Академический Документы

Профессиональный Документы

Культура Документы

Attachments For Engine Lathe

Загружено:

Ahmed Kaoud SakrИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Attachments For Engine Lathe

Загружено:

Ahmed Kaoud SakrАвторское право:

Доступные форматы

Attachments For Engine Lathe

) ( Turret , countouring , ball

:. /

Turret Attachments For Engine Lathe:

the turret which is mounted upon a compound rest and contains the tools which are successively brought into the working position by rotating the turret. In many instances, all the tools required can be held in the turret, although it is often necessary to use other tools, held on a cross-slide, for cutting off the finished part, facing a radial surface, knurling, or for some other operation. After a turret lathe is equipped with the tools needed for machining a certain part, it produces the finished work much more rapidly than would be possible by using an ordinary engine lathe, principally because each tool is carefully set for turning or boring to whatever size is required and the turret makes it possible to quickly place any tool in the working position. Turret lathes also have systems of stops or gages for controlling the travel of the turret carriage and cross-slide, in order to regulate the depth of a bored hole, the length of a cylindrical part or its diameter; hence, turning machines of this type are much more efficient than ordinary lathes for turning duplicate parts, unless the quantity is small, in which case, the advantage of the turret might be much more than offset by the cost of the special tool equipment and the time required for setting up the machine.

Contouring Attachments For Engine Lathe:

By using contouring attachments, the cross slide or a special copying slide is correspondingly moved forcibly in cross direction, according to the corresponding longitudinal position. In the case of the hydraulic copying attachment, a probe samples a copying template that incorporates the shape to be manufactured, and with this input it controls a hydraulic piston, which, in turn, is connected to the cross slide via a valve. There, velocity in longitudinal direction remains constant (constant lead) and is generated, as during normal cylindrical turning, by the lathes feed rod and leadscrew. In other design variants, such as with piston and cylinder in longitudi-nal direction, it is possible to change the lead according to the workpiece contour.

Fig.2. Diagram showing a hydraulic copying attachment.

Ball Turning Rests:

When spherical turning must be done repeatedly, special attachments are sometimes used. The fig.1 shows an attachment applied to a lathe for turning the spherical ends of ball-and-socket joints. The height or radius of the cutting tool and, consequently, the diameter of the turned ball, is regulated by adjusting screw A. The tool is swung around in an arc, by turning handle B which revolves a worm meshing with an enclosed worm-wheel. As will be seen, the work is held in a special chuck, owing to its irregular shape.

Fig. 3. Spherical Turning Attachment for Engine Lathe.

Another spherical turning attachment is shown in Fig. 2. This is used for machining the ends of gasoline engine pistons. The cross-slide has bolted to it a bar A carrying a roller which is pressed against a forming plate B by a heavy spring C. The forming plate B, which is attached to a cross-piece fastened to the ways of the lathe bed, is curved to correspond with the radius required on the piston end, and when the tool is fed laterally by moving the cross-slide, it follows the curve of plate B. The piston is held in a special hollow chuck which locates it in a central position and holds it rigidly.

Fig. 4. Attachment for Turning Spherical End of Gasoline Engine Piston

Вам также может понравиться

- Relay MK2P 8pins 12Vdc/24Vdc 110Vac/220Vac: Stock Code Description BrandДокумент2 страницыRelay MK2P 8pins 12Vdc/24Vdc 110Vac/220Vac: Stock Code Description BrandAhmed Kaoud SakrОценок пока нет

- Rolling DefectsДокумент6 страницRolling DefectsAhmed Kaoud Sakr100% (1)

- Planer Type: These Heavy Duty Large MachinesДокумент2 страницыPlaner Type: These Heavy Duty Large MachinesAhmed Kaoud SakrОценок пока нет

- Section 2: Measuring & Diagnostic ToolsДокумент14 страницSection 2: Measuring & Diagnostic ToolsAhmed Kaoud SakrОценок пока нет

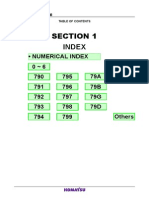

- Section 1: IndexДокумент124 страницыSection 1: IndexAhmed Kaoud SakrОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Detailed Lesson Plan in IctДокумент4 страницыDetailed Lesson Plan in IctJai AidamusОценок пока нет

- KM Adhikarya - TBK KomplitДокумент15 страницKM Adhikarya - TBK KomplitHelloMotion AcademyОценок пока нет

- PPE Microproject Report.Документ14 страницPPE Microproject Report.JAMES BOND100% (2)

- Friction Loss Calculations of Irrigation Design A Foot Ball CourtДокумент13 страницFriction Loss Calculations of Irrigation Design A Foot Ball Courtmathewmanjooran100% (2)

- Iv2906 Iveco Ad380t42h 6x4Документ2 страницыIv2906 Iveco Ad380t42h 6x4أبو خالد الأثرىОценок пока нет

- Excel ExercisesДокумент37 страницExcel ExercisesBERNIELLE DAVE FALDASОценок пока нет

- WSTP Week 10-13Документ6 страницWSTP Week 10-13Christian John Paul LijayanОценок пока нет

- Size Matters: (Type The Document Subtitle)Документ16 страницSize Matters: (Type The Document Subtitle)SamarthGoelОценок пока нет

- Guide To The Systems Engineering Body of Knowledge (Sebok), Version 1.1Документ51 страницаGuide To The Systems Engineering Body of Knowledge (Sebok), Version 1.1António FerreiraОценок пока нет

- SMA LACB Flyer Update BID21 ENДокумент4 страницыSMA LACB Flyer Update BID21 ENadilsonrodriguesОценок пока нет

- Instruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 AДокумент32 страницыInstruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 AYunisОценок пока нет

- A N Engineering Report On Unit 8: Engineering Design, Assignment 2 - Use of Computer Based Technology in Engineering DesignДокумент14 страницA N Engineering Report On Unit 8: Engineering Design, Assignment 2 - Use of Computer Based Technology in Engineering DesignTop Engineering SolutionsОценок пока нет

- PeltonДокумент7 страницPeltonKunal Kumar DasОценок пока нет

- Modeling and Control of Side Face Beam Cracking - FroschДокумент10 страницModeling and Control of Side Face Beam Cracking - FroschphamminhquangОценок пока нет

- Mazda rx7Документ3 страницыMazda rx7Jon WestОценок пока нет

- 5209 Aerospace T SealДокумент20 страниц5209 Aerospace T SealNicolasSuchОценок пока нет

- Service Manual: Model Code - Kib19Bp3-CmgДокумент11 страницService Manual: Model Code - Kib19Bp3-Cmgpravin jadavОценок пока нет

- HN1000 HN2000Документ44 страницыHN1000 HN2000Mose SodeОценок пока нет

- 1MDS06004 en en REL 100 RELZ 100 Numerical Line Protection TerminalДокумент8 страниц1MDS06004 en en REL 100 RELZ 100 Numerical Line Protection TerminalRuhuluruj100% (1)

- DsPIC33F - 01 - IntroductionДокумент8 страницDsPIC33F - 01 - IntroductionLau SandovalОценок пока нет

- B Indice F400 EДокумент8 страницB Indice F400 EIslam ShoukryОценок пока нет

- Fundamentals of Rock MechanicsДокумент4 страницыFundamentals of Rock Mechanicsmaomao_vt890% (1)

- Pompa WarmanДокумент2 страницыPompa WarmanRahmad Saleh SiregarОценок пока нет

- History of Control EngineeringДокумент2 страницыHistory of Control EngineeringAhmed HamoudaОценок пока нет

- Yale PD2, C85, D85Документ28 страницYale PD2, C85, D85LGWILDCAT73Оценок пока нет

- Java Swing Demo (Class Name Test)Документ2 страницыJava Swing Demo (Class Name Test)bejarunОценок пока нет

- A Review On Water ElectrolysisДокумент18 страницA Review On Water ElectrolysisSilvester KolicОценок пока нет

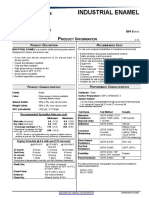

- DATA SHEET Industrial Enamel BlancoДокумент4 страницыDATA SHEET Industrial Enamel BlancoAlfredo OrellanaОценок пока нет

- TYBTech Syllabus MechanicalДокумент49 страницTYBTech Syllabus MechanicalswapnillkОценок пока нет