Академический Документы

Профессиональный Документы

Культура Документы

Tevi Necirculare - HOBAS

Загружено:

Anonymous 4MLEo9TVQИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tevi Necirculare - HOBAS

Загружено:

Anonymous 4MLEo9TVQАвторское право:

Доступные форматы

h NC Liner

Production of h NC Liner

Years of Experience

Many European cities started building modern sewer systems in the middle of the 19th century. Still surviving today, the large sewers with specially shaped cross sections are the result of great feats of engineering and the foresight shown by the city fathers at that time. After such long periods in use, however, renovation often becomes inevitable despite regular maintenance. HOBAS NC Line Pipes with their noncircular cross sections are ideal for rehabilitating these old sewers and building new ones. Manhole renovation solutions and relining pipes round off the HOBAS Rehabilitation range.

Manufacture

HOBAS NC Products feature a particularly resinrich inner layer. First this layer is applied to a release film and then the filament winding process begins. Pipes can be designed for specific loads and project requirements, while also taking structural dimensions, customer specifications and regulations regarding chemical resistance into account. Once the winding process is completed, the pipe undergoes finishing and is then removed from the mandrel. Depending on the size and wall thickness, the completed pipe is tempered for several hours to ensure that the polyester resin is fully cured. During installation, the pipes are pushed or pulled into the existing pipeline and the remaining annular space between the host and liner pipes is filled with pressure-resistant grouting, usually a mixture of binding materials. This fixes the inserted pipe in position, creating a pipeline of the same integrity as a new one.

Joints and Couplings

Old sewer Resin-rich outer layer with quartz sand filling Grout Sealing Existing connection pipe Hand lay-up laminate GRP protection pipe according to local measurement Structural layer with resin/randomly oriented fiber/winding roving and quartz sand filling

Barrier layer with randomly oriented fiber Resin-rich inner layer with quartz sand filling

NC Line Profile

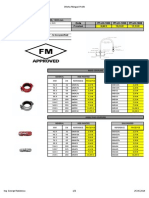

Verbindungssystem

Type I kit: Standard joint with EPDM gasket

EPDM gasket

Type II kit: Adhesive joint for special applications

Adhesive

h NC Liner Profiles

Kite-shaped cross section

The range of available HOBAS NC Line Profiles and therefore the pipe cross sections is just as varied as the history of wastewater disposal itself. In addition to classic regular cross sections, such as circular, egg, jaw or kite-shaped pipes, we more and more manufacture combinations of shapes on request. Having perfected the necessary manufacturing technologies, HOBAS is regarded as a specialist for solving complex rehabilitation problems.

Egg-shaped cross section

Such expertise naturally also includes the relevant joining technology. Where shapes are completely convex, we generally join the pipes with push-on couplings, while we use glued or laminated joints for combinations of convex and concave or even shapes. Suitable shaft structures and tangential manholes also feature in our range of products. We can therefore supply customers with a complete system including pipes with special cross sections, lateral connections and manhole structures.

Elongated egg-shaped cross section

Jaw-shaped cross section

Jaw-shaped cross section with dry weather channel

h NC Liner Applications

HOBAS NC Line Pipe Sections not only enable you to overcome a wide range of challenges in rehabilitation but also in building new supply and disposal systems. The material properties and cross-section shape to be used are determined for each specific application. Particularly when other materials have reached the end of their life cycle or failed prematurely, our pipe sections are a long-lasting option. NC Line Products are ideal for conveying Community sewage Industrial wastewater Raw water Potable water Chemically aggressive wastewater The special material properties, shapes and jointing options result in the following advantages: Good hydraulic performance under various loads Flexibility in difficult installation situations Self-cleaning properties when flow is low Low maintenance costs Connection options for various materials High static load capacity Short installation times Installation in fluid environments Long service life

Optimal Service and Highest Quality Standards

Reliable Service

As a system supplier, HOBAS attaches great importance to service. Our experts will support you to ensure that your project runs smoothly from initial planning right through to completion. HOBAS is committed to providing customers worldwide with a broad product range and professional support. A matter of course for us: Technical advice for planning, installation and rehabilitation Feasibility studies Structural analyses to comply with various regulations Design and drawings for manholes, structures and custom constructions in 2D and 3D Consultancy, training and support for building contractors Installation services Technical documentation and information material On-site support during construction work from HOBAS Technicians

Top Quality

HOBAS Plants are certified by independent institutes to various international standards, ensuring that the finished products meet the highest customer specifications. Not only compliance with ISO 9001 but also uniformly high quality standards is a key feature of HOBAS Products and firmly rooted in our corporate philosophy. The quality management system covers all areas, including new product development, quality control processes, shipping and service what you receive is consistently high quality without any ifs or buts. Our comprehensive quality control program meets international standards as well as taking special customer specifications into consideration. HOBAS holds the octagon quality mark issued by Germany's TV technical service and many other approvals. Auditors from renowned certification companies and our specialists in the HOBAS R&D departments, application engineering and installation teams ensure that you can rely on consistently high, uniform quality no matter from what country the pipes are delivered to you. Our internal HOBAS Quality Control Program also includes the following quality assurance measures: Testing the raw materials Testing the semi-finished products Testing the services Release testing for production Strength testing on finished products Visual inspection and dimension checks on finished products Hydrostatic and hydrodynamic testing Calibrating the instruments Ensuring the identification and traceability of the products Checking planning and design Checking the suppliers

h NC Liner: Impressive Benefits

HOBAS NC Line Products feature:

Variable length of pipeline (to customer specifications) Customizable cross-section shape Option of various jointing systems High static load capacity High hydraulic capacity High corrosion resistance Tested abrasion resistance Easy handling Installation without any significant traffic disruptions Installation irrespective of the weather Compatibility with all HOBAS Pipe ranges Little incrustation and sludge deposits Minimal trench width, therefore easier for working on sites with restricted space (inner city) Environmental benefits towns and landscapes do not suffer as a result of construction work Prevention of falls in the water table level Very long service life of up to 100 years

Unnoticed Under Historic Dresden

Year of Construction 2009 Total Length of Pipeline HOBAS Pipe: 880 m Pressure Class PN 1 Diameter 2157/2129, 2242/2195 mm Installation method Relining with short profiles Client Stadtentwsserung Dresden GmbH Special Features Pipe cross sections designed to fit the old sewer, no disruption to tourism/traffic, high quality, high delivery reliability

h NC Liner Pipe Sections Rehabilitate Sewer, DE

At the beginning of the 20th century Dresdens sewer system was already 430 kilometers long. An essential part of the sewer system with connection to the wastewater treatment plant Kaditz is to this date the Altstdter collector, which underpasses a big part of Dresdens historic center. One of the interceptors in the old town was made of tamped concrete. Inspections revealed damage meaning that their load capacity could no longer be guaranteed: the sewers urgently needed to be repaired. Over 1.3 km in length, the section to be rehabilitated ran through the old town and along the banks of the Elbe. As an attractive destination Dresden draws some 7 million visitors every year. In view of this situation, the only option was trenchless rehabilitation by relining. Compared with open-cut installation, construction time would be speeded up and disruptions to traffic and tourism reduced to a minimum. Dresdens utility company weighed up the various alternatives but decided in favor of HOBAS NC Line Pipe Sections made of GRP . Thanks to the smooth inner surface of the HOBAS Special Pipe Sections with a k value of 0.01 mm, the hydraulic requirements were still met despite the reduction in diameter. The first step was to assess the condition of the existing pipes by inspecting the old sewer, calibrating it by laser scan and manually with a template in places to determine the exact outside dimensions for the individual NC pipe sections. Our aim was to make best possible use of the old sewer while ensuring easy installation at the same time. What we came up with was an installation plan with regular, short and special pipe sections with bevel joints. In areas with particularly pronounced angular deflection the prefabricated curved parts were joined using GRP hand lay-up. The prefabricated HOBAS NC Pipe sections can be produced with any wall thicknesses required, thus compensating for any structural imperfections in the old sewer. Opting for two construction stages, we installed a total of 520 m HOBAS NC Sections with inside dimensions of 2,157 x 2,129 mm and 320 m with 2,242 x 2,195 mm. After completion, the interceptor was totally rehabilitated and will operate reliably for the next hundred years even in the event of flooding. The many tourists hardly noticed what was going on, with the only evidence being the pipes stored nearby and the few access shafts for the important work under the streets of Dresdens old town. Fmd: hobas.germany@hobas.com

No Dig Award for Relining with h NC Line

h NC Liner Sections Replace Sewer System in Tilburg, NL

The sewer in Sint Josephstraat is an important link to the wastewater treatment plant and the combined overflow. Built in 1928, the concrete sewer base with the brick arch is in the shape of an inverted egg with inside dimensions of 1.90 m wide by 2.15 m high. In the late 1990s, work on the road above put a considerable strain on the sewer. Inspections with radar systems revealed that cavities had formed beside it because cracks in the sewer had caused sand to be washed out here. As injecting resin into the cracks did not prove as successful as hoped, rehabilitation was unavoidable. Analyses showed that the sewer masonry was actually intact, but the concrete sewer base had suffered greatly in recent years. Attempts at repairing the base also failed because the structural damage was not rectified. In order to guarantee structural safety as well, the only answer was to rehabilitate the old sewer or install a new one. A total replacement would have involved extensive construction work in open trenches, which would have been very expensive, and so relining was the only feasible option. What was important to the local authorities was reducing the diameter by a maximum of 10 cm. Angular deformation in the horizontal plane over the route of the pipeline where rehabilitation was required also had to be taken into account. Tilburg city council opted for HOBAS NC Line Products to reline the pipeline. The decisive reasons were the high standards of HOBAS Products, experience with installation, the tested, consistent material quality, high stiffness and adaptability, enabling only a slight reduction in diameter. In addition, when HOBAS Products are used the sewer can continue to be operated during installation even if there is heavy rainfall. The tender also specified many different fittings (manholes, pipe inlets, etc.) which HOBAS supplied tailor made for the site. After calculating the wall thickness of the pipe segments to be 26 mm, the client designed a special transport cart for installing the pipeline. During the construction work the wastewater was diverted. In the event of heavy rainfall, the existing sewer could however be evacuated within 15 minutes and then be used. The pipes were fixed in place to prevent them from floating and the annulus between the new and existing pipeline filled with grouting. HOBAS NC Line Products proved to be the right choice for rehabilitation, as a panel of experts selected the project for the NSTT (Netherlands Society for Trenchless Technology) No Dig Award in 2009. Fmd: hobas.benelux@hobas.com

Year of Construction 2008 Construction Time 5 months Total Length of Pipeline 860 m Pressure Class PN 1 Diameter 2150/1900 mm Installation method Relining Client Community Tilburg Contractor Heijmans Infra techniek BV Special Features Custom pipes, leak tightness of the system, high quality, only slight diameter reduction when relining

10

h Pipes in All Shapes and Sizes

New Sewer System for Krakow, PL

Krakow is one of the oldest cities in Poland with a sewer system totaling 1,780 km in length. In 2007 , the city council put rehabilitation of 5 km of sewer pipes under 13 roads out to tender. The concrete pipes dated back to 1900 - 1945 and showed considerable damage: Leaks and cracks put the surrounding soil at risk and as most of the pipelines run under heavy traffic routes, the static load capacity of the sewers also had to be ensured. Having already had very good experience with HOBAS Products, contractors PBG - INFRA - PBRSP Kielce had no difficulty in selecting the right material.

Year of Construction 2008 - 2009 Total Length of Pipeline 3.8 km Diameter 600/900 - 2677/2075 Pressure Class PN 1 Installation method Relining Client Krakow water and sewer works Contractors ARGE PBG - INFRA PBRSP Kielce Special Features Special sections in various different shapes, mechanical properties, abrasion resistance, chemical resistance, easy installation

Numerous special sections were custom made to fit the sewers. To rehabilitate the oval sewers, HOBAS NC Sections in 1,710/1,810 mm were produced in three different lengths: 2.35 m long pipes were used in the straight parts and 0.5 - 1 m long ones in the curved parts. Most of the rehabilitation work was in the city center. Here the sewers not only have to withstand heavy traffic but also the weight of the streetcars. HOBAS Egg-Shaped Sections in sizes 600/900, 680/1,050, 750/1,120 and 900/1,350 mm were used under the city center streets. As far as the sections for rehabilitating Wandy road and Daszynskiego road were concerned, the HOBAS Experts had to be really creative. Given the special shape of the sewer, they could not use regular NC products. The HOBAS Engineers therefore took a HOBAS Jaw-Shaped Section, joined the bottom to a circular HOBAS Pipe and completed the part with a flat plate made of GRP . In Daszynskiego Road, a circular HOBAS Pipe was added to the underside of a jaw-shaped section, thus ensuring that even when the water level is low the sewage is reliably conveyed. The individual parts of the unusually shaped sections were securely joined together with laminate. Ever resourceful, the HOBAS Experts also found a custom solution for the couplings: As they could not use regular couplings, they joined the sections with epoxy adhesive. The next step was to carefully fill the annulus between the old sewer and HOBAS Section. Construction work was finished to the complete satisfaction of everyone involved in the project. The professional advice on the part of HOBAS, the tailor-made special sections and the quick and easy installation left the contractors in no doubt that they had made the right choice. Fmd: hobas.poland@hobas.com

11

Rehabilitation under Extreme Conditions

h System Solutions Impress French Guiana, GF

French Guiana (overseas department of France in Central America) set about renewing a large number of the culverts in its national road network in 2005 and 2006. Installed in the 1970s and 1980s, these culverts made of concrete or steel had become badly damaged and therefore had to be rehabilitated as fast as possible. Extreme tropical weather conditions, heavy loads over the culverts and water with a pH of between 3 and 6.5 placed high demands on both the material and building contractors. In addition, the hydraulic capacity also had to be maintained or increased and the material had to withstand abrasion from sand. The difficult geological conditions compounded the situation. Having taken many different materials into consideration, the client finally opted for HOBAS Products. The project required both circular and noncircular HOBAS Products, which were installed using open-cut, jacking and relining techniques. Custom HOBAS NC Line Pipes with a cross section of 1,660/1,260 mm through 3,200/2,050 mm and round HOBAS Pipes De 600 through 1,229, SN 10,000 through SN 40,000 now ensure a reliable, leaktight pipe system. Apart from corrosion resistance, what again proved to be the great benefit of HOBAS Products was fast and safe installation that did not disturb nature or disrupt the traffic flow. Everyone involved was very pleased with the results of the project and the custom system solutions supplied by HOBAS. So much so that the French authorities will also be happy to consider HOBAS for other tenders in the future. Fmd: hobas.france@hobas.com

Year of Construction 2005 - 2006 Diameter De 600 - 1229 NC Liner 1660/1260 3200/2050 mm Stiffness Class SN 10000 - 40000 Application Rehabilitation Client Ministry of Equipment and Transportation Contractors Devin Lemarchand Environnement Special Features Corrosion resistance, high static load capacity, installation irrespective of weather

E Engineering GmbH Responsible for content: Wilfried Sieweke, Sabrina Sereinig | Texts & Layout: Sabrina Sereinig, Sabine Friesser Publication: 04/2011 | Update: 03/2012 | Print: Carinthian Druck Beteiligungs GmbH 03/2012 All rights reserved. No part of this document may be reproduced or utilized in any form or by any means without our prior written permission. All information in the document is correct at the time of going to press. However, we reserve the right to make changes without notice, in particular to technical data. The data given is not binding and must therefore be checked in each individual case and revised as appropriate.

E Group Worldwide HOBAS manufactures and markets HOBAS GRP Pipe Systems. The HOBAS Network includes HOBAS Production Facilities and Sales Organizations in Europe and throughout the world.

E Engineering Austria Pischeldorfer Strasse 128 9020 Klagenfurt | Austria T +43.463.48 24 24 | F +43.463.48 21 21 info@hobas.com | www.hobas.com

We develop and manufacture HOBAS Products conserving natures resources and with respect for our environment. Visit our website to find out more about the HOBAS Environmental Policy.

Вам также может понравиться

- 1203 Jacking E WebДокумент16 страниц1203 Jacking E Webfbm9318Оценок пока нет

- Relining Pipes - HOBASДокумент12 страницRelining Pipes - HOBASAnonymous 4MLEo9TVQОценок пока нет

- 1203 Sewer E Web GRPДокумент12 страниц1203 Sewer E Web GRPArun VaithyanathanОценок пока нет

- The Complete HOBAS GuideДокумент76 страницThe Complete HOBAS GuideJoe RayОценок пока нет

- GS-Hydro piping systems optimize marine operationsДокумент7 страницGS-Hydro piping systems optimize marine operationsNilesh MistryОценок пока нет

- The Complete Guide To Pipe Selection For Trenchless ProjectsДокумент24 страницыThe Complete Guide To Pipe Selection For Trenchless ProjectsameygandhiОценок пока нет

- HOBAS Hydropower Pipelines - GPRДокумент12 страницHOBAS Hydropower Pipelines - GPRcesar munozОценок пока нет

- Nordipipe BrochureДокумент8 страницNordipipe BrochureLuis13956353Оценок пока нет

- Unicor 2Документ52 страницыUnicor 2Lam Ch100% (1)

- SEKISUI SPR CPIP & Sewer OnДокумент8 страницSEKISUI SPR CPIP & Sewer OnShaikh Muhammad AteeqОценок пока нет

- BUTTING Spools and Welded ComponentsДокумент16 страницBUTTING Spools and Welded ComponentsniqutomoОценок пока нет

- Rigid PVC PipesДокумент20 страницRigid PVC PipesNaeemSiddiquiОценок пока нет

- H CC-GRP Pipes Features, Tests and Benefits: Make Things HappenДокумент78 страницH CC-GRP Pipes Features, Tests and Benefits: Make Things HappenChin Keong ChengОценок пока нет

- PDF Version!: Flowtite Pipe SystemsДокумент0 страницPDF Version!: Flowtite Pipe SystemsDeva RajОценок пока нет

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!От EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Рейтинг: 5 из 5 звезд5/5 (2)

- Petroleum Production Engineering-I: Third Year Second TermДокумент46 страницPetroleum Production Engineering-I: Third Year Second Termsarfraz hussain100% (1)

- Water Transmission PipelinesДокумент16 страницWater Transmission Pipelinesdownloadused33% (3)

- New BrochureДокумент44 страницыNew Brochure0808276kОценок пока нет

- Flexible Pipe ThesisДокумент6 страницFlexible Pipe Thesisandrealeehartford100% (2)

- Types of PVC PipesДокумент5 страницTypes of PVC Pipesfarshan296015100% (1)

- Sanco Install Success.: Sanco - The Plain Copper Tube BrandДокумент12 страницSanco Install Success.: Sanco - The Plain Copper Tube Brandmoni43Оценок пока нет

- FLOWTITE Pipe Systems: For Subaqueous InstallationsДокумент12 страницFLOWTITE Pipe Systems: For Subaqueous InstallationsRusu CatalinОценок пока нет

- USE of DWC Giga Pipes in Highway ConstructionДокумент16 страницUSE of DWC Giga Pipes in Highway ConstructionSuresh TripathiОценок пока нет

- Cone Type Flow MetersДокумент6 страницCone Type Flow MetersHussam AhmedОценок пока нет

- Hobas FTBДокумент78 страницHobas FTBdarkroomzc100% (1)

- Underground Drainage SystemsДокумент56 страницUnderground Drainage Systemssudhialakkal100% (1)

- GRP Pipe Systems PDFДокумент6 страницGRP Pipe Systems PDFaliarbiОценок пока нет

- MCD Water Management BrochureДокумент78 страницMCD Water Management BrochureBerat DalyabrakОценок пока нет

- British Precast Drainage AssociationДокумент24 страницыBritish Precast Drainage AssociationpaularupОценок пока нет

- Tevi Si Fitinguri Din Fonta Ductila de La DN 60 La DN 2000 Conform en 545-2010 (En)Документ52 страницыTevi Si Fitinguri Din Fonta Ductila de La DN 60 La DN 2000 Conform en 545-2010 (En)Gabi CristacheОценок пока нет

- SRDA - A Guide To Siphonic Drainage - 2007Документ18 страницSRDA - A Guide To Siphonic Drainage - 2007Erin Lim100% (1)

- Bridges - EN - AcelorMittalДокумент52 страницыBridges - EN - AcelorMittalstavros_stergОценок пока нет

- Flowtite Product Guide 2010Документ28 страницFlowtite Product Guide 2010Anonymous 87xpkIJ6CFОценок пока нет

- Coiled Tubing StringДокумент10 страницCoiled Tubing StringVirnando NainggolanОценок пока нет

- Gruvlok Water-Wastewater ProductsДокумент16 страницGruvlok Water-Wastewater Productsmax_powerОценок пока нет

- Bespoke Fabrication Systems for Unique Site SolutionsДокумент13 страницBespoke Fabrication Systems for Unique Site Solutionswish uОценок пока нет

- Linde LNG PipelineДокумент4 страницыLinde LNG PipelineSatis MadhavanОценок пока нет

- Flexible Risers: AquaticДокумент1 страницаFlexible Risers: AquaticjiokoijikoОценок пока нет

- Offshore and Onshore Pipeline SolutionsДокумент18 страницOffshore and Onshore Pipeline SolutionsAshray KvОценок пока нет

- GRP Product GuideДокумент20 страницGRP Product Guidedp75Оценок пока нет

- Structural Liner BrochureДокумент5 страницStructural Liner BrochureNu FlowОценок пока нет

- SRDA-The Siphonic Guide-V1-1305 PDFДокумент18 страницSRDA-The Siphonic Guide-V1-1305 PDFYaseen MallickОценок пока нет

- Belt ConveyorДокумент12 страницBelt ConveyorNath Boyapati100% (1)

- Product Range Sheet Pile Sections: Status: August 2012Документ32 страницыProduct Range Sheet Pile Sections: Status: August 2012Nanescu LilianaОценок пока нет

- RTi-Broschuere EN 20191010-WEBДокумент24 страницыRTi-Broschuere EN 20191010-WEBFlorentin DumitruОценок пока нет

- Hanson Structural Precast ProductsДокумент24 страницыHanson Structural Precast ProductsTanja DjordjevicОценок пока нет

- Well StreamДокумент6 страницWell StreamErick de la CruzОценок пока нет

- Keramo - Report 01 - 2015Документ20 страницKeramo - Report 01 - 2015sasa.vukojeОценок пока нет

- 01 Appende PDFДокумент21 страница01 Appende PDFArun VaithyanathanОценок пока нет

- Sewage Disposal Works: Their Design and ConstructionОт EverandSewage Disposal Works: Their Design and ConstructionОценок пока нет

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringОт EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringРейтинг: 4 из 5 звезд4/5 (5)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerОт EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerРейтинг: 5 из 5 звезд5/5 (1)

- Handbook of PVC Pipe Design and Construction: (First Industrial Press Edition)От EverandHandbook of PVC Pipe Design and Construction: (First Industrial Press Edition)Оценок пока нет

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОценок пока нет

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionОт EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionРейтинг: 4.5 из 5 звезд4.5/5 (16)

- Belaria+SRM+ +technical+ INM-en+ 2017 PDFДокумент30 страницBelaria+SRM+ +technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQОценок пока нет

- Dpu PDFДокумент4 страницыDpu PDFTEIUSANUОценок пока нет

- Katalog Fire Protection Systems G 105Документ108 страницKatalog Fire Protection Systems G 105lucasОценок пока нет

- Belaria+SRM+ +technical+ INM-en+ 2017 PDFДокумент30 страницBelaria+SRM+ +technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQОценок пока нет

- Correspondance Pouce MMДокумент4 страницыCorrespondance Pouce MMhichamОценок пока нет

- Bio Lyt (50 - 160) - Carte Tehnica PDFДокумент14 страницBio Lyt (50 - 160) - Carte Tehnica PDFAnonymous 4MLEo9TVQОценок пока нет

- Catalogue NST PDFДокумент12 страницCatalogue NST PDFTEIUSANUОценок пока нет

- Tuyau Sme PDFДокумент2 страницыTuyau Sme PDFteiusanuОценок пока нет

- Guide Technique - FLUXO PDFДокумент24 страницыGuide Technique - FLUXO PDFteiusanuОценок пока нет

- Belaria+twin+ Technical+ INM-en+ 2017 PDFДокумент38 страницBelaria+twin+ Technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQОценок пока нет

- Bio Lyt (50 - 160) - Carte Tehnica PDFДокумент14 страницBio Lyt (50 - 160) - Carte Tehnica PDFAnonymous 4MLEo9TVQОценок пока нет

- Bio Lyt (50 - 160) - Carte Tehnica PDFДокумент14 страницBio Lyt (50 - 160) - Carte Tehnica PDFAnonymous 4MLEo9TVQОценок пока нет

- PowerBloc EG20 - COGENERARE PDFДокумент12 страницPowerBloc EG20 - COGENERARE PDFAnonymous 4MLEo9TVQОценок пока нет

- Catalogue CST PDFДокумент29 страницCatalogue CST PDFTEIUSANUОценок пока нет

- Belaria+SRM+ +technical+ INM-en+ 2017 PDFДокумент30 страницBelaria+SRM+ +technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQОценок пока нет

- Gear Box CouplingДокумент30 страницGear Box Couplingdeepthik27100% (2)

- Belaria+twin+ Technical+ INM-en+ 2017 PDFДокумент38 страницBelaria+twin+ Technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQОценок пока нет

- Catalogue Escospeed PDFДокумент8 страницCatalogue Escospeed PDFAnonymous 4MLEo9TVQОценок пока нет

- Max-3 - Carte Tehnica PDFДокумент17 страницMax-3 - Carte Tehnica PDFAnonymous 4MLEo9TVQОценок пока нет

- Ofeta Fitinguri Cu DiscountДокумент6 страницOfeta Fitinguri Cu DiscountAnonymous 4MLEo9TVQОценок пока нет

- PowerBloc EG20 - COGENERARE PDFДокумент12 страницPowerBloc EG20 - COGENERARE PDFAnonymous 4MLEo9TVQОценок пока нет

- Wellsee Wind Turbine CatalogueДокумент10 страницWellsee Wind Turbine CatalogueAnonymous 4MLEo9TVQОценок пока нет

- Katalog Fire Protection Systems G 105Документ108 страницKatalog Fire Protection Systems G 105lucasОценок пока нет

- Sisteme Fixare - Sustinere - INKA PDFДокумент36 страницSisteme Fixare - Sustinere - INKA PDFMatthew SuttonОценок пока нет

- Prospect DuctДокумент1 страницаProspect DuctAnonymous 4MLEo9TVQОценок пока нет

- Catalogue Escorail PDFДокумент4 страницыCatalogue Escorail PDFTEIUSANUОценок пока нет

- Solar Controller and Inverter CatalogueДокумент10 страницSolar Controller and Inverter CatalogueAnonymous 4MLEo9TVQОценок пока нет

- Therapetic Apparatus CatalogueДокумент14 страницTherapetic Apparatus CatalogueAnonymous 4MLEo9TVQОценок пока нет

- DC Inverter aer conditionat caseta ideal pentru spatii comercialeДокумент1 страницаDC Inverter aer conditionat caseta ideal pentru spatii comercialeAnonymous 4MLEo9TVQОценок пока нет

- MCQsДокумент29 страницMCQsSuhaib QaisarОценок пока нет

- FilterClear Brochure Rev9Документ2 страницыFilterClear Brochure Rev9Shashi BhushanОценок пока нет

- Characteristics of a Healthy Community EnvironmentДокумент16 страницCharacteristics of a Healthy Community EnvironmentGilbert ObingОценок пока нет

- Project ProposalДокумент4 страницыProject ProposalNahom Dagne100% (1)

- Case Study On Solid Waste Management Under Agaratla CityДокумент16 страницCase Study On Solid Waste Management Under Agaratla CityJeet SutharОценок пока нет

- Air EmissionsДокумент34 страницыAir EmissionsdmshahidchОценок пока нет

- Process Hazard Analysis ChecklistДокумент7 страницProcess Hazard Analysis ChecklistNicholas WhiteОценок пока нет

- Fosroc Chemical Breaker PDFДокумент2 страницыFosroc Chemical Breaker PDFrkvaitlaОценок пока нет

- TA2889-RHI-XX-XX-CA-N-1001 Fire Fighting Hidraulic Calculation-R1Документ25 страницTA2889-RHI-XX-XX-CA-N-1001 Fire Fighting Hidraulic Calculation-R1Iskandar HasibuanОценок пока нет

- Ground Water Quality of RanchiДокумент4 страницыGround Water Quality of RanchiAsif RazaОценок пока нет

- Scope of Work (Plumbing)Документ1 страницаScope of Work (Plumbing)Mochammad Waris S100% (1)

- An Update On New and Future Earthworks Standards in The UK and EuropeДокумент6 страницAn Update On New and Future Earthworks Standards in The UK and EuropetsuakОценок пока нет

- Dissertation Antigoni-Maria VrochidouДокумент63 страницыDissertation Antigoni-Maria Vrochidouallaboutshipping100% (1)

- Lorentz Ps2-100 Product BrochureДокумент3 страницыLorentz Ps2-100 Product BrochureSINES FranceОценок пока нет

- Shiitake Production On LogsДокумент22 страницыShiitake Production On LogsΙΩΑΝΝΗΣ ΤΖΕΚΑΣОценок пока нет

- Site Analysis of KanchipuramДокумент23 страницыSite Analysis of KanchipuramVivek Kumar0% (2)

- TS14CДокумент18 страницTS14Clrbs3083Оценок пока нет

- SDR VanoniДокумент17 страницSDR VanoniAron AlvaОценок пока нет

- How To Reduce Your Electricity Bill Using Lean Six SigmaДокумент17 страницHow To Reduce Your Electricity Bill Using Lean Six SigmazaydFGОценок пока нет

- Philippine Pride RevisedДокумент36 страницPhilippine Pride RevisedPedz LaguitaoОценок пока нет

- Determination of Sludge Volume IndexДокумент7 страницDetermination of Sludge Volume IndexDani MughalОценок пока нет

- Environmental guidelines for multi-purpose hallsДокумент5 страницEnvironmental guidelines for multi-purpose hallsAbishek SAОценок пока нет

- Harmful Algal Blooms and Nutrient LoadingДокумент23 страницыHarmful Algal Blooms and Nutrient LoadingmarisabelОценок пока нет

- Plumber Lecture Design Guide PDFДокумент32 страницыPlumber Lecture Design Guide PDFNick GeneseОценок пока нет

- Nr-30 Safety and Health at Work-WaterwayДокумент62 страницыNr-30 Safety and Health at Work-WaterwayAnonymousОценок пока нет

- Dat IatДокумент4 страницыDat Iatscribd birdОценок пока нет

- Water Supply and Sanitary EngineeringДокумент12 страницWater Supply and Sanitary Engineeringash100% (1)

- Producing Activated Carbon from Mahogany Fruit HusksДокумент7 страницProducing Activated Carbon from Mahogany Fruit HusksCeddie UnggayОценок пока нет

- MiniVecLoader50 MiniVecLoaderДокумент2 страницыMiniVecLoader50 MiniVecLoaderr_anzarОценок пока нет

- Breathable Soil WaterproofingДокумент2 страницыBreathable Soil WaterproofingANILОценок пока нет