interface will "e s own.

I pro"a"ly forgot some stuff in t e list a"ove "ut you get t e idea. .learly t ere can "e a lot of information to s ow on a P0ID. #nd for t is reason! t ere are various degrees of detail t at a particular company will generally c oose to s ow. + ere is no formal standard for t e various amounts of information a P0ID must include. =at er! it is left to t e discretion of t e engineers involved.

In terms of detail provided! my opinion is t at a good P0ID will stri&e a "alance of 8clarity wit out confusion9. If you can$t see t e process for all t e sym"ols! t en it$s pro"a"ly overdone. >n t e ot er and! if you can$t even discern ow a pump may "e operated or w at interloc&s may e/ist! t en you pro"a"ly need to em"ellis it a "it. P0ID <upport Documents

7or t ose t ings t at are deli"erately left off P0IDs for t e sa&e of clarity! ot er documents are used to provide t e details. .ommon documents t at serve vital support functions to P0IDs includeB

Process 7low Drawings %P7Ds' are simple flow drawings t at illustrate t e general plant streams! ma1or e?uipment and &ey control loops. + ey also provide detailed mass@energy "alance data along wit stream composition and p ysical properties. P0IDs originate from P7Ds. Piping and material specifications. ,ere! you can dig into all t e gory details a"out materials of construction! gas&ets! "olts! fittings! etc. for eac of t e services. %I will tal& a"out t is more in a future post.' E?uipment and instrumentation specifications. Jodern .#D software used to produce P0IDs are sometimes called 8smart9 "ecause t ey can incorporate specifications! standards and details t at go into t e design. 5ea! t ey are cool "ut 1ust as you can$t fi/ stupid! you can$t see 8smart9. + us! it$s good to ave tangi"le documents t at fol&s can access and digest outside t e masters of .#D. 7unctional@process control documents t at descri"e in detail! ow t e plant operates. # good one will include preferred standards for use on control screens@displays. 7ol&s involved in programming t e computers used to operate t e plant need t ese. ,ow < ould P0IDs "e >rganiDed6

Now you &now w at a P0ID is and w at goes on t em "ut you$re not ?uite ready for t e corner office. #t t is point it$s wort considering ow a set of P0IDs can %and s ould' "e organiDed for a particular process.

+ ere is no single good answer to t is ?uestion and most companies will ave a defined precedent or standard t at t ey follow "ut if you find yourself at 7ile H New wit not ing to go on! "ecause you 1ust started your own company and %w oa4 dude I 1ust realiDed t ere is no mec anical group anymore' my advice is to &eep in mind t at w en you set out to develop a set of P0IDs you are essentially writing a structured document! not unli&e a "oo& or report wit c apters@sections and a logical progression. >I! a really "oring "oo& wit no plot or c aracters! "ut you get t e idea3 Jy point is! you s ould plan t e structure and "rea& t e tas& down into managea"le sections "ased on area in t e plant! function and ot er criteria t at mig t "e of importance to t e pro1ect@process.

,ere$s a ?uic& e/ample. .onsider a process plant wit t at receives raw feedstoc& in a storage area! feeds t em into some reactor train%s' to ma&e some product and t en includes a storage and pac&aging "ac& end. + is particular process mig t "e sitting inside a larger comple/ and leveraging e/isting utility infrastructure and tan& farms. In t is case! you mig t elect to "rea& t e P0IDs down as suc B =aw material receiving and storage

Process trains for product manufacture Product storage and pac&aging +ie;ins to facility utilities and distri"ution Environmental controsl and specialty unit operations@vendor pac&ages suc as t ermal fluid! comple/ unit operations! etc.

-rea&ing a set of P0IDs down into logical sections ma&es t e drawing set easier to develop! digest and! per aps most importantly c ange. #ny of you t at ave tampered wit o"1ect;oriented programming s ould "e nodding in agreement at t is point. >nce you ave t e categorical areas "ro&en down! t e drawing set is t en lin&ed toget er via arrows and notations. Lltimately! it all fits toget er to li&e a puDDle to yield a continuous masterpiece.

<ome companies li&e to develop t eir P0IDs so t at if you ad a uge wall! you could tape t em toget er and all of t e various interconnecting arrows would line up as t e parts of a 1igsaw puDDle. I ave found t at suc an approac places unreasona"le restrictions on t e convenient location of e?uipment and arrows and generally doesn$t afford any greater understanding of t e olistic process. It$s not uncommon for even relatively simple processes to ave a doDen or more P0IDs so you would need a really "ig wall and t en you wouldn$t "e a"le to read anyt ing wit out getting close.

Jy advice is to ma&e efficient use of t e space provided! use t e interconnect arrows as re?uired to lin& t em toget er and not get caug t up on ow well t ey align wit t e god of geometric continuity %I t in& t at was a :ree& god! not sure'. 2 at are P0IDs Lsed 7or6

P0IDs really do ave vital roles. In fact! if I ad to pare it down to t e top two! t is is my listB #ct as t e definition of t e process from w ic all engineering! fa"rication! construction and operation is "ased. <erve as reference for Process <afety Information %P<I' in Process <afety Janagement %P<J'.

+o effectively accomplis t ese o"1ectives! a good set of P0IDs s ould do t e followingB

Provide a clear and concise illustration of all e?uipment! pipes! valves! instruments! sensors! etc. so t at anyone involved as a solid understanding of t e process. Provide information to assist in analyDing process aDards! safeguards and potential faults so t at all &inds of errors %design! uman@operation! etc.' are minimiDed! ideally eliminated. <upport development of operating and maintenance procedures. <erve as an as;"uilt record of t e process so t at c anges can "e planned safely and effectively using Janagement of . ange %J>.'.

<o it$s pretty clear t at t e P0IDs define t e process at a root level. + ey serve as t e foundation upon w ic t e system is designed! "uilt and operated. #nyone w o tells you t at t ey can design a plant wit out first generating P0IDs eit er is a Deity or as endless funds t at t ey en1oy t rowing at poorly e/ecuted pro1ects during t e constructionM p ases. P0ID Aimitations

#t t is point! you mig t "e wondering w at P0IDs can$t do. #fter all! so far we$ve painted a picture t at t ey ave seeming supernatural powers. 2ell! t ere are a few t ings t at P0IDs don$t do well and it$s important t at you &now w at t ese are so t at no"ody ma&es any false assumptions "ecause we all &now w at appens w en one assumes.

Despite t eir illustrious super ero status in t e process engineering world! t ere are a couple t ings P0IDs don$t do well. Aet$s get it out in t e open nowB + ey don$t reveal scale or geometry! + ey don$t serve as a true model for ow t ings are oriented and placed in t e real world.

Ai&e I said in t e intro to t is series! I$ve "een doing process engineering for 15F years %in t e snow! up ill to wor& "ot ways' and I still run into instances w ere some"ody will "ase a decision on ow to ma&e a c ange or try to find somet ing in t e plant "ased on w ere or ow it loo&s on t e P0ID. ,ere$s a Pro+ip a "etter way to get a andle on w ere t ings really are at in t e field is to use t e P0IDs as a guide and do a wal&;down or find ot er scale drawings.

:ood e/amples of true scale drawings are t e ones used "y contractors to "uild t e plant. + ese include civil and piping plans! sections and@or isometrics! s&id@e?uipment fa"rication drawings! instrument location plans! etc. If you 1ust assume t at a pipe is located somew ere "ecause it loo&s t at way on t e P0ID! you mig t "e disappointed3

<ince we$re e/posing t e superman P0IDs to a "it of &ryptonite! let$s review some ot er wea&nesses of P0IDs 1ust to ma&e sure we$ve covered all t e &ey pointsB Not to <cale as stated a"ove! P0IDs can$t "e relied on as a scale guide for w ere pipes! e?uipment or ot er items are in pro/imity to e?uipment in t e real world. 5es! I$m repeating t at again "ecause it will "e on t e ?uiD. Not :eometrically #ccurate P0IDs don$t illustrate geometry. + e level of detail t at goes into sym"ols for e?uipment will vary! "ut is almost never geometrically correct3 .olor -lind P0IDs are not good at using color to convey meaning. 2 ile t e fol&s w o draw t em often use color to elp spot t ings on a monitor! don$t try too ard to glean meaning from color printouts or you may 1ust end up seeing stars4 Not Definitive P0IDs do not include complete specs for all of t e e?uipment in t e process. + ey are! after all drawings! not documents. If you need details! gra" t e pertinent data s eets or vendor specs. >r as& someone for some elp. Not Drawn .onsistently <adly! P0IDs seldom loo& consistent "etween companies. + at$s "ecause t ere is a lot of fle/i"ility in ow one can go a"out drawing a P0ID %due to various standards! .#D systems! etc.' and t at leaves t em open to company and@or personal preferences. #s a result! P0IDs often ta&e on a different 8loo& and feel9 from company;to;company or even from 1o";to;1o" inside t e same company. + is can "e a point of confusion w en you get used to a certain way of seeing t em. -ut don$t sweat itN 1ust reorient yourself to t e ways and means used "y t e process tri"e in your group. Did you 1ust t in& a"out lead s eets3 -onus point for you3

>I! so now you ave a solid feel for w at P0IDs are! t e purposes t ey serve and t eir limitations. ,opefully! you$ve ta&en t e time to at least glance at t e e/ample drawings provided. :reat! in Part C of t is series we will dig into t e sym"ology used so we can interpret t e gee& spea& of process engineers3 Part C <ym"ology Primer

2elcome "ac& to Part C fol&s3 Aet me apologiDe at t e outset for t e delay in getting t is posted sooner "ut we ad our Aa"or Day oliday ere in t e L<# last wee& and oddly enoug ! we tend N>+ to wor& on Aa"or Day. :o figure4 I suppose it s ould "e called slac&er day "ecause I really didn$t do muc t e w ole wee&end. In any event! I$m "ac& in t e saddle so let$s recap t e last two parts "efore we it t e trail again. 2e ave a lot of ground to cover "efore sunset. Part 1 tal&ed a"out w y t e interpretation of P0IDs is important to everyone involved in t e planning! design! and construction t roug operation of a process plant. Part ( descri"ed t e various functions P0IDs serve and ig lig ted t e &inds of information t ey convey! along wit t e support documents t at are commonly associated wit t em. 2e also tal&ed a"out some of t eir wea&nesses.

2it t e re?uisite academics out of t e way! it$s time to focus on t e e/citing stuff P0ID sym"ology interpretation. + at$s t e goal I ad w en I started t is series and "y golly! I$m stic&ing to it. ,owever! I$m going to warn you up front t is is a "ig part in t e series! figuratively and literally spea&ing.

I mig t even "e pus ing t e limits of . enected.com$s server capacity "ut I did my "est to "alance "readt of content wit dept of detail. If you t in& I s ort; c anged any areas and would li&e more detail on any topic! please let me &now via t e comment system. I$ll do my "est to o"lige. Aead < eets Define <ym"ology

#s I mentioned in Part (! t e meanings of t e various sym"ols used on P0IDs %a&a! sym"ology' are defined on separate drawings called 8Aead < eets9 %or Aegend < eets'. + ese are your 8secret decoder rings9 to P0ID sym"ology interpretation. Every company t at "uilds process plants s ould ave a set of lead s eets customiDed to t eir particular ways and means.

,aving seen a num"er of lead s eets over t e years! I can tell you t at most of t em are 1ust variations on a core set of generally accepted sym"ols and notations t at engineers and industry organiDations ave settled on as defacto standards over t e years.

+ e lead s eets I provide in t e supporting file download to t is series include t e followingN DFF1 Instrumentation and *alves

DFF( .odes! +ags! and Aa"els

,ere$s t e good news t ese lead s eets include EF.FF)F.F5G of w at you need to &now. <eriously! t e significant digits are rig t ere! I c ec&ed t em. 5ea ! I realiDe some companies ave more t an two lead s eets! four or five even.

Pro"a"ly even a few wit si/ or seven 1ust to prove a point I suppose! "ut t e num"er of lead s eets isn$t important. 2 at is important is t at t ey are logically organiDed so t at t e sym"ols and tags can "e located easily. Poorly organiDed and@or incomplete lead s eets will 1ust frustrate fol&s w o turn to t em for elp so it$s important to &eep t em neat! concise and logical. #nd t e two I present ere s ould "e up;front;and;center in your set.

=elated to t e content I include on t e e/ample lead s eets! you mig t ave noticed a conspicuous a"sence of lead s eets for ma1or e?uipment! i.e.! tan&s! pumps! and sundry items typically included in process plants! etc. It$s good to ave lead s eets for t at &ind of stuffN I$m not going to say ot erwise. ,owever! I ave generally stopped using t em in my group "ecauseN It is almost always self;evident w at a sym"ol represents for ma1or e?uipment! and Even if it$s not apparent! t e ma1or e?uipment is always tagged and named wit some general specifications provided along one edge of t e drawing. I underline always "ecause t at$s t e way it s ould "e. I don$t want to de"ate it. Kust ma&e it so3

#side from t ese reasons! it$s toug to &eep an e?uipment lead s eet updated w en new or custom e?uipment t at doesn$t really ave an industry standard sym"ol is added to a drawing for a particular 1o".

I could go on regarding t e topic of sym"ols for ma1or e?uipment "ut t is is a topic I decided not to e/pand on in t e interest of focusing more on t e instrumentation and controls side of sym"ology. < oot me a note if you want to discuss t is more. .aveat Emptor

-efore we move on! I want to address t e operations fol&s ere in attendanceB Ieep in mind t at reading and understanding P0IDs is a core topic of operator training. #nd t at training appens long "efore you step on;site. In fact! you

s ould &now t is stuff "efore you enter t e room as a team mem"er on a Process ,aDards #nalysis.

#s a process engineer at eart! I view operations as my O1 client and wor& ard to ma&e sure t at t ey fully understand t e plant and its procedures so t at it can safely and efficiently meet its o"1ectives. If you are in an operations group! you are not e/pected to ave it all figured out 1ust from reading t is series alone. ,owever! t e following sections s ould serve as a solid primer.

#nd I will ma&e you a simple promise so long as you don$t get "ored and start daydreaming a"out w et er -roc& Aesner will remain t e L7. eavyweig t c ampion for t e ne/t five years %I don$t even4'! you will definitely wal& away from t is series wit a solid! functional understanding of P0IDs3 If you don$t! call me and I will refund your money! no ?uestions as&ed. Instrumentation and .ontrols <ym"ology

2e$ll &ic& t ings off wit w at as traditionally "een viewed as t e 8 ardest part9 of P0ID interpretation! t at of course "eing instrumentation and controls. In my e/perience! t is is t e area t at gives newcomers t e most grief. +rust me! it$s not t at ard and once you ave t is area con?uered! everyt ing after t at is stupid simple and t e learning curve will s&yroc&et.

+ e main sym"ols used for Instrumentation and .ontrol %I0.' are s own in t e ta"le a"ove. 2 en you spot one of t ese on a P0ID! you will "e a"le to glean t ree t ings from it! includingB 2 at is t at device6 2 ere is it located6 2 y is it t ere6

+ e Pw at$ and Pw ere$ aspects can "e determined from t e sym"ol s ape. + e Pw y$ part comes from te/t placed inside t e sym"ol t at is made up of two parts t at form t e 8tag num"er9. + is includesB #n a""reviation for w at t e device is %"ased on I<# <5.1'! com"ined wit a

Aoop num"er "ased on your company$s preferred num"ering system

-efore I dig into t is topic more eavily! it$s wort providing a couple simple tag num"er e/amples as a lead;in. Pressure indicators ave t e a""reviation PI and temperature indicators use t e a""reviation +I. It follows logically t at flow and level indicators use t e a""reviations 7I and AI! respectively. <ince most plants can ave many instruments of t e same type! a uni?ue num"er is applied so t at eac one can "e individually identified.

+ is num"er is often referred to as t e 8loop num"er9. + us! t e device a""reviation M loop num"er "ecome t e uni?ue 8tag num"er9. 2 ile t e device a""reviations are largely "ased on accepted standards %I<# <5.1'! t e loop num"ering system is company specific.

Jy group appens to use a four digit num"ering system. In t is case! typical tag num"ers for pressure and temperature indicators in our plants will "e PIF1CQ and +IQCQR! respectively. 5ou could even reuse t e loop num"er 8F1CQ9 to define ot er types of devices! suc as a level indicator! AIF1CQ or flow indicator! 7IF1CQ. + e same olds true for loop num"er 8QCQR9N it may "e used for PIQCQR! AIQCQR and ,<QCQR %w ere ,< stands for ,and <witc '.

+ e &ey point is t at t e a""reviation M loop num"er must "e uni?ue for eac device ot erwise! it cannot "e uni?uely identified. 5ou can get creative and apply special prefi/es %or suffi/' num"ers to t e tag num"er w en you want to reuse t e same tag %li&e in cases w ere you ave redundant devices "ut you don$t want t em to ave different loop num"ers'. I will get into t ose w en we loo& at t e e/ample P0IDs. -ut t at is detail stuff. 2 at is t at control sym"ol6

=efer to t e first row in t e ta"le a"ove. # circle sym"ol is ?uite simply any p ysical instrument or device in t e field or on a panel. It doesn$t matter if it is a level transmitter! a flow meter! a pressure gauge or some ot er type of indicator. If it is a p ysical device t at measures or displays somet ing! it will "e illustrated "y t e use of a circle on a P0ID.

Notice also ow I placed t e tag num"er PIF1CQ inside t e sym"ol. + e common practice is to place t e device function a""reviation on t e top line! wit t e loop num"er at t e "ottom. 2 en t e device is ordered and a stamped tag is re?uested! it s ould matc t e tag num"er placed inside t e sym"ol on t e P0ID.

#sideB <ometimes! you will ear fol&s refer to t e sym"ols as instrument 8"u""les9. + is is 1ust 1argon t at is commonly used. 2 en you ear it! t ey are simply referring categorically to t e sym"ol s apes I am tal&ing a"out in t is part. Kust act li&e you$ve "een calling t em "u""les for years and s ow now sign of confusion3

Jove down to t e sym"ols on t e second row of t e ta"le t e ones t at s ow a circle inside of a s?uare. + ese are used to represent a grap ic on a computer screen or control panel t at you can see and possi"ly interface wit via touc panel or a computer mouse. It mig t "e used to s ow t e level in a tan& %as t e ta" num"er in t e "u""le s own ere suggests' or represent a and switc t at you can clic& on wit t e mouse to start a pump %or a million ot er t ings3'. + e point is if you can see it on a control screen! it will "e represented as a circle inside a s?uare on P0IDs. Don$t as& me w o decided t is! it wasn$t me3

+ e last two rows are for sym"ols t at let t e reader &now a computer is used to do some sort of comple/ processing. In t e case of t e e/agon! it means a 8computer9 is used. + at$s a pretty vague description don$t you t in&6 I mean! is your plant a 8P. or a Jac96 I don$t want to get into t at de"ate %my wife uses a Jac! ot erwise I would' "ut my point is t at some of t ese sym"ols "egin to s ow t eir ?uaint age.

In t e case of a s?uare wit a diamond in it! t at means a programma"le logic controller %PA.' is used. # yes! t e venera"le PA. still anging toug after all t ese years. Even if you are not familiar wit control computers or PA.s! don$t sweat it. Kust &now t at t ese sym"ols really represent software instructions t at engineers write to define t e automated "e avior of t e plant.

7or e/ample! code t at tells a pump to automatically stop w en t e tan& it is pumping from runs low. + at would "e a so;called low level interloc& type function t at would e/ist as instructions inside a PA.. In t is instance! a level element provides t e input and t e computer runs a set of instructions t at say Pstop t e pump$ if tan& level is low.

+ ese sym"ols are often left off of P0IDs "ecause t ey really don$t provide any usa"le information t at you could get out of 1ust loo&ing at t e sym"ol. 7or e/ample! in t e simple e/ample t at I 1ust provided! ow could you descri"e t e low level interloc& using a sym"ol t at loo&s li&e a s?uare wit a diamond in it6 5ou couldn$t3

5ou would need to supplement t e P0ID wit a written description of w at t e plant is supposed to do wit all of t e input it receives. <o t e sym"ols would 1ust ta&e up space and clutter t e drawing for no good reason ot er t an per aps provide some pointer via a tag num"er to coded instructions. -ut t e P0IDs serve t e process! not t e programmer so we can$t ave t at3 <ym"ology <tar Power3

+ is "rings me to t e ar"itrary star rating I gave all of t e sym"ols in t e ta"le %see 8-o"$s =eview9 &ey at "ottom of ta"le'. 7ol&s! t is isn$t pu"lis ed "y t e I<# %as if I ad to ?ualify t is4' "ut we$ve "een toget er long enoug for you to &now

t at t is is ow I roll. It$s my way of e/plaining t e fre?uency and importance of t ese sym"ols in most cases. ,ere goes.

7or eac sym"ol! I rate it "ased on ow often it typically s ows up on drawings t at I ave wor&ed on over t e years. Every plant is different "ut t ere is a general t eme ere. I view sym"ols wit only one star as pretty muc useless "ecause t e a"stract concept t ey are trying to illustrate simply can$t "e done effectively wit 1ust sym"ology.

+wo star sym"ols ave value "ut may not s ow up very often or at all in many cases! depending on t e type of plant and its design. #nyt ing at or a"ove t ree stars is a cele"rity in our P0ID feature presentations. 2e$re tal&ing #rnold <c warDenegger! w ereas t e one star sym"ol is a&in to t e nondescript ensign &illed off in t e first five minutes of a <tar +re& episode.

<o w at a"out t ose ?uiDDical computer sym"ols t at I po&e fun of6 2ell! you can still use t em if you want "ut t ey need eavy support from a document t at descri"es all of t e functional re?uirements of a plant and t at is typically called a 7unctional [.ontrol] Description. Jay"e in a future series %if you$re good'! we will cover functional control aspects. > :oody3 I can almost sense your 1oy at t e t oug t3 ,ey! pay attention and no smart remar&s. 2e still ave wor& to do ere3 2 ere is t e device located6

If you glance "ac& at t e ta"le! you will see t at t ere are four columns t at provide t e P2 ere$ part of a sym"ol. Now! as we discussed in Part ( of t is series! P0IDs generally aren$t good at s owing you w ere somet ing is located in t e field. 2e aren$t tal&ing a"out t at &ind of Pw ere$. In t is case! we are using w ere as a relative reference. =elative location is indicated via t e presence of a centered! oriDontal line %or lac& t ereof'! a dual centered oriDontal line! or a das ed centered oriDontal line placed inside t e sym"olN <ingle oriDontal line located on a main control panel near t e control room or some computer screen in t e main control room! No oriDontal line located somew ere in t e field! pro"a"ly close to t e general area s own on t e P0ID! Dou"le oriDontal line on some secondary %satellite' local panel in t e field. <ingle das ed oriDontal line inaccessi"le or not generally located w ere it can "e easily accessed or viewed. Jay also "e used for idden or password protected areas of a control system.

Notice in t e a"ove items! no specific location information is provided! only t at t e device or grap ic is associated wit a relative! general location. In many cases! it$s not ard to figure out w ere somet ing is 1ust from w ere t e sym"ol is at on t e drawing. -ut t ere are limits to w at t e sym"ol can convey. Jore on t e Das es

I ave found t at t e das ed line sym"ols can cause confusion so I want to spea& on t ose a "it more. 2 en you see a sym"ol suc as t e one s own at left! t at simply means t at you can$t normally see it or wor& wit t at device it in t e field. It mig t "e installed "e ind or inside of a panel so t at it is normally not in view %inaccessi"le to t e operator'.

<o in t e sym"ols s own ere! a circle wit a das ed line in t e middle means it is an instrument or device t at you can$t normally see or get to. If you are an operator! it is pro"a"ly somet ing you do not need to get to "ut it mig t still "e vitally important to t e plant control system! so we s ow it t is way on a P0ID.

In a similar fas ion! a grap ic display sym"ol wit a das ed line in t e middle simply means t at t is portion of t e control system is password protected or idden from normal view on a screen or operating panel so you can$t get to it unless you &now t e secret access code. It$s not t at people are &eeping secrets from you %or may"e t ey are4 mmmm'N it$s 1ust t at it mig t contain important settings t at no"ody s ould ever need to mess wit . 2 y is t at device ere6

5ou$ve come a long way towards understanding control sym"ology. 5ou can now identify w at a control sym"ol represents and its relative location in t e plant. -ut you still don$t &now w y it$s t ere. It$s not elpful to &now ow to identify a control sym"ol type if you cannot e/plain w at purpose it serves in t e plant. + at is t e point of t e te/tual a""reviations placed inside t e sym"ols.

2e touc ed on t is a "it a"ove so now lets cover t e essence of w at you need to &now and &eep in mind! come of t is is t e way I li&e to do t ings! w ic doesn$t necessarily mean it is t e "est or only way.

=efer to t e figure "elow entitled 8Instrument <ym"ol +ag Identification9. # control sym"ol will typically contain two lines inside it! as followsB Lpper Aine an a""reviation for t e functionality it provides %"ased on t e I<# 5.1 standard'! and Aower Aine a loop num"er t at corresponds to t e e?uipment or area it is associated wit %or "ased on your company$s preferred standard'.

+ e upper line te/t a""reviation! along wit t e lower line tag num"er ma&es up t e uni?ue sym"ol identification tag. It is important t at eac sym"ol ave a uni?ue tag so t at it can "e individually identified. In t is e/ample! t e sym"ol would "e referred to as PDI+1SFC in a process document or operating procedure.

+ ere may "e a "unc of ot er sym"ols wit 1SFC in t em! "ut t ey must ave a different te/t a""reviation "efore t e 1SFC or you won$t "e a"le to uni?uely identify it. Part Q of t is series will tal& more a"out typical device tagging protocols "ut for nowN consider t is your 8Introduction to +agging 1F19.

+ e letters on t e first line are in accordance wit I<# standard 5.1! as descri"ed in t e upper left corner of lead s eet DFF1. Eac letter provides uni?ue information. 2e can use t e ta"le in DFF1 to determine t at t is sym"ol representsB 8P9 7irst Aetter stands for 8Pressure9 8D9 <econd letter is a modifier for t e first and stands for 8Differential9

8I9 + ird letter stands for 8Indicating9 8+9 7ourt letter stands for 8+ransmitter9 1SFC is t e loop num"er %t e Electrical Engineering egg eads need loop num"ers too'

I li&e to "ase loop num"ers off t e associated ma1or e?uipment. + at$s 1ust me! and I t in& it ma&es good sense. -ut if your company uses a different tec ni?ue! roll wit it. Now is not t e time to "e a renegade creator of new tagging systems. 7ig t your "attles "ut win your wars3

<o in t is case! we ave a pressure differential indicating transmitter installed on e?uipment 1SFC. 5ou mig t see suc a device across a strainer inlet and outlet to let you &now w at t e pressure drop is across it so t at you can clean it w en it gets ig . .ommon Instrument #""reviations

+ ere are a num"er of instrument letter com"inations t at you are li&ely to come across a lot. # few of t ese are listed in t e figure titled 8.ommon Primary Device <ym"ols9. + ese e/amples will elp you get some practice understanding t e a""reviations used for control sym"ols. 5ou can compare t e e/amples to t e ta"le on DFF1 to get t e ang of it. + ese e/amples all represent field;mounted devices. 2e &now t at "ecause t ey are all simple circle sym"ols wit no oriDontal lines. I told you t is was pretty straig t forward3

+ e ardest part in decip ering t e a""reviations inside control sym"ols is figuring out w at t e letters designate w en t ere are t ree or more letters used. ,ere are a couple rules of t um"B In t e case of a""reviations wit four letters! t e second letter is a modifier to t e first. 2 en only t ree letters are used! t e second letter pro"a"ly is not a modifier.

#s wit any 8rule of t um"9! you mileage may vary! so if in dou"t! loo& it up using t e ta"le on DFF1 %or your own company lead s eets'. <ym"ol #ttri"utes

Depending on t e sym"ol purpose! various ot er attri"utes may "e placed near control sym"ols in 8supporting role9. + e section called 8Instrument

#""reviations9 on lead s eet DFF1 defines some of t e more common ones you mig t run into. + ese are simply elpful "its t at provide furt er clarification for t e situation at and.

In many cases! it is elpful to &now 8at a glance9 t at a valve is 7. %7ail .losed' or t at DI is a %Digital Input'. =efer to t is ta"le w en you encounter a""reviations used around control sym"ols. Instrument Input;>utput %I@>'

Despite ma1or advances in computer tec nology and communications protocols! many instruments still transmit t eir signals using a trusty analog signal %via a Q; (Fma! (Q*'. 7or switc ed devices! t e input is typically a switc t at simply provides a voltage input.

2 ile it is not a common practice to s ow t e type of signal a particular device sends to and@or receives from t e control system %collectively referred to as t e I@>'! in my company I li&e to employ simple triangular sym"ols along t e interconnecting lines to elp illustrate t e I@> flow %if you will' on a P0ID. + is is illustrated using t e sym"ols s own in t e figure "elow.

+ e important point to remem"er w en you see t ese sym"ols is t at t e I@> flow is always from t e control computer$s perspective. + us! all outputs %D>! #>' come out of a output module and go to some field device. .onversely! all inputs %DI! #I' are signals from field devices t at flow into some input module.

>t er types of I@> t at may re?uire specialiDed transducer cards or networ& protocols are sometimes used. 7or e/ample! t e I+ signal is a common type of signal t at a t ermocouple employs. 5ou may ave also eard of =+D temperature sensors. + ere are a myriad of transmission protocols used today and as process engineers! we don$t need to get caug t up in t at. -ut it is elpful to understand t e flow of I@> in a plant and using t ese sym"ols is a c eap! easy way of s owing t at wit no penalty on t e comple/ity of t e drawing3

#ll of t e I@> sym"ols invaria"ly lin& to t e software line type %descri"ed "elow'! as t is is used to illustrate software processing wit in a computer or PA.. 5ou don$t &now w at is ta&ing place 1ust "y loo&ing at a line! "ut you can "e sure t at w atever it is! t e 7unctional .ontrol Description is t e place to loo& to find out. Aine <ym"ols

+ e &ey line types are ig lig ted in t e figure at rig t. -y far! t e most common line type is t e solid line! w ic is used to represent a pipe. #lt oug not s own! a process line wit long das es means t e pipe is e/isting or is outside t e "attery limits %><-A' of t e plant.

>t er common line types t at you s ould "e a"le to identify are electrical signal %anyw ere wires are employed'! instrument air to control valves@devices %la"eled as pneumatic signal' and software or data lin& w ic includes 8virtual9 communication suc as w at occurs inside a computer program or PA. ladder logic.

+ e software can include anyt ing t at appens inside a computer! "ut you need a functional description to actually &now w at t at is! as we discussed earlier in t is

"rief. Kust &now t at w en you see a software line! it means computers are at wor& lin&ing t e devices in some meaningful way t at relates to t e system controls. .omputing 7unctions

+ ese sym"ols descri"e t e types of functions t at run inside a computer program. # pro"lem wit applying t ese sym"ols is t at t ey do not really provide solid insig ts into ow t e plant is controlled in comple/ instances. 7or t is reason! most P0IDs will ma&e limited use of computing function sym"ols.

5ou can safely ignore t ese and not miss out on muc "ecause t e functional control description is really intended to descri"e control details t at t ese sym"ols try to illustrate.

*alve <ym"ols

+ e figures "elow s ow t e &ey sym"ols for t e various types of manually; operated valves and actuator details for automated valves. Note t e attri"uted stems on t e actuators to indicate fail state. + is is a good e/ample of using attri"utes to provide &ey information t at is valua"le to operations.

.onnection +ypes

=egarding connections! t e sym"ology s own in t e figure "elow is standard. >ne point I will ma&e is t at in plastic piping systems %P*.! .P*. and #-<'! everyt ing is generally glued using a connection type called 8soc&et weld9. ,owever! soc&et weld can also "e applied to metallic piping systems w ere a welded connection is employed using soc&eted %versus "utt weld' fittings.

+ ere is no specific designation "etween glued or welded soc&et connections. Nor is t ere a sym"ol for t readed connections.

2 en you start getting into w at type of connection s ould "e used in a particular pipe! t is is not really somet ing t at is "ased on personal preference or simply w at you mig t ave on and in t e maintenance trailer. + is is somet ing t at is "ased on t ings li&e t e line service %w at$s in t e line'! conditions %temperature! pressure'! and ot er factors %li&e supporting re?uirements'.

+ is &ind of stuff is defined in a Jaterial and Aine <pecification <tandard. 2e won$t cover t at in detail ere "ut you &now w at6 I 1ust got an idea3 + is is great topic for a future series. + e fun never ends does it6 2 at a"out pipe fittings6

In case you are wondering %and I &now you were'! P0IDs generally do not s ow pipe fittings %el"ows! tees! unions! o;lets! etc.'. Nor will t ey include all t e various flanged connections t at mig t actually e/ist in t e plant. + ese are details t at s ow up on piping plans@sections! isometrics and fa"rication drawings. <o! unless it is important to t e process design for some reason! fittings and e/traneous flanged connection are generally not s own. If you need to get a fitting ta&e;off! loo& elsew ere3

+ransducer 7unctions

+ is is an area t at defines signal conversion. >nly electrical engineers get e/cited a"out t is stuff! and you really don$t need to focus too muc on t is. In fact! I almost s&ipped it "ut I 1ust &now t at if I did someone would as&! so let$s get t is out of t e way "ecause t is electrical stuff is starting to get a tad "oring4

# transducer is somet ing t at ta&es a signal in one form and converts in into anot er form so t at it can "e used "y a downstream device. 7or e/ample! a control valve may need air to actuate "ut receive an electrical signal to tell it to do t at. <ome ow! you ave to get t e electric signal converted into an e?uivalent air signal so t e valve can move. ,ello signal transducer.

In t is particular e/ample! an I@P %current to pneumatic' transducer is necessary so t at t e valve can "e positioned to any desired opening point wit 1ust an electrical signal. + is is t e most common transducer function used in many plantsN t e ot ers listed are comparatively rare.

<o! understand w at I@P means w en you see it and don$t worry too muc a"out t e rest of t em for now. 2 en you graduate to Jaster Nin1a P0ID interpreter! t en we will focus on t ese details.

Primary 7low Elements

+ ese sym"ols are not ing more t an grap ic illustrations t at complement t e control "u""les to elp readers of t e drawing more easily identify t e type of flow element "eing employed. + e most common types are s own in t is ta"le on DFF1.

+ ese sym"ols are not really critical towards an understanding of t e instrumentation or controls. Aevel elements don$t ave an e?uivalent. Nor do ot er common instrument types.

-rea&time3

>I! so now you ave a solid feel for w at P0IDs are! t e purposes t ey serve! t eir limitations and supporting document re?uirements and now a pretty solid andle on t e sym"ology used. Despite all t e ground we covered in t is part! we aven$t really ad a c ance to go t roug a few e/amples.

Everyone &nows t at w en it comes to learning new information! application it is &ey. + e old adage 8use it or lose it9 applies. I still aim to get to some e/amples "ut for now! 1ust ta&e a well deserved "rea& and let t is stuff sin& it. -esides! I$m sure t ey need to go "uy a couple more ard drives for Parts Q and 5. -e sure to drop me any comments you ave so t at I can tailor t e remaining parts.

,ang in t ere! we are almost done. 5our on t e "ac& side of t e race and eading towards t e finis line. + an&s for 1oining me3 Part Q .odes! +ags and Aa"els

<o you are "ac& for more in Part Q6 #fter all we went t roug in Part C! t ose still standing pro"a"ly deserve a medal or somet ing. + at said! unli&e Part C w ere we really covered a lot of detailed 8nuts;and;"olts9! t is part will "e a comparative piece of ca&e. Iind of li&e t e last day of sc ool w ere you &now you still need to go and it mig t even "e &ind of fun! "ut you don$t ave to do any real wor& and t e stuff you do ta&e ome will "e memories not omewor&. + at$s t e frame of mind you need to ave for Part Q! o&6

-ut "efore you ta&e t is as a cue to start s ooting spit"alls at your ost! sit up straig t "ecause t is part is vital to your understanding and development of clean! clear! odor;free P0IDs.

<ince t is series is &ind of long % ey! w o snorted36'! let$s get t e re?uisite recap out of t e way for t ose w o missed t e previous parts and need to circle "ac&B Part 1 tal&ed a"out w y t e interpretation of P0IDs is important to everyone involved in t e planning! design! and construction t roug operation of a process plant. Part ( descri"ed t e various functions P0IDs serve and ig lig ted t e &inds of information t ey convey! along wit t e support documents t at are commonly associated wit t em. 2e also tal&ed a"out some of t eir wea&nesses. Part C covered t e nitty;gritty aspects of instrumentation and control sym"ology. #long wit t at! we dissected tag a""reviations and ow loop num"ers uni?uely identify devices. <ince we were on a roll! we closed out t is part wit all t e ancillary I@> sym"ols! line types! piping connections and ot er various sundry items perip eral to t e main t eme.

Lp till now! we ave spent a great deal of our time focusing on t e first lead s eet! DFF1 Instrumentation and *alves! provided along wit ot er drawings in t e supporting file download to t is series. In t is Part Q! we will turn our attention to t e remaining lead s eet! DFF( .odes! +ags! and Aa"els.

#s I ave mentioned previously! DFF( is an e/ample lead s eet typical of t e ones I ave used in t e past. It may loo& different from t e ones your company uses and t at$s >I. It$s not as important ow a company prefers to do la"eling on a P0ID! only t at t ey do it clearly! consistently and "ased on a ro"ust system t at is amena"le to future c ange and additions. #n e/tensi"le tagging system if you will. + at$s a concept t at may "e a "it unfamiliar to some so I will discuss t at as a sort of prere?uisite. ,ang in t ere! I see t e finis line41ust around t e corner3 P0IDs #re =eally Data"ases! 2ait..w at6

2 ile P0IDs are representations of t e process to t e casual o"server! t eir underlying structure more closely resem"les a relational data"ase. In fact! for t ose of you familiar wit today$s common computer aided drafting pac&ages! you may realiDe t at a .#D drawing is really a data"ase of o"1ects assem"led in a structured manner. Even if you reuse t e same o"1ect over and over in a drawing! t e .#D system &eeps trac& of it wit a uni?ue identifier. + is is very similar to a process plant in t at! well for starters! we apply tags to &eep trac& of e?uipment! piping! valves! devices! etc.Tt ings t at we reuse over and over again in any given process design.

<o I am ere to tell you fol&s! w en you design a process and develop t e P0IDs in .#D! you are really assem"ling a data"ase along t e way. + is isn$t lunacy wit alf a "owtie. I$m serious and I would urge you to get familiar wit relational data"ase design! if only from an academic standpoint. Ai&e o"1ect;oriented programming! t ese a"stract concepts are e/tremely valua"le towards implementation in our line of wor&.

<ome e/amples6 >&! "e old my e/ i"itsTli&e a data"ase! a process plant illustrated using .#D on a set of P0IDsB .ontains collections of similar o"1ects wit uni?ue tags so t at even identical o"1ects %valves! pumps! instruments! etc.' can "e uni?uely identified. Is assem"led in a structured manner t at lends itself to additions! deletions! c anges! etc. wit a granularity as coarse as w ole unit areas! down to a single valve on a pipe anyw ere in t e plant. .ontains lots of metadata in t e tagging systems t at can in erently provide %or lin& to' muc more detail suc as specifications! materials of construction! data s eets! etc.

+ ere$s more t an 1ust t e a"ove "ut I will rest my case. I ope you agree t at w ile t e tags and la"els t emselves are self;evident! t e real power is in t e underlying tagging system used. #nd so you$re still t in&ing! 8w y must a tagging system "e so ro"ust and e/tensi"le6 I mean! come on -o"! aren$t you ma&ing a mountain out of mole ill69

2ell! glad you as&edN t e answer is ?uite simply "ecause most plants c ange over t eir useful life. . ange comes from a lot of different anglesB

>perational +wea&sTimprovements often come from t e operations fol&s. In my e/perience! some of t e "est improvements to a plant don$t come from t e egg ead engineers sitting in t eir cu"icles! "ut from t e fol&s in t e plant dealing wit t e mac ine eac and every day. It is in t eir interest to ma&e it wor& "etter! safer and c eaper. .apacity@Production . angesToften! a particular unit operation needs to "e e/panded to meet new production re?uirements or c anges in feedstoc& or product re?uirements t at s ift t e process design needs. I$ve seen instances w ere complete new trains ave to "e added to a system. P<J #udit =eviewTProcess <afety Janagement re?uires t at process documentation "e &ept up to date and routine plant audits and Process ,aDard =eview may reveal c anges t at s ould "e implemented to a plant t at is already in operation. + e P0IDs are t e reference upon w ic suc reviews are "ased and must always "e in a current 8#s;-uilt9 state.

+ e &ey ta&e;away from t e list a"ove is t at t e P0IDs serve initially as t e process definition upon w ic t e plant is designed. -ut t en t ey serve operations long after t e plant is "uilt. + is is w y earlier in t is series I espoused t e need for engineers to "e routinely! actively engaged in ongoing operations. Not only will you learn a lot a"out t e plant t at you yourself may ave elped "uild! t e feed"ac& you receive will "e invalua"le to maintaining a safe operation. Plus! you can implement t e lessons learned on future pro1ects.

Now t at I$ve driven ome t e importance of a structured tagging system! let$s turn attention to t e meat of t is Part QTt e actual tagging of e?uipment and devices. E?uipment +ags

Aots of companies use w at appears initially to "e an intuitive! simple system to tag e?uipment. It later reveals itself not to "e very intuitive or ro"ust. Aet$s pause for fictitious e/ample %t at "ears no resem"lance to my past! really'.

:it=Dun Process! Inc. as decided to "uild a new plant to produce +rimet yl&a"if! a precursor to a drug t at yields ?uic& weig t loss! improved memory and muscle tone w ile eliminating irrita"le "owl! gastric reflu/ and attention deficit. + e process fol&s start out tagging e?uipment as followsB Pumps are simply tagged P;1! P;(! P;C %ma&es sense rig t6' #gitators are tagged #:;1! #:;(! #:;C! etc. Dude t is is so simple3

#nd of course tan&s and vessels are tagged +I;1! +I;(! +I;C %or *;1! *;(! *;C'. .ould do t is in my sleep4

#nd so on4Aife is good. Aater on! t oug less common e?uipment starts getting added! and t is starts to stress t e 8intuitive9 nature of t e system.

7or e/ample! a centrifuge is initially tagged .;1 "ut now t ey need to add a conveyor "ut . is ta&en so t ey decide to call t e conveyor .>;1. Now t ey t in&! well! we will 1ust revise t e centrifuge tag to .E;1. .risis avoided4-ut wait! later t ey need to add a c emical feed pac&age and want to tag t at .7;1. >I! t at$s cool "ut t en a "unc of cross flow filter modules is added t ey decide to 8steal9 t e .7 la"el for t ose and c ange t e c emical feed to .E! no wait4can$t do t at! .E is ta&en "y t e centrifuge. <o t ey "ite t e prover"ial "ullet and call t e c emical feed s&id .<;1 w ere < is 8intuitive9 for supply. =ig t6 +ry again ?uiD &id. No"ody is going to see t at as intuitive. #nd t en one day! it its :it=Dun$s process engineers t at t eir initially conceived so;called intuitive tagging system is a eap of "ro&en confusion and no"ody &nows t eir .E$s from t eir .>$s. .ue t e Kac&son 5 song # - .! simple as 1 ( C3 # -etter +ag Num"ering <ystem

+o avert t e pro"lems in erent in t e a"ove e/ample! many process industries utiliDe a numeric;only system for tagging e?uipment. + is elps simplify t e logical categoriDation of e?uipment during t e process design p ase. Joreover! a structured tag system is more intuitive for t e development of design documentation! operating procedures and training! and general documentation up&eep@maintenance. 2it t at in mind %and considering t e points presented earlier in t is Part'! t e following met od is "ut one e/ample of ow to tag process e?uipment using an e/tensi"le system.

#rea Num"er! #N

Jost siDa"le process plants are comprised of multiple areas. #n area is a p ysical! geograp ical! or logical grouping determined "y t e site. It may contain process cells! units! e?uipment modules! and control modules %more details can "e found

at isa.org'. +o facilitate a ierarc ical organiDation of e?uipment! e?uipment tags s ould t en incorporate area designation.

# small or simple pro1ect may ave only one area. .onversely! larger more comple/ pro1ects may ave multiple areas. + e assignment of areas is at t e discretion of t e process engineer and can "e su"1ective. + e only general rule t at I li&e to employ is t at common e?uipment t at serves multiple areas! e.g.! utility and infrastructure system "e placed into a 8.ommon =esources9 area rat er t an "e made a part of any ot er process area. >nce areas ave "een designated for a particular pro1ect type! engineers s ould strive to maintain common area designations on future! similar pro1ects. 7or e/ample! t e areas s own in t e figure a"ove may "e defined on t e lead s eet for a fictitious pro1ect. E?uipment +ypes! E+

E?uipment can "e identified "ased on its type using a numeric system suc as t e simple one s own "elow. In cases w ere e?uipment as multiple functions! user discretion is advised in selecting t e most suita"le type code.

<e?uence Num"er! <U

+ is is t e consecutive num"ering of li&e e?uipment in a particular area. + e se?uence "egins wit F1. #ll e?uipment is to a ave its own se?uence num"er. + e use of alp a"etic or ot er tag suffi/es is to "e avoided. E/ample E?uipment +ags

Lsing t e system outlined a"ove! a four;digit system emerges t at may not "e instantly recogniDa"le in terms of w at t e specific e?uipment is %or w ere'! "ut it will eventually "ecome very familiar to t ose w o are intimate wit t e plant. # few e/amples using t e area num"ers defined a"ove are provided "elowB 11F1 + e first pump in t e tan& farm area. 1SF1 + e first tan& in t e tan& farm area. 1QF5 + e fift mi/er in t e tan& farm area. (EF1 # vendor pac&age in t e +rain 1 area.

+ e e?uipment tag num"er s ould "e prominently displayed near t e sym"ol used for t e e?uipment. 7or e/ample! t e tag num"er for a centrifuge mig t appear as follows on a P0ID.

Aastly! all ma1or e?uipment s ould "e named and provided general specifications in a la"el placed along t e drawing "order. # couple e/amples for a pump and tan& follow.

It is up to your company to decide on t e final formatting! location %some companies li&e to put certain e?uipment la"els near t e top of t e "order'! and w ic particular specifications s ould "e included along wit eac ma1or e?uipment la"el. + e system presented ere is fairly simple and "roadly applica"le. Irrespective of t ese details! I ig ly recommend t at every piece of ma1or e?uipment receive a la"el wit a similar level of detail. Instrument Aoop Num"ers

# "enefit of using four digit e?uipment num"ering system suc as t e one presented a"ove is t at t e tags lend t emselves toward application in defining

associated instrument loops. + is ma&es grouping e?uipment and associated instrumentation devices more logical.

+ in& "ac& to our friends at :it=Dun Process! Inc. + eir tagging system consisted of tags li&e P;1! #:;1! .E;(! etc. + ese tags are not amena"le for use in defining instrument loops. ,owever! a four digit system does neatly tuc& into instrument "u""les and w en you t in& a"out it! most instruments and devices serve or are primarily associated wit a piece of e?uipment. #nd even w en t at is not t e case! t ey can readily "orrow from t e e?uipment type code 8E9 in cases w ere! for instance! a pressure gauge on an air eader serving t e entire area must "e defined.

.onsidering t e a"ove points! t e following instrument and device tagging system is "ut one effective way to tag instruments and devicesB

2 ereN PV device type prefi/ %as per I<# 5.1' EU t e associated e?uipment tag %as defined a"ove' <V duplicate or redundant device suffi/ %see details "elow' Duplicate <uffi/! <V =ules

# suffi/ is provided to accommodate instances were many devices of t e same type are associated wit a given piece of e?uipment. 7or e/ample! a vessel may ave many lines connected to it! eac aving its own actuated valve. +o resolve t ese instances so t at eac device as its own uni?ue loop num"er! t ere are two suffi/ tag met ods t at can "e employed! If a piece of e?uipment as redundant devices associated wit it! an alp a"etic suffi/ may "e appended to t e loop num"er! e.g.! 7*11F1#! 7*11F1-! 7*11F1.! etc. %NoteB =edundant means serving t e same purpose as anot er device in a "ac&up fas ion.' If a piece of e?uipment as multiple items of t e same type! eac of w ic wit different functions %not redundant' t en a numeric system s ould "e employed! e.g.! 7*11F1;1! 7*11F1;(! etc. E/ample Aoop +ags

-ased on t e a"ove discussion! some e/ample loop tags are provided "elow. If needed! t e reader can visit a more t oug discussion in Part C regarding instrument a""reviations. %NoteB In t e e/amples provided! I use t e e/ample #rea Num"ers presented as e/amples a"ove.' PI11F1 # pressure indicator on t e disc arge of t e first pump in t e tan& farm area. A+1SF1 # level transmitter on t e first tan& in t e tan& farm area. I+1QF5 # current transmitter %for t e motor' on t e fift agitator in t e tan& farm area. #E1SF1# >ne of at least two redundant analyDers on t e first tan& in t e tan& farm. ,ence! one would e/pect to see #E1SF1-! #E1SF1.4 as indicated. V*1SF1;1 #n actuated valve on t e first tan& in t e tan& farm area. + e suffi/ ;1 implies t ere are ot er valves associated wit tan& 1SF1 "ut in an alternate service %i.e.! not redundant'. 7or e/ample! V*1SF1;1 may "e on t e inlet to t e tan&! w ile V*1SF1;( may "e on t e outlet. Aine Num"ers

<imilar to e?uipment and instrumentation! every pipe on a P0ID re?uires a uni?ue tag num"er so t at it can "e uni?uely identified during design! or referenced in operating procedures. <ince most lines are also affiliated wit a ma1or piece of e?uipment to w ic t ey connect! I li&e to employ a num"ering system similar to t at used for instrument loops w ere"y t e e?uipment tag is integrated into t e line tag in t e following manner %NoteB DFF( provides an alternate met od t at

employs drawing num"er instead of e?uipment num"er "ut I generally prefer t e met od given "elow.'

V9T<*.TE+B<UTA<

2 ereN V9 t e nominal siDe of t e pipe <*. t e service code for t e material t at normally flows in t e line %see e/amples "elow for list' E+B<*. a uni?ue line tag t at includes two parts! t e e?uipment tag from w ic t e line originates followed "y a uni?ue se?uential num"er A< line specification for t e pipe! including class and material type! valves etc. <ervice .odes! <*.

<ervice codes are a""reviations for t e fluid t e line primarily andles.

<ince some lines can serve many different process fluids! t e fluid used to specify t e materials for t e line s ould go ere. + e list s ould "e availa"le on a lead s eet in a manner similar to t at provided in t e e/ample a"ove. Aine <pecifications! A<

Aine specifications cover all t e details related to t e piping system used to andle t e fluid for t e line. + is s ould include all details regarding material of construction! valves and trim! gas&ets! fittings! +@P limits! and muc more. + is is "eyond t e scope of t is series "ut is suc a critical component of plant design t at I mig t e/pand on t is in a future post. ,and *alves

,and valves re?uire a consistent and clear tagging system for reference in operating procedures. + ere are a num"er of tec ni?ues t at can "e used! "ut one t at I generally prefer is as follows.

In t e e/ample provided at left! one can discern valve siDe! spec and tag num"er. + is mig t "e more information t an you want to include on some P0IDs. In cases w ere you 1ust want to s ow t e valve tag and allow t e spec and siDe to "e derived implicitly from t e line tag! t e following met od is one optionB

8*9 DO <U

2 ereN ,* or * # literal and re?uired part of all and valve tags DO last two digits of P0ID drawing num"er <U <e?uence Num"er %F1 to EE' *FFF1 + e first and valve on P0ID D1FF *1(F5 + e fift and valve on P0ID D1F(

E/ample ,and *alve +ags *FFF1 + e first and valve on P0ID D1FF *1(F5 + e fift and valve on P0ID D1F(

2rap;Lp

7urt er to t e content in t is part! DFF( includes a few more e/amples of common tags and codes applied in P0IDs! suc as insulation! interconnecting arrows! etc. + ese are important parts "ut are pretty self;evident. #side from t at! most companies ave very specific ways and means on t ese items so I won$t cover t em in dept ere.

2ell! I started t is out "y saying it was going to "e fun and simple and I ope you leave t is series feeling li&e I made some solid points t at will "e of value to you going forward. In a follow;up to t is series! I will put toget er a complementary video w ere I ta&e a few typical P0IDs %li&e t e ones I$ve attac ed ere' and discuss all of t ese aspects in w at I ope to "e a muc more engaging manner. 5ou will t en "e a"le to get a muc "etter feel for seeing and earing t is information.

Now venture fort wit your new &nowledge and apply it for good. <tay safe and ave fun. Part 5 <eries *ideos

:ra" some popcorn and turn t e lig ts down! it$s "eer;t irty and time for a "rea&. 2e$ve tal&ed enoug a"out P0IDs! and now it$s time to infuse t e %sometimes' dry material wit a "it dare I say e/citement6 2 ile I$ve ad fun wit t is series and even po&ed fun at myself for "eing a little nerdy %w ic I$m not'! trut is! reading a"out process drawings can get a "it stale.

<o! as I promised at t e outset of t e series! I$ve put toget er a few videos to elp cement and ig lig t aspects t at are ard to do "y t e written word. In so doing! I even manage to slip in some "onus features t at I didn$t tal& a"out in t e written parts of t is series3

7irst! an introductory videoB >r you can ead on over to my page at 5ou+u"e to c ec& t em out3 ,intB -e sure to start wit t e introductory video and wor& your way down t e series. <ince 5ou+u"e limits videos to 15 min eac ! I ad to "rea& some of t e videos up into parts.

+ ese videos don$t cover t e second lead and ot er items t at I want to cover. I plan to cover t ose in an appended post.

7ol&s! t an&s for anging toug wit me on t is e/tended 1ourney. I put you t roug it "ecause it$s important stuff and! in all onesty! I still love tal&ing a"out it. #ristotle said 8Pleasure in t e 1o" puts perfection in t e wor&.9

; -o"

Вам также может понравиться

- Okay Data LoggerДокумент4 страницыOkay Data LoggerAnonymous HFIQgANMQОценок пока нет

- General Data Logger ReviewДокумент7 страницGeneral Data Logger ReviewAnonymous HFIQgANMQОценок пока нет

- Middle Range General Data LoggerДокумент3 страницыMiddle Range General Data LoggerAnonymous HFIQgANMQОценок пока нет

- Bimetalic ThermometerДокумент6 страницBimetalic ThermometerAnonymous HFIQgANMQОценок пока нет

- CalibrationBrochure 2016 REVДокумент2 страницыCalibrationBrochure 2016 REVAnonymous HFIQgANMQОценок пока нет

- 5762N Tinsley DatasheetДокумент2 страницы5762N Tinsley DatasheetAnonymous HFIQgANMQОценок пока нет

- Valves PDFДокумент12 страницValves PDFAnonymous HFIQgANMQОценок пока нет

- Reed Relay Data SheetДокумент8 страницReed Relay Data SheetAnonymous HFIQgANMQОценок пока нет

- Description & Features:: Specifications Dial Case LensДокумент7 страницDescription & Features:: Specifications Dial Case LensAnonymous HFIQgANMQОценок пока нет

- 2011 PRT Report Cal Certificate Sample PDFДокумент3 страницы2011 PRT Report Cal Certificate Sample PDFAnonymous HFIQgANMQОценок пока нет

- Life Membership Form: Under The Aegis of The Embassy of IndiaДокумент1 страницаLife Membership Form: Under The Aegis of The Embassy of IndiaAnonymous HFIQgANMQОценок пока нет

- Description & FeaturesДокумент3 страницыDescription & FeaturesAnonymous HFIQgANMQОценок пока нет

- Manual Supplement: © 2013-2015 Fluke Corporation. All Rights ReservedДокумент2 страницыManual Supplement: © 2013-2015 Fluke Corporation. All Rights ReservedAnonymous HFIQgANMQОценок пока нет

- TKSA 20 Data SheetДокумент2 страницыTKSA 20 Data SheetAnonymous HFIQgANMQОценок пока нет

- Truly Portable Insulation Resistance TestersДокумент1 страницаTruly Portable Insulation Resistance TestersAnonymous HFIQgANMQОценок пока нет

- HV Divider Dvr150 - BrochureДокумент1 страницаHV Divider Dvr150 - BrochureAnonymous HFIQgANMQОценок пока нет

- Fluke 80CK M Datasheet PDFДокумент1 страницаFluke 80CK M Datasheet PDFAnonymous HFIQgANMQОценок пока нет

- Master Thermocouple TTCДокумент1 страницаMaster Thermocouple TTCAnonymous HFIQgANMQОценок пока нет

- Extexh - Vibration MeterДокумент1 страницаExtexh - Vibration MeterAnonymous HFIQgANMQОценок пока нет

- CR:511F Acoustic Calibrator: FeaturesДокумент2 страницыCR:511F Acoustic Calibrator: FeaturesAnonymous HFIQgANMQОценок пока нет

- Fully Automated Three Phase Transformer Turns Ratio Meter: Features and BenefitsДокумент4 страницыFully Automated Three Phase Transformer Turns Ratio Meter: Features and BenefitsAnonymous HFIQgANMQОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Halfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PДокумент92 страницыHalfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PTulusОценок пока нет

- Process Costing Exercises Series 1Документ23 страницыProcess Costing Exercises Series 1sarahbeeОценок пока нет

- 9 5 - 358 362 PDFДокумент5 страниц9 5 - 358 362 PDFمالك مناصرةОценок пока нет

- AssessmentДокумент3 страницыAssessmentpalflaxОценок пока нет

- Plans PDFДокумент49 страницPlans PDFEstevam Gomes de Azevedo85% (34)

- 外贸专业术语Документ13 страниц外贸专业术语邱建华Оценок пока нет

- Worksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)Документ6 страницWorksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)AswithОценок пока нет

- Provision of EPCI Services For EPCIC Sidayu Wellhead Platforms and Pipelines Sidayu Field DevelopmentДокумент7 страницProvision of EPCI Services For EPCIC Sidayu Wellhead Platforms and Pipelines Sidayu Field Developmentriandi100% (1)

- 1762 Ob8 PDFДокумент16 страниц1762 Ob8 PDFRodríguez EdwardОценок пока нет

- Cynosure Starlux 500 Palomar Technical Service ManualДокумент47 страницCynosure Starlux 500 Palomar Technical Service ManualJF SilvaОценок пока нет

- The Indian Mining Sector: Effects On The Environment & FDI InflowsДокумент10 страницThe Indian Mining Sector: Effects On The Environment & FDI InflowsMehul MandanakaОценок пока нет

- Nasopharyngeal Angiofibroma - PPTX Essam SrourДокумент10 страницNasopharyngeal Angiofibroma - PPTX Essam SrourSimina ÎntunericОценок пока нет

- EN Manual Lenovo Ideapad S130-14igm S130-11igmДокумент33 страницыEN Manual Lenovo Ideapad S130-14igm S130-11igmDolgoffОценок пока нет

- Learning Activity Sheets Introduction To World Religions and Belief SystemДокумент56 страницLearning Activity Sheets Introduction To World Religions and Belief SystemAngelica Caranzo LatosaОценок пока нет

- Standard Cost EstimateДокумент21 страницаStandard Cost EstimateMOORTHYОценок пока нет

- Ham Radio Balu N ManualДокумент7 страницHam Radio Balu N Manualcolinbeeforth100% (1)

- AKI in ChildrenДокумент43 страницыAKI in ChildrenYonas AwgichewОценок пока нет

- Tuberculosis PowerpointДокумент69 страницTuberculosis PowerpointCeline Villo100% (1)

- Gamak MotorДокумент34 страницыGamak MotorCengiz Sezer100% (1)

- Drilling & GroutingДокумент18 страницDrilling & GroutingSantosh Laxman PatilОценок пока нет

- Food Taste Panel Evaluation Form 2Документ17 страницFood Taste Panel Evaluation Form 2Akshat JainОценок пока нет

- Rekomendasi AnimeДокумент11 страницRekomendasi Animeosvaldo manurungОценок пока нет

- 123 09-Printable Menu VORДокумент2 страницы123 09-Printable Menu VORArmstrong TowerОценок пока нет

- Oil Whirl and Whip Instabilities - Within Journal BearingsДокумент27 страницOil Whirl and Whip Instabilities - Within Journal BearingsTalha AamirОценок пока нет

- CapstoneДокумент23 страницыCapstoneA - CAYAGA, Kirby, C 12 - HermonОценок пока нет

- Seminar On Solar Mobile Charger: Submitted To: Submitted byДокумент16 страницSeminar On Solar Mobile Charger: Submitted To: Submitted byAkhila GottemukkulaОценок пока нет

- Hydraulic Fan Speed - Test and AdjustДокумент12 страницHydraulic Fan Speed - Test and Adjustsyed ahmedОценок пока нет

- 41z S4hana2021 Set-Up en XXДокумент46 страниц41z S4hana2021 Set-Up en XXHussain MulthazimОценок пока нет

- Goliath 90 v129 eДокумент129 страницGoliath 90 v129 eerkanОценок пока нет

- H107en 201906 r4 Elcor Elcorplus 20200903 Red1Документ228 страницH107en 201906 r4 Elcor Elcorplus 20200903 Red1mokbelОценок пока нет