Академический Документы

Профессиональный Документы

Культура Документы

MMC 16

Загружено:

Muhammad Raihan BalfasИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MMC 16

Загружено:

Muhammad Raihan BalfasАвторское право:

Доступные форматы

12

PROCESSING

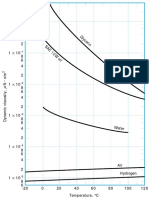

processes while the alloy temperature is between liquidus and solidus (Flemings 1991). In both cases, that is, above liquidus temperature or between liquidus and solidus temperature, the metal-particulate slurries exhibit a non-newtonian behavior. Their viscosity decreases up to an order of magnitude as the shear rate increases (see Figure 1.6). Moreover, it has been experimentally observed that composite slurries are thixotropic, meaning that when the shear rate is abruptly changed, the viscosity of the slurry changes only progressively to reach the steady-state value of the new shear rate. Such behavior has been reported by Moon on SiC/Al-6.5 wt 940 Si (Moon et al. 1991) in both semisolid and liquid metal cases, and by Mada and Ajersch (1990) on similar systems in the semisolid state only, for a smaller range of shear rates. The mechanisms underlying the pseudoplastic behavior of composite slurries are not yet clearly understood. The existence of such behavior in slurries above the metal liquidus suggests that clustering and declustering of particles plays a major role. Interfacial chemical reaction between reinforcement and metal has also been reported to increase the slurry viscosity, apparently because the reaction products have a different density, break loose, or change the morphology of the reinforcement (Lloyd 1991). In the semisolid metal temperature range, the behavior of composite slurries is generally explained on the same basis as is their unreinforced counterparts. That is, there is a change in morphology of the solid phase under shear as a result of dendrite fragmentation, ripening and abrasion, and collision and coalescence of solid particles (Flemings 1991). Mada and Ajersch

(1990) developed an analytical model of thixotropic behavior in semisolid composite slurries, based on an analogy between rate constants for chemical reactions and the rates of dissociation and formation of solid aggregates. From their analysis and experimental results, they concluded that particle addition has little influence on the thixotropic nature of the melt, and that the primary metal solid phase is the major factor. Yet, an effect of particle addition on the pseudoplastic behavior has been observed by Moon (Moon et al. 1991); at a given shear rate, the viscosity of slurries composed of Sic particles combined with Al-6.5 wt % Si in the semisolid range was lower than that of unreinforced semisolid slurry of the same total volume fraction solid. This result is tentatively explained by the preferential location of reinforcement particles between dendrites arms, limiting contact and agglomeration of dendritic solid particles.

1.2.2.3 Particle Migration

After mixing, the semisolid composite may be at rest before complete solidification. The issue of particle migration because of gravity differences between metal and reinforcement then arises. For high volume fractions, the sedimentation is influenced by interactions between particles and by their size distribution (Lloyd 1991). When solidification takes place, particle migration caused by solidificationeffects competes with migration caused by gravity. Understanding and controlling the interaction between growing solid metal and the particles is crucial to producing homogeneously reinforced composites. Thus, when encountering a moving liquid/ solid interface, particles may be engulfed in the solid metal, or they may be pushed by the interface and consequently migrate into areas that solidified last, for example, interdendritic regions as illustrated in Figure 1.7. Work on this issue has recently been reviewed by several authors (Mortensen and Jin 1992; Rohatgi et al. 1990b; Stefanescu and Dhindaw 1988). From experimental observations, some particle/metal systems feature a critical interface velocity, V,, below which the particles are pushed and above which they are trapped. The value of V, depends on a number of factors, including particle size, shape and composition, metal composition, differences in thermal conductivity between particle and metal, and cooling rate. Several models have been developed to quantify particlepushing phenomena, but they are somewhat difficult to compare with experiments because the parameters do not all vary independently, and the castings generally do not solidify at steady-state.

Figure 1.6. Influence of shear rate on the viscosity of A-356-15volYo Sic. (Reprinted by permission from D. J. Lloyd, 1991.)

Вам также может понравиться

- Strengthening Mechanisms in Solid Solution Aluminum AlloysДокумент8 страницStrengthening Mechanisms in Solid Solution Aluminum AlloysJavier HerediaОценок пока нет

- Liquid Metal Embrittlelment-B.joseph Et Al.-Eur - Phys.journal AP 5-19-31 - 1999Документ13 страницLiquid Metal Embrittlelment-B.joseph Et Al.-Eur - Phys.journal AP 5-19-31 - 1999angelogontijoОценок пока нет

- Paper RPCMOD2007Документ10 страницPaper RPCMOD2007Jorge_UFCGОценок пока нет

- 16PRM C401 AlvarezДокумент11 страниц16PRM C401 AlvarezCristobal Matias PОценок пока нет

- The Research Status of The Wetting of Metal/Ceramic in The High Temperature Self-Lubricating MaterialsДокумент5 страницThe Research Status of The Wetting of Metal/Ceramic in The High Temperature Self-Lubricating MaterialsIlham Ary WahyudieОценок пока нет

- Stacking Fault Energy and Twin Effect For FCC CrystalДокумент20 страницStacking Fault Energy and Twin Effect For FCC CrystalEric TsaiОценок пока нет

- Oden Bach 2016Документ11 страницOden Bach 2016shreedharkolekarОценок пока нет

- Corrosion of Materials in Liquid Magnesium Alloys and Its PreventionДокумент40 страницCorrosion of Materials in Liquid Magnesium Alloys and Its PreventionAkram Ben KhemisОценок пока нет

- Mechanisms of Anelastic Deformation in Solid Polymers: Solidlike and Liquidlike ProcessesДокумент13 страницMechanisms of Anelastic Deformation in Solid Polymers: Solidlike and Liquidlike Processesنرگس باویОценок пока нет

- A Study of Mechanisms Affecting Molybdenite Recovery in A Bulk Copper Molybdenum Flotation CircuitДокумент11 страницA Study of Mechanisms Affecting Molybdenite Recovery in A Bulk Copper Molybdenum Flotation CircuitVerónica CharresОценок пока нет

- Metals 05 00504Документ26 страницMetals 05 00504Jelena OreljОценок пока нет

- Phase Transformation 1973Документ37 страницPhase Transformation 1973Palash SwarnakarОценок пока нет

- Metal Sorption On MineralДокумент25 страницMetal Sorption On MineralasasОценок пока нет

- Corrosion Rate Vs Grain Size PDFДокумент4 страницыCorrosion Rate Vs Grain Size PDFGajendra Pratap SinghОценок пока нет

- Pure and Applied GeophysicspageophДокумент4 страницыPure and Applied GeophysicspageophMane BarretoОценок пока нет

- 5.transport and Adhesion of Ash SpeciesДокумент13 страниц5.transport and Adhesion of Ash SpeciesPrakash WarrierОценок пока нет

- Using The Hollomon Model To Predict Strain-Hardening in MetalsДокумент4 страницыUsing The Hollomon Model To Predict Strain-Hardening in MetalsGuilherme ResendeОценок пока нет

- Metamorphic IndexДокумент18 страницMetamorphic Indexamit kumar guptaОценок пока нет

- TMP A4 DFДокумент26 страницTMP A4 DFFrontiersОценок пока нет

- Earth and Planetary Science Letters: Katherine L. Crispin, Saumitra Saha, Dane Morgan, James A. Van OrmanДокумент12 страницEarth and Planetary Science Letters: Katherine L. Crispin, Saumitra Saha, Dane Morgan, James A. Van OrmanLiviu BadeaОценок пока нет

- Materials: Special Issue: Radiation Damage in Materials-Helium EДокумент4 страницыMaterials: Special Issue: Radiation Damage in Materials-Helium EIsmatov TolibОценок пока нет

- Theory For Intermetallic Phase Growth Between Cu and Liquid SN-PB Solder Based On Grain Boundary Diffusion ControlДокумент10 страницTheory For Intermetallic Phase Growth Between Cu and Liquid SN-PB Solder Based On Grain Boundary Diffusion ControlsorescuОценок пока нет

- Factors Affecting Fatigue Life: Shot PeeningДокумент5 страницFactors Affecting Fatigue Life: Shot PeeningDeliaChiaОценок пока нет

- Jahn 2008Документ7 страницJahn 2008Trí DũngОценок пока нет

- 11IJCMR-Porosity DMSCatalinaДокумент8 страниц11IJCMR-Porosity DMSCatalinaBassel AlshamiОценок пока нет

- Chu 2011Документ14 страницChu 2011Abdullah AslanОценок пока нет

- Effect of Melt Convection and Solid Transport On Macrosegregation and Grain Structure in Equiaxed Al Cu AlloysДокумент12 страницEffect of Melt Convection and Solid Transport On Macrosegregation and Grain Structure in Equiaxed Al Cu AlloysMarcelo Lima CardosoОценок пока нет

- Interfacial Phenomena Metal-Slag-Gas in Aod-OutokumpuДокумент7 страницInterfacial Phenomena Metal-Slag-Gas in Aod-OutokumpuDaiara Budi AlvesОценок пока нет

- Crystals: Computer Simulations of Crystal Growth Using A Hard-Sphere ModelДокумент27 страницCrystals: Computer Simulations of Crystal Growth Using A Hard-Sphere ModelZANTHERОценок пока нет

- The Surface Self-Organization in Process Friction and Corrosion of Composite MaterialsДокумент4 страницыThe Surface Self-Organization in Process Friction and Corrosion of Composite MaterialsWalber BragaОценок пока нет

- Solid Solution Strengthening Is A Type ofДокумент7 страницSolid Solution Strengthening Is A Type ofkarthik3071988Оценок пока нет

- Surface Effects of Ordering in Binary Alloys: Topical ReviewДокумент34 страницыSurface Effects of Ordering in Binary Alloys: Topical RevieweidelsayedОценок пока нет

- Numerical Simulation of Droplet Impact and SolidifДокумент10 страницNumerical Simulation of Droplet Impact and Solidifeeng.ali6515Оценок пока нет

- Stack 1995 WearДокумент9 страницStack 1995 WearsureshjeevaОценок пока нет

- Basics of SinteringДокумент50 страницBasics of SinteringKeyur PatelОценок пока нет

- Engineering Metallurgy Presentation 2Документ87 страницEngineering Metallurgy Presentation 2Jay DedhiaОценок пока нет

- Mahaut2008 PDFДокумент28 страницMahaut2008 PDFMehdi EzadiОценок пока нет

- IJOGST - Volume 3 - Issue 4 - Pages 26-40Документ15 страницIJOGST - Volume 3 - Issue 4 - Pages 26-40David LópezОценок пока нет

- Mathematical Modeling of Single Peak Dynamic Recrystallization Flow Stress Curves in Metallic AlloysДокумент19 страницMathematical Modeling of Single Peak Dynamic Recrystallization Flow Stress Curves in Metallic AlloysJoselo HRОценок пока нет

- Proceedings of The 5th Canmet/ACI International Conference On Superplasticizers and Other Chemical Admixtures in ConcreteДокумент20 страницProceedings of The 5th Canmet/ACI International Conference On Superplasticizers and Other Chemical Admixtures in ConcreteAbdelaziz HasnaouiОценок пока нет

- Faroughi - 2017 - A Self-Similar Behavior For The Relative Viscosity of Concentrated Suspensions of Rigid Spheroids - 2016Документ15 страницFaroughi - 2017 - A Self-Similar Behavior For The Relative Viscosity of Concentrated Suspensions of Rigid Spheroids - 2016Bhimesh JОценок пока нет

- Lychagin 2020Документ11 страницLychagin 2020jonathan arayaОценок пока нет

- Engineering Science and Technology, An International JournalДокумент7 страницEngineering Science and Technology, An International JournalGil CastilloОценок пока нет

- Sorption and Speciation of Heavy Metals On Hydrous Fe and MN Oxides. From Microscopic To MacroscopicДокумент23 страницыSorption and Speciation of Heavy Metals On Hydrous Fe and MN Oxides. From Microscopic To Macroscopicmarwodaher1997Оценок пока нет

- The Rate-Limiting Mechanism For The Heterogeneous Burning of Cylindrical Iron RodsДокумент39 страницThe Rate-Limiting Mechanism For The Heterogeneous Burning of Cylindrical Iron RodsTeodoraОценок пока нет

- Drying of Supported Catalysts: A Comparison of Model Predictions and Experimental Measurements of Metal ProfilesДокумент9 страницDrying of Supported Catalysts: A Comparison of Model Predictions and Experimental Measurements of Metal Profilesvazzoleralex6884Оценок пока нет

- Fan Zhang, Paul A. Thibault and Rick Link - Shock Interaction With Solid Particles in Condensed Matter and Related Momentum TransferДокумент23 страницыFan Zhang, Paul A. Thibault and Rick Link - Shock Interaction With Solid Particles in Condensed Matter and Related Momentum TransferGhoree23456Оценок пока нет

- tốc độ trượtДокумент7 страницtốc độ trượtNhung VuОценок пока нет

- Burdukova Et Al. 2006. Effect of CMC and PH On The Rheology of Suspensions of Isotropic and Anisotropic MineralsДокумент15 страницBurdukova Et Al. 2006. Effect of CMC and PH On The Rheology of Suspensions of Isotropic and Anisotropic MineralsAnonymous T02GVGzBОценок пока нет

- Metasomatism and Metsomatic RocksДокумент17 страницMetasomatism and Metsomatic RocksDave StarOneОценок пока нет

- Unit IV Pilling Bedworth RatioДокумент7 страницUnit IV Pilling Bedworth RatioManikandan MuthuvijayanОценок пока нет

- Cummins 2007Документ15 страницCummins 2007Mayara SaОценок пока нет

- Geochem Geophys Geosyst - 2017 - DannbergДокумент28 страницGeochem Geophys Geosyst - 2017 - Dannbergharya bima heruajiОценок пока нет

- Effects of Metallurgical Structure On Forming ProcessДокумент14 страницEffects of Metallurgical Structure On Forming ProcessKuma DebelaОценок пока нет

- Basics of Solidification Processing of MДокумент17 страницBasics of Solidification Processing of M006KAbhishek KumarОценок пока нет

- On The Compression Behaviour of Reconstituted SoilsДокумент14 страницOn The Compression Behaviour of Reconstituted SoilsRusefFandiОценок пока нет

- 147 GiurannoДокумент6 страниц147 GiurannoV R SrinivasanОценок пока нет

- Computational Study of Uctuating Motions and Cluster Structures in Gas-Particle OwsДокумент25 страницComputational Study of Uctuating Motions and Cluster Structures in Gas-Particle OwsMuhammad Adnan LaghariОценок пока нет

- Bab3 MatrikulasiДокумент31 страницаBab3 MatrikulasiMuhammad Raihan BalfasОценок пока нет

- CobaДокумент2 страницыCobaMuhammad Raihan BalfasОценок пока нет

- Introduction - Concept of StressДокумент26 страницIntroduction - Concept of StressMuhammad Raihan BalfasОценок пока нет

- Stress and Strain - Axial LoadingДокумент36 страницStress and Strain - Axial LoadingMuhammad Raihan BalfasОценок пока нет

- PD2-23 Okt-2007Документ39 страницPD2-23 Okt-2007Muhammad Raihan BalfasОценок пока нет

- Sûrat Al-Muddatstsir (74) : Orang Yang Berkemul (The One Enveloped) Verses 1-56Документ3 страницыSûrat Al-Muddatstsir (74) : Orang Yang Berkemul (The One Enveloped) Verses 1-56Muhammad Raihan BalfasОценок пока нет

- Ceramics Glasses Superconductors HOДокумент4 страницыCeramics Glasses Superconductors HOMuhammad Raihan BalfasОценок пока нет

- Glycerin: WaterДокумент1 страницаGlycerin: WaterMuhammad Raihan BalfasОценок пока нет

- MMC 21Документ1 страницаMMC 21Muhammad Raihan BalfasОценок пока нет

- MMC 20Документ1 страницаMMC 20Muhammad Raihan BalfasОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Metal Matrix Composites 8Документ1 страницаMetal Matrix Composites 8Muhammad Raihan BalfasОценок пока нет

- You Are Invited To A Vernier Labquest Workshop!Документ1 страницаYou Are Invited To A Vernier Labquest Workshop!Edward BujakОценок пока нет

- Lighting or Illumination Is The Deliberate Use of Light To Achieve A Practical or Aesthetic EffectДокумент4 страницыLighting or Illumination Is The Deliberate Use of Light To Achieve A Practical or Aesthetic EffectasОценок пока нет

- Xe e Gate 2015Документ3 страницыXe e Gate 2015Ankit Kumar AJОценок пока нет

- Satellite Image ClassificationДокумент13 страницSatellite Image ClassificationTejaswi KatragaddaОценок пока нет

- Efficient Three-Dimensional Seismic Analysis of A High-Rise Building Structure With Shear WallsДокумент14 страницEfficient Three-Dimensional Seismic Analysis of A High-Rise Building Structure With Shear WallsArber RapushiОценок пока нет

- 2 Magnetic FieldsДокумент5 страниц2 Magnetic Fieldsrebbieg100% (1)

- Mid1 Review Solutions PDFДокумент4 страницыMid1 Review Solutions PDFRiza AriyaniОценок пока нет

- Course Material For GCFFДокумент235 страницCourse Material For GCFFBeena BОценок пока нет

- Loads For Supporting Beams: LX Ly UDL On SlabДокумент6 страницLoads For Supporting Beams: LX Ly UDL On SlabAnonymous sfkedkymОценок пока нет

- A Guide To Understanding Color CommunicationДокумент28 страницA Guide To Understanding Color CommunicationSeafar YachtingОценок пока нет

- Estimation of Wave Making Resistance by Wave Analysis Ship Wave at SeaДокумент11 страницEstimation of Wave Making Resistance by Wave Analysis Ship Wave at SeaPosei DonОценок пока нет

- Drilling Assembly HandbookДокумент198 страницDrilling Assembly HandbookAdil Aytekin100% (6)

- Simulation of Airbag Simulation ProcessДокумент9 страницSimulation of Airbag Simulation ProcessNikhil IngaleОценок пока нет

- Technical Note: Rockfall Impact Analysis On Fo Cable ISS.3Документ7 страницTechnical Note: Rockfall Impact Analysis On Fo Cable ISS.3SRARОценок пока нет

- ChecalДокумент8 страницChecalmigabraelОценок пока нет

- Transformer ThesisДокумент152 страницыTransformer Thesisramses197150% (2)

- Turnitin - FYP COMPLETED KOH XING KAI PDFДокумент158 страницTurnitin - FYP COMPLETED KOH XING KAI PDFXing Kai100% (1)

- Us 4331572Документ5 страницUs 4331572Bella AnggraОценок пока нет

- Unit - 5 Electric DipolesДокумент9 страницUnit - 5 Electric DipolesELMURОценок пока нет

- Design and Development of Weldinng RobotДокумент13 страницDesign and Development of Weldinng RobotÊswâr SîñghОценок пока нет

- The Nature and Properties of WavesДокумент24 страницыThe Nature and Properties of WavesMeryl PalenciaОценок пока нет

- Lecture 08Документ9 страницLecture 08Shahzad RehmanОценок пока нет

- Nist Air Density FormulaДокумент4 страницыNist Air Density FormulaMichael FanОценок пока нет

- PLC Automation of Steam TurbineДокумент5 страницPLC Automation of Steam TurbineWinarsita Gilang100% (1)

- PHY 2 - Problem Solution of CH 1Документ10 страницPHY 2 - Problem Solution of CH 1Mohamed El-GoharyОценок пока нет

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Документ9 страниц09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- BQUA - Hydranautics CPA5-LD MembraneДокумент1 страницаBQUA - Hydranautics CPA5-LD MembraneBassemОценок пока нет

- DOC316.53.01252 4ed PDFДокумент6 страницDOC316.53.01252 4ed PDFJean Carlos ArangoОценок пока нет

- Unit I MCQ Ii-2Документ7 страницUnit I MCQ Ii-2Kavitha Pasumalaithevan0% (1)

- Comparison of Methods For Calculation of Settlements of Soft Clay. H.P. Jostad and S.A. Degago (2010)Документ6 страницComparison of Methods For Calculation of Settlements of Soft Clay. H.P. Jostad and S.A. Degago (2010)Seif EddineОценок пока нет

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseОт EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseРейтинг: 3.5 из 5 звезд3.5/5 (69)

- A Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceОт EverandA Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceРейтинг: 4 из 5 звезд4/5 (51)

- Summary and Interpretation of Reality TransurfingОт EverandSummary and Interpretation of Reality TransurfingРейтинг: 5 из 5 звезд5/5 (5)

- The End of Everything: (Astrophysically Speaking)От EverandThe End of Everything: (Astrophysically Speaking)Рейтинг: 4.5 из 5 звезд4.5/5 (157)

- A Brief History of Time: From the Big Bang to Black HolesОт EverandA Brief History of Time: From the Big Bang to Black HolesРейтинг: 4 из 5 звезд4/5 (2193)

- Giza: The Tesla Connection: Acoustical Science and the Harvesting of Clean EnergyОт EverandGiza: The Tesla Connection: Acoustical Science and the Harvesting of Clean EnergyОценок пока нет

- Knocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldОт EverandKnocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldРейтинг: 3.5 из 5 звезд3.5/5 (64)

- AP Physics 1 Premium, 2024: 4 Practice Tests + Comprehensive Review + Online PracticeОт EverandAP Physics 1 Premium, 2024: 4 Practice Tests + Comprehensive Review + Online PracticeОценок пока нет

- Quantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessОт EverandQuantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessРейтинг: 4 из 5 звезд4/5 (6)

- Midnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterОт EverandMidnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterРейтинг: 4.5 из 5 звезд4.5/5 (410)

- The Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeОт EverandThe Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeОценок пока нет

- Quantum Physics: What Everyone Needs to KnowОт EverandQuantum Physics: What Everyone Needs to KnowРейтинг: 4.5 из 5 звезд4.5/5 (49)

- Packing for Mars: The Curious Science of Life in the VoidОт EverandPacking for Mars: The Curious Science of Life in the VoidРейтинг: 4 из 5 звезд4/5 (1396)

- Bedeviled: A Shadow History of Demons in ScienceОт EverandBedeviled: A Shadow History of Demons in ScienceРейтинг: 5 из 5 звезд5/5 (5)

- The Power of Eight: Harnessing the Miraculous Energies of a Small Group to Heal Others, Your Life, and the WorldОт EverandThe Power of Eight: Harnessing the Miraculous Energies of a Small Group to Heal Others, Your Life, and the WorldРейтинг: 4.5 из 5 звезд4.5/5 (54)

- Lost in Math: How Beauty Leads Physics AstrayОт EverandLost in Math: How Beauty Leads Physics AstrayРейтинг: 4.5 из 5 звезд4.5/5 (125)

- What If?: Serious Scientific Answers to Absurd Hypothetical QuestionsОт EverandWhat If?: Serious Scientific Answers to Absurd Hypothetical QuestionsРейтинг: 5 из 5 звезд5/5 (5)

- A Natural History of Color: The Science Behind What We See and How We See itОт EverandA Natural History of Color: The Science Behind What We See and How We See itРейтинг: 4 из 5 звезд4/5 (13)

- The Beginning of Infinity: Explanations That Transform the WorldОт EverandThe Beginning of Infinity: Explanations That Transform the WorldРейтинг: 5 из 5 звезд5/5 (60)