Академический Документы

Профессиональный Документы

Культура Документы

Ari Stone Specs

Загружено:

Lalit BhatАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ari Stone Specs

Загружено:

Lalit BhatАвторское право:

Доступные форматы

SECTION 03450 ARCHITECTURAL PRECAST CONCRETE SCOPE: The work preformed under this section of the specifications shall

include all labor, material, equipment, services and supervision required for the manufacture of the architectural precast concrete units shown on the drawings. Related work specified elsewhere: 1. All anchors, inserts and other hardware or attachments cast into poured-in-place concrete or welded to supporting structural framework 2. The provision and/or application of any insulation or vapor barrier material 3. Inserts, embedment, sleeves, holes or other attachments required by other trades. 4. Window frames, sash or glazing, louvers, grilles or other items and including the installation or weatherproofing of these items. 5. Joint fillers, sealants and caulking REFERENCES A. American Concrete Institute (ACI) 1. ACI318 - Building Code Requirements for Reinforced Concrete B. American Society for Testing and Materials (ASTM) 1. ASTM A615 - Spec for Deformed and Plain Billet-Steel Bars for Concrete Reinforcement 2. ASTM A767/A767M - Spec for Zinc Coating (Galvanized) Steel Bars for Concrete Reinforcement. 3. ASTM A780 - Standard Practice for Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings. 4. ASTM C33 - Spec for Concrete Aggregates. 5. ASTM C150 Spec for Portland Cement. 6. ASTM C26 Spec for Air-Entraining Admixtures for Concrete. 1

C. Precast Concrete Institute (PCI) 1. PCI Design Handbook for Precast and Pre-stressed Concrete. 2. PCI MNL-117 Manual for Quality Control for Plants and Production of Architectural Precast Concrete Products. QUALITY ASSURANCE: Acceptable manufacturer: Aristone Designs Inc. 1615 E. Weber Drive Tempe, AZ 85281 480-967-3035 Fax 480-967-1181 www.aristonedesigns.com 1. Production of architectural precast concrete units shall comply with the provisions of Precast Concrete Institute (PCI) MNL 117, Manual for Quality Control for Production of Architectural Precast Concrete Products A minimum of 5 years production experience in architectural precast concrete work of quality and scope for a specified project is required. Manufacture shall be by a company specializing in providing architectural concrete products and services Manufacture of architectural precast concrete units shall meet the allowable tolerances as set forth in PCI MNL 117. A competent Erection Contractor having experience in the erection of this type of material shall perform installation of architectural precast concrete units.

2. 3. 4. 5.

SUBMITTALS: A. The Manufacture shall submit for approval, prior to production of precast units, one sample representative of the actual elements as to quality and type of finish. The sample shall be at least 12 x 12 x 1 in size. B. Upon request of the Architect, test cylinders and product data shall be available for review. C. The Manufacturer shall submit shop drawings for approval prior to undertaking any work. These drawings shall show all finishes, dimensions, connection, and related details.

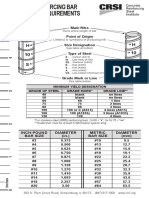

PRODUCTS MATERIALS: A. All concrete and steel shall be outlined in ACI 318 AISC Manual of Steel Construction and confirm to the latest ASTM standards STRUCTURAL DESIGN: A. Concrete shall confirm to the requirements for 28-day minimum compressive strength as shown on the structural drawings or in approved design calculations. FABRACATION A. Architectural precast concrete units shall be fabricated in accordance with the provisions of PCI MNL 117. B. Finishes shall match in texture and color the approved sample and actual finishing techniques shall be developed by the Manufacturer so as to meet the architectural specifications. Due to the nature of the product, slight variations in color will occur. C. The dimensions of precast concrete units shall be as shown on the plans. Products shall be fabricated and furnished to the following tolerances: *Bowing 1. Bowing, Length of bow or maximum. 360 2. Differential bowing, two adjacent members, *Warpage: 1. Maximum warpage of one corner from the nearest corner, 1/16/ft. to nearest corner Thickness: -1/8, +1/4 Squareness: 1/8 per 6ft. or max, whichever is greater Dimensions: 10 or under, + or- 1/8 Weld plates, anchors and inserts: + or 1 of centerline Block outs and reinforcements: Within or the indicated position to meet structural requirements. Length and width of block outs: + or 3

DAMAGE AND REPAIR: A. In house patching may be required by the Manufacturer prior to shipping. These repairs will be deemed acceptable if the structural integrity and/or aesthetic appearance is not impaired, subject to the approval of the Architect. STORAGE: A. Products shall be stored and handled in such a manner that prevents damage and protects the product. Aristone assumes no responsibility for the storing of our product on job site. EXECUTION Delivery, handling and storage: A. Care shall be used in the delivery and handling of architectural precast concrete units and in their storage at the jobsite. Members shall be handled in such a manner so as to prevent physical damage. ERECTION: A. A Competent Erection Contractor having experience in the erection of this type of material shall perform installation of architectural precast concrete units. If required, members shall be lifted by means of suitable lifting devices at points provided by the Manufacturer. B. The erector shall execute a final clean down to remove dirt and stains that are direct result of the erection process. C. Any damage that occurs during the erection will be the responsibility of the erector. These repairs will be deemed acceptable if the structural adequacy and/or aesthetic appearance is not impaired, subject to the approval of the architect. D. After completion, any further soiling or damage to architectural precast concrete units is the responsibility of the General Contractor. END OF SECTION

Вам также может понравиться

- Sections of Your Proposal:: Word Limit - 2000 WordsДокумент1 страницаSections of Your Proposal:: Word Limit - 2000 WordsLalit BhatОценок пока нет

- TQM in Construction Companies of Developing CountriesДокумент5 страницTQM in Construction Companies of Developing CountriesLalit BhatОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Class 10 Math Areas Related To Cirles Notes As PDF: Name Email Mobile CityДокумент1 страницаClass 10 Math Areas Related To Cirles Notes As PDF: Name Email Mobile CityLalit BhatОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Proposed Approach To Comparing The BIM Maturity of CountriesДокумент11 страницA Proposed Approach To Comparing The BIM Maturity of CountriesLalit BhatОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Cife Ecc CifeproposalДокумент13 страницCife Ecc CifeproposalLalit BhatОценок пока нет

- NIT FacilitiesДокумент2 страницыNIT FacilitiesLalit BhatОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Project Management Construction Management Services ENGДокумент37 страницProject Management Construction Management Services ENGLalit Bhat100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Cost of QualityДокумент6 страницCost of QualityLalit BhatОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Code of Practice On Environmental Health (COPEH) 1998Документ24 страницыCode of Practice On Environmental Health (COPEH) 1998Trang NgoОценок пока нет

- 1912 Choosing + Using The Right NEC ContractДокумент2 страницы1912 Choosing + Using The Right NEC ContractLalit BhatОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Guid SPCДокумент10 страницGuid SPCAshok SubramaniyanОценок пока нет

- SdarticleДокумент19 страницSdarticleLalit BhatОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Performance of Pfi Construction: A Review by The Private Finance PracticeДокумент40 страницPerformance of Pfi Construction: A Review by The Private Finance PracticeLalit BhatОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- SdarticleДокумент8 страницSdarticleLalit BhatОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Hotel Building Load CalculationsДокумент5 страницHotel Building Load CalculationsJERALDОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Jose V. Yap Sr. Access RoadДокумент3 страницыJose V. Yap Sr. Access RoadRobin PabustanОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Ferrocement Construction Technology and Its Applications PDFДокумент20 страницFerrocement Construction Technology and Its Applications PDFPranavaDart0% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- COPRA Anchoring Coupler: For Bolted ConnectionsДокумент24 страницыCOPRA Anchoring Coupler: For Bolted ConnectionsKusuma Indra KlanaОценок пока нет

- Equivalents of Carbon Steel QualitiesДокумент10 страницEquivalents of Carbon Steel Qualitiessentilmech07Оценок пока нет

- LRFD Bridge Design Specifications Method B Procedure. Shear ModulusДокумент1 страницаLRFD Bridge Design Specifications Method B Procedure. Shear Modulusmuhd.qasimОценок пока нет

- Al Hamra Tower: Kuwait's Iconic 412m Spiral SkyscraperДокумент2 страницыAl Hamra Tower: Kuwait's Iconic 412m Spiral Skyscrapermiyoko miyokoОценок пока нет

- Metode Kerja Erection Girder Bentang 50M: Dengan LAUNCHER 150T - 50MДокумент29 страницMetode Kerja Erection Girder Bentang 50M: Dengan LAUNCHER 150T - 50Mciptastrada japek selatanОценок пока нет

- Technological Institute of The Philippines 938 Aurora Boulevard, Cubao, Quezon CityДокумент21 страницаTechnological Institute of The Philippines 938 Aurora Boulevard, Cubao, Quezon CityKIAN CARLO AREVALOОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Structural Cracks in ConcreteДокумент14 страницStructural Cracks in ConcreteMahesh SinglaОценок пока нет

- W1, W2 Long Span StructureДокумент81 страницаW1, W2 Long Span StructureMuhammad AizatОценок пока нет

- Fatigue Provision in IRS Girder Vs InternationalДокумент27 страницFatigue Provision in IRS Girder Vs Internationalpant_tcОценок пока нет

- Structural Analysis - WikipediaДокумент10 страницStructural Analysis - WikipediaEn Iyisi İnşaat MühendisiОценок пока нет

- 60 M.bow String Girder-10411-7-RДокумент1 страница60 M.bow String Girder-10411-7-RkesharinareshОценок пока нет

- HSK Lot4312 Louvre Fixing Detail Comment 11august2023Документ1 страницаHSK Lot4312 Louvre Fixing Detail Comment 11august2023rickysw 7Оценок пока нет

- AWC Beam FormulasДокумент26 страницAWC Beam FormulasR ASTUSОценок пока нет

- Pin Base ModuleДокумент16 страницPin Base ModuleMd Ahsanul KabirОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Types and Uses of TrussesДокумент14 страницTypes and Uses of TrussesRomani Noel S. Chavez Jr.Оценок пока нет

- Factual Civil Engineering: Cement ReconcilationДокумент5 страницFactual Civil Engineering: Cement ReconcilationDeepak Kaushik100% (1)

- Steel tripod, wrench, frame and arch beam load calculationsДокумент19 страницSteel tripod, wrench, frame and arch beam load calculationsRenne Jude Rollorata100% (1)

- Building Tech 5: AR Joseph Rea UapДокумент4 страницыBuilding Tech 5: AR Joseph Rea UapDaryl AguilarОценок пока нет

- Design of Hollow Core Slab PDFДокумент50 страницDesign of Hollow Core Slab PDFMatthew ChinОценок пока нет

- Macro-Modeling of Reinforced Concrete Structural Walls: State-of-the-ArtДокумент28 страницMacro-Modeling of Reinforced Concrete Structural Walls: State-of-the-ArtHemant SonawadekarОценок пока нет

- Code of Practice For Concrete Road Bridges IRC:112: Case Study 1 - Design of I GirderДокумент15 страницCode of Practice For Concrete Road Bridges IRC:112: Case Study 1 - Design of I GirderSony JsdОценок пока нет

- Vernacular TermsДокумент3 страницыVernacular TermsSamson, Maisie DominiqueОценок пока нет

- Astm Reinforcing Bar Marking Requirements: (Inch-Pound)Документ2 страницыAstm Reinforcing Bar Marking Requirements: (Inch-Pound)Babrak Khan NoorzoiОценок пока нет

- December 18, 2003 6:30 - 8:30 P.M.: Pocket-SizedДокумент5 страницDecember 18, 2003 6:30 - 8:30 P.M.: Pocket-SizedYUK LAM WONGОценок пока нет

- Mid Term PresentationДокумент21 страницаMid Term PresentationSujan SinghОценок пока нет

- Civil Questions and Answers-Building-Construction PDFДокумент45 страницCivil Questions and Answers-Building-Construction PDFAkd Deshmukh100% (7)

- Checklist For RCC Slab and BeamsДокумент8 страницChecklist For RCC Slab and BeamsRupesh KhandekarОценок пока нет

- An Architect's Guide to Construction: Tales from the Trenches Book 1От EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Оценок пока нет