Академический Документы

Профессиональный Документы

Культура Документы

Us 20130139424

Загружено:

tyrer567899Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Us 20130139424

Загружено:

tyrer567899Авторское право:

Доступные форматы

US 20130139424A1

(19) United States (12) Patent Application Publication (10) Pub. N0.: US 2013/0139424 A1

Devine

(54) MULTI CALIBER QUICKLY RECONFIGURABLE AUTOMATIC MACHINE GUN

. . . ,

(43) Pub. Date:

F41 C 23/22 F41A 15/12 (52) us. Cl.

USPC ................ ..

Jun. 6, 2013

(2006.01)

(2006.01)

42/16; 42/25; 42/75.02; 42/71.01

(76) Inventor: Benjamin Cory Devine, Hillsboro, OH

(Us)

(21) Appl. No.: 13/312,738

(22) Filed: Dec. 6, 2011 Publication Classi?cation

(2006.01) (2006.01)

(57)

ABSTRACT

An automatic machine gun capable of being quickly recon ?gured to ?re different calibers of ammunition. The elements

necessary to recon?gure the Weapon are all stored and con

(51)

Int. Cl.

F41A 3/12 F41A 21/00

tained Within the stock of the Weapon. The recon?guration process does not require any external tools.

' Excessive text removed as per

notice to ?le corrected papers 1112/2612

9 of the ?ied

ape mm .m .0. eiemem descriptions

Patent Application Publication

Jun. 6, 2013 Sheet 1 of7

US 2013/0139424 A1

v2 xi gmauma .mm

Patent Application Publication

Jun. 6, 2013 Sheet 2 0f 7

US 2013/0139424 A1

Fig. A3 Prior Art

Fig. A4 Doubie Extractor Ciaw

Extractm? Biaw

Eiecto-r Button

Right Extractor (24)

Left Extractor (25)

Bolt Body (22)

Patent Application Publication

Jun. 6, 2013 Sheet 3 0f 7

US 2013/0139424 A1

Fig. 81 Gperatianal P?sitinn

5:5

Fig. 82 Opened Pesitian

Fig. 83 Remove and Repiace Barret

Patent Application Publication

Jun. 6, 2013 Sheet 4 0f 7

US 2013/0139424 A1

Fig. {ii Staiiz; Posaitisn

Fig, (33 Ruiatm Meshanmn Qeweawd

2'!

1

_>

i9

/.*' 2Q

22

Patent Application Publication

Jun. 6, 2013 Sheet 5 0f 7

US 2013/0139424 A1

Fig D1 Stewed Position

E an

Patent Application Publication

Jun. 6, 2013 Sheet 6 0f 7

US 2013/0139424 A1

bmnzQ,mwxbEu2Smu

m@E 8u39s5;a 5 8 NEgQN.

Patent Application Publication

Jun. 6, 2013 Sheet 7 of7

US 2013/0139424 A1

Pica F? - Siwrt Bazrs'ai m: Quit SStcmk

we

Ea. iii Shari Bane;

w

But? Stack

US 2013/0139424 A1

Jun. 6, 2013

MULTI CALIBER QUICKLY

RECONFIGURABLE AUTOMATIC MACHINE GUN DESCRIPTION OF DRAWINGS

This capability allows the war?ghter to effectively con?gure

the weapon for engaging the enemy at long range as well as in

[0001] Drawing A001iEjector and Extractor Mechanism

close quarters. This represents a signi?cant advantage over other modular weapons which can be recon?gured. The ele ments used to recon?gure other modular weapons must be carried separately from the weapon and require the use of

(Plan Section)

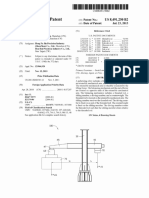

[0002] [0003] FIG. AliBolt Full Back Position FIG. A2iBolt Full Forward Position

[0004] Drawing A002iEj ector and Extractor Mecha nismiPrior Art (Elevation) [0005] FIG. A3iPriorArt [0006] FIG. A4iDouble Extractor [0007] Drawing B001iSection of Barrel Recon?guration

tools to replace. [0026] The bolt of this weapon can be quickly recon?gured to handle different caliber ammunition by replacing the por tion of the bolt containing the extractor mechanisms without replacing the entire operational bolt of the weapon.

[0027] The multiple extractor system gives 120 degrees of extracting coverage (FIG. A4) at the base of the shell casing

verses less than 50 degrees on a modern AR style ri?e (FIG. A3). This innovation is achievable because one extractor also acts as the ejector. When the bolt travels backward an ejector ram hits a lug on the outside of the extractor. During this

(Elevation Section)

[0008] [0009] [0010]

[0012] [0013] [0014] [0016] [0017]

FIG. B14Operational Position FIG. B24Open Position FIG. B3iRemove and Replace Barrel

FIG. CliStatic Position FIG. C2iRotator Mechanism Depressed FIG. C3iExtractor Claw Mechanism FIG. DliStowed Position FIG. D2iRemoved Position

action the Right Extractor (24) holds the right lip of the casing

while the Left Extractor (25) moves forward. A second lug on the inside of the Left Extractor (25) strikes the back of the

[0011] Drawing C001iBolt Recon?guration (Axon)

casing forcing the cartridge out of the weapon.

DESCRIPTION OF PREFERRED EMBODIMENT

[0015] Drawing D001iStock Storage (Axon)

[0018] Drawing M001iDiagram of Parts (Exploded

Description

[0028] The design is composed of a three part stock com

Elevation)

[0019] Drawing F001iExamples of Preferred Embodi

ment

prised of a Left Stock (55) Right Stock (56) and MagaZine

Stock Bracket (52). The main components which are attached

to the stock include the Left Barrel Housing Hinge (50), Right

FIG. FliLong Barrel and Butt Stock (Elevation)

FIG. F2iShort Barrel no Butt Stock (Elevation) FIG. F3iShort Barrel no Butt Stock (Axon)

BACKGROUND OF INVENTION

[0020]

[0021] [0022]

Barrel Housing Hinge (51), MagaZine Receiver (53),

Receiver Block (49), Master Connector Bracket (61) and Butt Stock Mount (66). [0029] The Barrel Housing Closure (44), Bolt Pull Rod

Cover (34), Gas Piston (43), Front Sight (42), Charging Handle Retainer (35) Charging Handle Spring (37), Charging

Handle (36) all attach to the Barrel Housing (47) while the Main Spring (45), and the Bolt Pull Rod (38), go inside The Barrel Housing (47). This assembly attaches to the Barrel Housing Hinges (50,51). The Barrel (58 or 59) is inserted into the Barrel Housing and the Barrel Housing Latch (46)

engages the receiver block to hold the Barrel Housing in

General Purpose

[0023] The purpose for this gun design arises from the varied battle?elds and combat scenarios faced by US combat forces throughout the world. This automatic machine gun is designed with the ability to quickly and without the use of tools switch barrels and bolts allowing the war?ghter to quickly recon?gure their weapon in the ?eld of battle. Also as part of this design the components used to recon?gure the

weapon are stored within compartments which are integrated into the stock of the weapon. As an integrated weapons sys

place.

[0030] The Trigger Assembly is comprised of the Trigger

tem this design integrates all of the standard machine gun design elements necessary to provide accurate and sustained automatic ?re as well as add the bene?ts of quick recon?gu

ration to barrels of different length as well as barrels and bolts

Group Bracket (4), Trigger (1), Safety (2), Trigger Bolt (3), MagaZine Release (5), Hammer Bolt (6), Secondary Firing Spring (7), MagaZine Release Pin (8), MagaZine Catch Spring (9), MagaZine Catch (10), Secondary Firing Mecha

nism (11), Hammer Spring (12), Hammer Arrestor (13),

Hammer (14), Left Trigger Group Plate (15), Right Trigger

Group Plate (16). The Trigger Group Assembly is attached to

the stock with a pin though the Master Connector Bracket

of three different common military calibers. Furthermore, the

convenient storage of the components used for recon?gura

tion on the weapon itself makes this design a self contained

(61).

[0031] The Bolt is comprised ofthe Bolt Slide (21) which is screwed to the Bolt Body (22). The Rotator Mechanism is inserted into the bolt body as well as the Firing Pin Spring

weapons system.

SUMMARY OF INVENTION

(19) and the Firing Pin (18) all of which is held in place by the

Bolt Closure (17). The Extractor Claw Mechanism is com

[0024] This weapon is designed to be recon?gured to handle three common military calibers 0.308, 0.223/5.

56X45, and 7.62X39. The weapon carries one bolt in the

prised of the Upper Extractor Claw Body (23), Lower Extrac tor Claw Body (26), Right Extractor Claw (24), Left Extractor

Claw (25). The Extractor Claw Mechanism is inserted into Bolt.

operational position and one auxiliary Extractor Claw Mechanism (23/24/25/26) in the storage position.

[0025] The weapon also carries one barrel in the operation

position and one auxiliary barrel in the storage position. The

weapon can deploy and store a barrel between 10" and 21"

[0032] The Upper is comprised chie?y of the Bolt Housing Upper (29) and the Bolt Housing Pull Rod Cover (33).

Attached to these pieces are Extractor Ram Housing (30),

US 2013/0139424 A1

Jun. 6, 2013

Extractor Ram Spring (31), and Extractor Ram (32). This assembly is attached to the Weapon by a pin though the Bolt

Bolt Slam Automatic Action:

Housing Upper Hinge (28) into the Butt Stock Mount (66).

The bolt is inserted into the slid rail of the Bolt Housing Pull Rod Cover (33). The Upper is held in place When the Barrel

[0039] The automatic ?re capability of this Weapon is achieved by utiliZing the forWard motion of the bolt to release

the hammer. The ?rst shot is ?red by pulling the Trigger (1)

rearWard. This releases the HammerArrestor (13) thus releas ing the Hammer (14) to strike the Firing Pin (18). As the

Housing assembly is locked into position.

Use

Hammer (14) strikes the Firing Pin (18) the cartridge is dis

charged. High pressure gas exits through a hole in the barrel and is released into the Bolt Pull Rod (38). This forces the Bolt Pull Rod (38) and equally the bolt rearWards. As the bolt travels rearWard the Hammer (14) is forced doWn engaging the Hammer Arrestor (13). As the bolt slides forWard the hammer tensions the Hammer Arrestor (13) Which is stopped

Recon?guration:

[0033] One of the chief innovations of this design is the Weapons ability to quickly change barrels and bolts Without the use of tools. The Barrel (58 or 59) is replaced by sliding

the Barrel Housing Latch (46) on the side of the Barrel Hous

ing (47) forWard. The Barrel Housing (47) is secured to the Stock (56/57) by the Bolt Housing Hinge (50/51) at the very end of the forestock. Once the Barrel Housing Latch (46) is

slid forWard the Barrel Housing (47) rotates upWard on the

in position by the Secondary Firing Mechanism (11). As the bolt travels forWard it trips the Secondary Firing Mechanism

(11) Which releases the Hammer Arrestor (13) Which in turn

releases the Hammer (14) starting the ?ring cycle over again.

Double Extractor ClaW:

Bolt Housing Hinge (50/ 51) alloWing the barrel to be

removed backwards out Barrel Housing (47). [0034] The desired replacement barreled can then be inserted into the Barrel Housing (47) through the Main Spring

[0040]

The Extractor ClaW Mechanism (FIG. A1 and A2)

of this Weapon features a Left Extractor ClaW (25) and Right Extractor ClaW (24). This provides a positive extraction of the

(45) and through the yoke of the Bolt Pull Rod (38). (FIG. B2) The Barrel Housing (47) is then rotated into the operational position (FIG. B1) locking the barrel into the Weapon. A lug

near the breech of the barrel assures proper alignment of the barrel. I rubber peg near the hinge tensions the barrel tight to

empty cartridge from the barrel chamber. (FIG. A1) The Right

Extractor ClaW (24) is stationary While the Left Extractor ClaW (25) moves forWard When engaged by the Extractor Ram (32) upon cocking the bolt into the fully rearWard posi

tion or in ?ring When the Bolt Pull Rod (38) moves the bolt

the stock increasing accuracy. The Barrel Housing Latch (46) secures the Barrel Housing (47) into position for operation. This simple system for barrel replacement makes a quick

recon?guration of the Weapon to handle barrels of different

fully rearWard.

Recon?guration Unit Storage:

[0041] The ability of this gun to store an extra Extractor

lengths and caliber possible. [0035] The bolt is recon?gured by removing the portion of

the bolt containing the Extractor ClaW Mechanism (23/ 24/ 25/

ClaW Mechanism (23/ 24/ 25/26) and Barrel (58/59) Within the

Weapon itself is a signi?cant battle?eld advantage. The Barrel (58/59) is stored in a tube Which is an integrated part of the Stock (56/57). A spring loaded Barrel Tube Lid (65) at the loWer end of tube retains the barrel Within the tube. The extra Extractor ClaW Mechanism (23/24/25/26) is stored in the Extractor ClaW Dock (62) Which slides into handle of the Weapon. The Extractor ClaW Dock (62) is slid out the side of

the handle to access the Extractor ClaW Mechanism (23/24/

26) from the Bolt Body (22) This is done by ?rst opening the Barrel Housing (47). The Master Assembly Pin (67) is then rotated 90 degrees and removed partially alloWing the Bolt

Housing Upper (29) to rotate rearWard. The bolt can then be slid forWard out of the Bolt Pull Rod Cover (33) Which is

a?ixed to the Bolt Housing Upper (29). To recon?gure the

bolt the Rotator Mechanism (20) is rotated counterclockWise until fully depressed. This alloWs the Extractor ClaW Mecha nism (23/24/25/26) to be rotated clockWise aligning the retaining lugs With slots in the main bolt. This alloWs the Extractor ClaW Mechanism (23/24/25/26) to be slid forWard

25/26). Manufacturing

[0042] l. The stock is injection molded from Impact Resis tant ABS plastic. The stock is composed of a Left Stock (56), a Right Stock (57), and a MagaZine Stock Bracket (52) These pieces are assembled using standard screWs and ferrules. The

and removed from the Bolt Body (22). [0036] With the Rotator Mechanism (20) fully depressed

the desired Extractor ClaW Mechanism (23/24/25/26) can

then be inserted into the Bolt Body (22). Once the Rotator Mechanism (20) is released the Extractor ClaW Mechanism (23/24/25/26) Will be locked into the bolt. [0037] This Weapon also features a Main Spring (45) Which is forWard of the bolt and surrounding the barrel. This feature is designed to decreases muZZle rise and makes the overall Weapon shorter by eliminating a spring behind the bolt. This

Bolt Housing Closure (44), Extractor ClaW Dock (62), Butt

Stock (70), and Butt Stock Pad (71) are also constructed of

Impact Resistant ABS plastic.

[0043] 2.All Barrels (58/59) are constructed of lathed stain less steel

[0044]

[0045]

3. Bolt Pull Rod Cover (34) and Bolt Housing Pull

4. All bolt elements include Rotator Mechanism

spring pushes against the breech driving the Bolt Pull Rod (38) forWard pulling the bolt into the breech and engaging the locking bolt locking lugs into the breech. [0038] This design also features an automatically releasing magaZine. When the magaZine is empty a spring Within the magaZine folloWer pushes a stud through the magaZine catch hole pushing the magaZine catch out of the magaZine and releasing the magaZine to fall free of the Weapon.

Rod Cover (33) are cast from steel and milled to reach ?nal ?nished state.

(20) Bolt Body (22) Firing Pin (18) Bolt Closure (17) Extrac

tor ClaW Mechanism (23/24/25/26) are constructed of milled stainless steel. The Bolt Closure screWs into the back of the

Bolt Body retaining the Bolt Spring (19) Rotator Mechanism (20) and Firing Pin (18) Within the Bolt Body (22) The Extractor ClaW Mechanism is constructed by placing the lugs

US 2013/0139424 A1

Jun. 6, 2013

of the Right Extractor Claw (24) and the Left Extractor ClaW (25) into the slots on the Extractor ClaW LoWer (26). The Extractor Claw Upper (23) is then placed on top and the edges of the Extractor ClaW Upper (23) and Extractor ClaW LoWer (26) are Welded together.

[0050] 9. All operational springs are constructed of spring

steel.

1. A bolt Which can be recon?gured to hold and ?re car

tridges of different calibers by means of replacing and or

[0046] 5. All other metallic pieces including Trigger (1),

Safety (2), Trigger Bolt (3), Trigger Group Bracket (4),

Magazine Release (5), Hammer Bolt (6), Magazine Release Pin (8), Magazine Catch (10), Secondary Firing Mechanism (11), Hammer Arrestor (13), Hammer (14), Left Trigger Group Plate (15), Right Trigger Group Plate (16), Bolt Hous ing Upper Latch (27), Bolt Housing Upper Hinge (28), Ej ec tor Ram Housing (30), Ejector Ram (32), Charging Handle Retainer (35), Charging Handle (36), Bolt Pull Rod (38),

Receiver Cover (40), Receiver Cover Bracket (41), Front

otherWise modifying the portion of the bolt containing the mechanism for holding and or extracting the cartridge. (FIG. C1, C2, C3) The portion of the bolt containing the mechanism for holding and or extracting the cartridge may also include other elements including but not limited to ?ring pin, ?ring

pin spring, and any mechanisms used to rotate the bolt for

locking into the breech, excluding only the main housing used

to contain these parts conventionally.

2. A cartridge extractor system Where, one or more of the mechanisms used to extract the cartridge from the Weapon chamber, is also used as the mechanism Which ejects the

Sight (42), Gas Piston (43), Barrel Housing Latch (46), Barrel Housing (47), Receiver Block (49), Left Barrel Housing

cartridge from the breech of the Weapon. (FIG. A1, A2) 3. And Where multiple extractors interface the cartridge

from disconnected positions around the axis of the center of

Hinge (50), Right Barrel Housing Hinge (51), Trigger Guard

(60) Master Connector Bracket (61), Barrel Tube Lid (64) Butt Stock Mount (66), MasterAssembly Pin (67), Butt Stock Bracket (68), Butt StockArm (69), Catch Bracket (72), Catch

(73), Catch Lever (74) are constructed of milled stainless

steel.All metal elements are parkerized on faces not subject to

abrasion and Wear.

the cartridge. (FIG. A4)

4. A Weapon Where the barrel is inserted into a mechanism

rotating parallel to the length of the barrel With the purpose of removing and replacing the barrel. The mechanism is rotated

aWay from the Weapon to remove the barrel and rotated into

operational position When the barrel is ready for ?ring action.

[0047]

6. The Magazine Receiver (53) is stamped and

(FIG. B1, B2, B3)

5. A Weapon Where the components for recon?guring the

Weapon are stored in the body of the Weapon for quick access. A Weapon Which has space to hold the extra bolt adapter

formed from sheet steel. The Magazine (54) is constructed of

punched sheet steel elements held together by punched sheet

steel elements spot Welded into position. [0048] 7. The Barrel Tensioning Block (48) is constructed

of vulcanized rubber [0049] 8. All screWs and ferrules are hardWare store grade.

mechanism comprised of the portion of the bolt for holding and or extracting the cartridge and Which also has space to hold at least one extra replacement barrel. (FIG. D1, D2)

* * * * *

Вам также может понравиться

- US20110274550A1Документ9 страницUS20110274550A1雷黎明Оценок пока нет

- Brief Description of The: Semi-Automatic RifleДокумент53 страницыBrief Description of The: Semi-Automatic Riflejustin_j_gaudet100% (1)

- Toy Derringer Handgun Firing Mechanism PDFДокумент5 страницToy Derringer Handgun Firing Mechanism PDFyuehan0% (1)

- Us4358986 PDFДокумент9 страницUs4358986 PDFJin SongОценок пока нет

- United States Patent (19) : HoenigДокумент5 страницUnited States Patent (19) : HoenigminiselОценок пока нет

- United States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashДокумент7 страницUnited States Patent (19) : (75) Inventor: Nahemia Sirkis, King County, WashSandeep SОценок пока нет

- Zastava ZC 99 Precision DespieceДокумент20 страницZastava ZC 99 Precision Despiecejose luis vidal prietoОценок пока нет

- TM Ep 206a German 7 9 MM Dual Purpose Machine Gun Mg34 13 April 1943 PDFДокумент71 страницаTM Ep 206a German 7 9 MM Dual Purpose Machine Gun Mg34 13 April 1943 PDF@macОценок пока нет

- Recoil Spring - Disassemble: Disassembly and AssemblyДокумент6 страницRecoil Spring - Disassemble: Disassembly and Assemblyeshopmanual limaОценок пока нет

- A 3 Dis AssemblyДокумент48 страницA 3 Dis AssemblyubichОценок пока нет

- Recoil Spring - Disassemble: Disassembly and AssemblyДокумент7 страницRecoil Spring - Disassemble: Disassembly and AssemblyNidya Wardah JuhanaОценок пока нет

- TEPZZ - 97 9B - T: European Patent SpecificationДокумент24 страницыTEPZZ - 97 9B - T: European Patent SpecificationСлэйтер Строительная компанияОценок пока нет

- Stoner 63 LMG ManualДокумент43 страницыStoner 63 LMG ManualGasMaskBob100% (3)

- Us 4407085Документ5 страницUs 4407085Слэйтер Строительная компанияОценок пока нет

- Us4252504 PDFДокумент7 страницUs4252504 PDFAhmed EltemsahОценок пока нет

- Stoner 63A Rifle ManualДокумент47 страницStoner 63A Rifle ManualGasMaskBobОценок пока нет

- TM 9 1276 Carbines Cal 30 M1 M1A1 M2 and M3 1947Документ111 страницTM 9 1276 Carbines Cal 30 M1 M1A1 M2 and M3 1947hammonje100% (3)

- US Army Operator's Manual For The AK-47 Assault Rifle: 203d Military Intelligence BattalionДокумент33 страницыUS Army Operator's Manual For The AK-47 Assault Rifle: 203d Military Intelligence BattalionAlexis DragonОценок пока нет

- "Tank, Combat, 120 MM GUN, Challenger" - Part 2 "Fighting Systems"Документ439 страниц"Tank, Combat, 120 MM GUN, Challenger" - Part 2 "Fighting Systems"Denis89% (18)

- Colt's Double Action Revolver 45 M1909Документ32 страницыColt's Double Action Revolver 45 M1909Tim Bonine100% (1)

- Stoner 63 MMG ManualДокумент44 страницыStoner 63 MMG ManualGasMaskBobОценок пока нет

- EP1321438B1Документ10 страницEP1321438B1Alessandro PatanèОценок пока нет

- Operating InstructionsДокумент34 страницыOperating InstructionsCarlos IntriagoОценок пока нет

- Us4522105 PDFДокумент10 страницUs4522105 PDFJin SongОценок пока нет

- Overview of WWII Vehicular MountsДокумент30 страницOverview of WWII Vehicular Mountsali059100% (3)

- ремонт рулевой рейки е39Документ65 страницремонт рулевой рейки е39qqwwОценок пока нет

- Us4854065 PDFДокумент7 страницUs4854065 PDFJin SongОценок пока нет

- cz52 Detail StripДокумент22 страницыcz52 Detail StripKirk LawsonОценок пока нет

- The Jewell Trigger ManualДокумент7 страницThe Jewell Trigger ManualFrederik LavoieОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0257940 A1Документ13 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0257940 A1gowdas2011Оценок пока нет

- BMW e39 Ремонт рулевой рейки тип 7831 7832 7852 только СервотроникДокумент61 страницаBMW e39 Ремонт рулевой рейки тип 7831 7832 7852 только СервотроникqqwwОценок пока нет

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Документ15 страницUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Jin Song100% (1)

- FM 23-32, 3.5 Inch Rocket LauncherДокумент113 страницFM 23-32, 3.5 Inch Rocket LauncherSOKUEN JUNGОценок пока нет

- United States Carbines, Caliber .30, M1, M1A1, M2 and M3 TM 9-1276 - 1947 PDFДокумент109 страницUnited States Carbines, Caliber .30, M1, M1A1, M2 and M3 TM 9-1276 - 1947 PDFDana Phillips100% (1)

- TM 9-1305 (Gun and Carriage, 75-MM, M1897, All Types, and PDFДокумент159 страницTM 9-1305 (Gun and Carriage, 75-MM, M1897, All Types, and PDFferdockm100% (1)

- FM23-45 Browning 1919 Machine GunДокумент35 страницFM23-45 Browning 1919 Machine GunjeffОценок пока нет

- QuestionДокумент2 страницыQuestionMoe MyuОценок пока нет

- Description of The Automatic Pistol, Caliber .45, Model of 1911Документ38 страницDescription of The Automatic Pistol, Caliber .45, Model of 191145jackОценок пока нет

- Pros Man II Handout 02 Turning 1Документ41 страницаPros Man II Handout 02 Turning 1Andriono SlametОценок пока нет

- 071-030-0001 (SL1) - Maintain An MK19 Machine GunДокумент16 страниц071-030-0001 (SL1) - Maintain An MK19 Machine Gungearhead1Оценок пока нет

- Revolver PatentДокумент5 страницRevolver PatentdududadamikeОценок пока нет

- Chicago Updated "Assault Weapon" OrdinanceДокумент13 страницChicago Updated "Assault Weapon" Ordinancetngbl100% (1)

- Machining Process 2 MarkДокумент23 страницыMachining Process 2 MarkM.ThirunavukkarasuОценок пока нет

- Pump Governer D6m Rastavljanje I SatavljanjeДокумент33 страницыPump Governer D6m Rastavljanje I SatavljanjezeljkoОценок пока нет

- Colt 1911 ManualДокумент14 страницColt 1911 ManualLouis Neri100% (11)

- US5304036Документ24 страницыUS5304036wen longОценок пока нет

- 242B3 - M.serviceДокумент2 226 страниц242B3 - M.serviceJuliano Daiana Muller SantosОценок пока нет

- Us 4407085Документ5 страницUs 4407085rte678Оценок пока нет

- United States Patent (10) Patent No.: US 8.491,250 B2Документ10 страницUnited States Patent (10) Patent No.: US 8.491,250 B2RoyLoraGallardoОценок пока нет

- Caterpillar Cat 329DL EXCAVATOR (Prefix WLT) Service Repair Manual (WLT00001 and Up) PDFДокумент22 страницыCaterpillar Cat 329DL EXCAVATOR (Prefix WLT) Service Repair Manual (WLT00001 and Up) PDFfkdmmaОценок пока нет

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheОт EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Prompting Science and Engineering Students in Practical TrigonometryОт EverandPrompting Science and Engineering Students in Practical TrigonometryОценок пока нет

- Operation Barbarossa: the Complete Organisational and Statistical Analysis, and Military Simulation, Volume IОт EverandOperation Barbarossa: the Complete Organisational and Statistical Analysis, and Military Simulation, Volume IОценок пока нет

- Ammunition, Demystified: The (non) Bubba's Guide to How Ammo Really WorksОт EverandAmmunition, Demystified: The (non) Bubba's Guide to How Ammo Really WorksОценок пока нет

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsОт EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsОценок пока нет

- EP0566320B1Документ14 страницEP0566320B1duffy5555Оценок пока нет

- EP0423678A2Документ13 страницEP0423678A2karl56aОценок пока нет

- EP0423677A2Документ11 страницEP0423677A2karl56aОценок пока нет

- Ep0252036b1 PDFДокумент12 страницEp0252036b1 PDFdfus603Оценок пока нет