Академический Документы

Профессиональный Документы

Культура Документы

Me1302 Dme 2

Загружено:

sumikannuОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Me1302 Dme 2

Загружено:

sumikannuАвторское право:

Доступные форматы

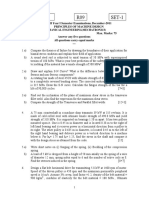

Reg. No.

L-~~

__

L-~~

__

~-k~~~~~

Question Paper Code:

P 1417

B.E./B.Tech. DEGREE EXAMINATION,NOVEMBERIDECEMBER 2009. Fifth Semester Mechanical Engineering ME 1302 - DESIGN OF MACHINE ELEMENTS (Common to B.E. (Part-Time) Fourth Semester - Regulation 2005) (Regulation 2004) Time: Three hours Answer ALL questions. Use of approved design data book is permitted. Assumptions and assumed data have to be stated clearly. PART A - (10 x 2 = 20 marks) 1. 2. 3. 4. 5. 6. Define resilience. What is Gerber theory? Why is maximum shear stress theory used for shaft? In what situation is flexible coupling used? What is a stud? Write down the expression for strength of parallel fillet weld in terms of permissible shear stress, leg of weld and length of welded joint. What are the different styles of end for helical compression spring? What do you mean by leverage? State the-disadvantages of thrust ball bearing. Define coefficient of fluctuation of energy. Maximum: 100 marks

7. 8. 9. 10.

PART B - (5 x 16 = 80 marks) 11. (a)

(i)

Two rods, made of plain carbon steel 40C8(Syt =380N/mm2)

are

connected by means of a cotter joint. The diameter of each rod is 50 mm and the cotter is made from a steel plate of 15 mm thickness. Calculate the dimensions of the socket end making the following assumptions: (1) The yield strength in compression is twice of the tensile yield strength; and (2) The yield strength strength. The factor of safety is 6.

(ii)

In shear is 50% of the tensile yield

(10)

Explain in detail the maximum shear stress theory. Or

(6)

(b)

(i)

A rod of a linkage mechanism made of steel40Crl(Sut = 550 N/mm 2) is subjected to a completely reversed axial load of 100 kN. The rod is machined on lathe and the expected reliability is 95%. There is no stress concentration. Determine the diameter of the rod (10) using a factor of safety of 2 for an infinite life condition.

(ii)

Explain Soderberg and Goodman lines in detail.

(6)

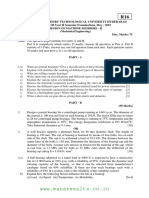

12.

(a)

A solid shaft of diameter 'd' is used in power transmission. Due to modification of existing transmission system, it is required to replace the solid shaft by a hollow shaft of the same material and equally strong in torsion. Further, the weight of hollow shaft per meter length should be half of the solid shaft. Determine the outer diameter of hollow shaft in terms ofd. Or

(b)

It is required to design a rigid type of flange coupling to connect two

shafts. The input shaft transmits 37.5 kW power at 180 rpm to the output shaft through the coupling. The service factor for the application is 1.5, i.e. the design torque is 1.5 times of rated torque. Select suitable materials for various parts of the coupling, design the coupling and specify the dimensions of its components. 2

P 1417

13.

(a)

Bolts are used to hold the cover plate on a pressure vessel, which is subjected to an internal pressure varying from zero to 2 MPa. The area over which the pressure acts may be taken to correspond to 400 mm diameter circle. The bolts are preloaded to the extent of 1.3 times the maximum force exerted by the fluid on the cover plate. The combined stiffness of the parts, held together by the bolt (including copper gasket), is four times the stiffness of the bolt. Following data is given for the bolts: Ultimate tensile strength = 900 NzmmYield Strength = 700 Nzmm'' Endurance limit in bending = 300 Nzmm'' Fatigue stress concentration factor = 2.2 Factor of safety Number

= 1.5 of bolts = 8

Determine the size of the bolts assuming fine thread. Or (b) Derive an expression to find out the maximum shear stress in transverse fillet weld. A helical compression spring is used to absorb the shock. The initial compression of the spring is 30 mm and it is further compressed by 50 mm while absorbing the shock. The spring is to absorb 250 J of energy during the process. The spring index can be taken as 6. The"spring is made of patented and cold drawn steel wire with ultimate strength of 1500 N/mm2 and modulus of rigidity of 81370 Nzmm-. The permissible shear stress for the spring wire should be taken as 30% of the ultimate tensile strength. Design the spring and calculate:

(i) (ii) (iii)

14.

(a)

Wire diameter Mean coil diameter Number of active turns

(iv) Free length; and (v) Pitch of the turns. Or

P 1417

(b)

A right angled bell-crank lever is designed to raise a load of 5 kN at the short arm end. The lengths of short and long arms are 100 and 450 mm respectively. The lever and the pins are made of steel 30C8(Syt= 400 N/mm2) and the factor safety is 5. The permissible bearing pressure on the pin is 10 Nzmm".The lever has a rectangular cross section and the ratio of width to thickness is 3: 1. The length to diameter ratio of fulcrum pin is 1.25:1. Calculate:

(i) (ii)

The diameter and length of fulcrum pin; The shear stress in the pin;

(iii) The dimensions of boss of the lever at the fulcrum; and (iv) The dimensions of the cross section of the lever Assume that the arm of bending moment on the lever extends up to the axis of fulcrum. 15. (a)

CD

A ball bearing is operated on work cycle consisting of three parts- a radial load of 3000 N at 1440 rpm for one quarter cycle, a radial load of 5000 N at 720 rpm for one half cycle, and radial load of 2500 N at 1440 rpm for the remaining cycle. The expected life of bearing is 10,000 hr. Calculate the dynamic load carrying capacity of the bearing. (10) Explain in detail rolling contact bearing failure remedies. Or causes and (6)

(ii)

(b)

(i)

The turning moment diagram of a multi cylinder engine is drawn with a scale of (Lmm+T'Ton the abscissa and (1 mm = 250 N-m) on the ordinate. The intercepted areas between the torque developed by the engine and the mean resisting torque of the machine, taken in order from one end are - 350 + 800 - 600 + 900 - 550 + 450 and - 650 mm-. The engine is running at a mean speed of 750 rpm and the coefficient of speed fluctuations is limited to 0.02. A rimmed flywheel made of grey cast iron FG 200(p = 7100kg/m3)is provided. The spokes, hub and shaft are assumed to contribute 10% of the required moment of inertia. The rim has rectangular cross section and the ratio of width to thickness is 1.5. Determine the dimensions of rim. (10)

(ii)

List the types of lubrication used in journal bearings and their characteristics. (6)

P 1417

Вам также может понравиться

- Section 1: Hardware & SoftwareДокумент30 страницSection 1: Hardware & SoftwareNorth Ruimveldt Secondary SchoolОценок пока нет

- Selenium WebdriverДокумент8 страницSelenium WebdriverMOHAN SОценок пока нет

- Conversion ChartДокумент1 страницаConversion ChartLibinОценок пока нет

- Exercises in Structural DynamicsДокумент13 страницExercises in Structural DynamicsObinna ObiefuleОценок пока нет

- Happy Startup EbookДокумент72 страницыHappy Startup EbookLucca CinquarolliОценок пока нет

- Lease Agreement or Rental Agreement FormatДокумент3 страницыLease Agreement or Rental Agreement Formatyuvashreesharmi60% (5)

- Mental Math Magic 6212 Practice Problems, Tips, and Hacks To Help You Calculate FasterДокумент465 страницMental Math Magic 6212 Practice Problems, Tips, and Hacks To Help You Calculate FasterKindman KindmanОценок пока нет

- 3850 Mathematics Stage 3 Marking Guide Sample 2Документ1 страница3850 Mathematics Stage 3 Marking Guide Sample 2AshleeGedeliahОценок пока нет

- Warehouse Performance QuestionsДокумент7 страницWarehouse Performance QuestionsjjjithendraОценок пока нет

- PMD ModelДокумент8 страницPMD ModelDamodara SatyaDeva MadhukarОценок пока нет

- 9A14503 Principles of Machine DesignДокумент8 страниц9A14503 Principles of Machine DesignsivabharathamurthyОценок пока нет

- Mech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsДокумент5 страницMech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsARIGARAN SОценок пока нет

- 4363 111 Machine Design IДокумент6 страниц4363 111 Machine Design Iyogesh_b_k100% (2)

- No of Pages Course Code:: Fig.1 Fig 2Документ4 страницыNo of Pages Course Code:: Fig.1 Fig 2CRAZY PIANO PLAYERОценок пока нет

- Snist Dom Previous PaperДокумент9 страницSnist Dom Previous PaperKapil Siddhant DevulapalliОценок пока нет

- ME 331 - DESIGN OF MACHINE ELEMENTS EXAMДокумент5 страницME 331 - DESIGN OF MACHINE ELEMENTS EXAMarumugam_rОценок пока нет

- Machine Members Design AssignmentДокумент13 страницMachine Members Design AssignmentHafiz Mahar28Оценок пока нет

- DME Model QuesДокумент3 страницыDME Model QuesSiva RamanОценок пока нет

- Tutorial Sheet-II MEC3110/317 (Machine Design II)Документ4 страницыTutorial Sheet-II MEC3110/317 (Machine Design II)Prateeksha ShakyaОценок пока нет

- 12ME5DCDM2Документ3 страницы12ME5DCDM2Abhyudaya SinghОценок пока нет

- 08 r05310305 Design of Machine Members IДокумент9 страниц08 r05310305 Design of Machine Members IKrupanandareddyYarragudiОценок пока нет

- Me1302 DmeДокумент4 страницыMe1302 DmesumikannuОценок пока нет

- 3-1 DMM1 (Nov 2009 Regular)Документ9 страниц3-1 DMM1 (Nov 2009 Regular)micmechОценок пока нет

- Machine Design Exam QuestionsДокумент2 страницыMachine Design Exam QuestionsSamNihalОценок пока нет

- QB Unit-1,2Документ5 страницQB Unit-1,2Agranshu BhardwajОценок пока нет

- DME Chapter Three: or (Summer 15)Документ7 страницDME Chapter Three: or (Summer 15)honeyfunnyОценок пока нет

- MDДокумент5 страницMDYogesh DanekarОценок пока нет

- Design of Machine Elements exam questionsДокумент4 страницыDesign of Machine Elements exam questionsSathis kumar0% (1)

- Design of machine elements exam questions and solutionsДокумент3 страницыDesign of machine elements exam questions and solutionsvikaskumar1986Оценок пока нет

- Dme Model 2Документ6 страницDme Model 2YashwanthI-StyleKuttiОценок пока нет

- Design of Machine Elements 2 Jan 2014Документ2 страницыDesign of Machine Elements 2 Jan 2014Prasad C M100% (1)

- R7310305 Design of Machine Members - IДокумент1 страницаR7310305 Design of Machine Members - IsivabharathamurthyОценок пока нет

- dmm1 PDFДокумент9 страницdmm1 PDFmohan_rapaka6095Оценок пока нет

- Question Paper Code:: Reg. No.Документ3 страницыQuestion Paper Code:: Reg. No.lavanya babuОценок пока нет

- DME Question Bank - 3171917Документ4 страницыDME Question Bank - 3171917fgyjnsv786Оценок пока нет

- Time Allowed: 1.5 Hours Full Marks: 70: 604 (S) August 2021Документ3 страницыTime Allowed: 1.5 Hours Full Marks: 70: 604 (S) August 2021Sourav BhowmikОценок пока нет

- Supp Nov 2009Документ10 страницSupp Nov 2009prk74Оценок пока нет

- QuestionsДокумент11 страницQuestionsSundara MoorthyОценок пока нет

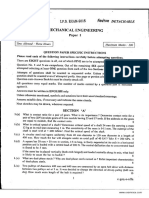

- WWW - Manaresults.co - In: (Mechanical Engineering)Документ2 страницыWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailОценок пока нет

- 07a6ec05 Designofmachinemembers IIДокумент11 страниц07a6ec05 Designofmachinemembers IIzahid_polyОценок пока нет

- Design of Machine Elements Exam with Questions on Shafts, Couplings, Keys, Springs, Bearings, FlywheelsДокумент3 страницыDesign of Machine Elements Exam with Questions on Shafts, Couplings, Keys, Springs, Bearings, FlywheelsHariharanAutoОценок пока нет

- Dme Model Key 2019Документ25 страницDme Model Key 2019Siva RamanОценок пока нет

- Me 2303 - Design of Machine Elements December 2010Документ3 страницыMe 2303 - Design of Machine Elements December 2010Ilaya Perumal K0% (1)

- ME6503-Design of Machine Elements PDFДокумент15 страницME6503-Design of Machine Elements PDFkarthikОценок пока нет

- Machine Design Answer KeyДокумент16 страницMachine Design Answer KeyK.KESAVARAJ HICET STAFF MCTSОценок пока нет

- Machine DesignДокумент6 страницMachine DesignRishi SinghОценок пока нет

- UNIT-1: Department of Mechanical EngineeringДокумент14 страницUNIT-1: Department of Mechanical EngineeringManivannan JeevaОценок пока нет

- Register Number NIT Mechanical Design Machine Elements ExamДокумент2 страницыRegister Number NIT Mechanical Design Machine Elements ExamdharaniventhanОценок пока нет

- Kings: Department of Mechanical EngineeringДокумент14 страницKings: Department of Mechanical EngineeringAdam AhmadОценок пока нет

- Dme Quest Ut-2Документ9 страницDme Quest Ut-2aadhithyarajasekaranОценок пока нет

- QB Unit-3,4,5Документ7 страницQB Unit-3,4,5Agranshu BhardwajОценок пока нет

- Dme Lab Sheets Ii Iii IvДокумент4 страницыDme Lab Sheets Ii Iii IvA58Vikas UbovejaОценок пока нет

- 12me52 MQP-1Документ3 страницы12me52 MQP-1SumitKumarОценок пока нет

- Assignment No-01 MEPC-301Документ6 страницAssignment No-01 MEPC-301SANDEEP BUDANIAОценок пока нет

- MODEL QUESTION PAPER Mechanical VibrationsДокумент3 страницыMODEL QUESTION PAPER Mechanical VibrationsDarani PriyaОценок пока нет

- 15 151905 Machine Design IДокумент3 страницы15 151905 Machine Design IPeeka Prabhakara RaoОценок пока нет

- B.Tech Exam Design of Machine Members QuestionsДокумент8 страницB.Tech Exam Design of Machine Members Questionsprk74Оценок пока нет

- No of Pages: 4 Course Code: 12M502: Fig.1 Fig 2Документ4 страницыNo of Pages: 4 Course Code: 12M502: Fig.1 Fig 2CRAZY PIANO PLAYERОценок пока нет

- Instructions:: No of Pages Course CodeДокумент2 страницыInstructions:: No of Pages Course CodeCRAZY PIANO PLAYERОценок пока нет

- Machine Elements Design QuestionsДокумент5 страницMachine Elements Design QuestionsbalameckОценок пока нет

- IFS Mechanical Engineering 2015 Part 1Документ4 страницыIFS Mechanical Engineering 2015 Part 1Saurabh BhardwajОценок пока нет

- Gujarat Technological UniversityДокумент2 страницыGujarat Technological UniversityHerat HirparaОценок пока нет

- r05321403 Principles of Machine DesignДокумент8 страницr05321403 Principles of Machine DesignSRINIVASA RAO GANTAОценок пока нет

- Me6503 Dme023Документ4 страницыMe6503 Dme023Bakkiya RajОценок пока нет

- Me 2303 Imp QnsДокумент3 страницыMe 2303 Imp QnsAJAY63Оценок пока нет

- WWW - Manaresults.Co - In: (Common To Ame, Me)Документ3 страницыWWW - Manaresults.Co - In: (Common To Ame, Me)Vikranth DeepakОценок пока нет

- Integrated Product and Process Development Unit I A. IntroductionДокумент19 страницIntegrated Product and Process Development Unit I A. IntroductionsumikannuОценок пока нет

- 2013 BE Mechanical Engineering A Section Student Name ListДокумент6 страниц2013 BE Mechanical Engineering A Section Student Name ListsumikannuОценок пока нет

- 7541 1462 5100 1 SyllabusДокумент8 страниц7541 1462 5100 1 SyllabussumikannuОценок пока нет

- PT II SyllabusДокумент1 страницаPT II SyllabussumikannuОценок пока нет

- DV03PUB7 Study GuideДокумент4 страницыDV03PUB7 Study GuidesumikannuОценок пока нет

- 1 - 8th BoG Agenda NotesДокумент20 страниц1 - 8th BoG Agenda NotessumikannuОценок пока нет

- 11EC801Документ1 страница11EC801sumikannuОценок пока нет

- Agenda: Team Orientation DayДокумент3 страницыAgenda: Team Orientation DaysumikannuОценок пока нет

- Apt I NumbersДокумент2 страницыApt I NumberssumikannuОценок пока нет

- Explain Briefly How The ChipДокумент4 страницыExplain Briefly How The ChipsumikannuОценок пока нет

- Dr. Mahalingam College of Engineering and Technology, Pollachi - 642 003Документ1 страницаDr. Mahalingam College of Engineering and Technology, Pollachi - 642 003sumikannuОценок пока нет

- WWW WWW WWWWДокумент1 страницаWWW WWW WWWWsumikannuОценок пока нет

- Dr. Mahalingam College of Engineering and Technology, PollachiДокумент1 страницаDr. Mahalingam College of Engineering and Technology, PollachisumikannuОценок пока нет

- Hints 1Документ19 страницHints 1sumikannuОценок пока нет

- Ivyeara&b Hostel Stdnts DataДокумент2 страницыIvyeara&b Hostel Stdnts DatasumikannuОценок пока нет

- Calendar of Activies For14-15 CTДокумент1 страницаCalendar of Activies For14-15 CTsumikannuОценок пока нет

- Lec 28Документ13 страницLec 28sumikannuОценок пока нет

- Calendar of Activies For14-15 CTДокумент1 страницаCalendar of Activies For14-15 CTsumikannuОценок пока нет

- BE SW EEE Opting - List 2010 2015Документ5 страницBE SW EEE Opting - List 2010 2015sumikannuОценок пока нет

- Student block diagram and output reportДокумент3 страницыStudent block diagram and output reportsumikannuОценок пока нет

- 3306 7730 1 PBДокумент6 страниц3306 7730 1 PBsumikannuОценок пока нет

- Non-Conventional Energy SystemsДокумент2 страницыNon-Conventional Energy SystemsJAMESJANUSGENIUS5678Оценок пока нет

- MTS Prepaid Mobile Top Up, MTS Data Card Recharge With Credit Cards & Net BankingДокумент1 страницаMTS Prepaid Mobile Top Up, MTS Data Card Recharge With Credit Cards & Net BankingsumikannuОценок пока нет

- DR - Mahalingam College of Engineering & Technology, Pollachi - 3Документ12 страницDR - Mahalingam College of Engineering & Technology, Pollachi - 3sumikannuОценок пока нет

- Course 9Документ2 страницыCourse 9faster123Оценок пока нет

- Student Project Block Diagram and OutputДокумент3 страницыStudent Project Block Diagram and OutputsumikannuОценок пока нет

- Itc LTD Interview QuestionsДокумент2 страницыItc LTD Interview QuestionssumikannuОценок пока нет

- Maximising Energy Performance and Productivity With Solar ShadingДокумент28 страницMaximising Energy Performance and Productivity With Solar ShadingsumikannuОценок пока нет

- Zimmermann - 'Beyond The Physics of Logic' PDFДокумент17 страницZimmermann - 'Beyond The Physics of Logic' PDFKam Ho M. WongОценок пока нет

- Final Examination: Print DateДокумент1 страницаFinal Examination: Print Datemanish khadkaОценок пока нет

- Social Web Analytics Using R Graph TheoryДокумент7 страницSocial Web Analytics Using R Graph TheoryParveshОценок пока нет

- (ENGL2112) Week 012-Course ModuleДокумент3 страницы(ENGL2112) Week 012-Course ModuleKaraОценок пока нет

- Auth Shield - MFID - Secure Access and Authentication SolutionДокумент46 страницAuth Shield - MFID - Secure Access and Authentication SolutionAuthShield LabОценок пока нет

- Problems SIH2019Документ16 страницProblems SIH2019hksОценок пока нет

- Scope of The StudyДокумент13 страницScope of The StudyKather ShaОценок пока нет

- Plagiarism: Giving Credit Where Credit Is DueДокумент16 страницPlagiarism: Giving Credit Where Credit Is DueAshish GuptaОценок пока нет

- SOP SampleДокумент2 страницыSOP SampleLikhit VermaОценок пока нет

- Marketing Theory and PracticeДокумент18 страницMarketing Theory and PracticeRohit SahniОценок пока нет

- Open NebulaДокумент7 страницOpen NebulaNaresh KumarОценок пока нет

- Lethe Berner Keep Warm Drawer BHW 70 2 MANДокумент17 страницLethe Berner Keep Warm Drawer BHW 70 2 MANGolden OdyesseyОценок пока нет

- Aho - Indexed GrammarsДокумент25 страницAho - Indexed GrammarsgizliiiiОценок пока нет

- SPH Mass ConservationДокумент15 страницSPH Mass ConservationnahkbceОценок пока нет

- Ampac Xp95 DetectorДокумент4 страницыAmpac Xp95 DetectortinduongОценок пока нет

- Classical Conditioning Worksheet 1Документ2 страницыClassical Conditioning Worksheet 1api-642709499Оценок пока нет

- Educational Base For Incorporated Engineer Registration - A22Документ5 страницEducational Base For Incorporated Engineer Registration - A22Prince Eugene ScottОценок пока нет

- Human Flourishing ReducedДокумент6 страницHuman Flourishing ReducedJanine anzanoОценок пока нет

- DNA Isolation PracticalДокумент8 страницDNA Isolation PracticalAniket MandalОценок пока нет

- Ushvinder Kaur - SSN PDFДокумент48 страницUshvinder Kaur - SSN PDFShraddha ShaduОценок пока нет

- Booklet - EpfpclДокумент9 страницBooklet - EpfpclAnonymous G5Od0CTrmeОценок пока нет

- 3rd International Conference On Managing Pavements (1994)Документ9 страниц3rd International Conference On Managing Pavements (1994)IkhwannurОценок пока нет