Академический Документы

Профессиональный Документы

Культура Документы

Waste Biomass Conversion

Загружено:

cumpio425428Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Waste Biomass Conversion

Загружено:

cumpio425428Авторское право:

Доступные форматы

COMPENDIUM OF WASTE BIOMASS CONVERSION TECHNOLOGIES

PART I: CONVERSION TO ENERGY DAP

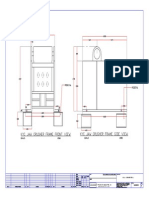

PADISCOR Rice Hull Cylconic Furnace

Philippines, Commercial Crop Residue Process Equipment Main Product Rice Hulls Combustion Furnace Heat for crop drying

Technical Description of Technology:1

Figure 1. Rice Hull Cyclonic Furnace

1

http://www.bpre.gov.ph/scripts/cornmecfinder.asp?categ=13 1

COMPENDIUM OF WASTE BIOMASS CONVERSION TECHNOLOGIES

PART I: CONVERSION TO ENERGY DAP

Rice hulls are fed into the furnace (Fig. 1) in a cyclonic motion inside the combustion chamber. The cyclonic motion allows the rice hulls to be burned while in suspension. Suspension burning of rice hulls allows the separation of its ash from the air, thus producing a clean flue gas. The flue gas is released on top of the furnace and directed to a fire tube hot water heat exchanger. The hot water is then pumped to another hot water air heat exchanger where drying air is passed through before the drying plenum. The furnace includes an automatic feeder, which controls the fuel carried by air jet and injected tangentially inside the combustion chamber. A rotating grate at the bottom of the furnace discharges the ash continuously at the rate synchronized with the fuel feed rate. Three air inlets strategically located along the periphery of the furnace provide secondary air for better combustion efficiency and temperature control. It reduces the risk of overheating the furnace and at the same time avoids the crystallization of the ash. The furnace has a grate surface area of 0.203 m2 and a combustion space volume of 0.514 m3. It is constructed mainly out of 12.7 cm thick refractory firebricks and enclosed by 0.48 cm thick mild steel plates. An automatic feeder coupled with 2.55 m3/ min centrifugal blower feeds the rice hull. Combustion air is supplied by a 4.53 m3/ min centrifugal blower through three ports. Detailed Process Descriptions: 1. Biomass fuel is feed into the furnace in cyclonic motion inside the combustion chamber. 2. The cyclonic motion allows the biomass fuel to be burned while in suspension. 3. Suspension burning of the biomass fuel also allows separation of the ash of combustion from the air thus producing a pollution-free flue gas. 4. Water is heated by the fire-tube boiler 5. The hot water is pumped to the hot water heat exchanger where the drying air is passed through before the drying column. Operation and Maintenance Requirements:2 1. It must provide uniform feeding of rice hull for uniform combustion. 2. Primary air and secondary air must be provided at certain ratio to provide complete combustion of rice hull. Assumed ratio of primary to secondary air is 25/75 to 35/65. 3. Excess air of over 60 percent is recommended. 4. Ash must be discharged at regular rate to prevent clogging of the combustion chamber. Ash disposal must be synchronized with fuel feeding. 5. Grate area must be 50 to 60 kg/h.m2 or 840 MJ/h.m2. 6. Combustion chamber volume must be 40 to 60 kg/h.m3 or 840 MJ/h.m3.

http://www.retsasia.ait.ac.th/Publications/WREC%202000-UPLB.pdf 2

COMPENDIUM OF WASTE BIOMASS CONVERSION TECHNOLOGIES

PART I: CONVERSION TO ENERGY DAP

The biomass furnace that was developed can consume an average of 39 kg of rice hull per hour. Estimated overall thermal efficiency is 61 percent. The average burning efficiency obtained was 96.7%. The relatively high burning efficiency of the furnace may be due to the longer retention time of the char in the grate and sufficient supply of combustion air. Social Considerations The furnace required less labor compared to the traditional rice hull step-grate furnaces. Labor was needed only in loading the rice hull into the feed hopper. Resource assessment made on rice hull indicated that there are a number of rice mills where the drying plant can get fuel. Advantages to Developing Countries Most if not all of the mills dispose the hulls along the highway. However, after the commissioning of the plant, millers started selling their rice hulls instead of giving it for free. The rice hull cyclonic furnace that was developed can also be used in the rural areas to provide heat for crop drying. It can be modified according to the heat load requirement of the clientele. Examples of Real Life Applications Manufacturer: PADISCOR Supplier: Pasig Agr'l Dev't. & Ind'l Supply Corp Address: 1 Lopez Jaena St. Kapasigan, Pasig City Telephone No: 916-0701; 643-5736; 641-1804

Вам также может понравиться

- Barchart SteleronДокумент4 страницыBarchart Steleroncumpio425428Оценок пока нет

- ABC Offer To TelequitДокумент1 страницаABC Offer To Telequitcumpio425428Оценок пока нет

- Auxin Price MargaritaДокумент2 страницыAuxin Price Margaritacumpio425428Оценок пока нет

- 30,000 DWT Dolomite Out-Loading FacilityДокумент2 страницы30,000 DWT Dolomite Out-Loading Facilitycumpio425428Оценок пока нет

- Abcumpio MJV DP BillingДокумент1 страницаAbcumpio MJV DP Billingcumpio425428Оценок пока нет

- Weight Per Course Tank AДокумент1 страницаWeight Per Course Tank Acumpio425428Оценок пока нет

- Fire Protection Labor Cost Final (Riofil Ref)Документ2 страницыFire Protection Labor Cost Final (Riofil Ref)cumpio425428Оценок пока нет

- Drum Scrubber Ausimm PDFДокумент11 страницDrum Scrubber Ausimm PDFcumpio425428Оценок пока нет

- Billing For Rotary ScrubberДокумент1 страницаBilling For Rotary Scrubbercumpio425428Оценок пока нет

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterДокумент7 страницYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf Printercumpio425428Оценок пока нет

- Kyc Jaw Crusher Detail: Canatuan, Tabayo, Siocon, Zamboanga Del NorteДокумент1 страницаKyc Jaw Crusher Detail: Canatuan, Tabayo, Siocon, Zamboanga Del Nortecumpio425428Оценок пока нет

- 12.5 Ton Per Hour Sugar RefineryДокумент1 страница12.5 Ton Per Hour Sugar Refinerycumpio425428Оценок пока нет

- A.B. Cumpio Engineering Services: Agro Power PhilippinesДокумент3 страницыA.B. Cumpio Engineering Services: Agro Power Philippinescumpio425428Оценок пока нет

- Attachment B - Bid PriceДокумент14 страницAttachment B - Bid Pricecumpio425428Оценок пока нет

- Shell Thickness CalculationДокумент247 страницShell Thickness Calculationcumpio425428Оценок пока нет

- TVI Resource Development Phils., Inc: Canatuan, Tabayo, Siocon, Zamboanga Del NorteДокумент1 страницаTVI Resource Development Phils., Inc: Canatuan, Tabayo, Siocon, Zamboanga Del Nortecumpio425428Оценок пока нет

- BLG2000 Plant Design Matl BalanceДокумент51 страницаBLG2000 Plant Design Matl Balancecumpio425428100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- SIPBANANAPEELING Paper FinalДокумент7 страницSIPBANANAPEELING Paper FinalALoma JaneОценок пока нет

- Design To Prevent Fire and Explosion PDFДокумент29 страницDesign To Prevent Fire and Explosion PDFGangapuram SrikanthОценок пока нет

- Energy Efficiency Existing Ship Index (Eexi) : Regulatory DebriefДокумент8 страницEnergy Efficiency Existing Ship Index (Eexi) : Regulatory DebriefSalomonlcОценок пока нет

- ACRP 07-09: Apron Planning and Design GuidebookДокумент23 страницыACRP 07-09: Apron Planning and Design GuidebookMarcelo MarcussoОценок пока нет

- Health in MapehДокумент11 страницHealth in MapehMary Rose Odtuhan ConejosОценок пока нет

- Seveso IДокумент18 страницSeveso IAlexandra LiliОценок пока нет

- Abu Dhabi Sew, SWD Irr Specsc Design CriteriaДокумент30 страницAbu Dhabi Sew, SWD Irr Specsc Design Criteriamalgendy0Оценок пока нет

- DLL - Mapeh-Health 6 - Q3 - W2Документ3 страницыDLL - Mapeh-Health 6 - Q3 - W2jemmar arandilla100% (2)

- SWST MSDSДокумент8 страницSWST MSDSAndri YantoОценок пока нет

- CPCB Effluent Discharge StandardsДокумент9 страницCPCB Effluent Discharge StandardsPavan Tamiri100% (1)

- ASBR PresentationДокумент37 страницASBR PresentationDileep C DileepОценок пока нет

- Hydrology Final PPTX - GRP.5 PDFДокумент55 страницHydrology Final PPTX - GRP.5 PDFAlvin DeliroОценок пока нет

- Advantages and Disadvantages of UrbanizationДокумент3 страницыAdvantages and Disadvantages of UrbanizationVina100% (2)

- MSDS CpkoДокумент4 страницыMSDS CpkoNicholas Panoguan0% (1)

- Week 4 Assignment PDFДокумент5 страницWeek 4 Assignment PDFTilakLNRangaОценок пока нет

- Assignment of Environmental ScienceДокумент6 страницAssignment of Environmental ScienceAakar SethОценок пока нет

- Industrial Proliferation and Environmental PreservationДокумент10 страницIndustrial Proliferation and Environmental PreservationGauri RaoОценок пока нет

- Environmental Laws in India: Challenges For EnforcementДокумент12 страницEnvironmental Laws in India: Challenges For EnforcementPawan Kumar SinghОценок пока нет

- The Garbage Disposal Here in Barangay Pasonanca Is All Over The PlaceДокумент4 страницыThe Garbage Disposal Here in Barangay Pasonanca Is All Over The PlaceNoldan King FranciscoОценок пока нет

- Office Health HazardsДокумент4 страницыOffice Health HazardsPlinio CabreraОценок пока нет

- Reaction PaperДокумент2 страницыReaction PaperAustin Viel Lagman MedinaОценок пока нет

- Environment.: Brgy. Malabanban Sur, Candelaria, QuezonДокумент4 страницыEnvironment.: Brgy. Malabanban Sur, Candelaria, QuezonkkОценок пока нет

- Natalie Prokes - Argumentative EssayДокумент3 страницыNatalie Prokes - Argumentative Essayapi-483436017Оценок пока нет

- NR-420302-Environmental & Pollution ControlДокумент4 страницыNR-420302-Environmental & Pollution ControlSrinivasa Rao GОценок пока нет

- Green Energy at Cement Kiln in Cyprus-Use ofДокумент11 страницGreen Energy at Cement Kiln in Cyprus-Use ofPopovac NetОценок пока нет

- Draft Brunswick CDM Smith Report March 2018 220pm PDFДокумент68 страницDraft Brunswick CDM Smith Report March 2018 220pm PDFAnonymous 90jptQ5wAОценок пока нет

- Zhen Hau Sing - Feasibility & Treatability StudyДокумент59 страницZhen Hau Sing - Feasibility & Treatability StudySean SingОценок пока нет

- Lesson 4: Food, Green Revolution and BiotechnologyДокумент15 страницLesson 4: Food, Green Revolution and BiotechnologyJeson GaiteraОценок пока нет

- Chemicals Zetag MSDS Powder Magnafloc LT 20 - 0710Документ6 страницChemicals Zetag MSDS Powder Magnafloc LT 20 - 0710PromagEnviro.comОценок пока нет

- Calculation: B Weight of Dry Empty Evaporating Dish, G C Volume of Sample Used, MLДокумент7 страницCalculation: B Weight of Dry Empty Evaporating Dish, G C Volume of Sample Used, MLsamtomОценок пока нет