Академический Документы

Профессиональный Документы

Культура Документы

Bio-Mimetic Behaviour of IPMC Artificial EMG Signal

Загружено:

Muhammad Royyan ZahirАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bio-Mimetic Behaviour of IPMC Artificial EMG Signal

Загружено:

Muhammad Royyan ZahirАвторское право:

Доступные форматы

2010 International Conference on Advances in Recent Technologies in Communication and Computing

Bio-mimetic Behaviour of IPMC Artificial Muscle Using EMG Signal

R.K. Jain*, S. Datta*, S. Majumder*, S. Mukherjee**, D. Sadhu**, S. Samanta** and K. Banerjee**

*Scientists, **Students DMS/Micro Robotics Laboratory Central Mechanical Engineering Research Institute, Durgapur-713209, (CSIR), West Bengal, India. Corresponding author e-mail: rkjain@cmeri.res.in

AbstractAssistive devices such as prosthetic and orthotic devices as well as micro robotic arm can perform similar operation of a human arm when these are actuated by muscle power. The generated force is transferred through an electro-mechanical system. Most of electro mechanical devices are heavy and are not compatible with muscular system. However, an ionic polymer metal composite (IPMC) has tremendous potential as an artificial muscle and is driven by a low voltage range between -3 to +3 V. In this paper, bio-mimetic actuation of IPMC is studied. The electric voltage is detected by electromyographic (EMG) signal through human muscle and is transferred to IPMC. It is observed that an IPMC shows similar behaviour and controls of a human fore arm. Keywordsbio-mimetic, actuator and EMG. artificial muscle, IPMC,

I.

INTRODUCTION

The assistive devices such as prosthetic and orthotic devices need soft actuating systems which are controlled through human muscle power. The emergence of effective electroactive polymer (EAP), also known as artificial muscles can potentially address this need [1,2]. EAP responds to an electrical stimulation with a significant change of shape or size and this characteristic behavior can be implemented for designing actuation-driving mechanism and improve the quality of life. Especially, ionic polymer metal composite can be widely applied to the artificial muscle

This work is supported in part by the Council of Scientific and Industrial Research (CSIR), New Delhi, India (Grant No. NWP-30, 2007-2012) under eleventh five year plan on Modular Reconfigurable Micro Manufacturing Systems (MRMMS) for Multi Material Desktop Manufacturing Capabilities. S. Mukherjee, D. Sadhu, S. Samanta and K. Banerjee are students of Asansol Engineering College, Asansol, India who are carrying out the final year B. Tech Project at CMERI, Durgapur, India. Rests of the authors are with the Design of Mechanical System Group and Micro Robotics Laboratory, Central Mechanical Engineering Research Institute (CMERI), Durgapur-713209, West Bengal, India. (Corresponding author email: rkjain@cmeri.res.in; Tel No +91-3436452137)

because it is easily manufactured and is driven by relatively low input voltage (3V) [3]. IPMC bends towards the anode when subjected to a voltage across its thickness due to cation migration towards cathode in the polymer network. When the polarity is changed, it bends in the reverse direction. In this aspect, the actuating voltage for IPMC is given through our human muscle in place of battery source. For this purpose, an electromyographic (EMG) signal approach is carried out to transfer the signal from our muscle power. In past, Jou et al. (2006) has studied an articulatory feature classification of face muscles using surface electromyography [4]. Natarajan et al. (2002), Karakostas et al. (2003) and Kunju et al. (2009) have modeled the human arm interface for muscle activity, the quantification index of co-contraction at the knee during walking gait and walking pattern respectively [5-7]. Daley et al. (1990), Hudgins et al. (2000) and Light et al. (2002) have focused towards the microprocessor-based multifunctional myoelectric control system. Abdallah et al. (2009) and Ahsan et al. (2009) have concentrated on step signal of EMG [6-13]. Two-dimensional myoelectric control system of a robotic arm for an upper limb amputee and real-time upper limb motion from non invasive biosignals with physical human-machine interactions have been studied by Celani et al. (2007) and Kwon et al. (2009) respectively [14, 15]. Naik et al. (2010) has also studied the pattern classification of myo-electrical signal during different maximum voluntary contractions using BSS techniques for a blind person [16]. Murphy et al. (2009) has explored the micro electro-mechanical systems based sensor for mechanomyography [17]. Lee et al.s (2004) and Al-Faiz et al.s (2009) research work are related to the control of IPMC system for hand prosthesis and arm movement recognition based on EMG signal respectively [18,19]. In further continuation, we are exploring the bio-mimetic behavior of an IPMC using EMG for micro robotic arm. The objective of this paper is to examine the biomimetic behavior of IPMC through EMG signal. When a forearm moves in different angles, generated signal is

186

978-0-7695-4201-0/10 $26.00 2010 IEEE DOI 10.1109/ARTCom.2010.49

transferred to IPMC which allows bending. This bending behavior is utilized in IPMC based micro robotic arm movements for micro manipulation system. II. FORE ARM BEHAVIOR

A. EMG signal behavior for fore arm During actuation of an IPMC, an EMG signal is the measured electric potential produced by voluntary contraction of muscle fiber. The frequency range of the EMG signal is within 4 to 900 Hz. The dominant energy is concentrated in the range of 100 Hz and amplitude of voltage range is 5.5 mV according to muscle contraction. Using these parameters, the circuit for filter signal is designed using MATLAB SIMULINK software as shown in Figure 1. In block diagram, the active EMG signal is taken from muscle and uniform noise is considered. The electric potential is first amplified with gain 32 dB and then band pass filter (BPF) is used with frequency range 4 to 900 Hz. Using band stop filter (BSF), noise signal that arises due to AC coupler power is eliminated. The signal is then passed through an amplifier with gain 60 dB. Subsequently, integrators are used to acquire better damping signal. The filtered signal is then passed to IPMC through ADC/DAC along with control system. The output signal after filtering is shown in Figure 2. It shows that the EMG signal is taken from muscle in the range of 5.5 mV. After filtering the noise, steady state signal is obtained.

B. Configuration of fore arm motion The different configurations ranging from 00 to 1800 are considered for measurement of displacement in actual environment as shown in Figure 3. The initial articulation of the arm is formed by having 00 between the upper arm and forearm. IPMC actuates in a similar manner according to the fore arm movement. The magnified displacement of IPMC strip with fore arm position is obtained as shown in Figure 4. It follows the exponential curve with maximum displacement 14 mm. This displacement would be utilized as an IPMC based micro robotic arm for lifting operation.

Fore arm position= 00 (a)

Fore arm position= 450 (b)

Fore arm position= 900 (c)

Fore arm position= 1350 (d)

Fore arm position= 1800 (e)

Figure 3 Schematic layout for different positions of fore arm

Figure 1 Block diagram of EMG signal behavior

8 6 4 x 10

-3

EMG behaviour Voltage Vs. Time

Voltage (V)

2 0 -2 -4 -6 -8 0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

Figure 4 IPMC displacement response with fore arm position

III.

EXPERIMENTAL SETUP

Time (s)

Figure 2 Voltage corresponding to EMG signal behavior

The testing setup for bio-mimetic behavior of IPMC is shown in Figure 5. For actuation of IPMC through human muscles, EMG electrodes are positioned at forearm. EMG electrodes generate the voltage from the muscles which is then fed into the input port of an ADC

187

ADC/DAC

PXI System

IPMC control circuit

DAQ assistant IPMC

Figure 5 Basic testing layout of IPMC actuation through muscles

(Analogto-Digital Converter). Electric field and current are imposed on the two faces of IPMC which is entered through the IPMC driver circuit. This data is amplified through PXI system along with DAQ Assistant Express VI in LabVIEW 8.5 software. The current and voltage analysis of the human flexor carpi ulnaris and extensor carpi ulnaris muscles is also done through oscilloscope. IV. RESULT AND DISCUSSION

Figure 7 IPMC configuration before fore arm movement

During experimentation, the input parameter from muscle ranging from 5.5 mV is taken through referenced single-ended (RSE) signal along with continuous sampled pulses as shown in Figure 6. The pulse is amplified with the help of a PXI system. The amplification factor is 550. The desired output voltage range is generated through a DAC output port with the same frequency range. The output signal is connected to IPMC strip. Due to amplified output voltage from the DAC, an IPMC strip bends in one direction. By changing the polarity of the signal, the bending behavior can be reversed. The input and output configurations of the IPMC are shown in Figures 7 and 8.

Figure 8 Bending configuration after fore arm movement

The input flexor and extensor pulses are extracted from EMG signal which is fed to IPMC and various cases have been studied as shown in Table-I. It has been analyzed that output signal (fed to IPMC) is directly proportional to flexor and extensor muscles signal when it is working in either on or off mode.

TABLE-I THE POWER POLARITY ON BOTH SIDES OF IPMC Cases Flexor muscles Off Off On On Extensor muscles Off On Off On State Polarity Side A None Extensor Flexor None None Negative Positive None Side B None Positive Negative None

I II III IV

The voltage signal behavior is taken from EMG and fed to IPMC for actuation as shown in Figure 9. It is found that the trend of IPMC actuation voltage is similar to EMG voltage with amplification factor.

Figure 6 EMG placements on fore arm

188

x 10

-3

EMG Voltage Vs Time

EMG Voltage (V)

4 2 0 -2 -4 -6 0 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.1

feature can be applied in the field of rehabilitation technology and micro manipulation. In future, we will focus on developing well equipped micro robotic arm system. Human fore arm movement could be transferred into IPMC based micro robotic arm in a similar manner. It can be concluded that IPMC behavior shows replacement of an electro-mechanical system like electric motors in the application field of micro manipulation. ACKNOWLEDGEMENT The authors are grateful to the Director, Central Mechanical Engineering Research Institute (CMERI), Durgapur, West Bengal, India for granting the permission to publish this paper. The project is financially supported by the Council of Scientific and Industrial Research, New Delhi, India under eleventh five year plan on Modular Re-configurable Micro Manufacturing Systems (MRMMS) for Multi Material Desktop Manufacturing Capabilities (NWP-30) at CMERI. Authors are also thankful to Mr. Souvick Chowdhury (Project Assistant, CMERI) for assistance in this project. REFERENCES

Y. Bar-Cohen, Focus issue on bio-mimetics using electroactive polymers as artificial muscles, Bio-inspiration & bio-mimetics, vol. 2, 2007. [2] Y. Bar-Cohen, Electroactive polymer (EAP) actuators as artificial muscles - reality, potential and challenges, 2nd Edition, ISBN 0-8194-5297-1, SPIE Press, vol. PM136, March, 2004. [3] K. J. Kim and M. Shahinpoor, A novel method of manufacturing three dimensional ionic polymer metal composites (IPMCs), bio-mimetic sensors, actuators and artificial muscles, Polymer, 43, 2002, pp. 797-802. [4] S. C. Jou, L. M. Hein, T. Schultz and A. Waibel, Articulatory feature classification using surface electromyography, IEEE ICASSP, Germany, 2006, pp. 605-608. [5] S. Natarajan, M. Kazi and G. Muralidharan, Biosignal based human-machine interface for robotic arm, IEEE conference, 2002, Available: http://www.mechatroniks.net/index_files/5.pdf [6] T. Karakostas, N. Berme, M. Parnianpour, W.S. Pease and P.M. Quesada, Muscle activity and the quantification of cocontraction at the knee during walking gait, Summer Bioengineering Conference, Florida, June 25-29, 2003, pp.1-2. [7] N. Kunju, N. Kumar, D. Pankaj, A. Dhawan and A. Kumar, EMG signal analysis for identifying walking patterns of normal healthy individuals, Indian Journal of Biomechanics: Special Issue, NCBM, March 7-8, 2009. [8] T. L. Daley, R. N. Scott, P. A. Parker and D. F. Lovely, Operator performance in myoelectric control of a multifunction prosthesis stimulator, Journal of Rehabilitation Research and Development, vol. 27, 1990, pp. 920. [9] B. Hudgins, K. Englehart, P. Parker and R. N. Scott, A microprocessor-based multifunction myoelectric control system, Institute of Biomedical Engineering, University of New Brunswick Fredericton, NB Canada, 1997. Available: http://www.ee.unb.ca/kengleha/papers/ CMBES97 [10] C. M. Light, P. H. Chappell, B. Hudgins and K. Englehart, Intelligent multifunction myoelectric control of hand [1]

IPMC Actuation Voltage (V)

3 2 1 0 -1 -2 -3 0 0.01 0.02

Time (s) IPMC Actuation Voltage Vs Time

0.03

0.04

0.05

0.06

0.07

0.08

0.09

0.1

Time (s)

Figure 9 Different voltage responses with time

The EMG voltage VEMG (t) and IPMC actuation voltage VIPMC actuation (t) equations are respectively given below;

VEMG (t ) = V01Sin(2 f01t + 01 )

t =0

0.1

(1)

and

VIPMCactuation (t ) = V02 Sin(2 f 02t + 02 )

t =0

0.1

(2)

Where, V01 is mean value of EMG voltage (V); f01 is EMG frequency range (Hz) ; t is time (s) ; 01 is phase difference when signal is taken through EMG (radian); V02 is mean value of IPMC actuation voltage (V); f02 is IPMC actuation frequency range (Hz); 02 is phase difference when signal is given to IPMC (radian). For finding the frequency range of each signal, the experimental datas are taken and solved through MATLAB curve fitting tool. The numerical values are V01= 0.0047070.0000415, f01= 3.950.018, 01= 2.8840.175, V02= 2.6110.045, f02= 48.50.65 and 02= -0.040040.03. From these datas, it is found that EMG frequency range (f01) is similar to simulated data and IPMC actuation frequency range is 48.50.65 Hz which is nearly human muscle frequency range. After these observations, it is understood that IPMC behaves as an artificial muscle and the fore arm movement (in terms of voltage) can be transferred to IPMC through EMG. Thus, IPMC strip can be applicable as micro robotic arm in micro manipulation application. V. CONCLUSION

In this paper, IPMC control system with a bio-mimetic function through EMG is discussed. EMG signals are taken from forearm and actuation of IPMC is obtained when fore arm moves at different angles. To obtain larger displacement, the voltage signal is amplified at different forearm positions. An EMG signal is generated by an intended contraction of muscles in the forearm which provides the actuation to an IPMC. An IPMC acts as both capacitive and resistive element actuator that behaves like biological muscle. This

189

[11]

[12]

[13]

[14]

[15]

[16]

[17] [18]

[19]

prostheses, Journal of Medical Engineering & Technology, vol. 26, no. 4, July/August, 2002, pp. 139 146. G. Cheron, J. P. Draye, M. Bourgeiosas and G. Libert, A dynamic neural network identification of electromyography and arm trajectory relationship during complex movements, IEEE Transactions on Biomedical Engineering, vol. 43, no. 5, 1996, pp. 552-558. M. Abdallah and B. Zahran, Analysis: signal-step analysis of surface myoelectric signal, European Journal of Scientific Research, ISSN 1450-216X, vol. 26, no. 2, 2009, pp. 298-304. Available: http://www.eurojournals.com/ejsr.htm. M. R. Ahsan, M. I. Ibrahimy and O. O. Khalifa, EMG signal classification for human computer interaction: a review, European Journal of Scientific Research, ISSN 1450-216X, vol. 33, no. 3, 2009, pp. 480-501, Available: http://www.eurojournals.com/ejsr.htm N. M. L. Celani, C. M. Soria, E. C. Orosco, F. A. D. Sciascio and M. E. Valentinuzzi, Two-dimensional myoelectric control of a robotic arm for upper limb amputees, Journal of Physics: Conference Series, 90, 012086, IOP publishing, 2007, pp. 1-8. S. Kwon and J. Kim, Real-time upper limb motion prediction from non invasive biosignals for physical human-machine interactions Proceedings of the 2009 IEEE International Conference on Systems, Man and Cybernetics, San Antonio, TX, USA, October, 2009, pp. 847-852. G. R. Naik, D. K. Kumar and S. P. Arjunan, Pattern classification of myo-electrical signal during different maximum voluntary contractions: a study using BSS techniques, Measurement Science Review, vol. 10, no. 1, 2010, pp. 1-6. C. Murphy, N. Campbell, B. Caulfield, T. Ward and C. Deegan, Micro electro mechanical systems based sensor for mechanomyography, Biosignal, 2008. M. J. Lee, S. H. Jung, S. Lee, M. S. Mun and I. Moon, Control of IPMC-based artificial muscle for myoelectric hand prosthesis, R&D Project, Ministry of Health & Welfare, Republic of Korea, 2004. M. Z. Al-Faiz and Y. I. Al-Mashhadany, Human arm movements recognition based on EMG signal, MASAUM Journal of Basic and Applied Sciences, vol. 1, no. 2, September, 2009, pp. 164-171.

190

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Ieee C57.125Документ11 страницIeee C57.125suresh kumarОценок пока нет

- Engine PDFДокумент254 страницыEngine PDFtipo333194% (18)

- 9098i Circuit Diagrams Overlays Issue 2Документ321 страница9098i Circuit Diagrams Overlays Issue 2Robert Morris100% (1)

- Error-Correcting Codes For Automatic Control: IEEE Transactions On Information Theory August 2009Документ15 страницError-Correcting Codes For Automatic Control: IEEE Transactions On Information Theory August 2009Muhammad Royyan ZahirОценок пока нет

- J. de Vries Indonesian Abbreviations and Acronyms: This PDF-file Was Downloaded From HTTP://WWW - Kitlv-Journals - NLДокумент10 страницJ. de Vries Indonesian Abbreviations and Acronyms: This PDF-file Was Downloaded From HTTP://WWW - Kitlv-Journals - NLMuhammad Royyan ZahirОценок пока нет

- User Manual: Zenith W/carrier AdapterДокумент37 страницUser Manual: Zenith W/carrier AdapterMuhammad Royyan ZahirОценок пока нет

- Scientific Deception of New Athiest - Mohammed HijabДокумент34 страницыScientific Deception of New Athiest - Mohammed HijabOmarОценок пока нет

- Young1972 PDFДокумент20 страницYoung1972 PDFRodrigopn10Оценок пока нет

- Response To Reviewers' Comments For Manuscript IEEE L-CSS 20-0350, Version 1Документ13 страницResponse To Reviewers' Comments For Manuscript IEEE L-CSS 20-0350, Version 1Muhammad Royyan ZahirОценок пока нет

- ELEC-E3520 Digital Microelectronics I: Marko KosunenДокумент38 страницELEC-E3520 Digital Microelectronics I: Marko KosunenMuhammad Royyan ZahirОценок пока нет

- A Study of LoRa - Long Range and Low Power Networks For The Internet of ThingsДокумент19 страницA Study of LoRa - Long Range and Low Power Networks For The Internet of ThingsMuhammad Royyan ZahirОценок пока нет

- GAN Solution Session 2021Документ44 страницыGAN Solution Session 2021Muhammad Royyan ZahirОценок пока нет

- PaperДокумент5 страницPaperMuhammad Royyan ZahirОценок пока нет

- POSTECH Graduate Admissions Guide For International Students (Fall 2015 & Spring 2016)Документ14 страницPOSTECH Graduate Admissions Guide For International Students (Fall 2015 & Spring 2016)Muhammad Royyan ZahirОценок пока нет

- SopДокумент2 страницыSopMuhammad Royyan ZahirОценок пока нет

- What Is Recount? A. Definition of RecountДокумент6 страницWhat Is Recount? A. Definition of RecountMuhammad Royyan ZahirОценок пока нет

- AC-AC Converter: - Muhammad Royyan - Nandika Wibowo - Rio Pamungkas - M. Jundi Arrofi - Aris AndistaДокумент14 страницAC-AC Converter: - Muhammad Royyan - Nandika Wibowo - Rio Pamungkas - M. Jundi Arrofi - Aris AndistaMuhammad Royyan ZahirОценок пока нет

- Ticket ConfirmationДокумент2 страницыTicket ConfirmationMuhammad Royyan ZahirОценок пока нет

- Anh Fault Estimation Scheme of Wireless Networked Control Systems For Industrial Real-Time ApplicationsДокумент39 страницAnh Fault Estimation Scheme of Wireless Networked Control Systems For Industrial Real-Time ApplicationsMuhammad Royyan ZahirОценок пока нет

- Biologi Pengamatan Preparat KeringДокумент4 страницыBiologi Pengamatan Preparat KeringMuhammad Royyan ZahirОценок пока нет

- Python CommandsДокумент3 страницыPython Commandsempty_Оценок пока нет

- Python BasicsДокумент20 страницPython BasicsMuhammad Royyan ZahirОценок пока нет

- Page - 1: This Is The Header of The Included PDF DocumentДокумент30 страницPage - 1: This Is The Header of The Included PDF DocumentMuhammad Royyan ZahirОценок пока нет

- To Whom It May ConcernДокумент1 страницаTo Whom It May ConcernMuhammad Royyan ZahirОценок пока нет

- King Abdullah University of Science and Technology - Muhammad Royyan ZahirДокумент2 страницыKing Abdullah University of Science and Technology - Muhammad Royyan ZahirMuhammad Royyan ZahirОценок пока нет

- AnnintroДокумент31 страницаAnnintroSyed Beeban BashaОценок пока нет

- Lab Complex enДокумент2 страницыLab Complex enMuhammad Royyan ZahirОценок пока нет

- VHDL CookbookДокумент111 страницVHDL Cookbookcoolboyz81990Оценок пока нет

- Asm Editor enДокумент3 страницыAsm Editor enMuhammad Royyan ZahirОценок пока нет

- Muhammad Royyan: ZahirДокумент2 страницыMuhammad Royyan: ZahirMuhammad Royyan ZahirОценок пока нет

- A Robotic Arm Design For Stroke PatientsДокумент4 страницыA Robotic Arm Design For Stroke PatientsMuhammad Royyan ZahirОценок пока нет

- Wednesday, September 18, 2013 11:30 AM: General Page 1Документ4 страницыWednesday, September 18, 2013 11:30 AM: General Page 1Muhammad Royyan ZahirОценок пока нет

- NS3000 Modem BD 2Документ2 страницыNS3000 Modem BD 2Andy ChanОценок пока нет

- Recent Trends in Retardation FilmsДокумент10 страницRecent Trends in Retardation FilmsJeevan JalliОценок пока нет

- A History of The Invention of The Transistor and Where It Will Lead UsДокумент9 страницA History of The Invention of The Transistor and Where It Will Lead UstthenryОценок пока нет

- Protocol Efficiency and HDLCДокумент31 страницаProtocol Efficiency and HDLCBijoy04Оценок пока нет

- Isp321 2X PDFДокумент3 страницыIsp321 2X PDFBoroDragovicОценок пока нет

- Eee-Vi-Switchgear & Protection (10ee62) - Notes PDFДокумент92 страницыEee-Vi-Switchgear & Protection (10ee62) - Notes PDFRK KОценок пока нет

- Linux Input SubsystemДокумент139 страницLinux Input SubsystemDilipОценок пока нет

- FS2CREW 737 NGX Reboot Sop 2 Tutorial ButtonДокумент33 страницыFS2CREW 737 NGX Reboot Sop 2 Tutorial Buttonbibou boubiОценок пока нет

- Aire Acondicionado ASY12FSBCWДокумент2 страницыAire Acondicionado ASY12FSBCWJano NymusОценок пока нет

- Electronic Devices and Circuit Theory 11th Edition by Boylestad Nashelsky Test BankДокумент9 страницElectronic Devices and Circuit Theory 11th Edition by Boylestad Nashelsky Test BankgghtОценок пока нет

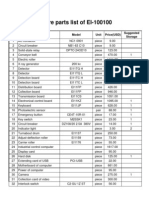

- Ei 100100Документ2 страницыEi 100100Tabassum BanuОценок пока нет

- Transmission and Distribution For Electrical Engineering - Electricalnotes4uДокумент10 страницTransmission and Distribution For Electrical Engineering - Electricalnotes4uNitin Maurya100% (1)

- Electrical Position Indicators For Quarter Turn Actuators: LS SeriesДокумент6 страницElectrical Position Indicators For Quarter Turn Actuators: LS SeriesSanjay MaheshОценок пока нет

- Sis & SilДокумент65 страницSis & SilGecОценок пока нет

- Indesit Idce745euДокумент13 страницIndesit Idce745euMилош ЛукићОценок пока нет

- LM117 Voltage RegulatorДокумент26 страницLM117 Voltage Regulatore_bahamondesОценок пока нет

- Week 11 Lab - Faradays LawДокумент13 страницWeek 11 Lab - Faradays LawRowen PratherОценок пока нет

- Electronics Washing Machine ControlДокумент4 страницыElectronics Washing Machine ControlMohd ShukriОценок пока нет

- Bob Blue2 Ring TesterДокумент4 страницыBob Blue2 Ring Testerbybu74Оценок пока нет

- Clamp Meters: Quick Reference GuideДокумент2 страницыClamp Meters: Quick Reference GuideRaul InzunzaОценок пока нет

- Compressor L7044GSI-7045 - 1210Документ2 страницыCompressor L7044GSI-7045 - 1210Dedy Chasan Aflah MutoharОценок пока нет

- KingtoneДокумент2 страницыKingtoneUlla WirtanenОценок пока нет

- Recurrent Surge Oscillograph (RSO) For Rotor Winding Shorts DetectionДокумент5 страницRecurrent Surge Oscillograph (RSO) For Rotor Winding Shorts Detectionmayur dhandeОценок пока нет

- Nema SB 50-2008Документ32 страницыNema SB 50-2008Irwin CastroОценок пока нет

- Ee3015 PDFДокумент1 страницаEe3015 PDFRovick TarifeОценок пока нет

- What Is A Phase SequenceДокумент5 страницWhat Is A Phase SequencedanielОценок пока нет

- IEEE Standard Requirements For Secondary Network ProtectorsДокумент56 страницIEEE Standard Requirements For Secondary Network ProtectorsMahmoud LotfyОценок пока нет