Академический Документы

Профессиональный Документы

Культура Документы

Manual de Trampas

Загружено:

Hector MagallonИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Manual de Trampas

Загружено:

Hector MagallonАвторское право:

Доступные форматы

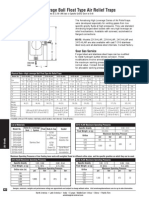

High Leverage Spring-Loaded Ball Float Type Drain Traps

For Low Flows at Pressures to 3,700 psi (255 bar) and Specific Gravity Down to 0.40

The Armstrong High Leverage Series of liquid drain traps

was developed especially for draining low specific gravity

fluids from gases at high pressures. They use standard

Armstrong forged steel bodies with very high leverage

systems and spring assist.

Sour Gas Service

Forged steel and stainless steel traps can be modified

to resist hydrogen sulfide stress corrosion. These

modifications involve annealing the float, which will reduce

the maximum working pressure of the float to about half its

normal value. Consult Armstrong Application Engineering

for allowable working pressures.

NOTE: Models 2313-HLS, 2316-HLS, 2413-HLS and

2415-HLS are also available with cast T-316 stainless steel

body and all-stainless steel internals. Consult factory.

Table LD-26. Reference Data

Because of design considerations in this drain trap, it is

essential that a safety factor of at least 2 be applied to the

peak liquid load for sizing purposes.

Model No.

2313-HLS

2413-HLS

25133G-HLS

2315-HLS

2415-HLS

25155G-HLS

26155G-HLS

2316-HLS

2416-HLS

Do not use HLS drain traps on steam service.

Float Diameter

Unbalanced Float Weight

3-1/2" (89 mm)

4 oz (113 g)

4" (102 mm)

4-1/2 oz (128 g)

5" (127 mm)

6 oz (170 g)

Table LD-27. Maximum Operating Pressures for Handling Different Specific Gravity Liquids With Orifices Available in High Leverage Drain Traps

(See pages LD-29 and LD-30.)

Liquid Drainers

Model

No.

506

LD-45

Sp. Grav.

1.00

.95

.90

.85

.80

Orifice

in

1/16

5/64

2313-HLS

3/32

7/64

1/8

3/32

1/8

2315-HLS

5/32

3/16

3/32

1/8

2316-HLS

5/32

3/16

7/32

1/16

5/64

2413-HLS

3/32

7/64

3/32

1/8

2415-HLS

5/32

3/16

3/32

1/8

2416-HLS

5/32

3/16

7/32

1/16

5/64

25133GHLS

3/32

7/64

5/64

3/32

25155G1/8

HLS

5/32

3/16

5/64

3/32

26155G1/8

HLS

5/32

3/16

Specific Gravity

.75

.70

.65

.60

.55

.50

.45

.40

Maximum Operating Pressure psig (bar) at 100F (38C)

psig

bar

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,500 103

1,500 103

1,500 103

1,500 103

1,800 124

1,800 124

1,720 119

1,210 83

1,600 110

1,600 110

1,600 110

1,600 110

1,600 110

2,120 146

2,120 146

2,120 146

1,870 129

2,520 174

2,520 174

2,520 174

1,720 119

1,210 83

3,700 255

3,700 255

2,650 183

1,720 119

1,210 83

1.00

psig

bar

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,500 103

1,500 103

1,500 103

1,500 103

1,800 124

1,800 124

1,610 111

1,130 78

1,600 110

1,600 110

1,600 110

1,600 110

1,600 110

2,120 146

2,120 146

2,120 146

1,740 120

2,520 174

2,520 174

2,470 171

1,610 111

1,130 78

3,700 255

3,700 255

2,470 171

1,610 111

1,130 78

.95

psig

bar

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,500 103

1,500 103

1,500 103

1,500 103

1,800 124

1,800 124

1,490 103

1,050 72

1,600 110

1,600 110

1,600 110

1,600 110

1,600 110

2,120 146

2,120 146

2,120 146

1,600 110

2,520 174

2,520 174

2,300 159

1,490 103

1,050 72

3,700 255

3,700 255

2,300 159

1,490 103

1,050 72

.90

psig

bar

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

970 67

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,500 103

1,500 103

1,500 103

1,460 101

1,800 124

1,800 124

1,380 95

970 67

1,600 110

1,600 110

1,600 110

1,600 110

1,600 110

2,120 146

2,120 146

1,960 135

1,460 101

2,520 174

2,520 174

2,130 147

1,380 95

970 67

3,700 255

3,680 254

2,130 147

1,380 95

970 67

.85

psig

bar

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

890 61

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,500 103

1,500 103

1,500 103

1,320 91

1,800 124

1,800 124

1,270 87

890 61

1,600 110

1,600 110

1,600 110

1,600 110

1,600 110

2,120 146

2,120 146

1,770 122

1,320 91

2,520 174

2,520 174

1,950 135

1,270 87

890 61

3,700 255

3,380 233

1,950 135

1,270 87

890 61

.80

psig

bar

1,000 69

1,000 69

1,000 69

1,000 69

920 63

1,000 69

1,000 69

1,000 69

810 56

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,500 103

1,500 103

1,500 103

1,180 82

1,800 124

1,780 122

1,150 80

810 56

1,600 110

1,600 110

1,600 110

1,600 110

1,570 108

2,120 146

2,120 146

1,590 110

1,180 82

2,520 174

2,520 174

1,780 122

1,150 80

810 56

3,700 255

3,080 212

1,780 122

1,150 80

810 56

.75

psig

bar

1,000 69

1,000 69

1,000 69

1,000 69

810 56

1,000 69

1,000 69

1,000 69

730 50

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,500 103

1,500 103

1,400 97

1,050 72

1,800 124

1,600 110

1,040 72

730 50

1,600 110

1,600 110

1,600 110

1,600 110

1,440 99

2,120 146

1,980 137

1,400 97

1,050 72

2,520 174

2,520 174

1,600 110

1,040 72

730 50

3,700 255

2,770 191

1,600 110

1,040 72

730 50

.70

psig

bar

1,000 69

1,000 69

1,000 69

910 63

700 48

1,000 69

1,000 69

930 64

650 45

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,500 103

1,500 103

1,220 84

910 63

1,800 124

1,430 98

930 64

650 45

1,600 110

1,600 110

1,600 110

1,600 110

1,300 90

2,120 146

1,720 119

1,220 84

910 63

2,520 174

2,470 170

1,430 98

930 64

650 45

3,490 241

2,470 170

1,430 98

930 64

650 45

.65

psig

bar

1,000 69

1,000 69

1,000 69

770 53

600 41

1,000 69

1,000 69

810 56

570 39

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,500 103

1,460 101

1,030 71

770 53

1,800 124

1,250 86

810 56

570 39

1,600 110

1,600 110

1,600 110

1,580 109

1,170 81

2,120 146

1,460 101

1,030 71

770 53

2,520 174

2,170 150

1,250 86

810 56

570 39

3,060 211

2,170 150

1,250 86

810 56

570 39

.60

psig

bar

1,000 69

1,000 69

850 58

630 44

490 34

1,000 69

1,000 69

700 48

490 34

1,000 69

1,000 69

1,000 69

1,000 69

1,000 69

1,500 103

1,200 83

850 58

630 44

1,800 124

1,080 74

700 48

490 34

1,600 110

1,600 110

1,600 110

1,400 97

1,040 71

1,820 125

1,200 83

850 58

630 44

2,520 174

1,870 129

1,080 74

700 48

490 34

2,630 182

1,870 129

1,080 74

700 48

490 34

.55

psig

bar

1,000 69

940 65

660 46

490 34

380 26

1,000 69

900 62

590 40

410 28

1,000 69

1,000 69

1,000 69

1,000 69

880 61

1,420 98

940 65

660 46

490 34

1,560 108

900 62

590 40

410 28

1,600 110

1,600 110

1,600 110

1,220 84

900 62

1,420 98

940 65

660 46

490 34

2,210 152

1,560 108

900 62

590 40

410 28

2,210 152

1,560 108

900 62

590 40

410 28

.50

psig

bar

1,000 69

670 47

480 33

360 25

280 19

1,000 69

730 50

470 33

330 23

1,000 69

1,000 69

1,000 69

1,000 69

750 52

1,020 71

670 47

480 33

360 25

1,260 87

730 50

470 33

330 23

1,600 110

1,600 110

1,480 102

1,040 72

770 53

1,020 71

670 47

480 33

360 25

1,780 123

1,260 87

730 50

470 33

330 23

1,780 123

1,260 87

730 50

470 33

330 23

.45

psig

bar

630

43

410

29

290

20

220

15

170 11.7

960

66

550

38

360

25

250

17

1,000 69

1,000 69

1,000 69

830

57

620

43

630

43

410

29

290

20

220

15

960

66

550

38

360

25

250

17

1,600 110

1,600 110

1,220 84

860

59

640

44

630

43

410

29

290

20

220

15

1,350 93

960

66

550

38

360

25

250

17

1,350 93

960

66

550

38

360

25

250

17

.40

NOTE: If actual specific gravity falls between those shown in above table, use next lower. For example, if actual gravity is 0.73, use 0.70 data.

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

North America Latin America India Europe / Middle East / Africa China Pacific Rim

armstronginternational.com

High Leverage Spring-Loaded Ball Float Type Drain Traps

For Low Flows at Pressures to 3,700 psi (255 bar) and Specific Gravity Down to 0.40

List of Materials

Table LD-28.

Valve &

Seat

Model No.

Leverage

Float Body & Cap

System

2313-HLS

2315-HLS

2316-HLS

Gasket

ASTM A105

Forged Steel

2413-HLS

2415-HLS

2416-HLS

25133G-HLS

25155G-HLS

26155G-HLS

Compressed

ASTM A182 Asbestos-free

Grade F22

Forged Steel

Stainless Steel

G

L

Vent

K

A

Figure LD-42.

High leverage ball float drain trap.

For a fully detailed certified drawing, refer to CD #1074.

Physical Data

Table LD-29. High Leverage Spring-Loaded Ball Float Type Drain Traps

Pipe

Connections

A

2313-HLS

in

mm

2315-HLS

2316-HLS

in

in

mm

mm

1/2, 15, 20, 1, 1-1/4, 25, 32,

40,

1-1/2, 2

3/4, 1

25

1-1/2

40

50

1/2, 3/4, 1

15, 20,

25

2415-HLS

2416-HLS

25133G-HLS

25155G-HLS

in

in

in

in

mm

1, 1-1/4, 25, 32,

1-1/2, 2

1-1/2

40

mm

40,

50

mm

1/2, 3/4, 1 15, 20, 25

26155G-HLS

mm

in

mm

3/4, 1,

1-1/4

20, 25, 32

1, 1-1/4,

1-1/2

25, 32,

40

9-3/4

248

11-7/8

302

8-5/8

219

10-3/4

273

12-1/2

318

8-1/2

216

10-3/8

263

11-3/4

298

11-9/16 294

15-1/16

383

17-1/8

435

11-7/8

3002

15

381

17-3/4

451

14-1/4

362

16-7/32

412

24-1/8

613

6-1/16

154

7-13/16

198

229

5-3/8

137

7-1/4

184

229

75

102

127

5-1/8

130

6-7/8

175

8-3/8

213

5-3/8

137

6-7/8

175

8-5/8

219

5-3/4

146

7-3/8

187

8-3/8

213

1-7/16

37

1-3/4

44

2-1/8

54

1-7/16

37

1-3/4

44

2-1/8

54

1-5/16

33

1-3/4

44

1-3/4

44

3-7/8

98

4-11/16

119

5-3/4

146

102

4-13/16

122

5-13/16

148

Maximum

Allowable

Pressure

(Vessel

Design)

203

mm

Weight,

lbs(kg)

2413-HLS

in

46 (21)

98 (44)

160 (73)

1,000 psig @ 100F (69 bar @ 38C)

600 psig @ 750F (41 bar @ 400C)

69 (31)

130 (59)

210 (95)

113 (51)

1,500 psig @ 100F

2,120 psig @ 100F

1,800 psig @ 100F (125 bar @

(103 bar @ 38C)

(146 bar @ 38C)

38C)

900 psig @ 850F

1,700 psig @ 900F

900 psig @ 900F (62 bar @ 482C)

(62 bar @ 454C)

(117 bar @ 482C)

171 (78)

325 (147)

2,520 psig @ 100F

(174 bar @ 38C)

2,000 psig @ 900F

(138 bar @ 482C)

3,700 psig @ 100F

(255 bar @ 38C)

3,000 psig @ 900F

(207 bar @ 482C)

Liquid Drainers

Model No.

Note: Available with screwed, socketweld or flanged connections.

Available with cast 316 stainless steel body and all stainless steel internals. Consult factory.

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

North America Latin America India Europe / Middle East / Africa China Pacific Rim

Next

armstronginternational.com

507

LD-46

Вам также может понравиться

- Yidro PoutsesqwerfqwefvqwerfgvqrvqerfvgqrfДокумент2 страницыYidro PoutsesqwerfqwefvqwerfgvqrvqerfvgqrfTravelergr KallogiroyОценок пока нет

- Belgas P630R IOMДокумент3 страницыBelgas P630R IOMSMcОценок пока нет

- Series LFB6080, LFB6081 Specification SheetДокумент2 страницыSeries LFB6080, LFB6081 Specification SheetWattsОценок пока нет

- Catalogo Bomba Gabbioneta Modelo DHДокумент2 страницыCatalogo Bomba Gabbioneta Modelo DHcristobal_tl2277Оценок пока нет

- Commercial ComponentsДокумент0 страницCommercial ComponentsChevronelleОценок пока нет

- Hedland H805B 030 F1 PDFДокумент2 страницыHedland H805B 030 F1 PDFCarlosEnriqueFalconZapataОценок пока нет

- Ensival Moret PRE Pumps (French-English)Документ3 страницыEnsival Moret PRE Pumps (French-English)Benicio Joaquín Ferrero BrebesОценок пока нет

- Antlies Hudro Pumps ServiceqwerfvqervqerДокумент2 страницыAntlies Hudro Pumps ServiceqwerfvqervqerTravelergr KallogiroyОценок пока нет

- Miljoco CatalogoДокумент96 страницMiljoco CatalogoyanbarrientosОценок пока нет

- SPW Immersion Fired - Specification Data Sheet (7000)Документ9 страницSPW Immersion Fired - Specification Data Sheet (7000)daemonohОценок пока нет

- High Leverage Spring-Loaded Ball Float Type Drain Traps: Sour Gas ServiceДокумент2 страницыHigh Leverage Spring-Loaded Ball Float Type Drain Traps: Sour Gas Serviceandy131078Оценок пока нет

- KIMRAY ValveДокумент16 страницKIMRAY ValveDenny Iskandar 'S-chuck'Оценок пока нет

- Armstrong Lever Drain Trap SpecificationsДокумент6 страницArmstrong Lever Drain Trap Specificationscivil270986Оценок пока нет

- SFS Products BrochureДокумент14 страницSFS Products BrochureJoshuaОценок пока нет

- Techno AppliancesДокумент11 страницTechno AppliancesJenel Ionovici100% (1)

- TEMA FlangesДокумент38 страницTEMA FlangesAshfaq Anwer100% (1)

- Jesco Ejector PresiuniДокумент2 страницыJesco Ejector PresiuniNicolae Ciprian AnghelОценок пока нет

- Equipo Pruebas de Presion LiquidosДокумент5 страницEquipo Pruebas de Presion Liquidosmfj79607555Оценок пока нет

- A23-28 656seriesДокумент6 страницA23-28 656serieskevinmathew27Оценок пока нет

- Hydraulic & Mechanical PullersДокумент9 страницHydraulic & Mechanical PullersMeilvy Rahmadani PaneОценок пока нет

- Series 805YD Specification SheetДокумент2 страницыSeries 805YD Specification SheetFEBCOОценок пока нет

- Eta CurvesДокумент38 страницEta Curvesfebime60% (5)

- Bombas Tuthill Curvas-Gg050Документ6 страницBombas Tuthill Curvas-Gg050ValentinaGuerraОценок пока нет

- Dynex PF 1300 SpecsДокумент7 страницDynex PF 1300 SpecsAdeel HassanОценок пока нет

- 150 MДокумент6 страниц150 M7761430Оценок пока нет

- Sports High MastДокумент2 страницыSports High MastmaxtamОценок пока нет

- Series LF223, LF223S Specification SheetДокумент2 страницыSeries LF223, LF223S Specification SheetWattsОценок пока нет

- According To BS-standard: Gas Clamps & CouplingsДокумент0 страницAccording To BS-standard: Gas Clamps & CouplingsAfrica OdaraОценок пока нет

- Reverse Osmosis Spare Parts Solenoid Valves Sensors CatalogДокумент48 страницReverse Osmosis Spare Parts Solenoid Valves Sensors CatalogSinergroup Water Filters Water Purifiers Water SoftenersОценок пока нет

- Pipe Sizing Steam Supply and Condensate Return Lines Sizing Charts Chart CG-25, page CG-51, is the basic chart for determining the flow rate and velocity of steam in Schedule 40 pipe for various values of pressure drop per 100 ft, based on 0 psig saturated steam. Using the multiplier chart (Chart CG-24), Chart CG-25 can be used at all saturation pressures between 0 and 200 psig (see Example). These Charts are based on the Moody Friction Factor, which considers the Reynolds number and the roughness of the internal pipe surfaces. Notes: Based on Moody Friction Factor where flow of condensate does not inhibit the flow of steam. See Chart CG-24 for obtaining flow rates and velocities of all saturation pressures between 0 to 200 psig: see Example. Pipe Sizing Two principal factors determine pipe sizing in a steam system: 1. The initial pressure at the boiler and the allowable pressure drop of the total system. The total pressure drop in the system should not exceed 20% ofДокумент3 страницыPipe Sizing Steam Supply and Condensate Return Lines Sizing Charts Chart CG-25, page CG-51, is the basic chart for determining the flow rate and velocity of steam in Schedule 40 pipe for various values of pressure drop per 100 ft, based on 0 psig saturated steam. Using the multiplier chart (Chart CG-24), Chart CG-25 can be used at all saturation pressures between 0 and 200 psig (see Example). These Charts are based on the Moody Friction Factor, which considers the Reynolds number and the roughness of the internal pipe surfaces. Notes: Based on Moody Friction Factor where flow of condensate does not inhibit the flow of steam. See Chart CG-24 for obtaining flow rates and velocities of all saturation pressures between 0 to 200 psig: see Example. Pipe Sizing Two principal factors determine pipe sizing in a steam system: 1. The initial pressure at the boiler and the allowable pressure drop of the total system. The total pressure drop in the system should not exceed 20% of1970acoОценок пока нет

- Vctds 02324 Figure 4020a enДокумент5 страницVctds 02324 Figure 4020a enFreddy Gómez GuillénОценок пока нет

- Totalcomp S Type Load Cells Brochure JECДокумент24 страницыTotalcomp S Type Load Cells Brochure JECInkieto BtkОценок пока нет

- Api 598Документ2 страницыApi 598Nitin Aggarwal78% (9)

- Bell Jurop Tanker Accessories Swivelling Hose Reel Brochure-1Документ4 страницыBell Jurop Tanker Accessories Swivelling Hose Reel Brochure-1It. jinyiОценок пока нет

- 04-Pump Curves 400 SeriesДокумент44 страницы04-Pump Curves 400 SeriesJuliancho Gomez100% (1)

- E4Документ14 страницE4juanca_eduОценок пока нет

- HPB Brochure 0708Документ12 страницHPB Brochure 0708musaluddinОценок пока нет

- Capstan BrochureДокумент12 страницCapstan BrochurepuspitaОценок пока нет

- Reg RedQ Specialy Regulators PDFДокумент20 страницReg RedQ Specialy Regulators PDFDavid SaldarriagaОценок пока нет

- Catalogo OblДокумент2 страницыCatalogo OblHarold Fernando Guavita ReyesОценок пока нет

- Gate Valve CataogueДокумент4 страницыGate Valve CataogueAditya B. RyantoОценок пока нет

- LD 01Документ6 страницLD 01Michael HaiseОценок пока нет

- HYD VLV, Fire Hose, HR & Breeching - Export2014Документ7 страницHYD VLV, Fire Hose, HR & Breeching - Export2014Jonathan MartinezОценок пока нет

- Válvulas Bola SegmentadaДокумент12 страницVálvulas Bola SegmentadarehynaldoОценок пока нет

- Rudarski Motor 4KTCRДокумент7 страницRudarski Motor 4KTCRAmir LemesОценок пока нет

- A3a PDFДокумент7 страницA3a PDFJaved MohammedОценок пока нет

- 6400-6600 Series Catalog (394C) PDFДокумент8 страниц6400-6600 Series Catalog (394C) PDF20106285Оценок пока нет

- App B Piping Specifications PDFДокумент4 страницыApp B Piping Specifications PDFirawan_epОценок пока нет

- PFQДокумент9 страницPFQVictorSanchezОценок пока нет

- 'C' Series Control ValvesДокумент12 страниц'C' Series Control Valvesابزار دقیق100% (1)

- Imo Pump 3DДокумент6 страницImo Pump 3DHadi Utomo100% (1)

- BelGAS P627 2014 RegulatorДокумент10 страницBelGAS P627 2014 RegulatorkaviarasuОценок пока нет

- G&L Series Commercial Products: - Pumps - Controls - Pressure BoostingДокумент20 страницG&L Series Commercial Products: - Pumps - Controls - Pressure BoostingCI MI GuadalupeОценок пока нет

- Bombas de Pistones Serie PREMIER DenisonДокумент40 страницBombas de Pistones Serie PREMIER DenisonOscar JavierОценок пока нет

- Line ProportionerДокумент2 страницыLine ProportionerpsycopaulОценок пока нет

- Fuel Oil PumpДокумент8 страницFuel Oil PumprezashahalamОценок пока нет

- Valves CatalogueДокумент33 страницыValves CatalogueDheeraj ThakurОценок пока нет

- Flyer DBS SeriesДокумент2 страницыFlyer DBS SeriesddadaraОценок пока нет

- Oil and Gas Artificial Fluid Lifting TechniquesОт EverandOil and Gas Artificial Fluid Lifting TechniquesРейтинг: 5 из 5 звезд5/5 (1)

- Merge From Ofoct (4) CompressedДокумент38 страницMerge From Ofoct (4) CompressedKalyani ingoleОценок пока нет

- Indian Standard: Code of Practice FOR Design and Construction Pile Foundations OFДокумент44 страницыIndian Standard: Code of Practice FOR Design and Construction Pile Foundations OFKhushaliОценок пока нет

- Aalco Stainless Steel Handrail SystemsДокумент72 страницыAalco Stainless Steel Handrail SystemsUnang SupriatnaОценок пока нет

- Filler Metal - Bestseller - Engl - NT - BohlerДокумент29 страницFiller Metal - Bestseller - Engl - NT - BohlerMaher BmdОценок пока нет

- Module 2 Bernoulli's Equation - ME 319-ME32S3 - Fluid MachineriesДокумент8 страницModule 2 Bernoulli's Equation - ME 319-ME32S3 - Fluid MachineriesOkay Printing100% (1)

- 2017 Fdot July Ebook PDFДокумент1 226 страниц2017 Fdot July Ebook PDFDamen JohnsonОценок пока нет

- Flue Gas Condenser: More Than Years Proven QualityДокумент2 страницыFlue Gas Condenser: More Than Years Proven QualityemadОценок пока нет

- Welding Questions 1Документ26 страницWelding Questions 1dselvakuuОценок пока нет

- Guidance-On-The-Design-Construction-And-Testing-Of-Standard-Rail Tank-Cars-For-The-Transport-Of-Chemicals-In-BulkДокумент15 страницGuidance-On-The-Design-Construction-And-Testing-Of-Standard-Rail Tank-Cars-For-The-Transport-Of-Chemicals-In-BulkarisandiyusufОценок пока нет

- Megara 150 3000K - 4 Beams: Michele de LucchiДокумент2 страницыMegara 150 3000K - 4 Beams: Michele de LucchiEdison GonzalezОценок пока нет

- Mahesabu Mikocheni - July2018Документ10 страницMahesabu Mikocheni - July2018David SabaflyОценок пока нет

- GE Panle BoardДокумент52 страницыGE Panle Boardchandrakanth0083396Оценок пока нет

- 03-Physic F5 2018-ElectricityДокумент32 страницы03-Physic F5 2018-ElectricitySreedrannОценок пока нет

- BS 5911-230-1994Документ19 страницBS 5911-230-1994laurentiuОценок пока нет

- Circuit DiagramsДокумент63 страницыCircuit DiagramsMax RojasОценок пока нет

- Corrosion ResistanceДокумент482 страницыCorrosion ResistanceJosé Ramírez100% (1)

- Avalon Astoria Service Manual PDFДокумент106 страницAvalon Astoria Service Manual PDFexchangenriОценок пока нет

- Astm 524-96Документ8 страницAstm 524-96JOSEPH REFUERZOОценок пока нет

- Table of Estimation 2Документ15 страницTable of Estimation 2Mylene Robles GupitОценок пока нет

- 2005 (A Colori) TAHER - Strenghtening of Critically Designed Girders With Dapped EndsДокумент31 страница2005 (A Colori) TAHER - Strenghtening of Critically Designed Girders With Dapped EndsEleonora InghelleriОценок пока нет

- Polystone P Homopolymer: Technical Data SheetДокумент1 страницаPolystone P Homopolymer: Technical Data Sheetmuchamad yasinОценок пока нет

- Hypertherm 2012 Torch and Consumables CatalogДокумент48 страницHypertherm 2012 Torch and Consumables CatalogDaniel AustinОценок пока нет

- JL-89-January-February Lateral Stability of Long Prestressed Concrete Beams-Part 1Документ20 страницJL-89-January-February Lateral Stability of Long Prestressed Concrete Beams-Part 1Dong-Yong KimОценок пока нет

- Lysaght Trimdek-Optima 2021Документ12 страницLysaght Trimdek-Optima 2021Fahmi YusoffОценок пока нет

- Corrosion Ring CalculationДокумент6 страницCorrosion Ring CalculationEko Januarto0% (1)

- Presentation of Circuit Breaker: Name of Student: Rubina Begum Id: 172-142-003 Batch: EEE-EVE/34thДокумент12 страницPresentation of Circuit Breaker: Name of Student: Rubina Begum Id: 172-142-003 Batch: EEE-EVE/34thMoniruzzaman JuwelОценок пока нет

- NPSHДокумент7 страницNPSHsateesh chandОценок пока нет

- Brick Work: Laurie BakerДокумент22 страницыBrick Work: Laurie BakerShaiwal_2997Оценок пока нет

- Columns and StrutsДокумент10 страницColumns and StrutsamitsagaОценок пока нет

- Boulanger Ziotopoulou 2013 - Formulation of A Sand Plasticity Plane-Strain Model For Earthquake Engineering Applications PDFДокумент14 страницBoulanger Ziotopoulou 2013 - Formulation of A Sand Plasticity Plane-Strain Model For Earthquake Engineering Applications PDFDebdeep SarkarОценок пока нет