Академический Документы

Профессиональный Документы

Культура Документы

Metal Matrix Composites 10

Загружено:

Muhammad Raihan BalfasИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Metal Matrix Composites 10

Загружено:

Muhammad Raihan BalfasАвторское право:

Доступные форматы

6

PROCESSING

bundle of cylindrical capillary tubes (Martins et al. 1988; Maxwell et al. 1990). Other analyses, initially proposed in Japan and the United Kingdom, model the preform as a continuum (Clyne et al. 1985; Fukunaga and Goda 1985a; Fukunaga and Goda 1984; Fukunaga and Goda 198Sb; Fukunaga et al. 1983; Fukunaga and Kuriyama 1982; Fukunaga and Ohde 1982; Nagata and Matsuda 1981). In this approach, analysis is based on consideration of a differential volume element AV, which contains pores, metal, and reinforcement elements such as fibers or particles, and is schematically represented in Figure 1.2. Within AV, parameters such as fraction solid metal g,, fiber volume fraction Vf or temperature Tare uniform. Velocities of the fluid phase vi and solid phase v, are also averaged over AV. In most cases, preform deformation is neglected, so the solid phase is assumed to be stationary (v, = 0). However, it is necessary to take the solid velocity into account when preform deformation occurs during infiltration (Sommer 1992). The continuum approach is generally legitimate given the small size of the reinforcements (typically 1 to 20 km in diameter) compared to preform dimensions. Using this continuum approach, Nagata and Matsuda illustrated the possibility of infiltrating preforms having initial temperatures below the metal liquidus (Nagata and Matsuda 1981). Fukunaga and Goda proposed an explanation for the case of pure aluminum: a layer of solidified metal forms around the fibers, allowing for flow of liquid metal around it (Fukunaga and Goda 1984). More recently, the role and interaction of transport phenomena influencing infiltration kinetics and composite microstructure have been investigated

and analyzed quantitatively (Lacoste and Dank 1991; Lacoste et al. 1991; Mortensen et al. 1989; Mortensen and Michaud 1991; Mortensen and Wong 1990). The basic governing equations of these continuum models in general form will now be discussed. Vfi V , and V , are the local volume fraction of reinforcement, , pores, and metal, respectively, such that Vf + V, + V = 1. If a fraction of the metal g, solidifies during infiltration, and V,f represents the local fraction solid in the composite, including reinforcement and solidified g,V,. For a given alloy and metal, then V,f = Vf reinforcement, the following laws govern.

1.1.2*1 F1uid F1ow

F1ow of liquid metal though A v generally fOllom the Forscheimer equation:

f - VP

[pVm(l - gs)K-'

+BprnGG21(v,

- vs)

(1-1)

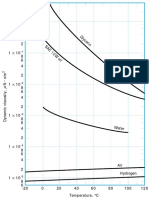

where f is the local volumetric value of the gravitational, centrifugal, or electromagnetic force applied to AV, P the average pressure in AV, and p the viscosity of the liquid metal, which is a function of the metal temperature and composition. K, the local permeability tensor of the preform, and B are functions of V , and of the morphology and volume fraction of the solidified metal (Beavers and Sparrow 1969; Coulaud et al. 1988). pm is the metal density, assumed here to be the same in the solid and liquid state. When the relevant Reynolds number is below a critical value near one:

Figure 1.2. Schematic representation of a volume element AV, containing liquid metal, solid metal, fibers, and pores.

Вам также может понравиться

- Bab3 MatrikulasiДокумент31 страницаBab3 MatrikulasiMuhammad Raihan BalfasОценок пока нет

- PD2-23 Okt-2007Документ39 страницPD2-23 Okt-2007Muhammad Raihan BalfasОценок пока нет

- Introduction - Concept of StressДокумент26 страницIntroduction - Concept of StressMuhammad Raihan BalfasОценок пока нет

- Stress and Strain - Axial LoadingДокумент36 страницStress and Strain - Axial LoadingMuhammad Raihan BalfasОценок пока нет

- CobaДокумент2 страницыCobaMuhammad Raihan BalfasОценок пока нет

- Sûrat Al-Muddatstsir (74) : Orang Yang Berkemul (The One Enveloped) Verses 1-56Документ3 страницыSûrat Al-Muddatstsir (74) : Orang Yang Berkemul (The One Enveloped) Verses 1-56Muhammad Raihan BalfasОценок пока нет

- Ceramics Glasses Superconductors HOДокумент4 страницыCeramics Glasses Superconductors HOMuhammad Raihan BalfasОценок пока нет

- Glycerin: WaterДокумент1 страницаGlycerin: WaterMuhammad Raihan BalfasОценок пока нет

- MMC 21Документ1 страницаMMC 21Muhammad Raihan BalfasОценок пока нет

- MMC 20Документ1 страницаMMC 20Muhammad Raihan BalfasОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- MMC 16Документ1 страницаMMC 16Muhammad Raihan BalfasОценок пока нет

- Metal Matrix Composites 8Документ1 страницаMetal Matrix Composites 8Muhammad Raihan BalfasОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Magnesium Metal Production in IndiaДокумент7 страницMagnesium Metal Production in IndiaYogesh LadolaОценок пока нет

- Introduction and History of - Docx PenetrantДокумент56 страницIntroduction and History of - Docx PenetrantHamydОценок пока нет

- Rack B-2Документ535 страницRack B-2waqas001Оценок пока нет

- Application of Nanoparticles in Biofuels - An OverviewДокумент18 страницApplication of Nanoparticles in Biofuels - An OverviewYashvir SinghОценок пока нет

- Submersible Motor PumpДокумент52 страницыSubmersible Motor PumpTiago GodinhoОценок пока нет

- Reviewer Dec ExamДокумент3 страницыReviewer Dec ExamCamille Dela PazОценок пока нет

- Paint Chip AnalysisДокумент11 страницPaint Chip AnalysisIlyana ShalahudinОценок пока нет

- Fracture of Ceramics and Glasses: PhysДокумент43 страницыFracture of Ceramics and Glasses: PhysMridanku Shekhar PramanickОценок пока нет

- Ch3a ManualДокумент16 страницCh3a ManualAllen YuОценок пока нет

- Co Ordination Compounds MHT CET Synopsis PDFДокумент11 страницCo Ordination Compounds MHT CET Synopsis PDFAbhishek MandlikОценок пока нет

- 02 Pemesinan Abrasif Dan Penyelesaian Akhir OkДокумент40 страниц02 Pemesinan Abrasif Dan Penyelesaian Akhir OkAfdhil Salim100% (1)

- Extraction of Banana FiberДокумент2 страницыExtraction of Banana Fibermuthamil05Оценок пока нет

- Experiment-4: AIM: To Study The Effect of Cutting Speed, Feed Depth of Cut and Rake Angle OnДокумент7 страницExperiment-4: AIM: To Study The Effect of Cutting Speed, Feed Depth of Cut and Rake Angle OnKoushal SinghОценок пока нет

- Hydraulic, Thermodynamics Economic AnalysisДокумент34 страницыHydraulic, Thermodynamics Economic AnalysisEr. Ramji TripathiОценок пока нет

- Brosur Genteng M ClassДокумент6 страницBrosur Genteng M Classanon_795575819Оценок пока нет

- CHEMISTRY Question Paper 2022Документ16 страницCHEMISTRY Question Paper 2022Bornil PaulОценок пока нет

- Al-Obaidi - 2021 - IOP - Conf. - Ser. - Earth - Environ. - Sci. - 779 - 012010Документ12 страницAl-Obaidi - 2021 - IOP - Conf. - Ser. - Earth - Environ. - Sci. - 779 - 012010Cladi DanaОценок пока нет

- Anh 2017Документ11 страницAnh 2017Võ Quốc CườngОценок пока нет

- Composite Bridge Assessment To BD61.10Документ5 страницComposite Bridge Assessment To BD61.10stavros_stergОценок пока нет

- Chapter Two Literature ReviewДокумент6 страницChapter Two Literature ReviewMcLeo AliriОценок пока нет

- Chem Workshop - Question Paper CompilationДокумент197 страницChem Workshop - Question Paper Compilations1672snehil6353Оценок пока нет

- High Density Polyethylene Hdpe Pipes InstallationДокумент9 страницHigh Density Polyethylene Hdpe Pipes InstallationDedy YuniarchoОценок пока нет

- Technical Specification FOBДокумент6 страницTechnical Specification FOBANDRESОценок пока нет

- PDIL Cable Tray RackДокумент6 страницPDIL Cable Tray Rack9044nksОценок пока нет

- Amines Print PDFДокумент6 страницAmines Print PDFsinghatmesh685Оценок пока нет

- Sonocrystallization - The Use of Ultrasound For Improved Industrial Crystallization PDFДокумент10 страницSonocrystallization - The Use of Ultrasound For Improved Industrial Crystallization PDFJessica FengkaiОценок пока нет

- RetroJet System ManualДокумент11 страницRetroJet System ManualetritОценок пока нет

- Bomba de Vacio Sihi LPHX 40516Документ12 страницBomba de Vacio Sihi LPHX 40516Dante Coloma JimenezОценок пока нет

- Flange Bolting Torque Values API 6AДокумент1 страницаFlange Bolting Torque Values API 6Aparthameister100% (1)

- Ammonia ProductionДокумент5 страницAmmonia ProductionHarsh WaliaОценок пока нет