Академический Документы

Профессиональный Документы

Культура Документы

Template Seat Heat Peeland Stick Heater Control Planposted

Загружено:

vfuntanillaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Template Seat Heat Peeland Stick Heater Control Planposted

Загружено:

vfuntanillaАвторское право:

Доступные форматы

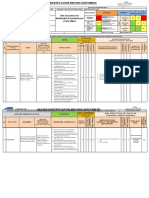

Supplier Standards Manual Seat Heat Peel and Stick Heater Control Plan Chapter 7 Quality Section March

2008 Revision 1.0

Document #: Program: Model Year: RFQ # / Basis #: Back Office Chief / Manager Back Office Lead Program Manager Phase: ECO #: Rev: A

1444481

Template - Peel and Stick Heater Control Plan

N/A N/A Deana Borghi Joe Hebda Robert Hicks N/A

Change Description: Initial Release Date:

Supplier Standards Manual Seat Heat Peel and Stick Heater Control Plan Chapter 7 Quality Section March 2008 Revision 1.0

Control Plan Form Instructions

Responsibility The Quality Manager is responsible for defining the control methods and the reaction plan, and approving and maintaining the Control Plan for the system or subsystem (i.e., Components, etc) level product manufactured at the AG plant. The Product Engineer is responsible for delivering the information about the part number and description, the product and process characteristics, the significant and critical (SC/CC), and the Design Failure Mode and Effects Analysis (DFMEA) results where they relate to the Control Plan. The Manufacturing Engineer is responsible for delivering PFMEA and the process steps and description information.

Instruction: The AQE/QE develops a Control Plan taking into consideration all requirements applicable to the system or subsystem (I.e. , Components, etc) level product manufactured at the AG plant. The AQE/QE must review the FMEA forms to identify the necessary controls. Special consideration must be given to Critical and Significant characteristics The Control Plan form has 3 distinct forms that must be completed at the required phase in the PLUS process: DV Build Control Plan: completed to support the development of prototype builds. Pre-launch Control Plan: completed after the Prototype Control Plan with the introduction of saleable vehicle builds made from production tools; used until all customer and AG requirements are met. Production Control Plan: Provided with Customer Part Submission and becomes effective upon customer approval. The above Control Plans must include/identify all known Customer Special Characteristics, AG internal Special Characteristics and Safety/Regulatory requirements (i.e., All SCs and CCs). applicable to the system or subsystem (i.e., Components, etc) level product manufactured at the AG plant. Customer SC/CCs, including those controlled at suppliers, must be addressed in the control plan. AG SC/CCs controlled in the manufacturing process must be addressed in the control plan. Note: System or subsystem level SC/CCs may be controlled at internal or external supplier/s. In this case, the AQE should complete all fields on the Control Plan up to and including the Evaluation Method field. A suggested reference in the Evaluation Method through Reaction Plan fields would be , "See Supplier Control Plan/s".

Continuous Compliance Test (CCT) requirements are reflected in the Control plan or the control plan may refer to the DVP&R for CCT requirements. Customer specific requirements, such as annual dimensional lavout, shall be identified on the Control Plan. Refer to the Control Plan Example tab in this document for examples of the above requirements. For Customer / Component BU within the scope of VDA: Note that the Control Plan shall be identified with "A" in the top right corner whenever there is at least 1 critical characteristic mentioned. This identification is required to highlight special archiving requirement (eg. 15 years) for this document. See VDA 1 brochure for details. Records / Logs The Control Plan is stored by the Quality Manager. References Advanced Product Quality Planning and Control Plan (AIAG reference manual) Characteristic Management standard (WW-PLUS-ST-02-01)

WW-PLUS-FR-02-01-E / Rev 08 (01-October-2004) Page 2 of 6

Supplier Standards Manual Seat Heat Peel and Stick Heater Control Plan Chapter 7 Quality Section March 2008 Revision 1.0

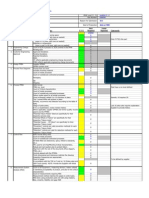

Control Plan

DV Build Control Plan Number Part Number/Latest Change Level Core Team Seat Heater team Part Name/Description Supplier/Plant Approval/Date Customer Quality Approval/Date (If Req'd) Customer Engineering Approval/Date (If Req'd) Pre-launch Production Key Contact/Phone Date (Orig.) Date (Rev.)

Supplier/Plant

Supplier Code

Other Approval/Date (If Req'd)

Other Approval/Date (If Req'd)

Part / Process Number

Process Name / Operation Description

Machine, Device, Jig, Tools For Mfg. No. Product

Characteristics Process

Special Char. Class. Product / Process Specification/Tolerance Evaluation

Methods Sample Size Freq. Control Method Reaction Plan

Measurement Technique

Operator responsibilities Stock seat heater at correct station on assembly line assure correct part number per ODS

each container

visual management

Remove incorrect product from line. Aside units handled improperly for disposition

Remove seat heater assembly from container without stress on wire harness

Use handling technique which does not stress harness, per ODS

each assembly

visual management

Post assembly, assure heater is in correct position

assure position of heater on cover meets requirements of ODS

each assembly

visual management, template

Aside assemblies positioned improperly for disposition

post assembly, assure adhesive backing tape is removed

visually check each adhesive area such that the appropriate color is showing in the tape windows

each assembly

visual check

Aside cushion assemblies which do not meet criteria

assure no foreign objects traped under heater post assembly to pad

run hand over heater to detect foreign objects

each assembly

manual check

Aside assemblies with poor adhesion to the pad for disposition

Auditor responsibilities tion, contact supervisor who mus correct operation, quarrentine all product built since last succcessful audit for verification. Stock seat heater at correct station on assembly line assure correct part number per ODS Check visually to print and ODS

Remove seat heater assembly from container without stress on wire harness

Use handling technique which does not stress harness per ODS

observe handling technique used

WW-PLUS-FR-02-01-E / Rev 08 (01-October-2004)

once per job rotation

5 consecutive assemblies

Post assembly, assure heater is in correct position

assure position of heater on cover meets requirements of ODS within +/10 mm

scale

Page 3 of 6

Part / Process Number

Process Name / Operation Description

Machine, Device, Jig, Tools For Mfg. No. Product

Characteristics Process

Special Char. Class. Product / Process Specification/Tolerance Evaluation

Methods

Sample

once per job rotation

5 consecutive assemblies

Supplier Standards Manual Seat Heat Peel and Stick Heater Control Plan Chapter 7 Quality Section March 2008 Revision 1.0

Control Method

Reaction Plan

Measurement Technique

Size

Freq.

Operator responsibilities post assembly, assure adhesive tape backing has been removed

correct color shows in tape windows

visual check

assure no foreign objects traped under heater post assembly to pad

run hand over heater to detect foreign objects

manual check

WW-PLUS-FR-02-01-E / Rev 08 (01-October-2004)

Page 4 of 6

Stop operation, contact supervisor who mus correct operation, quarrentine al built since last succcessful audit for verification.

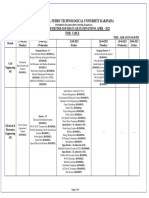

Supplier Standards Manual Seat Heat Peel and Stick Heater Control Plan Chapter 7 Quality Section March 2008 Revision 1.0

Control Plan - Example

DV Build Control Plan Number Part Number/Latest Change Level Pre-launch X Production Key Contact/Phone Date (Orig.) Date (Rev.) Core Team Customer Engineering Approval/Date (If Req'd) Part Name/Description Supplier/Plant Approval/Date Customer Quality Approval/Date (If Req'd)

Supplier/Plant

Supplier Code

Other Approval/Date (If Req'd)

Other Approval/Date (If Req'd)

Part / Process Number

Process Name / Operation Description

Machine, Device, Jig, Tools For Mfg. No.

Characteristics Product Process

Special Char. Class. Product / Process Specification/Tolerance Evaluation

Methods Sample Size Freq. Control Method Reaction Plan

Measurement Technique

A) Control at Supplier

Option 1) System/Subsystem level SC/CC Controlled at a Component/Part SC/CC Level at Multiple Suppliers Option 1a) All effected parts-see list Option 1b) All effected parts-see list Annual Supplier PPAP/Recertifcation FMVSS 201 CC Per FMVSS 201 Suppliers PPAP/Cert Review Each LF part see list Annual Annual Supplier PPAP/Recertific ation. Review PPAP. Follow Corrective Action procedure Receiving Flammability: FMVSS 302 CC Per FMVSS 302 See Supplier Control Plans See Supplier Control Plans See Supplier Control Supplier Plans Control Plans See Supplier Control Plans

Option 2) System/Subsystem level SC/CC Controlled at a Component/Part SC/CC Level at Multiple/or Single Supplier/s. This would be used a) If you choose to list all Supplier SC/CC's in the control plan b) To highlight the key SC/CC components. Option 2a) Cushion foam Part # abcdefg Option 2b) Part # 123 Annual Supplier PPAP/Recertifcation FMVSS 201 CC Per FMVSS 201 PPAP/Cert Review 1 Package Annual Annual Supplier PPAP/Recertific ation. Review PPAP. Follow Corrective Action procedure Receiving FMVSS 202 SC Foam ILD See Supplier Control Plan See Supplier Control Plan See See Supplier Supplier Control Plan Control Plan See Supplier Control Plan

(Optional) Highlight Control of a Key JCI Identified Supplier SC/CC at a Supplier (not a System/Subsystem Characteristic) This would be used to highlight a key SC/CC on components. Plastic Part # 12345 Receiving Part Length SC 30mm +/- 2mm See Supplier Control Plan See Supplier Control Plan See See Supplier Supplier Control Plan Control Plan See Supplier Control Plan

B) Control at AG Plant

Incoming Inspection Seq Number/ Etc Process # Incoming Inspection Material Specification ABC CC Must meet spec DCE Incoming Inspection 1 Cert Each Lot Review Supplier Return to Certification Supplier

Assembly Process Marriage of back to track assembly Bolt Torque Atlas Copco Torque Driver Torque Monitoring SC 24 NM +/- 4NM Torque Monitoring System Controller 100% 100% Atlas Copco Follow Corrective action plan on ODS Part not released. Following NC Material/Re work procedure Follow Corrective Action plan on ODS Follow Corrective Action procedure

Final Inspection Station 15 Set-up Shipping position Indexing Build fixture Shipping Positon SC Seat Angle 30Deg +/-5 Station 17 deg lasers 100% Continuo Automated us Inspection

Station P

Dimensional inspection Overhead System Check fixture Periodic Checks (at JCI) Dimensional inspection Overhead System Check fixture

SC1, SC2 SC3, SC4

SC

Perimeter Inspection checklist +10mm/10mm

Overhead System Check fixture

Per Shift Check Sheets

Surface Contour points A-F

SC

Perimeter Inspection checklist +10mm/10mm

CMM

Annual Layout Inspection Record

WW-PLUS-FR-02-01-E / Rev 08 (01-October-2004)

Page 5 of 6

Supplier Standards Manual Seat Heat Peel and Stick Heater Control Plan Chapter 7 Quality Section March 2008 Revision 1.0

Control Plan - Example

DV Build Control Plan Number Part Number/Latest Change Level Pre-launch X Production Key Contact/Phone Date (Orig.) Date (Rev.) Core Team Customer Engineering Approval/Date (If Req'd) Part Name/Description Supplier/Plant Approval/Date Customer Quality Approval/Date (If Req'd)

Supplier/Plant

Supplier Code

Other Approval/Date (If Req'd)

Other Approval/Date (If Req'd)

Part / Process Number

Process Name / Operation Description

Machine, Device, Jig, Tools For Mfg. No.

Characteristics Product Process

Special Char. Class. Product / Process Specification/Tolerance Evaluation

Methods Sample Size Freq. Control Method Reaction Plan

Measurement Technique

Continuous Compliance Testing - Visor Assembly Continuous Compliance Testing - Console Assembly

Flammability: FMVSS 302

CC

Per FMVSS 302

Laboratory Test

Annual Continuous Compliance Testing Annual Continuous Compliance Testing

Follow Corrective Action procedure Follow Corrective Action procedure

Flammability: FMVSS 201 and 302

CC

See DVP&R

See DVP&R

See DVP&R

WW-PLUS-FR-02-01-E / Rev 08 (01-October-2004)

Page 6 of 6

Вам также может понравиться

- List of ISO Implementation Policy-R1Документ33 страницыList of ISO Implementation Policy-R1Mohammed Shabbir LunawadiОценок пока нет

- 01 Lumut Balai2 Project HSSE PlanДокумент40 страниц01 Lumut Balai2 Project HSSE Planihajar9Оценок пока нет

- 15 Driving Safety and Training ProcedureДокумент6 страниц15 Driving Safety and Training Procedureihajar9Оценок пока нет

- HIRA No 22 Installation Use of Temp Electrical Supplies SBDДокумент2 страницыHIRA No 22 Installation Use of Temp Electrical Supplies SBDMobin Thomas AbrahamОценок пока нет

- CV TahirДокумент5 страницCV TahirPawan MaheshwariОценок пока нет

- Work Method StatamentДокумент4 страницыWork Method StatamentAmril Al RizaОценок пока нет

- NR 33 - Confined - SpacesДокумент20 страницNR 33 - Confined - SpacesCPSSTОценок пока нет

- Payroll Process Flow ChartДокумент1 страницаPayroll Process Flow ChartUmang JainОценок пока нет

- Certificate - Mohd Ahmed AbdelrazekДокумент1 страницаCertificate - Mohd Ahmed AbdelrazekAnonymous eFF9uwuuОценок пока нет

- Purchase Process FlowChartДокумент1 страницаPurchase Process FlowChartMahajan VickyОценок пока нет

- Integrated Management System: Yash Papers LTDДокумент1 страницаIntegrated Management System: Yash Papers LTDpawan sengatОценок пока нет

- Permit To Work GuidelinesДокумент12 страницPermit To Work GuidelinesalanjcherryОценок пока нет

- HIRA Fuel FiringДокумент13 страницHIRA Fuel FiringAbzad HussainОценок пока нет

- Ohs-Pr-09-15-F05 (A) Working at Heights Rescue PlanДокумент11 страницOhs-Pr-09-15-F05 (A) Working at Heights Rescue PlanBalaОценок пока нет

- Trizac Automation - Presentation - BG - 08.07.2016Документ29 страницTrizac Automation - Presentation - BG - 08.07.2016Atemp-mail.orgInboxОценок пока нет

- S3EMIA - 315 - PR1 - Working On and Near WaterДокумент7 страницS3EMIA - 315 - PR1 - Working On and Near WaterSiwaОценок пока нет

- 1074 RT PH II Risk Assessment ERP - Template XLSX 01Документ109 страниц1074 RT PH II Risk Assessment ERP - Template XLSX 01aorukoОценок пока нет

- HSE-PRO-09-D01 0.2 - Interested Party Needs and Expectations 2020 HSE (NEW ONE)Документ7 страницHSE-PRO-09-D01 0.2 - Interested Party Needs and Expectations 2020 HSE (NEW ONE)Soufian BahmadОценок пока нет

- Lps 01 Hti MST El 005 Point WiringДокумент22 страницыLps 01 Hti MST El 005 Point WiringJomy JohnyОценок пока нет

- Sappress Implementing Employee Manager Self ServicesДокумент27 страницSappress Implementing Employee Manager Self ServicesArk JamesОценок пока нет

- Performance Assessment Form - April 2014 To March 2015: Cluster Engineer O&M Asad MubasshirДокумент4 страницыPerformance Assessment Form - April 2014 To March 2015: Cluster Engineer O&M Asad Mubasshirashu548836Оценок пока нет

- 2.2 C New Safety Dashboard Nov2022Документ1 страница2.2 C New Safety Dashboard Nov2022subodh kumarОценок пока нет

- Health, Safety and Environmental: GoalsДокумент15 страницHealth, Safety and Environmental: Goalsprojects sureshОценок пока нет

- 17 Subcon RequirementsДокумент38 страниц17 Subcon RequirementsMohammed MinhajОценок пока нет

- Monitoring of OHS Objectives & Targets v-0.1Документ2 страницыMonitoring of OHS Objectives & Targets v-0.1Nomaan MalikОценок пока нет

- DOSH Master PlanДокумент6 страницDOSH Master PlanJafar Sedek OmbitОценок пока нет

- Permit To Work FormДокумент2 страницыPermit To Work FormNate JamesОценок пока нет

- Tanveer CVДокумент4 страницыTanveer CVtahirfaridОценок пока нет

- Audit Summary ReportДокумент2 страницыAudit Summary Reportas rginorОценок пока нет

- Observation On Quality Aspects 083Документ3 страницыObservation On Quality Aspects 083Moorthy NaveenОценок пока нет

- 4 4 2 TrainingProcedureДокумент7 страниц4 4 2 TrainingProcedurekartikaОценок пока нет

- Spare Parts Flow ChartsДокумент2 страницыSpare Parts Flow ChartsOkey OkoliОценок пока нет

- Technician Plant MaintenanceДокумент78 страницTechnician Plant MaintenanceJonathan LinjeОценок пока нет

- Mobilization Tanajib Cogeneration and Desalination Plant HIRAДокумент4 страницыMobilization Tanajib Cogeneration and Desalination Plant HIRAZishan AliОценок пока нет

- Ab 521 Requirements For Engineered Pressure EnclosuresДокумент39 страницAb 521 Requirements For Engineered Pressure EnclosuresCarlos Maldonado SalazarОценок пока нет

- Quality Records: Neptune OrthopaedicsДокумент1 страницаQuality Records: Neptune Orthopaedicsdhir.ankurОценок пока нет

- 5) SWP-05 Hot WorksДокумент4 страницы5) SWP-05 Hot WorksRachel NoraОценок пока нет

- ChecklistДокумент14 страницChecklistInstrument SCIОценок пока нет

- Subcontractor Requirements / Responsibilities: A. GeneralДокумент36 страницSubcontractor Requirements / Responsibilities: A. Generalmalik jahanОценок пока нет

- TOPIC: Personal Protective Equipment ChecklistДокумент1 страницаTOPIC: Personal Protective Equipment ChecklistMd ShОценок пока нет

- Competency MappingДокумент11 страницCompetency MappingJia04Оценок пока нет

- Sohail Malik - CV PDFДокумент2 страницыSohail Malik - CV PDFamjad ali khawarОценок пока нет

- Flow Chart Symbols - ABC CompanyДокумент3 страницыFlow Chart Symbols - ABC CompanyLooi Kok HuaОценок пока нет

- Esta Di SticaДокумент6 страницEsta Di SticaEduardoVillaОценок пока нет

- 9.0 - Workplace Wellness v3.0 EnglishДокумент10 страниц9.0 - Workplace Wellness v3.0 EnglishVi VekОценок пока нет

- COSHH DrakerДокумент2 страницыCOSHH DrakerzaimОценок пока нет

- 04 Sop For Objectives, Targets & EnvtalДокумент7 страниц04 Sop For Objectives, Targets & EnvtalMusyoka UrbanusОценок пока нет

- Manual Handling Management Assesment ChecklistДокумент3 страницыManual Handling Management Assesment Checklistk000Оценок пока нет

- Co-Requisite: Prerequisite: Data Book / Codes/Standards Course Category Course Designed by ApprovalДокумент14 страницCo-Requisite: Prerequisite: Data Book / Codes/Standards Course Category Course Designed by Approvalakash kumarОценок пока нет

- Michigan State University: Personal Protective Equipment GuidelinesДокумент40 страницMichigan State University: Personal Protective Equipment GuidelinesRuby SmithОценок пока нет

- ERP Editable Flow ChartДокумент1 страницаERP Editable Flow ChartVictorОценок пока нет

- EIA Registration FormДокумент2 страницыEIA Registration FormOluwaseun Babs LawalОценок пока нет

- 5 QMS Document Master List - Asset Resources Management (Fleet)Документ2 страницы5 QMS Document Master List - Asset Resources Management (Fleet)Safix YazidОценок пока нет

- CoP - 9.0 - Workplace WellnessДокумент9 страницCoP - 9.0 - Workplace WellnessAnonymous y1pIqcОценок пока нет

- T13E CoSHH RegisterДокумент1 страницаT13E CoSHH RegisterAmanОценок пока нет

- Contractor HSE Profile FormДокумент2 страницыContractor HSE Profile FormebyjoyОценок пока нет

- Control PlanДокумент6 страницControl PlanFahmy Khoerul HudaОценок пока нет

- Anexo 06 - PA - Process Audit v1.1Документ19 страницAnexo 06 - PA - Process Audit v1.1BalajiОценок пока нет

- F1021 PPAP Check List Instructions 04JN18Документ9 страницF1021 PPAP Check List Instructions 04JN18Sharmad TamhaneОценок пока нет

- SQD-025 PPAP ChecklistДокумент7 страницSQD-025 PPAP ChecklistMadhan RajОценок пока нет

- HSSE File IndexДокумент4 страницыHSSE File IndexvfuntanillaОценок пока нет

- How To Identify Workplace Safety ChampionsДокумент3 страницыHow To Identify Workplace Safety ChampionsvfuntanillaОценок пока нет

- Caterpillar SARL - CL - 07.01.2021Документ1 страницаCaterpillar SARL - CL - 07.01.2021vfuntanillaОценок пока нет

- Flush Report - TemplateДокумент1 страницаFlush Report - TemplatevfuntanillaОценок пока нет

- Safety Calendar (Template)Документ1 страницаSafety Calendar (Template)vfuntanillaОценок пока нет

- Site Safe Days Template.Документ1 страницаSite Safe Days Template.vfuntanillaОценок пока нет

- Training Needs 2021Документ4 страницыTraining Needs 2021vfuntanillaОценок пока нет

- Car Transporters - HSE ExecutiveДокумент4 страницыCar Transporters - HSE ExecutivevfuntanillaОценок пока нет

- NCEMA 6000 EnglishДокумент60 страницNCEMA 6000 EnglisheastОценок пока нет

- HIRARC SupportДокумент65 страницHIRARC Supportvfuntanilla100% (1)

- Fire Risk Assessment (FRA) - Blank FormДокумент15 страницFire Risk Assessment (FRA) - Blank FormvfuntanillaОценок пока нет

- Community Guidelines: Ealth Afety & NvironmentДокумент32 страницыCommunity Guidelines: Ealth Afety & NvironmentvfuntanillaОценок пока нет

- Regulation IO-9.0 Equipment Operations Machinery Installations RevДокумент26 страницRegulation IO-9.0 Equipment Operations Machinery Installations RevNatalie BlackmoreОценок пока нет

- Ramoul AE Andrew BC FF TZ Sharjah BC Bala Ajman BC Bala RAK BC Jaseem TZ Musaffah BC Hari TZ Fujairah BC Hilal FF Yas Island FF Jaseem DIP CWD SalimДокумент7 страницRamoul AE Andrew BC FF TZ Sharjah BC Bala Ajman BC Bala RAK BC Jaseem TZ Musaffah BC Hari TZ Fujairah BC Hilal FF Yas Island FF Jaseem DIP CWD SalimvfuntanillaОценок пока нет

- IQA NCs MonitoringДокумент3 страницыIQA NCs MonitoringvfuntanillaОценок пока нет

- Safety in HeatДокумент33 страницыSafety in HeatvfuntanillaОценок пока нет

- Permit To WorkДокумент1 страницаPermit To WorkvfuntanillaОценок пока нет

- Process MapДокумент4 страницыProcess MapvfuntanillaОценок пока нет

- Raymond 2015 Hoshin Kanri - Projects Nov26Документ2 страницыRaymond 2015 Hoshin Kanri - Projects Nov26vfuntanillaОценок пока нет

- IMS Audit Program - DraftДокумент1 страницаIMS Audit Program - DraftvfuntanillaОценок пока нет

- IMS CorrespondenceДокумент20 страницIMS CorrespondencevfuntanillaОценок пока нет

- Hoshin KanriДокумент7 страницHoshin KanrivfuntanillaОценок пока нет

- Hse HirarcДокумент7 страницHse HirarcvfuntanillaОценок пока нет

- Fastfit Tyrezone Alac: Division Division DivisionДокумент2 страницыFastfit Tyrezone Alac: Division Division DivisionvfuntanillaОценок пока нет

- HSE Guidelines MatrixДокумент1 страницаHSE Guidelines MatrixvfuntanillaОценок пока нет

- Cyprus ReplyДокумент1 страницаCyprus ReplyvfuntanillaОценок пока нет

- Environmental Aspects and Impacts RankingДокумент2 страницыEnvironmental Aspects and Impacts RankingvfuntanillaОценок пока нет

- Hoshin KanriДокумент7 страницHoshin KanrivfuntanillaОценок пока нет

- Circle ChartДокумент2 страницыCircle ChartRasi FazizОценок пока нет

- HW550-3G FAQ How To Configure Wireless Security Under Wizard PageДокумент4 страницыHW550-3G FAQ How To Configure Wireless Security Under Wizard PageVerruumm AmineОценок пока нет

- Jira Tutorial PDFДокумент20 страницJira Tutorial PDFregiane100% (5)

- Change ManagementДокумент10 страницChange ManagementAhmed Ali Syed BrilliantОценок пока нет

- Underground Mining MarketДокумент4 страницыUnderground Mining MarketFrank GuevaraОценок пока нет

- Industial Training - Ashok Layland LTDДокумент14 страницIndustial Training - Ashok Layland LTDTechnical KingОценок пока нет

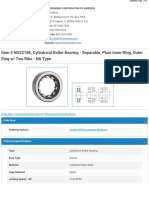

- NU2218E CylindricalRollerBearing Separable PlainInnerRing OuterRingwTwoRibs NUTypeДокумент3 страницыNU2218E CylindricalRollerBearing Separable PlainInnerRing OuterRingwTwoRibs NUTypeEmmanuel Quequesana VílchezОценок пока нет

- Centroid: Retrofit For Bridgeport BossДокумент12 страницCentroid: Retrofit For Bridgeport BossRudolf OppermannОценок пока нет

- Hydraulic Cylinders DesignДокумент20 страницHydraulic Cylinders Designyatin88860% (5)

- School Library Management SystemДокумент52 страницыSchool Library Management SystemBiplab AcharjeeОценок пока нет

- Daniel Master Thesis PresentationДокумент47 страницDaniel Master Thesis PresentationBuluc GheorgheОценок пока нет

- Pier SpecificationsДокумент168 страницPier SpecificationsRob MouzasОценок пока нет

- CS With VMIДокумент26 страницCS With VMINafiz AlamОценок пока нет

- Internship Report of Nimir ChemicalsДокумент43 страницыInternship Report of Nimir ChemicalsEhsan Danish100% (2)

- Comprehensive List of Excel Keyboard Shortcuts - 97 Shortcuts To Boost Your Productivity - ChandooДокумент23 страницыComprehensive List of Excel Keyboard Shortcuts - 97 Shortcuts To Boost Your Productivity - ChandoonrscОценок пока нет

- Earned Value Analysis TemplateДокумент10 страницEarned Value Analysis TemplateHugh JassОценок пока нет

- NCHRP RPT 395Документ143 страницыNCHRP RPT 395sakashefОценок пока нет

- Technical BidДокумент30 страницTechnical BidUPAVP CD 21Оценок пока нет

- PSP Fat Procedure - TemplateДокумент6 страницPSP Fat Procedure - TemplateMichael HaiseОценок пока нет

- Simulating Quadrotor UAVs in Outdoor ScenariosДокумент7 страницSimulating Quadrotor UAVs in Outdoor ScenariosRodolfo Castro E SilvaОценок пока нет

- CHatGPT Cover LetterДокумент2 страницыCHatGPT Cover LetterJoby PaulОценок пока нет

- Waterproofing Guarantee FormatДокумент2 страницыWaterproofing Guarantee Formatsan80% (51)

- RES6 Rules For Pleasure Yachts 2023 - Part B 1.1.2023Документ297 страницRES6 Rules For Pleasure Yachts 2023 - Part B 1.1.2023Emanuele ButtàОценок пока нет

- CSAC10Документ27 страницCSAC10Abolaji Olafare BeejayОценок пока нет

- PSTC-14 - Adhesion of Pressure Sensitive Tapes To Fiberboard at 90°angle and Constant StressДокумент6 страницPSTC-14 - Adhesion of Pressure Sensitive Tapes To Fiberboard at 90°angle and Constant StressChung LeОценок пока нет

- 42 BT R19-April-2023Документ6 страниц42 BT R19-April-2023Leela KumarОценок пока нет

- Assignment 1 Bsr257Документ14 страницAssignment 1 Bsr257MUHAMMAD FARIS IQBAL BIN RIDUANОценок пока нет

- BestendigheidstabelДокумент32 страницыBestendigheidstabeldroessaert_stijnОценок пока нет

- Latest Trends in Automation For Automotive Industry-Case StudyДокумент18 страницLatest Trends in Automation For Automotive Industry-Case StudymjdeshpandeОценок пока нет

- 3 ERP ArchitectureДокумент100 страниц3 ERP ArchitectureShriyanshi JaitlyОценок пока нет

- Soldering How To Solder Jewelry JMDДокумент16 страницSoldering How To Solder Jewelry JMDPedala Darling-Petrocelli100% (1)

- EPC ContractsДокумент36 страницEPC Contractskesharinaresh50% (2)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveОт EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveОценок пока нет

- Cyber War: The Next Threat to National Security and What to Do About ItОт EverandCyber War: The Next Threat to National Security and What to Do About ItРейтинг: 3.5 из 5 звезд3.5/5 (66)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОт EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОценок пока нет

- Algorithms to Live By: The Computer Science of Human DecisionsОт EverandAlgorithms to Live By: The Computer Science of Human DecisionsРейтинг: 4.5 из 5 звезд4.5/5 (722)

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityОт EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityРейтинг: 5 из 5 звезд5/5 (1)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldОт EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldРейтинг: 4.5 из 5 звезд4.5/5 (55)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyОт EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyРейтинг: 4 из 5 звезд4/5 (51)

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumОт EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumРейтинг: 3 из 5 звезд3/5 (12)

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyОт EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyРейтинг: 3.5 из 5 звезд3.5/5 (111)

- Reality+: Virtual Worlds and the Problems of PhilosophyОт EverandReality+: Virtual Worlds and the Problems of PhilosophyРейтинг: 4 из 5 звезд4/5 (24)

- Generative AI: The Insights You Need from Harvard Business ReviewОт EverandGenerative AI: The Insights You Need from Harvard Business ReviewРейтинг: 4.5 из 5 звезд4.5/5 (2)

- AI Superpowers: China, Silicon Valley, and the New World OrderОт EverandAI Superpowers: China, Silicon Valley, and the New World OrderРейтинг: 4.5 из 5 звезд4.5/5 (398)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideОт EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideРейтинг: 5 из 5 звезд5/5 (2)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessОт EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessОценок пока нет

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОт EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОценок пока нет

- Chip War: The Quest to Dominate the World's Most Critical TechnologyОт EverandChip War: The Quest to Dominate the World's Most Critical TechnologyРейтинг: 4.5 из 5 звезд4.5/5 (227)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyОт EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyОценок пока нет

- The Future of Geography: How the Competition in Space Will Change Our WorldОт EverandThe Future of Geography: How the Competition in Space Will Change Our WorldРейтинг: 4 из 5 звезд4/5 (5)

- Who's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesОт EverandWho's Afraid of AI?: Fear and Promise in the Age of Thinking MachinesРейтинг: 4.5 из 5 звезд4.5/5 (13)

- Demystifying Prompt Engineering: AI Prompts at Your Fingertips (A Step-By-Step Guide)От EverandDemystifying Prompt Engineering: AI Prompts at Your Fingertips (A Step-By-Step Guide)Рейтинг: 4 из 5 звезд4/5 (1)