Академический Документы

Профессиональный Документы

Культура Документы

Bs 240 Is

Загружено:

lebematИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bs 240 Is

Загружено:

lebematАвторское право:

Доступные форматы

Installation

Base Transceiver Station Equipment IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

A30808-X3247-K380-4-7631

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

Important Notice on Product Safety

DANGER - RISK OF ELECTRICAL SHOCK OR DEATH - FOLLOW ALL INSTALLATION INSTRUCTIONS. The system complies with the standard EN 60950 / IEC 60950. All equipment connected to the system must comply with the applicable safety standards. Hazardous voltages are present at the AC power supply lines in this electrical equipment. Some components may also have high operating temperatures. Failure to observe and follow all installation and safety instructions can result in serious personal injury or property damage. Therefore, only trained and qualified personnel may install and maintain the system.

The same text in German: Wichtiger Hinweis zur Produktsicherheit LEBENSGEFAHR - BEACHTEN SIE ALLE INSTALLATIONSHINWEISE. Das System entspricht den Anforderungen der EN 60950 / IEC 60950. Alle an das System angeschlossenen Gerte mssen die zutreffenden Sicherheitsbestimmungen erfllen. In diesen Anlagen stehen die Netzversorgungsleitungen unter gefhrlicher Spannung. Einige Komponenten knnen auch eine hohe Betriebstemperatur aufweisen. Nichtbeachtung der Installations- und Sicherheitshinweise kann zu schweren Krperverletzungen oder Sachschden fhren. Deshalb darf nur geschultes und qualifiziertes Personal das System installieren und warten.

Caution:

This equipment has been tested and found to comply with EN 301489. Its class of conformity is defined in table A30808-X3247-X910-*-7618, which is shipped with each product. This class also corresponds to the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the relevant standards referenced in the manual Guide to Documentation, may cause harmful interference to radio communications. For system installations it is strictly required to choose all installation sites according to national and local requirements concerning construction rules and static load capacities of buildings and roofs. For all sites, in particular in residential areas it is mandatory to observe all respectively applicable electromagnetic field / force (EMF) limits. Otherwise harmful personal interference is possible.

Trademarks: All designations used in this document can be trademarks, the use of which by third parties for their own purposes could violate the rights of their owners.

Copyright (C) Siemens AG 2002.

Issued by the Information and Communication Mobile Group Hofmannstrae 51 D-81359 Mnchen Technical modifications possible. Technical specifications and features are binding only insofar as they are specifically and expressly agreed upon in a written contract.

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Reason for Update

Summary: Fourth edition for release BR 5.5 and BR 6.0 Details: Chapter / Section 2.6.5 / 2.6.7 / 2.6.8 2.6.6 Reason for Update Revised content Installation of the Mounting Kit OPEXAL

Issue History

Issue 1 2 3 4 Date of Issue 06/2002 07/2002 09/2002 11/2002 Reason for Update First edition for new release BR 6.0 Removal of sections for installation of BS-240U/XLU Third edition for release BR 6.0 Fourth edition for release BR 5.5 and BR 6.0

A30808-X3247-K380-4-7631

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

This document consists of a total of 114 pages. All pages are issue 4.

Contents

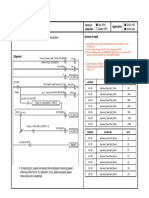

1 1.1 1.2 1.3 2 2.1 2.2 2.3 2.4 2.4.1 2.4.1.1 2.4.1.2 2.4.1.3 2.4.1.4 2.5 2.5.1 2.5.2 2.5.3 2.5.4 2.5.4.1 2.5.4.2 2.5.5 2.5.6 2.6 2.6.1 2.6.2 2.6.3 2.6.4 2.6.4.1 2.6.4.2 2.6.4.3 2.6.4.4 2.6.5 2.6.6 2.6.7 2.6.8 2.6.9 2.6.10 2.6.10.1 2.6.11 2.7 2.7.1 2.7.2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Purpose of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Handling of the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Base Station Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Position in the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Site Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Construction View of BS-Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rack Configuration of different BS - Variants . . . . . . . . . . . . . . . . . . . . . . . Rack Configurations BS-240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rack Configurations for BS-240 II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rack Configurations for BS-240XL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rack Configurations for BS-240XL II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Equipment Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Unpacking the Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Devices Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rack Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Setup of Earthquake Mounting Kit for BS-240 . . . . . . . . . . . . . . . . . . . . . . Setup of Earthquake Mounting Kit for BS-240XL . . . . . . . . . . . . . . . . . . . . Setup of Earthquake Mounting Kit for BS-240 II / 240XL II. . . . . . . . . . . . . Back-to-back Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . External Cabling Activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ground and AC- Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . Ground and DC- Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . Abis-Interface - PCM Link Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Abis-Interface for 120 Ohm Cable Impedance . . . . . . . . . . . . . . . . . . . . . . Abis-Interface with ABISCONCX / OVPTCOAX 75 Ohm . . . . . . . . . . . . . Abis-Interface without ABISCON / OVPT . . . . . . . . . . . . . . . . . . . . . . . . . . Monitoring Interfaces of ABISCON and OVPT . . . . . . . . . . . . . . . . . . . . . . Alarm Collection Terminal - external Alarm Sensors . . . . . . . . . . . . . . . . . Installation of the Mounting Kit OPEXAL . . . . . . . . . . . . . . . . . . . . . . . . . . Alarm Collection Terminal ACTC - internal Alarms / DC Supply. . . . . . . . . Alarm Collection Terminal ACTC-3 - internal Alarms / DC Supply . . . . . . . Local Maintenance Terminal (LMT) Interface . . . . . . . . . . . . . . . . . . . . . . . Antenna Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Preparation of Antenna Jumper Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation of the Tower Mounted Amplifier . . . . . . . . . . . . . . . . . . . . . . . . Rack Completion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Preparation of the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation of Backup Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 13 13 14 15 15 15 16 16 18 19 21 21 24 25 25 26 27 27 31 32 35 36 42 42 47 49 51 51 54 55 57 59 61 64 66 68 69 69 75 78 80 81

A30808-X3247-K380-4-7631

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

2.7.2.1 2.7.2.2 2.7.2.3 2.7.2.4 2.7.3 2.7.4 2.7.5 2.7.6 2.7.7 2.7.7.1 2.8 2.8.1 2.8.2 2.8.3 2.9 3 3.1 3.2 3.3 3.4 3.5 4

Installation of Backup Batteries Type Sonnenschein. . . . . . . . . . . . . . . . . 81 Installation of Backup Batteries Type Oerlicon . . . . . . . . . . . . . . . . . . . . . 84 Install Backup Batteries Type Hawker . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86 Battery Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88 DC-Cabling between the Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89 CAN-Bus Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 SELIC-Cabling between the Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 Installation of Link Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94 Installation of the LMU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98 LMU cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 Setup of System Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103 System Cabling with semi-rigid Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . 103 System Cabling with FlexiCables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105 Terminators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107 Post Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108 Installation Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108 Ancillary Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108 Technical Data of BS-240/240XL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109 Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111 Checklist for Base Station Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Illustrations

Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. 1.1 1.2 1.3 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14 2.15 2.16 2.17 2.18 2.19 2.20 2.21 2.22 2.23 2.24 2.25 2.26 2.27 2.28 2.29 2.30 2.31 2.32 2.33 2.34 2.35 2.36 2.37 2.38 2.39 ESD Symbol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 ESD jack for wrist strap connection of BS-240 / 240XL. . . . . . . . . . . . . 14 ESD press stud for wrist strap connection of BS-240 II / 240 XL II . . . . 14 Position of the Base Station within the SBS . . . . . . . . . . . . . . . . . . . . . 15 Site configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Rack types of the BS-240 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Service1 rack configurations of the BS-240. . . . . . . . . . . . . . . . . . . . . . 20 Service2 rack configurations of the BS-240. . . . . . . . . . . . . . . . . . . . . . 20 Types of BS-240 II racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Types of BS-240XL racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Types of BS-240XL II Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 ShockwatchTM-label and TiltwatchTM-label . . . . . . . . . . . . . . . . . . . . . . 25 Removal of the straps, opening of the top cover . . . . . . . . . . . . . . . . . . 26 Removal of the packing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Opening of the PE-wrap, lifting straps around the rack . . . . . . . . . . . . . 27 Removal of top cover for crane eye access. . . . . . . . . . . . . . . . . . . . . . 28 Guideline for crane transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Space necessary for installation of BS-240 / 240XL and BS-240 II / 240XL II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Removal of fastening claws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Adjusting of rack feeds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Floor and wall fixing of the racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Earthquake mounting kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Drilling sketch for eartquake mounting kit (2 racks) . . . . . . . . . . . . . . . . 32 Drilling scetch for earthquake mounting kit (2 racks) . . . . . . . . . . . . . . . 32 Parts of the earthquake mounting kit for the BS-240XL. . . . . . . . . . . . . 33 Mounting of Pos. 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Mounting of stiffening parts (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 Mounting of stiffening parts (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 Parts of the earthquake kit S3086-K4119-X . . . . . . . . . . . . . . . . . . . . . 35 Back-to-back configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 Side-by-side configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 Back-to-back configuration with Extension1 and Extension2 . . . . . . . . 37 Back-to-back configuration with Service1 and Service2 . . . . . . . . . . . . 37 Interfaces on top of the BS240/240XL service1 rack. . . . . . . . . . . . . . . 42 Interfaces on the top of the BS-240 II / 240XL II Service1A rack. . . . . . 43 Interfaces on top of the BS-240/240XL base rack . . . . . . . . . . . . . . . . . 43 Interfaces on the top of the BS-240 II / 240XL II base rack . . . . . . . . . . 44 Interfaces on top BS-240/240XL extension rack . . . . . . . . . . . . . . . . . . 44 Interfaces on the top of the BS-240 II / 240XL II extension rack . . . . . . 45 Locations of connection points for external cables . . . . . . . . . . . . . . . . 46 Ground and AC mains connections (example) . . . . . . . . . . . . . . . . . . . 47 Pinning of 230 Vac terminal block (Service1 Rack) . . . . . . . . . . . . . . . . 48

A30808-X3247-K380-4-7631

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig.

2.40 2.41 2.42 2.43 2.44 2.45 2.46 2.47 2.48 2.49 2.50 2.51 2.52 2.53 2.54 2.55 2.56 2.57 2.58 2.59 2.60 2.61 2.62 2.63 2.64 2.65 2.66 2.67 2.68 2.69 2.70 2.71 2.72 2.73 2.74 2.75 2.76 2.77 2.78 2.79 2.80 2.81 2.82 2.83

Ground-and power supply connections with -48V DC . . . . . . . . . . . . . . 49 Terminal block for -48 V DC input of MSU (BS-240 / 240 II) . . . . . . . . . 50 Terminal block for -48 dc input of MSU (BS-240XL / 240 XL II) . . . . . . . 50 Preparation of the PCM-cable, 120 impedance . . . . . . . . . . . . . . . . . 51 Fixing of PCM cables at OVPT / ABISCON (120 ) . . . . . . . . . . . . . . . . 52 Abis interface PCM0 Pinning, 120 Ohm . . . . . . . . . . . . . . . . . . . . . . . . 53 Abis interface PCM1 Pinning, 120 Ohm . . . . . . . . . . . . . . . . . . . . . . . . . 53 OVPTCOAX with 1,0/2,3 coaxial connectors, 75 . . . . . . . . . . . . . . . . 54 Monitoring interfaces for PCM lines of ABISCON / OVPT . . . . . . . . . . . 57 ACTM terminal numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 Contents of the MK:OPEXAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 Drilling scetch for MK:OPEXAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 Wall mounted MK:OPEXAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62 Routing of external alarm cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 Connector arrangement at ACTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 Connector arrangement at the ACTC-3 . . . . . . . . . . . . . . . . . . . . . . . . . 66 Cell numbering (top view from the antenna pole) . . . . . . . . . . . . . . . . . . 69 Tools for jumper fabrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 Parts of the connector unit kit (example) . . . . . . . . . . . . . . . . . . . . . . . . 70 Using the trimming tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 Removal of isolation and deburring of inner conductor. . . . . . . . . . . . . . 71 Removal of metal particles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 Assembly of the connector unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 Fixing of connector unit , removal of outer insulation . . . . . . . . . . . . . . . 72 Handling of heat protection tape and shrink sleeve . . . . . . . . . . . . . . . . 72 Shrinkage and removal of visible heat protection tape . . . . . . . . . . . . . . 73 Max. dimensions of antenna connectors . . . . . . . . . . . . . . . . . . . . . . . . 73 Opening of the cable feeding module . . . . . . . . . . . . . . . . . . . . . . . . . . . 74 Antenna jumpers at the cable feeding module . . . . . . . . . . . . . . . . . . . . 74 Antenna jumpers at cable feeding module . . . . . . . . . . . . . . . . . . . . . . . 74 Position of TMA (DUAMCO combiner used). . . . . . . . . . . . . . . . . . . . . . 75 Position of TMA (FICOM combiner used) . . . . . . . . . . . . . . . . . . . . . . . . 75 Configuration with HPDU, DUBIAS and TMA . . . . . . . . . . . . . . . . . . . . . 76 Installation of TMA and DUBIAS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 Bottom view of the Tower Mounted Amplifier . . . . . . . . . . . . . . . . . . . . . 76 TMA with mounting brackets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77 Contents of the connection kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78 Setup of EMC sealing stripes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79 Connection of the racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79 Top cover with removable pieces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 Paint retouche of the top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 Battery tray with backup batteries type Sonnenschein. . . . . . . . . . . . . 82 Connection of backup batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82 Contents of the air vent kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig.

2.84 2.85 2.86 2.87 2.88 2.89 2.90 2.91 2.92 2.93 2.94 2.95 2.96 2.97 2.98 2.99 2.100 2.101 2.102 2.103 2.104 2.105 2.106 2.107 2.108 2.109 2.110 3.1

Assembly of the air vent kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 Connection of backup batteries (Co. Oerlicon) . . . . . . . . . . . . . . . . . . . 84 Air vent system for Oerlicon battery set . . . . . . . . . . . . . . . . . . . . . . . . . 85 Setup of the backup batteries, fixing of the tray bracket . . . . . . . . . . . . 86 Connection between the batteries, battery cable connection . . . . . . . . 87 Routing of the air vent tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87 Terminal blocks for battery cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88 Overview of Battery Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89 Routing of DC cabling between the racks . . . . . . . . . . . . . . . . . . . . . . . 89 Routing of the DC power supply wires. . . . . . . . . . . . . . . . . . . . . . . . . . 89 DC terminal block access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90 Location of CAN-Bus interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 Example for CAN-Bus cable connections . . . . . . . . . . . . . . . . . . . . . . . 91 Location of SELIC interfaces BS-240 . . . . . . . . . . . . . . . . . . . . . . . . . . 92 Location of SELIC interfaces BS-240XL . . . . . . . . . . . . . . . . . . . . . . . . 92 SELIC-Cabling between the racks BS-240 / 240 II . . . . . . . . . . . . . . . . 93 SELIC-Cabling of BS-240XL / 240XL II . . . . . . . . . . . . . . . . . . . . . . . . . 93 Overview of microwave cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94 Cabling for link equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 Interfaces on frame F:NT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 Overview of NTPM cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 Mounting position of the LMU (Base Rack) . . . . . . . . . . . . . . . . . . . . . . 98 Mechanically installation of the LMU . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 Configuration of LMU (overview) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 LMU interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102 Example of system cabling with semi-rigid cable . . . . . . . . . . . . . . . . 103 Example of system cabling with flexible cables . . . . . . . . . . . . . . . . . . 105 Example for Configuration Overview (BS-240) . . . . . . . . . . . . . . . . . . 111

A30808-X3247-K380-4-7631

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

Tables

Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. Tab. 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14 2.15 2.16 2.17 2.18 2.19 2.20 2.21 2.22 2.23 2.24 2.25 2.26 2.27 2.28 2.29 2.30 2.31 2.32 2.33 2.34 2.35 2.36 2.37 2.38 2.39 2.40 2.41 2.42 2.43 Frame equipping variants, BS-240XL Base and Extension Racks . . . . . 22 Equipping variants, BS-240XL Service1 Rack . . . . . . . . . . . . . . . . . . . . 23 Equipping variants, BS-240XL Service2 Rack . . . . . . . . . . . . . . . . . . . . 23 Gap between Service2/1 and Service2/2 rack . . . . . . . . . . . . . . . . . . . . 38 Gap between Extension1and Extension2 rack . . . . . . . . . . . . . . . . . . . . 38 Gap between Base and Extension1 rack . . . . . . . . . . . . . . . . . . . . . . . . 39 Gap between Service2/1 and Service1 rack. . . . . . . . . . . . . . . . . . . . . . 39 Gap between Service1 and Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 Interrack-cables without extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 Types of flexible conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 Pinning of Abis interface PCM0, 75 . . . . . . . . . . . . . . . . . . . . . . . . . . 54 Pinning of Abis interface PCM1, 75 . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Pinning of the PCM0 interface (SubD 25 connector) . . . . . . . . . . . . . . . 55 Pinning of the PCM1 interface (SubD 25 connector) . . . . . . . . . . . . . . . 56 Pinning of the monitoring interfaces PCM0. . . . . . . . . . . . . . . . . . . . . . . 57 Pinning of the monitoring interfaces PCM1. . . . . . . . . . . . . . . . . . . . . . . 58 Pinning ACTM Connector X1...X4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 Pinning ACTM Connector X5...X8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Pinning ACTM Connector X9, X10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Internal alarms at the 24-pole terminal block of ACTC, BS-240 . . . . . . . 64 Internal alarms at the connectors of ACTC, BS-240. . . . . . . . . . . . . . . . 65 Internal alarms at the 16-pole terminal block of ACTC, BS-240XL . . . . . 65 Internal alarms at the connectors of ACTC, BS-240XL . . . . . . . . . . . . . 66 Internal alarms at the 24-pole terminal block of ACTC-3, BS-240 II . . . . 67 Internal alarms at the 24-pole terminal block of ACTC-3, BS-240XL II. . 67 Internal alarms at the connectors of ACTC-3, BS-240 II / XL II . . . . . . . 68 Pinning of the LMT interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 Pinning of the LMT RJ45 interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68 Capacity of backup battery sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 Selection of Slot ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81 List of battery cables between the racks. . . . . . . . . . . . . . . . . . . . . . . . . 88 List of tempresistor cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88 List of DC cable connections between the racks . . . . . . . . . . . . . . . . . . 90 Example for CAN-Bus cabeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 List of SELIC-Cabling BS-240 / 240 II. . . . . . . . . . . . . . . . . . . . . . . . . . . 92 SELIC-Cabling of BS-240XL / 240XL II . . . . . . . . . . . . . . . . . . . . . . . . . 93 Pinning of -48 V interface of frame F:NT . . . . . . . . . . . . . . . . . . . . . . . . 96 Pinning of PCM-Input connector of frame F:NT . . . . . . . . . . . . . . . . . . . 97 Pinning of PCM-Output connector of frame F:NT . . . . . . . . . . . . . . . . . . 97 Parts for LMU installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 Additional LMU cabling parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101 Functionality of LMU - specific RF cables . . . . . . . . . . . . . . . . . . . . . . . 101 Functionality of LMU - connection cables . . . . . . . . . . . . . . . . . . . . . . . 102

10

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Tab. Tab. Tab. Tab. Tab. Tab.

2.44 2.45 2.46 2.47 3.1 3.2

Functionality of system cables BS-240 / 240 II . . . . . . . . . . . . . . . . . . Functionality of system cables BS-240XL / XL II . . . . . . . . . . . . . . . . . BS-240 and BS-240 II system cable types . . . . . . . . . . . . . . . . . . . . . BS-240XL and BS-240XL II system cable types . . . . . . . . . . . . . . . . . Technical Data of BS-240/240XL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Checklist for BS-240/240XL Installation. . . . . . . . . . . . . . . . . . . . . . . .

104 104 106 106 109 112

A30808-X3247-K380-4-7631

11

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

12

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

1 Introduction

!

The CE and UL declaration of conformity for the product will be fulfilled if the setup and cabling is undertaken in accordance with the specification in the manual and the documentation listed there, such as mounting instructions, cable lists etc. Where necessary, project-specific documentation should be taken into account. Deviations from the specifications or independent changes during setup, such as use of cable types with lower screening values, for example, can lead to the CE requirements being violatad. In such cases the CE declaration of conformity is invalidated and the responsibility passes to the person who has caused the deviations. The applying technical standards are listed in Guide to Documentation (Siemens document number X3247-K52-*-6735).

1.1

Purpose of the Manual

This document is intended to give the information necessary for the installation of the BS-240 / BS-240 II and BS-240XL / BS-240XL II in the SBS Base Station System (BSS). It contains a description of all the necessary steps to install the BTS on site and integrate it into the required infrastructure: Power supply PCM - Network Grounding Receive / transmit antenna system Alarm connections Base constructions in addition to information regarding the connection of the base station to: Power supply PCM - Network Site ground system Receive / transmit antenna system Alarm connections Mechanical and electrical connection of the racks For installation of equipment not supplied by Siemens (battery chargers, antennas, power supplies, microwave etc.) refer to site specific documentation or vendor instructions provided with other equipment.

1.2

Installation Prerequisites

It is required that the installer pays attention to all relevant national EMC standards. EMF standard relevant for the choice of the antenna, the placement of the antennas and the max. output power of the BTS (cell coverage). Use the correct material as described in this manual. Installation according to the standards EN 50310 or ETS 300253, EN 50154 and the hints in this manual. The other equipment on site must be CE designated and must provide interfaces for connecting of external cables conformable to EMC instructions. The installation staff must have a basic knowledge of the relevant standards. The installation manual must be available for staff on site.

A30808-X3247-K380-4-7631

13

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

1.3

Handling of the Modules

All boards and modules must be handled with extreme care as each one contains electrostatically sensitive devices (ESD). The modules are marked with the ESD-label.

Fig. 1.1

ESD Symbol

These are sensitive to static discharge. Notice: Avoid handling the modules in a high-static environment When handling the modules, do not touch connector contacts An earthed high-impedance wrist strap must be worn when handling modules. Use the socket at the racks for wrist strap connection. The modules must be transported in appropriate packaging

Fig. 1.2

ESD jack for wrist strap connection of BS-240 / 240XL

Fig. 1.3

ESD press stud for wrist strap connection of BS-240 II / 240 XL II

14

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

2 Base Station Installation

2.1 Position in the System

The BS-240/240XL and BS-240 II / 240XL II interconnects the MS via the Um interface with the trunk network via the Abis interface.

Um interface

BTS Abis interface Mobile Station

BSC Asub interface

TRAU A interface

MSC

SBS

Position of the Base Station within the SBS

Fig. 2.1

2.2

Site Requirements

The installation site must fulfill installation rules according to ETS 300253 or EN 503010 and EN 50174. The lightning protection measures must be in accordance with IEC 1312 (in the future series IEC 61024) and IEC 61000-2-5 to achieve a lightning protection zone 1 interface to the communication equipment. With regard to explosion hazards, the installation room of the base transceiver station with integral battery back-up system must be guarantee a continuous ventilation, to keep the critical hydrogen concentration below 4% vol.. The cross section of the air inlet / outlet must be calculated in accordance to IEC/EN50272-2. Prior to the commencement of installation, the construction of the room in which the base transceiver station is to be housed must be complete and the room in good condition and dry heaters, if necessary, should be put up in the room. The BS-240/240XL and BS-240 II / 240XL II is intended to be installed in a restricted access area. The installing room should be free from possible water ingress, frost and excessive insect attack. Doors and windows must already have been installed and must be lockable. Openings in wall or ceiling of oor - if required - must be complete. The oor coverings must have been laid. Room lighting and wall sockets must have been installed. Heating or air-conditioning systems should be ready for operation. Walls and ceilings should have been painted. The room must be clean.

A30808-X3247-K380-4-7631

15

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

A minimum oor space of 1,70 m x 1,50 m must be provided (later extension not possible). optional cable runways must be installed rst The oor load of the construction room must be not less than 7500 N/m2. All installation works of 3 phase 230 V AC power supply, including a false current protection switch must be nished.

To prevent subsequent accumulation of dust and dirt, the parts and equipment units to be installed should be unpacked outside the room (if possible). After that it is advantageous to install the BTS, after all other installation works to create the required infrastructure (power supply, antenna cabling, PCM line...) are complete.

2.3

Site Conguration

Operation of the BS240/240XLrequires additional equipment on site: TX/RX antennas LMU GPS/RF antennas* microwave outdoor unit *

external alarms**

PCM24/30 2 Mbit/s 3 x 230V/50Hz AC

(or -48 V DC)

AC-counter/ main breaker in power distribution box

ground connection

*dependent on type of network integration **optional

Fig. 2.2

Site configuration

2.4

Construction View of BS-Types

The Base Station equipment of the BS-240 / 240 II is housed in racks with the dimensions 1600 mm x 600 mm x 450 mm (H x W x D). The Base rack and each optional Extension rack can be equipped with up to 8 Carrier Units. The Base rack and the Extension rack of the BS-240XL / 240XL II can be equipped with up to 12 Carrier Units. The dimensions of a BS-240XL / 240 XL II rack are 2050 mm x 600 mm x 450 mm (H x W x D). For a full-featured Base Station, the maximum number of TRX is limited to 24. The necessary space for installation is shown in Fig. 2.15. Because of the flexible configuration, several cable kits will be used for cable connections between the racks.

16

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

The first rack of Base Station is called Base rack and contains the following modules: Generic Modules: Core Basis (COBA): Essential components are the Base Core Controller, Advanced Clock Generation and the Carrier Unit Interfaces. The COBA can handle up to 8 CUs in the Base Rack and 2 PCM lines. Core Satellite (COSA): The COSA extends the BTSEplus configuration by 6 Abis-interfaces for 6 further PCM lines and 16 CC-links for 16 further CUs and is necessary for the feature cross connect. Alarm Collection Terminal (ACT): Collect all alarms for those units having no access to the CAN-Bus and pass them via CAN-Bus interface to COBA. Overvoltage Protection and Tracer (OVPT): Protect the PMC30 ports of core boards from overvoltage and provide a monitoring interface for connected Abis-lines. Carrier related Modules: Carrier Unit (CU): Consists of a receiving and transmitting part with synthesizer and power amplifier, a signal processing unit as well as a power supply unit. EDGE Carrier Unit (ECU): CU with supporting EDGE functionality in the up- and down link. Antenna System Modules: TX - and RX - Combiner: DUAMCO TX - Combiner: FICOM RX - Multicoupler: DIAMCO High Power Duplexer: HPDU The types and numbers of modules are subject to modification, it depends on the cell configuration and the type of antenna combining. Ancillary Module: Location Measurement Unit (LMU) For the Base Rack to function a Service Rack must be installed close to the Base Rack. If only one Service Rack is located on site, it contains all infrastructure equipment: AC/DC Converter (ACDC): Converts the AC mains voltage into the -48 Vdc supply voltage. Link Equipment (LE): Can be NTPM, if terrestrial line is used for connection to BSC or microwave. Backup Batteries: guarantees continuous operation for a certain time in case of mains breakdown or AC/DC failure.

Note: All empty slots in a partial equipped subrack must be closed with cover plates, so that the air flow inside the rack will not be affected. Cover plates are not necessary for link equipment and empty battery trays.

A30808-X3247-K380-4-7631

17

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

2.4.1

Rack Configuration of different BS - Variants

The following rack types exist: Base rack: Contains the core modules, up to 8 carrier units (BS-240 / 240U II) or up to 12 carrier units (BS240XL / 240XL II), antenna combiners and the optional LMU Extension rack: Contains up to 8 carrier units (BS-240 / 240 II) or up to 12 carrier units (BS240XL / 240XL II) and antenna combiners Service1 rack (BS-240 / 240XL): Contains AC/DC converters, backup batteries and link equipment in exible conguration Service1A rack (BS-240 II / 240XL II): Contains up to 6 AC/DC converters, an AC/DC distribution panel with Alarm Collection Terminal, backup batteries and link equipment in exible conguration Service2 rack (BS-240 / 240XL): Contains backup batteries and link equipment in exible conguration Service2 rack (BS-240 II / 240XL II): Contains a DC-LE Breaker Panel with Alarm Collection Terminal, backup batteries and link equipment in exible conguration The minimum configuration for a BS-240 / 240 II with a maximum of 8 carrier units requires a Base rack and a Service1 / Service1A rack (optional, not needed in the case of -48 Vdc supply from external power supply equipment). The serving of a site with the maximum number of carrier units (24) requires the Base rack, 2 Extension racks and a Service1 / Service1A rack. For extension of link equipment or battery backup, additional Service2 racks can be added. The BS-240 / 240 II site can consists of up to a maximum of 8 racks: Base rack, 2 Extension racks, Service1/Service1A rack, maximum 4 Service2 racks The minimum configuration for a BS-240XL / 240XL II with maximum 12 carrier units requires a Base rack and a Service1 / Service1A rack (optional, not needed in the case of -48 Vdc supply from external power supply equipment). The serving of a site with the max. number of carrier units (24) requires the Extension rack. For extension of link equipment or battery backup time, additional Service2 racks can be added. The number of Service racks depends on the number of installed carriers on site, the volume of required link equipment and the expected battery backup time. The BS-240XL / 240XL II site can consists of a maximum of 7 racks: Base rack, Extension rack, Service1 rack / Service1A rack, maximum 4 Service2 racks. The drawings and tables in the following sections will give an overview about rack configurations and rack layouts.

18

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

2.4.1.1

Rack Configurations BS-240

Fig. 2.3 shows the an example of rack types, that are needed for a BS-240 site with up to 16 carriers.

LMU

SIEMENS SIEMENS

LMT ETHERNET

SIEMENS

DC-PANEL ACT-C

DC-PANEL ACT-C

DC-PANEL ACT-C

AC/ AC/ AC/ AC/ AC/ AC/ AC/ DC DC DC DC DC DC DC CTRL 00 01 02 03 04 05 AC + DC Distribution

ACOM ACOM ACOM ACOM #1 #0 #3 #2

ACOM ACOM ACOM ACOM #1 #0 #3 #2

LE 0 LE 1 LE 2 LE 3 LE 4 LE 5

MUCO #0

MUCO #1

MUCO #0

CU CU #2 #3

CU #6

CU #7

CU CU #2 #3

MUCO #1

CU #6

CU #7

CU CU #0 #1

COBA 0 COSA 0 COBA 1 COSA 1

CU #4

CU #5

CU CU #0 #1

CU #4

CU #5

Service1 Rack

Base Rack

Extension Rack

Fig. 2.3

Rack types of the BS-240

A30808-X3247-K380-4-7631

19

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

SIEMENS DC-PANEL ACT-C

SIEMENS DC-PANEL ACT-C

SIEMENS DC-PANEL ACT-C

SIEMENS DC-PANEL ACT-C

SIEMENS DC-PANEL ACT-C

AC/ AC/ AC/ AC/ AC/ AC/ AC/ DC DC DC DC DC DC DC

CTRL

AC/ AC/ AC/ AC/ AC/ AC/ AC/ DC DC DC DC DC DC DC

CTRL

AC/ AC/ AC/ AC/ AC/ AC/ AC/ DC DC DC DC DC DC DC

CTRL

00 01 02 03 04 05

00 01 02 03 04 05

00 01 02 03 04 05

AC/ AC/ AC/ AC/ AC/ AC/ AC/ DC DC DC DC DC DC DC CTRL 00 01 02 03 04 05 AC + DC Distribution

CTRL

AC/ AC/ AC/ AC/ AC/ AC/AC/ DC DC DC DC DC DC DC 00 01 02 03 04 05 AC + DC Distribution

AC + DC Distribution

AC + DC Distribution

AC + DC Distribution

LE 0 LE 1 LE 2 LE 3 LE 4 LE 5

AC/AC/ AC/ AC/ AC/ AC/AC/ DC DC DC DC DC DC DC

CTRL 10

AC/AC/ AC/ AC/ AC/ AC/AC/ DC DC DC DC DC DC DC

CTRL 10

11 12 13 14 15

11 12 13 14 15

AC + DC Distribution

AC + DC Distribution

LE 0 LE 1 LE 2 LE 3 LE 4 LE 5

LE 0 LE 1 LE 2 LE 3 LE 4 LE 5 LE 6 LE 7 LE 8 LE 9 LE 10 LE 11

Fig. 2.4

Service1 rack configurations of the BS-240

SIEMENS DC-PANEL ACT-C

SIEMENS DC-PANEL ACT-C

SIEMENS DC-PANEL ACT-C

SIEMENS DC-PANEL ACT-C

LE 0 LE 1 LE 2 LE 3 LE 4 LE 5

LE 0 LE 1 LE 2 LE 3 LE 4 LE 5 LE 6 LE 7 LE 8 LE 9 LE 10 LE 11

LE 0 LE 1 LE 2 LE 3 LE 4 LE 5

LE 0 LE 1 LE 2 LE 3 LE 4 LE 5 LE 6 LE 7 LE 8 LE 9 LE 10 LE 11

Fig. 2.5

Service2 rack configurations of the BS-240

20

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

2.4.1.2

Rack Configurations for BS-240 II

The site configuration of racks and the functionality of a BS-240 II is equal to the BS-240. The rack layouts, are shown in the figure below (example of a 16 carrier site).

LMU

SIEMENS

0V -48V

SIEMENS

SIEMENS

SIEMENS

ACTC

FAN#0

FAN#1

ACTC

BR01BR02BR03 BR04BR05 BR06BR07BR08

ACTC

BR01BR02BR03 BR04BR05 BR06

LE Panel (S2)

0V -48V

0V -48V

FAN#0

FAN#1

FAN#0

FAN#1

FAN#0

FAN#1

HU # 0 forLE HU # 1 for LE HU # 2 for LE HU # 3 for LE HU # 4 for LE HU # 5 for LE

ACOM ACOM ACOM ACOM #1 #0 #3 #2

ACOM ACOM ACOM ACOM #1 #0 #3 #2

ACTC

LE

+-

Batt01/S2 Batt0/S1

AD Panel

- - -

+++

0V -48V

++

- -

FAN#2

MK: Battery

FAN#3

FAN#2

FAN#3

LE Panel (S1A)

MUCO #0

MUCO #0

HU #1 for LE HU #2 for LE HU #3 for LE HU #4 for LE

MK: Battery

MUCO #1

CU CU #2 #3

CU #6

CU #7

CU CU #2 #3

MUCO #1

HU #0 for LE

CU #6

CU #7

HU #5 for LE

FAN#4

FAN#5

FAN#4

FAN#5

COBA 0 COSA 0 COBA 1 COSA 1

CU CU #0 #1

CU #4

CU #5

CU CU #0 #1

CU #4

CU #5

Service2 Rack

Service1A Rack

Base Rack

Extension Rack

Note: CU can be Carrier Unit (CU) or EDGE Carrier Unit (ECU) Fig. 2.6 Types of BS-240 II racks

2.4.1.3

Rack Configurations for BS-240XL

The following types of rack exist: Base rack (contains core modules, up to 12 carrier units, antenna combiners and the optional LMU) Extension rack (contains up to 12 carrier units and antenna combiners) Service1 rack (contains AC/DC converters, backup batteries and link equipment in exible conguration) Service2 rack (contains backup batteries and link equipment in exible conguration) Refer to Tab. 2.1, Tab. 2.2, Tab. 2.3 for a selection of rack configurations.

A30808-X3247-K380-4-7631

21

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

LMU SIEMENS

DC-PANEL ACT-C

SIEMENS

DC-PANEL ACT-C

SIEMENS

ETHERNET DC-PANEL ACT-C LMT

SIEMENS

DC-PANEL ACT-C

FAN #0 LE #0 LE #1 LE #2 LE #3 LE #4 LE #5 LE #6 LE #7 LE #8 LE #9 LE #10 LE #11

FAN #1

FAN #0

FAN #1

FAN #0

FAN #1

AC/

DC AC/ AC/ AC/ AC/ AC/ AC/

CTRL

DC DC DC DC DC DC #00 #00 #01 #02 #03 #04 #05 AC + DC DISTRIBUTION

ACOM ACOM ACOM ACOM #0 #3 #2 #1

ACOM ACOM ACOM ACOM #0 #1 #2 #3

FAN #2

FAN #3

FAN #2

FAN #3

FAN #2

FAN #3

AC/

MUCO #2

MUCO #2

AC + DC DISTRIBUTION

MUCO #3

#4

#10

#11

#4

#5

MUCO #3

CTRL

DC AC/ AC/ AC/ AC/ AC/ AC/ DC DC DC DC DC DC #01 #10 #11 #12 #13 #14 #15

CU

CU #5

CU

CU

CU

CU

CU #10

CU #11

FAN #4 CU #2 CU MUCO #0 #3 MUCO #1

FAN #5 CU #8 CU #9

FAN #4 CU #2 CU MUCO #0 #3 MUCO #1

FAN #5 CU #8 CU #9

1/4 Battery

1/4 Battery

1/4 Battery

1/4 Battery

FAN #6 CU #0 CU #1

FAN #7 CU #6 CU #7

FAN #6 CU #0 CU #1

FAN #7 CU #6 CU #7

1/4 Battery

1/4 Battery

1/4 Battery

1/4 Battery

Service2 Rack

Service1 Rack

Base Rack

COBA #0 COSA #0 COBA #1 COSA #1

Extension Rack

Note: CU can be Carrier Unit (CU) or EDGE Carrier Unit (ECU) Fig. 2.7 Types of BS-240XL racks

frame no. 4 (top)

installed modules Base Rack 4 x DUAMCO 2:2 or 4 x DUAMCO 4:2 or 2 x DUAMCO 8:2 or 4 x FICOM modules (Base/Expansion modules in site specific configuration) 4 x CU or ECU 2 x DIAMCO 4 x CU or ECU 2 x DIAMCO 4 x CU or ECU 2 x COBA; 2 x COSA

installed modules Extension rack 4 x DUAMCO 2:2 or 4 x DUAMCO 4:2 or 2 x DUAMCO 8:2 or 4 x FICOM modules (Base/Expansion modules in site specific configuration) 4 x CU or ECU 2 x DIAMCO 4 x CU or ECU 2 x DIAMCO 4 x CU or ECU

3 2 1 (down)

Tab. 2.1

Frame equipping variants, BS-240XL Base and Extension Racks

22

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Service1 rack frame no. 4 (top) 3 2 type 1 F:AC/DC1/1 2 F:LE (6 x LE) type 2 F:AC/DC1/1 2 F:LE F:BATTERY F:BATTERY type 3 F:AC/DC1/1 2 F:AC/DC2 F:LE (6 x LE) up to 8000 W type 4 F:AC/DC1/1 2 F:AC/DC2 F:LE F:BATTERY type 5 F:AC/DC1/1 2 F:AC/DC2 F:BATTERY F:BATTERY

1 (down) F:BATTERY DC Output Power Tab. 2.2 up to 4000 W

Equipping variants, BS-240XL Service1 Rack

Service2 rack frame no. 4 (top) 3 2 1 (down) Tab. 2.3 F:LE (6 x LE) F:BATTERY F:BATTERY type 1 (R:BS120) F:LE F:BATTERY F:BATTERY F:BATTERY type 2 R:BS120)

Equipping variants, BS-240XL Service2 Rack

A30808-X3247-K380-4-7631

23

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

2.4.1.4

Rack Configurations for BS-240XL II

The rack layouts of the BS-240XL II are shown in the figure below (example of a 24 carrier site).

LMU SIEMENS

0V -48V

SIEMENS

ACTC

SIEMENS

FAN#1

ACTC

SIEMENS

ACTC

FAN#0

LE Panel (S2)

FAN#0

FAN#1

FAN#0

FAN#1

FAN#0

FAN#1

HU # 0 for LE HU # 1 for LE HU # 2 for LE HU # 3 for LE

ACTC

ACOM ACOM ACOM ACOM #0 #3 #2 #1

ACOM ACOM ACOM ACOM #0 #1 #2 #3

HU # 4 for LE HU # 5 for LE

AD Panel

- - -

+-

Batt01/S2 Batt0/S1

+++

0V -48V

++

- -

FAN#2

FAN#3

FAN#2

FAN#3

FAN#2

FAN#3

HU # 0 for LE HU # 1 for LE HU # 2 for LE HU # 3 for LE HU # 4 for LE HU # 5 for LE

MK: Battery

LE Panel (S1A)

CU #4

MUCO #2

MUCO #2

HU # 0 for LE HU # 1 for LE

HU # 2 for LE

HU # 3 for LE

FAN#4 FAN#5 FAN#4 FAN#5

MUCO #3

#10

#11

#4

#5

MUCO #3

CU #5

CU

CU

CU

CU

CU #10

CU #11

CU #2

CU MUCO #0 #3 MUCO #1

MUCO #0

#2

#3

MUCO #1

CU #8

CU #9

CU

CU

CU #8

CU #9

1/4 Battery

1/4 Battery

1/4 Battery

1/4 Battery

MK: Battery

MK: Battery

FAN#6

FAN#7

FAN#6

FAN#7

COBA #0 COSA #0 COBA #1 COSA #1

CU #0

CU #1

CU #6

CU #7

CU #0

CU #1

CU #6

CU #7

1/4 Battery

1/4 Battery

1/4 Battery

1/4 Battery

Service2 Rack

Service1A Rack

Base Rack

Extension Rack

Note: CU can be Carrier Unit (CU) or EDGE Carrier Unit (ECU) Fig. 2.8 Types of BS-240XL II Racks

24

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

2.5

Equipment Delivery

The racks are shipped vertically in wooden crates (or horizontally in case of transportation by airplane).The crates dimensions for the BS-240 / 240 II are 1800 mm x 800 mm x 650 mm (HxWxD). Depending on the pre-installed modules inside the racks, the crate can weigh up to approx. 190 kg. The crates dimensions for the BS-240XL / 240XL II are 2225 mm x 800 mm x 650 mm (HxWxD). The Service racks will be delivered without backup batteries (weight aspects). Additional crates will be used for transportion of the batteries. All crates have the following information printed on them for identification of delivery: customer order number serial number of rack or other supplied equipment destination gross and net weight overall dimensions (cm) symbol or inprint to identify the "Top" and the "Bottom" delivery papers For transportation of the crates from the unloading area into the construction room use handling aids (for example: fork-lift truck, goods elevator), a second person is needed for help. The 4 fastening clamps which fixing the rack-feets to the bottom of the crate should be used for later floor-fixing.

2.5.1

Preliminary Checks

The transportation crates are equipped with a ShockwatchTM -label and a TiltwatchTM-label. These labels are fixed at the crate for indication of fallover or strong shocks during the transport from factory to the site. Check that the crate and label are not damaged. In case of evident damage due to transport, unpack the equipment in presence of an insurance company representative and promptly claim any damage and inform the shipper for specifying the damage. Check whether the package is actually addressed to the site and complete.

ShockwatchTM -label

TiltwatchTM-label

Fig. 2.9

ShockwatchTM-label and TiltwatchTM-label

A30808-X3247-K380-4-7631

25

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

2.5.2

Unpacking the Racks

During the unpacking steps, great care must be taken to ensure that the rack is not scratched or damaged in any way. Unpack the rack according to the following figures.

unscrew

cut

Fig. 2.10

Removal of the straps, opening of the top cover

Safety gloves and goggles must be worn when cutting the straps. Pay attention to the tension of the straps. Use only plate shears. Cut the three straps (see Fig. 2.10). Unscrew the 10 M4 screws on the top of the crate (see Fig. 2.10). Remove the crates top cover . Take out the packing material protecting the rack (see Fig. 2.11). Remove the protection to the head and to the base of the rack. Open and remove the tubular PE-wrap protecting the rack (see Fig. 2.12). Take out the rack from the crate. Use the straps around the rack. Lift the rack in vertical position.

Fig. 2.11

Removal of the packing material

The burning of packing material should be avoided, as packaging may give off toxic gases.

26

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

cut

Fig. 2.12

Opening of the PE-wrap, lifting straps around the rack

Immediately after unpacking the rack, inspect it for damage and report the extent of any damage to the transportation company.

2.5.3

Devices Unpacking

Proceed as follows: Open the PVC wrap protecting the carton and withdraw it. Remove the dehydrating material bag from the box. Cut with a suitable knife the adhesive tape sealing the box. Take the device out. Open the PVC wrap protecting the device/board and withdraw it. The packing material should be preserved for possible future re-packing. For this purpose, reverse the procedure described above, taking into account the warnings specified for the packing. If the packing material is supplied by the customer, special care should be taken to avoid damage during the transport and storage of the devices.

2.5.4

Rack Installation

Prior to the commencement of rack installation, consult the site documentation to locate the installation point of the Base Station, the PCM24/30 network termination, AC mains or power supply unit (if -48Vdc will be provided from external equipment) and the access of the antenna cables into the construction room. After that check the proper installation of the earthing bar and the necessary cable runways. If the rack must be moved to the final installation position by crane and for later connection works, it is necessary to remove the topcover of the rack. Proceed as follows: Open the rack-door and unscrew both screws in the upper part of the front of rack. (see Fig. 2.13 ) Lift up the top cover and slide it back. Disconnect the green/yellow ground wire from the pin inside the top cover.

A30808-X3247-K380-4-7631

27

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

Before opening the rack-door take measures to prevent the rack falling over! Note the accident prevention regulations, when working with a fork lift truck or crane ! Dont remove the crane eyes after the crane transport is finished to guarantee the later EMI-closeness of the rack! If the racks stand side by side, they must be screwed together to one common unit with one nut and screw M8x20. For this purpose the top cover has to be removed as shown in the figure Fig. 2.13.

unscrew

ground wire

Fig. 2.13

Removal of top cover for crane eye access

min 65

60

BS-240 / 240XL Fig. 2.14 Guideline for crane transport

BS-240 II / 240XL II

The total weight of rack must not exeed 360 kg (BS-240 / 240 II) or 425 kg (BS-240XL / 240XL II) respectively when being lifted. For determination the weight refer to section Technical Data Under no circumstances must the sets of batteries be inserted into the Service Racks during transportation on site.The doors must be kept closed during transportation.

28

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

1900 mm BS-240XL

600 mm

1500 mm

1100 mm BS-240 2200 mm 1600 mm min. dimensions for 3-rack solution 2025 mm

1500 mm

1700 mm 450 mm

*)

min. dimensions for double rack solution

Note: BS-240 without earthquake kit close to wall Minimum clearance to wall for BS-240XL / 240XL II: 50 mm (without earthquake kit) Minimum clearance by back-to-back assambly for BS-240XL / 240XL II: 100 mm (without earthquake kit) Minimum clearence BS-240XL / 240XL II with earthquake kit Siemens serial no. S30861-K2179-X: 300 mm Minimum clearence BS-240 / 240 II with earthquake kit Siemens serial no. S30861-K2179-X: 300 mm Space necessary for installation of BS-240 / 240XL and BS-240 II / 240XL II Four fastening claws fixing the adjustable rack-feets to the base of the crate. The claws can be later used for floor fixing of the racks.

Fig. 2.15

450 mm

*) distance to wall 29

minimum room height

2350 mm

A30808-X3247-K380-4-7631

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

Fig. 2.16

Removal of fastening claws

4 3 1

Fig. 2.17

Adjusting of rack feeds

Proceed as described in the list below: Unscrew the 4 fastening claws from the crates base as shown in Fig. 2.16 and move the rack carefully to the nal installation position. Check the correct vertical rack position, using the spirit-level. In case, the position is incorrect, equalize differences in the oor height by adjusting the rack feets. (see Fig. 2.17). Loose the lock nut (1) and screw down or up the rack feed (2) for proper oor contact by using adjuster feed wrench M42 (SW65, Knrr part no. 01.139.965.7). Tighten the lock nut as fast as possible to avoid a gap between the bottom section (3) and the rack frame (4)

The electrical contact between lock nut and bottom section is absolute required for EMIcloseness of the rack. Push a claw on each of the 4 rack feets and mark the drilling point on the oor. Remove the clamps and drill the 4 holes and insert the 4 wallplugs (e.g. Fischer S8GK) into the holes. Push the claws on the rack feets and x them. Use a ratchet with a 10 nut. (see Fig. 2.18, left side)

The rack can alternatively fixed to wall. The rack has two right angle brackets on its top rear for fixing to wall (Fig. 2.18, right side).

30

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Fig. 2.18

Floor and wall fixing of the racks

! 2.5.4.1

In areas with the possibility of earthquake, the fixation to wall is prohibited. Use the earthquake mounting kit for floor fixation Siemens Serial No. S30861-K2086-X.

Setup of Earthquake Mounting Kit for BS-240

For setup the earthquake mounting kit (S30861-K2086-X) proceed in steps as follows: Mark the positions of the drilling holes in accordance with Fig. 2.20. Drill the holes with 18 mm in diameter and a depth of 90 mm. Dont pre-drill the holes! Produce an undercut of the drilling holes: drill the hole to stop and swivel the jack hammer 3-5 times keeping stop to concrete. Clean out the drilling holes by blowing or sucking. Put steel plug (e.g. Fischer FZA 18x80 M10 I) into the inserting tool (e.g. Fischer FZE 18) and hammer into each hole until the sleeve is ush with surface. Fit bolts M10 (1) with washer (2) through both holes of claw (3) and distance plate (4). Screw down the bolts into the steel plugs as fast as possible. Fix in this way all claws for the rearside rackfeeds rst. Shift the racks to the correct position, so that each of the rear adjuster feeds is placed in the cutout of a claw. Push a claw on each of the frontside feeds and x them with bolts and washers. The distance plates are not needed for the frontside row.

1 2

2 x for rearside of rack Fig. 2.19 Earthquake mounting kit

2x for frontside of rack

A30808-X3247-K380-4-7631

31

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

1085 1135

485 535

600 650

32,5 0 50

0 rear

Service1 Rack

Base Rack

front

463

Fig. 2.20

Drilling sketch for eartquake mounting kit (2 racks)

2.5.4.2

Setup of Earthquake Mounting Kit for BS-240XL

For setup the earthquake mounting kit (S30861-K2131-X) proceed in steps as follows: Mark the positions of the drilling holes in accordance with Fig. 2.21. Drill the holes with 22 mm in diameter and a depth of 90 mm. Dont pre-drill the holes! Produce an undercut of the drilling holes: drill the hole to stop and swivel the jack hammer 3-5 times keeping stop to concrete. Clean out the drilling holes by blowing or sucking. Put steel plug (e.g. Fischer FZA 22x100 M12I) into the inserting tool (e.g. Fischer FZE 22) and hammer into each hole until the sleeve is ush with surface. rack length 600 mm 600 mm rack depth 450 mm

335 mm

diameter 22 mm

88,5 mm Fig. 2.21 Drilling scetch for earthquake mounting kit (2 racks)

Check the completeness of the mounting kit according to the following gure and remove the rear panel of the rack.

32

A30808-X3247-K380-4-7631

57,5 mm

423 mm

423 mm

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

4 2

4 2 5

4 4

5 3 4

6 3 5

4 Fig. 2.22 Parts of the earthquake mounting kit for the BS-240XL

Remount the adjusting feets, setup the 4 metal angles (1) and x them with Allan screw (6) as shown in Fig. 2.23. 6

1 6 1

Fig. 2.23

Mounting of Pos. 1

Click spring nuts in the extrusions. Insert both stiffening parts (2). Move the stiffening parts to rear and lateral side to stop.

A30808-X3247-K380-4-7631

33

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

extrusion

2 4 3

Fig. 2.24

Mounting of stiffening parts (1)

Slide in the ller plates (3). Fix each stiffening part with 12 Allan screws M6 (4). 3 4

Fig. 2.25

Mounting of stiffening parts (2)

Screw the rack to the steel plugs in the oor with 4 bolts M12 (5). Remove the 4 Allan screws (6). This is absolute necessary, that the edge pieces can work free of strain in the case of earthquake . Mount again the rear panel.

i i

!

The use of the earthquake mounting kit for BS-240XL requires a minimum clearence to the wall of 400 mm. For mounting the earthquake mounting kit in a service rack, first the battery tray has to be remounted. Take measures to prevent the rack falling over during the removal of the adjusting feets and mounting of the metal angles. A second person is needed for help ! The rack door stay must be locked in the open position using the door stay provided, whilst work is being performed inside the rack.

34

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

2.5.5

Setup of Earthquake Mounting Kit for BS-240 II / 240XL II

The earthquake mounting kit (S30861-K4119-X) consist of the parts as shown in the figure below. Both stiffening parts (1) are already mounted by the factory.

3 4

3 4

Fig. 2.26

Parts of the earthquake kit S3086-K4119-X

Fix the rack to the floor in accordance with Fig. 2.26 in steps as follows: Mark the positions of the drilling holes in. Use the claws (2, 3) as a drilling template. Drill the holes with 22 mm in diameter and a depth of 90 mm. Dont pre-drill the holes! Produce an undercut of the drilling holes: drill the hole to stop and swivel the jack hammer 3-5 times keeping stop to concrete. Clean out the drilling holes by blowing or sucking. Put steel plugs (4) (e.g. Fischer FZA 18x80 M10I) into the inserting tool (e.g. FischerFZE 18) and hammer into each hole until the sleeve is ush with surface. Screw the double claw (2) to the rear steel plugs in the oor with bolts M10 and tighten the connection. Shift the rack to the appropriate position, so that each of the rear rack feet is placed in a cutout of the double claw. Insert a claw (3) on each of the front feet and afx them with the M10 bolts to the steel plugs in front of the rack.

The use of the mounting kit requires a minimum clearence between the rear of the rack and the wall of 150 mm.

A30808-X3247-K380-4-7631

35

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

2.5.6

Back-to-back Assembly

Back-to-back assembly means all configurations that are not lined up in a connected row, but with disstance between the sidewalls of racks. These configuration are according to customer requirements. The open cable channel for interrack cabling from one rack to the other one has to be closed with an EMI shielded mechanical EMI-kit. In this conduit, the DC-cables, battery cables and the temp.resistor cables will be routed from one rack to the other. An U-profile bar above the conduit will be used for routing of the Selic-bus-cables and CAN-bus-cable. The mechanical equipment and cables necessary for connecting the racks are part of corresponding mounting kits.

Other configurations with up to 5 m distance are possible and have to be defined for specific project. In this case additional mechanical support and sleeve equipment as well as extended cables, described in the following tables, are necessary. 2100 mm

conduit S30861-S2146-S Fig. 2.27 Back-to-back configuration

1600 mm max. 5 m 600 mm S30861-S2146-S profile bar conduit Fig. 2.28 Side-by-side configuration 36 A30808-X3247-K380-4-7631 450 mm

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Service1

Base

Extension1

S30861-S2146-S conduit profile bar

1500 mm

Extension2

Fig. 2.29

Back-to-back configuration with Extension1 and Extension2

Service1

Base

Extension1

1500 mm

2400 mm

S30861-S2147-S conduit profile bar

Service2

Fig. 2.30

Back-to-back configuration with Service1 and Service2

2400 mm 37

A30808-X3247-K380-4-7631

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

Additional to the standard configurations of back-to-back assembly as shown in the figures of this section other configuration with distances up to 5 metres are possible. In this case required components and extended cables have to be defined in accordance to customers rquirements depending on length of flexible conduit. The following tables informs about the mechanical components and typical cables for extension.Measure X is the length of the flexible conduit and means also the additional cable length. The relation between cables with Siemens code no. and cable no. is given in Tab.2.9. Service 2/3 Service 2/2 distance X Service 2/1 S2/1-S2/2 DC cable CAN-Bus cable Battery cable Temp.resitor cable conduit Rack Rack Rack Rack Rack 2) (110/3, 111/3)+X 1) (112/3) (110/4, 111/4)+X 1) (112/4) (33)+X (249)+X Service 1 Base S1-S2/2 Extension 1 S1-S2/3 Extension 2 E2-S2/2

1) max. distance of AC/DC frame 2,5 m otherwise use up to 5 m cable 112/4 2) type of flexible conduit see Tab.2.10 Tab. 2.4 Gap between Service2/1 and Service2/2 rack

Service 2/3

Service 2/2

Service 2/1

Service 1 S2/2-E2

Base S2/1-E2

Extension 1 S1-E2 1) (36)+X

distance X B-E2

Extension 2 E1-E2

DC cable CAN-Bus cable Selic cable

Rack Rack Rack (249)+X (248)+X

1) (277, 278)+X 2)

conduit

Rack

1) replace fix installed cable by extended cable (+X) 2) type of flexible conduit see Tab.2.10 Tab. 2.5 Gap between Extension1and Extension2 rack

38

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Service 2/2

Service 2/1

Service 1 S2/2-E1

Base

distance X S2/1-E1

Extension 1 S2/1-E2

Extension 2 S1-E1 1) (35)+X S1-E2 1) (36)+X B-E1 B-E2

S2/2-E2

DC cable CAN-Bus cable Battery cable

Rack Rack Rack (249)+X (247)+X (248)+X

(246)+X 1) (277,278 )+X 2) 1) (277,278 )+X

conduit

Rack

1) Replace fix installed cables by extended cables (+X) 2) type of flexible conduit see Tab.2.10 Tab. 2.6 Gap between Base and Extension1 rack

Service 2/3

Service 2/2

Service 2/1

distance X S2/2-E2

Service 1 S2/1-E1

Base

Extension 1 S1-S2/1 3) (33)+X

Extension 2 S1-S2/2 S1-S2/3

S2/1-E2

DC cable CAN-Bus cable Battery cable Temp.resistor cable conduit

Rack Rack Rack Rack Rack (249)+X (247)+X (248)+X

(110/2+ 111/2)+X 1) (112/2) 4)

(110/3+ 111/3)+X 2) (112/3)

(110/4+ 111/4)+X 2) (112/3)

1) max. distance from AC/DC frame to battery 2,5 m, otherwise use cable 112/3 2) max. distance from AC/DC frame to battery 5,5 m, otherwise a special must be defined 3) Replace fix installed cables by extended cables (+X) 4) type of flexible conduit see Tab.2.10 Tab. 2.7 Gap between Service2/1 and Service1 rack

A30808-X3247-K380-4-7631

39

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

Service 2/3

Service 2/2

Service 2/1

Service 1 S2/2-E1

distance X S2/2-E2

Base

Extension 1 S2/1-E2

Extension 2 S1-B 1) (34)+X S1-E1 1) (35)+X (246)+X S1-E2 1) (36)+X

S2/1-E1

DC cable CAN-Bus cable conduit

Rack Rack Rack (249)+X (247)+X (248)+X

(245)+X 2)

1) Replace fix installed cables by extended cables (+X) 2) type of flexible conduit see Tab.2.10 Tab. 2.8 Gap between Service1 and Base The following cables with Siemens code no. are typical cables for interrack-cabling without extension. cable code no. 110/2, 111/2 110/3, 111/3 110/4, 111/4 112/2 112/3 33 34 35 36 245 246 247 248 249 277 278 Tab. 2.9 Siemens code no. S30864-X211-A47 S30864-X211-A48 S30864-X211-A49 S30864-X211-A44 S30864-X211-A45 Component of S30864-X211-A29 Component of S30864-X211-A29 Component of S30864-X211-A29 Component of S30864-X211-A29 S30864-X210-A11 S30864-X210-A12 S30864-X210-A13 S30864-X210-A14 S30864-X210-A15 S30864-X210-A2 S30864-X210-A2 Interrack-cables without extension

The cables 33-36 are fix installed in the Service1 rack and have to be replaced by extended according to back-to-back configuration. The installation requires the temporary removal of the plate, located at the top of EMI-panel.

40

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

exibe conduit

Siemens code no.

type 1 (distance 0,625 m - 2,40 m) C50324-Z200-C22 type 2 (distance 1,25 m - 5,00 m) Tab. 2.10 Types of exible conduit C50324-Z200-C21

Note: Grounding connections to extended racks are required by seperate connections from external grounding bar !

A30808-X3247-K380-4-7631

41

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

2.6

2.6.1

External Cabling Activities

Overview

This chapter provides the information required for installing the external cables between the Base Station and the infrastructure equipment on site. The rack cannot function without the following cable connections: in case of using of an AC power supply: AC mains terminal block 5 pole - power distribution of 230 Vac, 3-phase supply by using of an external DC power supply: DC mains terminal block 2 pole - power distribution of -48Vdc ground screws - ground bar Abis interface - NTPM (in case of transmission via terrestrial lines) microwave indoor or outdoor units (if W equipment is used o f r transmission) transmit / receive antenna connectors - antenna system ground strip of antenna cable shields - ground bolt optional: serial interface - signalling link terminal alarm collection terminal - external alarm sensors LMU - GSM/GPS antennas All interfaces exept the antenna connectors are located at the EMI panel below the top rack cover. For cable installation the top enclosure has to be removed. For opening and removal of the roof unscrew the bolts in the top extrusions.

2 3

2 4 5

1 PE plate 2 ground bolts 3 AC terminals Fig. 2.31

4 CAN bus OUT 5 CAN bus IN 6 CAN bus TEST

7 lightning protection alarms

Interfaces on top of the BS240/240XL service1 rack

42

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Picture required ! Fig. 2.32 Interfaces on the top of the BS-240 II / 240XL II Service1A rack

3 11 PCM 0 1 2 PCM 1 13

3 5 6 12 Serial interface 9 14 CAN-bus 7 8 LPA 4 10 MSU

1 Abis interface on OVPT 0 2 Abis interface (OVPT 1) 3 ground bolts 4 DC terminal 5 CAN bus OUT Fig. 2.33

6 -48Vdc 7 CAN bus TEST 8 lightning protection alarms 9 serial interface 10 site inputs on ACK

11 extension 1 CU4...7 12 extension 1 CU0...3 13 extension 2 CU4...7 14 extension 2 CU0...3

Interfaces on top of the BS-240/240XL base rack

A30808-X3247-K380-4-7631

43

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

Picture required ! Fig. 2.34 Interfaces on the top of the BS-240 II / 240XL II base rack

3 3 1 2 9 4 5

1 CU4...7 2 CU0...3 3 ground bolts Fig. 2.35

4 CAN bus OUT 5 CAN bus IN 6 CAN bus TEST

7 lightning protection alarms 8 PE plate 9 DC terminal

Interfaces on top BS-240/240XL extension rack

44

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Picture required ! Fig. 2.36 Interfaces on the top of the BS-240 II / 240XL II extension rack

Some additional hints for the installation of external cabling: The rst cable that has to be installed is the ground cable between the main ground stud on top of the rack and the nearest ground bar on site. The second installation step is to connect the ground stud of the different racks in series. After that all other cables like AC mains, RF cabling or alarm wires can be installed. The screen of the RF jumpers has to be grounded before entering the BTSE via the cable feeding module, see Fig. 2.69. If cables are fed through coaxial cable access located at the top of the rack at the front, the screen has to be grounded like all other coaxial cables. The following figure shows the location of the external interfaces of the BS-240/240XL (example of BS-240 with Service1-, Base- and Extension rack).

A30808-X3247-K380-4-7631

45

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

Installation Base Transceiver Station Equipment

serial interface cable external alarms / commands Abis lines (OVPT PCM0, PCM1) antenna cables 3 x 230 Vac ** ground cable microwave

SIEMENS

LMT ETHERNET

LMU GSM antenna cables LMU GPS antenna cable

-48 Vdc*

LMU

SIEMENS DC-PANEL ACT-C

LMT ETHERNET

SIEMENS DC-PANEL ACT-C

LMT ETHERNET

DC-PANEL ACT-C

AC/ AC/ AC/ AC/ AC/ AC/ AC/ DC DC DC DC DC DC DC CTRL #0 #0 #1 #2 #3 #4 #5 AC + DC Distribution

ACOM ACOM ACOM ACOM #1 #0 #3 #2

ACOM ACOM ACOM ACOM #1 #0 #3 #2

LE 0 LE 1 LE 2 LE 3 LE 4 LE 5

MUCO #0

MUCO #1

MUCO #0

CU CU #2 #3

CU #6

CU #7

CU CU #2 #3

MUCO #1

CU #6

CU #7

COBA 0 COSA 0 COBA 1 COSA 1

CU CU #0 #1

CU #4

CU #5

CU CU #0 #1

CU #4

CU #5

Service1 rack

Base rack

Extension rack

*) only used if an external DC-power supply is available **) if an external 3 x 230 V ac power supply source will be used

Fig. 2.37

Locations of connection points for external cables

46

A30808-X3247-K380-4-7631

Installation Base Transceiver Station Equipment

IMN:BTSE BS-240/240XL BS-240 / 240 II / 240 XL / 240XL II

2.6.2

Ground and AC- Power Supply Connections

The racks have to be connected to the site specific ground system before starting the connection of AC mains cable. An external ground wire (16 mm2, copper conductor) has to be connected on the upper left side grounding bolt of the rack which must be attached to the ground bar on site. All adjoining racks will be grounded using a prefabricated wire bridge and is connected to top left and right corners of each rack respectively. If on site a main ground wire (50 mm2, copper conductor) is installed, it is possible to connect each rack on the shortest way to the main ground using 16 mm2 copper wires. Connect the racks to the ground system as follows: Use the nearest ground bar on site. Ascertain the distances between the connection points of the ground system and the ground bolt of the rack. Cut the cables to the required length. Remove the cable covering at the end to connect to the ground bolt (length approx. 15 mm) and x a cable lug M8. Connect the prepared cable end to the ground bolt. Tighten the nut rmly.

alternative solusion for rack grounding

50 mm2 main ground wire 16 mm 2ground wires ground wire bridges

H07-RN F 5 G4 AC distribution AC counter 3 x 25 A main breakers

3 x 230 Vac mains

connection to ground

Fig. 2.38