Академический Документы

Профессиональный Документы

Культура Документы

Hilti HIT System - Rebar Hand Out

Загружено:

mcwong_98Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hilti HIT System - Rebar Hand Out

Загружено:

mcwong_98Авторское право:

Доступные форматы

Hilti HIT

injection system

Post-installed

rebar design for

Hilti HIT-RE 500

and HIT-HY 200

1

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

1

Hilti HIT injection system

for rebar applications

5 3. Approvals and reports for HIT-RE 500 and HIT-HY 200

Contents

1. Post-installed simply works better than cast-in

2. Basic considerations for fire design of post-installed reinforcement

4. HIT dispenser and mixer platform

5. HIT-RE 500

6. HIT-HY 200

8. Hilti service for engineers

10. Frequently asked questions

11. Project reference in Malaysia

7. Differences of HIT-RE 500 and HIT-HY 200

9. Hilti solutions for post-installed rebar connections

6.1 Product information

6.2 Setting instruction

6.3 Precalculated value based on concrete splitting

6.4 Precalculated value based on chemical bond

6.5 Design example for HIT-HY 200

6.6 Hilti specification guideline for HIT-HY 200

5.1 Product information

5.2 Setting instruction

5.3 Precalculated value based on concrete splitting

5.4 Precalculated value based on chemical bond

5.5 Design example for HIT-RE 500

5.6 Hilti specification guideline for HIT-RE 500

2

4

6

7

17

27

29

31

26

28

7

8

11

13

15

16

17

18

20

22

24

25

2

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

Hilti HIT injection system

for rebar applications

1. Post-installed simply works better than

cast-in.

by Jakob Kunz

Post-installed reinforcement works at least as well as cast-in rebars. This has been

proven by the comprehensive testing required for European Technical Approvals

for post-installed reinforcement connections. Consequently, the design process is

straightforward and in accordance with structural concrete codes (ACI 318 & Eurocode

2) for post-installed overlap splices, reinforcement anchorage at simple supports and

connections of columns mainly loaded in compression.

Only straight bars can be post-installed in cured concrete, but cast-in reinforcement

often uses hooks to reduce anchorage length or bends to divert forces. Hilti has thus

invested in extensive research to find solutions that allow post-installed reinforcement

to be used in situations where standard structural concrete detailing would require

hooks or bends. A revolutionary new design method has now been developed on the

basis of this research.

Hilti HIT Rebar Design Method

According to structural concrete building codes, the bond strength of cast-in bars is

limited, even where depth of concrete cover is considerable. Accordingly, in some

zones such as in walls where anchorage depth is often limited, welded transverse

reinforcement or hooks are used to compensate for the reduction in available anchorage

depth. The Hilti Rebar Design Method also makes it possible to reduce anchorage

length while maintaining the high bond strength needed to replace hooks or welded

transverse reinforcement.

Better results through more detailed research

Research has shown that the bond strength of bars anchored with Hilti adhesive

mortars is higher than that of cast-in-place bars, provided there is adequate concrete

cover

1

. The Hilti HIT Rebar Design Method takes advantage of this increased bond

strength in order to achieve anchorage length reductions of up to 50% compared to

the figures given in building codes.

Frame node connections with straight bars

According to standard reinforcement design concepts, bends are required at moment-

resisting connections. Working together with the Technical University of Munich and

the American University of Beirut, Hilti has carried out theoretical and laboratory

research in order to propose an adequate strut-and-tie model that takes the specific

characteristics of frame node connections with straight bars

2

into account.

Connection of members under tension

Where a connection is made between concrete members under predominant tension,

the principles of anchor design should be applied

3

. As a specialist in anchoring to

concrete, Hilti is well qualified to provide the appropriate solutions. Factors such as the

possibility of concrete cone breakout must be given special consideration.

Post-installed reinforcement for shear loads

Thanks to many years of research, Hilti is also in an excellent position to provide

solutions for post-installed shear interface reinforcement

4

for concrete overlays or

post-installed punching shear reinforcement

5

.

3

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

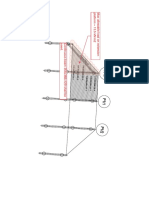

Strut-and-tie modeling of frame node

connections for straight (post-installed) and

bent (standard cast-in) bars.

post-installed cast-in

Hilti HIT Rebar Design Method.

Bond strength depends on concrete cover. Where cover is limited, splitting is the controlling

factor and the red and grey lines therefore show more or less linear functions. Where cover

is sufficient, pull-out begins to become the controlling factor. With Hilti adhesives, the cover

limit is usually higher than that specified for cast-in in concrete building codes (f

bd

=bond

strength, c=cover, =bar diameter).

Dr. Jakob Kunz is Scientific Consultant for the Hilti Anchor Business Unit. He gained his

doctorate at the ETH (Swiss Federal Institute of Technology) in Zurich and Lausanne and has

been with Hilti as a research engineer, project manager and chief scientific officer since 1989.

Dr. Jakob Kunz specializes in the fields of fastening technology and reinforced concrete design.

He is a member of fib, IABSE, ACI and SIA 179

References

1) Kunz, J., Muenger F.: Splitting and Bond Failure of Post-Installed Rebar Splices and

Anchorings. Bond in Concrete. fib, Budapest, 20 to 22 November 2002.

2) Hamad, B.S., Al-Hammoud, R., Kunz, J.: Evaluation of Bond Strength of Bonded-In or

Post-Installed Reinforcement. ACI Structural Journal, V. 103, No. 2, MarchApril 2006.

3) Design of Bonded Anchors. EOTA Technical Report TR 029. European Organisation for

Technical Approvals, June 2007.

4) Randk, N.: Untersuchungen zur Krftebertragung zwischen Alt- und Neubeton bei

unterschiedlicher Fugenrauhigkeit. University of Innsbruck, Austria, 1997 (Thesis in

German).

5) Fernandez Ruiz, M., Muttoni, A., Kunz, J.: Strengthening of Flat Slabs Against Punching

Shear Using Post-Installed Shear Reinforcement. ACI Structural Journal, V. 107, No. 4,

JulyAugust 2010.

4

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

2. Basic considerations for fire design

of post-installed reinforcement

Codes

specify minimum concrete cover for protection of the reinforcement against high

temperature depending on the required fire rating.

Since, in case of fire, the behaviour of the bonding material for post-installed bars is

somewhat different to cast-in reinforcement some back ground information is necessary

to provide equivalent behaviour of the post installed system.

Behaviour of steel in high temperatures

Steel changes material properties when its temperature is increased. This is especially

the case for yield strength as shown by fig.1.

Note: at 560C steel yield is approx. half of yield strength at room temperature.

Safety approach for fire design

The safety approach for fire design is semi- empirical because it is impossible to

determine a fire statistically. Therefore a standard fire temperature/time curve ISO 834

(fig. 2) has been agreed on for normal cases. In some cases, especially in road tunnels

more stringent temperature/time curves are applied.

Note: Safety concept is based on experience, many simplifications on the safe

side have been accepted for design.

Scope

The sensitivity for high temperatures of the adhesives used for bonded-in bars is

higher than the bond of cast-in bars. A design concept is provided for the design of fire

resistance for bonded-in bars with equivalent safety compared to cast-in bars.

Tests and design concept

Tests to evaluate the relationship between temperature and bond of the adhesives have

been performed. Taking into account the temperature gradients in the concrete for the

various fire ratings a design concept was derived. Testing, high temperature bond

relation and the design tables are shown in the corresponding reports.

Be aware that steel yield under fire is reduced considerably, and safety factors for fire

design are reduced accordingly as specified in the code.

Note that the fire design tables must not be used for cold design (accepted bond

stress under fire may be above the values acceptable for safe cold design).

a.) The maximum load for each individual fire design is performed by the engineer.

The designer determines his individual load depending on the load situation and

individual safety factor combination used.

With this load value he can determine the anchorage length by means of the Hilti fire

design tables.

b) It does not mean that the adhesives withstands the same temperatures as the steel

does, but the tables specify cover and anchorage length that are necessary to withstand

for the same duration the same force as is expected from the steel.

c) It is evident that for simplification the maximum load can be used on the safe side to

determine anchorage length, but maybe steel holds not the same force under fire in the

new building member e.g. with less cover.

Therefore if shorter embedment is requested it is worth to calculate the correct design

load for fire.

That is especially true if higher safety factors or global safety factors for cold design are

used (than there is more reserve in the steel).

Fig. 1. Strength reduction of carbon steel

due to temperature (various sources)

Fig.2 Standard temperature / time curve

(ISO 834)

State of the Art assessment of fire resistance for reinforced

concrete structures

Fire resistance of bonded-in bars

Conclusion

Fire Exposure Condition

5

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

3. Approvals and reports for HIT-RE 500

and HIT-HY 200

CE Conformity - Certificate for both Hilti HIT-RE 500 & HIT-HY 200

NSF Certification - for use in potable water systems when cured

HIT-HY 200 - is approved for to use automatic cleaning while drilling

LEED Certification - Both HIT-RE 500 & HIT-HY 200 contribute green building credits

6

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

4. HIT dispenser and mixer platform

HIT-RE-M Mixer

for HIT-RE 500 all sizes

for HIT-HY 200 all sizes

M

i

x

e

r

C

a

r

t

r

i

d

g

e

s

C

a

r

t

r

i

d

g

e

h

o

l

d

e

r

D

i

s

p

e

n

s

e

r

HDM 330 HDM 500 HDE

330ml

cartridge holder

500 ml

cartridge holder

330 ml

500 ml

7

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

Concrete

Small edge

distance

and spacing

Variable

embedment

depth

Diamond

drilled

holes

CE

conformity

Fire

resistance

European

Technical

Approval

DIBt

approval

Drinking

water

appoved

Corossion

tested

Benefits

Approval / Certificate

Setting detail

Setting detail

Installation equipment

Hilti HIT-RE 500

330 ml foil pack

(also available in 500 ml)

- Suitable for non-cracked concrete C 20/25 to C 50/60

- High loading capacity

- Suitable for dry and water saturated concrete

- Under water application

- Large diameter applications

- High corrosion resistant

- Long working time at elevated temperatures

- Odourless epoxy

Static mixer

Rebar

European technical approval DIBt, Berlin ETA-08/0105 / 2008-07-30

European technical approval DIBt, Berlin ETA-04/0027 / 2009-05-20

DIBt approval DIBt, Berlin Z-21.8-1790 / 2009-03-16

Fire test report IBMB Braunschweig 3357/0550-5 / 2002-07-30

Assessment report (fire) Warringtonfire WF 66402 / 2007-10-26

Description Authority / Laboratory No. / date of issue

Anchor size 8 10 12 14 16 20 25 28 32 36 40

12 14 16 18 20 25 32 35 40 45 55

Nominal diameter of

drill bit d

o

[mm]

Data according ETA-04/0027, issue 2009-05-20

Additional

Hilti tech.

data

Anchor size 8 10 12 14 16 20 25 28 32 36

Rotary

Drilling tools

Other tools

TE 2 - TE 30

DD EC-1, DD 100 ... DDxxx

Compressed air gun or blow out pump, set of cleaning brushes, dispenser

TE 40 - TE 70

5. HIT-RE 500

5.1 Product information

8

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

Bore hole drilling

Drill Hole to the required embedment depth with a hammer drill set in rotationhammer

mode using an appropriately sized carbide drill bit.

Blow 4 times from the back of the hole (if needed with nozzle extension) with the

hand pump until return air stream is free of noticeable dust.

Valid for:

bore hole diameter d

0

20 mm and

bore hole depth h

0

20 d (element diameter) or h

0

250 mm

Brush 4 times with the specified brush size (brush bore hole , see Table 7)

by inserting the steel brush Hilti HIT-RB to the back of the hole (if needed with

extension) in a twisting motion and removing it.

The brush must produce natural resistance as it enters the bore hole -- if not the

brush is too small and must be replaced with the proper brush diameter.

Blow again with hand pump 4 times until return air stream is free of noticeable

dust.

Bore hole cleaning

Just before setting an anchor, the bore hole must be free of dust and debris.

For under water application see Table 6 and 7, Annex 11

a) Manual Cleaning (MC)

for bore hole diameters d

0

20mm and limited bore hole depth h

0

Blow 2 times from the back of the hole (if needed with nozzle extension) over the

hole length with oil-free compressed air (min. 6 bar at 6 m/h) until return air

stream is free of noticeable dust.

Brush 2 times with the specified brush size (brush bore hole , see Table 7)

by inserting the steel brush Hilti HIT-RB to the back of the hole (if needed with

extension) in a twisting motion and removing it.

The brush must produce natural resistance as it enters the bore hole -- if not the

brush is too small and must be replaced with the proper brush diameter.

Blow again with compressed air 2 times until return air stream is free of noticeable

dust.

b) Compressed air cleaning (CAC)

for all bore hole diameters d0 and all bore hole depth h

0

5.2 Setting instruction

9

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

c) Cleaning for under water

for all bore hole diameters d

0

and all bore hole depth h

0

Injection preparation

Flush 2 times the hole by inserting a water hose (water-line pressure) to the back

of the hole until water runs clear.

Brush 2 times with the specified brush size (brush bore hole , see Table 7)

by inserting the steel brush Hilti HIT-RB to the back of the hole (if needed with

extension) in a twisting motion and removing it.

The brush must produce natural resistance as it enters the bore hole -- if not the

brush is too small and must be replaced with the proper brush diameter.

Flush again 2 times the hole by inserting a water hose (water-line pressure) to

the back of the hole until water runs clear.

Insert foil pack in foil pack holder. Never use damaged foil packs and/or

damaged or unclean foil pack holders. Attach new mixer prior to dispensing a

new foil pack (snug fit).

Tightly attach Hilti HIT-RE-M mixer to foil pack manifold. Do not modify the mixer

in any way.

Make sure the mixing element is in the mixer. Use only the mixer supplied with

the adhesive

Insert foil pack holder with foil pack into HIT-dispenser. Push release trigger,

retract plunger and insert foil pack holder into the appropriate Hilti dispenser.

Discard initial adhesive. The foil pack opens automatically as dispensing is initiated.

Depending on the size of the foil pack an initial amount of adhesive has to be discarded.

Discard quantities are 3 strokes for 330 ml foil pack,

4 strokes for 500 ml foil pack and

65 ml for 1400 ml foil pack.

.

10

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

Inject adhesive

from the back of the borehole without forming air voids

Inject the adhesive starting at the back of the hole, slowly withdrawing the mixer

with each trigger pull.

Fill holes approximately 2/3 full, or as required to ensure that the annular gap

between the anchor and the concrete is completely filled with adhesive along the

embedment length.

After injection is completed, depressurize the dispenser by pressing the release

trigger. This will prevent further adhesive discharge from the mixer.

Overhead installation and installation with embedment depth h

ef

> 250mm

For overhead installation or under water application the injection is only possible

with the aid of extensions and piston plugs. Assemble HIT-RE-M mixer,

extension(s) and appropriately sized piston plug (see Table 7).

Insert piston plug to back of the hole and inject adhesive. During injection the

piston plug will be naturally extruded out of the bore hole by the adhesive pressure.

Under water application fill bore hole completely with mortar.

Working time and curing time for general condition

Data according ETA-04/0027, issue 2009-05-20

Temperature

of the base material

40 C

30 C to 39 C

20 C to 29 C

15 C to 19 C

10 C to 14 C

5 C to 9 C

12 min 4 h 2 h

12 min 8 h 4 h

20 min 12 h 6 h

30 min 24 h 8 h

90 min 48 h 12 h

120 min 72 h 18 h

Working time in

which anchor can

be inserted and

adjusted tgel

Curing time before

anchor can be fully

loaded tcure

Preparation work

may continue.

Do not apply

design load. tcure, ini

Additional

Hilti technical data

11

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

bar size

drill bit size

edge distance

bar to bar spacing

length to develop yield

d

e

f

o

r

m

e

d

h

i

g

h

b

o

n

d

r

e

i

n

f

o

r

c

i

n

g

b

a

r

s

l

o

a

d

s

i

n

[

k

N

/

b

a

r

]

f

o

r

r

u

l

i

n

g

v

a

l

u

e

s

s

t

e

e

l

,

b

o

n

d

a

n

d

c

o

n

c

r

e

t

e

p

r

e

-

d

r

i

l

l

e

d

h

o

l

e

t

o

b

e

c

l

e

a

n

a

t

t

i

m

e

o

f

i

n

s

t

a

l

l

a

t

i

o

n

a

n

c

h

o

r

a

g

e

:

l

i

n

s

t

D

0

C

s1

s

l

b

10

12-14

40

50

280.4

25

30-32

62.5

125

876.2

32

39-42

80

160

1121.5

40

48-52

100

200

1401.9

20

25-28

50

100

602.4

16

20-22

40

80

448.6

12

16-18

40

60

336.5

[mm]

[mm]

[mm]

[mm]

[mm]

80

100

120

140

160

180

200

220

250

300

320

350

400

450

500

550

600

700

800

900

1000

1100

1200

1300

1400

Embedment depth Design loads in [kN/bar]

12.3

14.7 17.7

17.2 20.6

19.6 23.6 31.4

22.1 26.5 35.3

24.5 29.5 39.3 45.7

27.0 32.4 43.2 50.3

30.7 36.8 49.1 57.1 61.4

34.4 44.2 58.9 68.5 73.6

34.4 47.1 62.8 73.1 78.5 100.5

34.4 49.5 68.7 80.0 85.9 110.0

34.4 49.5 78.5 91.4 98.2 125.7 157.1

34.4 49.5 88.1 102.8 110.4 141.4 176.7

34.4 49.5 88.1 114.2 122.7 157.1 196.3

34.4 49.5 88.1 125.7 135.0 172.8 216.0

34.4 49.5 88.1 137.1 147.3 188.5 235.6

34.4 49.5 88.1 137.6 171.8 219.9 274.9

34.4 49.5 88.1 137.6 196.3 251.3 314.2

34.4 49.5 88.1 137.6 215.0 282.7 353.4

34.4 49.5 88.1 137.6 215.0 314.2 392.7

34.4 49.5 88.1 137.6 215.0 345.6 432.0

34.4 49.5 88.1 137.6 215.0 352.3 471.2

34.4 49.5 88.1 137.6 215.0 352.3 510.5

34.4 49.5 88.1 137.6 215.0 352.3 549.8

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

5.3 Precalculated value based on concrete splitting

Hilti HIT-RE 500 injection adhesive with Rebar application

Precalculated values based on BS8110 with ACI 318: Concrete Splitting Criteria

for Standard application/simply supported elements

Design Resistance for concrete grade (Fcu) =

Steel yield strength =

Installation condition =

Temperature =

30 N/mm

460 N/mm

dry concrete

Range II (-40C to +58C)

Note:

Data and results must be checked for agreement with the actual existing conditions and for plausibility

The calculation shown are proposals only and should be finally checked and approved by architect or

engineer responsible for the project

12

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

bar size

drill bit size

edge distance

bar to bar spacing

length to develop yield

d

e

f

o

r

m

e

d

h

i

g

h

b

o

n

d

r

e

i

n

f

o

r

c

i

n

g

b

a

r

s

l

o

a

d

s

i

n

[

k

N

/

b

a

r

]

f

o

r

r

u

l

i

n

g

v

a

l

u

e

s

s

t

e

e

l

,

b

o

n

d

a

n

d

c

o

n

c

r

e

t

e

p

r

e

-

d

r

i

l

l

e

d

h

o

l

e

t

o

b

e

c

l

e

a

n

a

t

t

i

m

e

o

f

i

n

s

t

a

l

l

a

t

i

o

n

a

n

c

h

o

r

a

g

e

:

l

i

n

s

t

D

0

C

s1

s

l

b

10

12-14

40

50

260.3

25

30-32

62.5

125

813.5

32

39-42

80

160

1041.3

40

48-52

100

200

1301.6

Embedment depth Design loads in [kN/bar]

20

25-28

50

100

559.3

16

20-22

40

80

416.5

12

16-18

40

60

312.4

[mm]

[mm]

[mm]

[mm]

[mm]

80

100

120

140

160

180

200

220

250

300

320

350

400

450

500

550

600

700

800

900

1000

1100

1200

1300

1400

13.2

15.9 19.0

18.5 22.2

21.1 25.4 33.8

23.8 28.5 38.1

26.4 31.7 42.3 49.2

29.1 34.9 46.5 54.1

33.0 39.7 52.9 61.5 66.1

34.4 47.6 63.4 73.8 79.3

34.4 49.5 67.7 78.7 84.6 108.3

34.4 49.5 74.0 86.1 92.5 118.4

34.4 49.5 84.6 98.4 105.7 135.3 169.2

34.4 49.5 88.1 110.7 119.0 152.3 190.3

34.4 49.5 88.1 123.0 132.2 169.2 211.5

34.4 49.5 88.1 135.3 145.4 186.1 232.6

34.4 49.5 88.1 137.6 158.6 203.0 253.8

34.4 49.5 88.1 137.6 185.0 236.9 296.1

34.4 49.5 88.1 137.6 211.5 270.7 338.4

34.4 49.5 88.1 137.6 215.0 304.5 380.7

34.4 49.5 88.1 137.6 215.0 338.4 422.9

34.4 49.5 88.1 137.6 215.0 352.3 465.2

34.4 49.5 88.1 137.6 215.0 352.3 507.5

34.4 49.5 88.1 137.6 215.0 352.3 549.8

34.4 49.5 88.1 137.6 215.0 352.3 550.5

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

Hilti HIT-RE 500 injection adhesive with Rebar application

Precalculated values based on BS8110 with ACI 318: Concrete Splitting Criteria

for Standard application/simply supported elements

Design Resistance for concrete grade (Fcu) =

Steel yield strength =

Installation condition =

Temperature =

35 N/mm

460 N/mm

dry concrete

Range II (-40C to +58C)

Note:

Data and results must be checked for agreement with the actual existing conditions and for plausibility

The calculation shown are proposals only and should be finally checked and approved by architect or

engineer responsible for the project

13

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

bar size

drill bit size

chemical bond based

on ETA approval

length to develop yield

d

e

f

o

r

m

e

d

h

i

g

h

b

o

n

d

r

e

i

n

f

o

r

c

i

n

g

b

a

r

s

l

o

a

d

s

i

n

[

k

N

/

b

a

r

]

f

o

r

r

u

l

i

n

g

v

a

l

u

e

s

s

t

e

e

l

,

b

o

n

d

a

n

d

c

o

n

c

r

e

t

e

p

r

e

-

d

r

i

l

l

e

d

h

o

l

e

t

o

b

e

c

l

e

a

n

a

t

t

i

m

e

o

f

i

n

s

t

a

l

l

a

t

i

o

n

a

n

c

h

o

r

a

g

e

:

l

i

n

s

t

D

0

F

bd,po

l

b

10

12-14

6.8

161.3

25

30-32

6.2

440.0

32

39-42

5.7

619.5

40

38-52

4.5

984.1

Embedment depth Design loads in [kN/bar]

20

25-28

6.2

352.0

16

20-22

6.2

281.6

12

16-18

6.8

193.6

[mm]

[mm]

[N/mm]

[mm]

80

100

120

140

160

180

200

220

250

300

320

350

400

450

500

550

600

700

800

900

1000

1100

1200

1300

1400

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

21.3

25.6 30.7

29.9 35.8

34.1 41.0 50.1

34.4 46.1 56.3

34.4 49.5 62.6 78.2

34.4 49.5 68.8 86.0

34.4 49.5 78.2 97.8 122.2

34.4 49.5 88.1 117.3 146.6

34.4 49.5 88.1 125.1 156.4 182.0

34.4 49.5 88.1 136.9 171.1 199.1

34.4 49.5 88.1 137.6 195.5 227.5 224.4

34.4 49.5 88.1 137.6 215.0 256.0 252.4

34.4 49.5 88.1 137.6 215.0 284.4 280.5

34.4 49.5 88.1 137.6 215.0 312.8 308.5

34.4 49.5 88.1 137.6 215.0 341.3 336.6

34.4 49.5 88.1 137.6 215.0 352.3 392.7

34.4 49.5 88.1 137.6 215.0 352.3 448.8

34.4 49.5 88.1 137.6 215.0 352.3 504.9

34.4 49.5 88.1 137.6 215.0 352.3 550.5

34.4 49.5 88.1 137.6 215.0 352.3 550.5

34.4 49.5 88.1 137.6 215.0 352.3 550.5

34.4 49.5 88.1 137.6 215.0 352.3 550.5

34.4 49.5 88.1 137.6 215.0 352.3 550.5

5.4 Precalculated value based on chemical bond

Hilti HIT-RE 500 injection adhesive with Rebar application

Precalculated values based on Chemical Bond Strength

for Standard application/simply supported elements

Design Resistance for concrete grade (Fcu) =

Steel yield strength =

Installation condition =

Temperature =

30 N/mm

460 N/mm

dry concrete

Range II (-40C to +58C)

Note:

Data and results must be checked for agreement with the actual existing conditions and for plausibility

The calculation shown are proposals only and should be finally checked and approved by architect or

engineer responsible for the project

14

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

bar size

drill bit size

chemical bond based

on ETA approval

length to develop yield

d

e

f

o

r

m

e

d

h

i

g

h

b

o

n

d

r

e

i

n

f

o

r

c

i

n

g

b

a

r

s

l

o

a

d

s

i

n

[

k

N

/

b

a

r

]

f

o

r

r

u

l

i

n

g

v

a

l

u

e

s

s

t

e

e

l

,

b

o

n

d

a

n

d

c

o

n

c

r

e

t

e

p

r

e

-

d

r

i

l

l

e

d

h

o

l

e

t

o

b

e

c

l

e

a

n

a

t

t

i

m

e

o

f

i

n

s

t

a

l

l

a

t

i

o

n

a

n

c

h

o

r

a

g

e

:

l

i

n

s

t

D

0

F

bd,po

l

b

10

12-14

6.9

158.8

25

30-32

6.3

433.2

32

39-42

5.7

610.0

40

38-52

4.5

966.4

Embedment depth Design loads in [kN/bar]

20

25-28

6.3

346.6

16

20-22

6.3

277.3

12

16-18

6.9

190.6

[mm]

[mm]

[N/mm]

[mm]

80

100

120

140

160

180

200

220

250

300

320

350

400

450

500

550

600

700

800

900

1000

1100

1200

1300

1400

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

21.7

26.0 31.2

30.3 36.4

34.4 41.6 50.8

34.4 46.8 57.2

34.4 49.5 63.5 79.4

34.4 49.5 69.9 87.4

34.4 49.5 79.4 99.3 124.1

34.4 49.5 88.1 119.1 148.9

34.4 49.5 88.1 127.1 158.8 184.8

34.4 49.5 88.1 137.6 173.7 202.2

34.4 49.5 88.1 137.6 198.6 231.0 227.9

34.4 49.5 88.1 137.6 215.0 259.9 256.4

34.4 49.5 88.1 137.6 215.0 288.8 284.8

34.4 49.5 88.1 137.6 215.0 317.7 313.3

34.4 49.5 88.1 137.6 215.0 346.6 341.8

34.4 49.5 88.1 137.6 215.0 352.3 398.8

34.4 49.5 88.1 137.6 215.0 352.3 455.7

34.4 49.5 88.1 137.6 215.0 352.3 512.7

34.4 49.5 88.1 137.6 215.0 352.3 550.5

34.4 49.5 88.1 137.6 215.0 352.3 550.5

34.4 49.5 88.1 137.6 215.0 352.3 550.5

34.4 49.5 88.1 137.6 215.0 352.3 550.5

34.4 49.5 88.1 137.6 215.0 352.3 550.5

Hilti HIT-RE 500 injection adhesive with Rebar application

Precalculated values based on Chemical Bond Strength

for Standard application/simply supported elements

Design Resistance for concrete grade (Fcu) =

Steel yield strength =

Installation condition =

Temperature =

35 N/mm

460 N/mm

dry concrete

Range II (-40C to +58C)

Note:

Data and results must be checked for agreement with the actual existing conditions and for plausibility

The calculation shown are proposals only and should be finally checked and approved by architect or

engineer responsible for the project

15

Hilti HIT-RE 500 Hilti HIT Injection System

for Rebar Applications

Concrete grade, fcu

=

Chemical Bond strength, d ,b =

Bar diameter, =

Steel yield strength, f yd =

edge distance, c =

bar to bar spacing, s =

Transverse reinforcement, K

tr

=

C =

Splitting bond, sp,d =

if, (C+ K

tr

) / < 2.5 :

if, (C+ K

tr

) / > 2.5 :

Parameters

Installation condition =

Temperature =

Length to achieve yield =

dry concrete

Range II (-40C to +80C)

f yd

A

s

min ( d ,sp ; d ,b )

d

s

Application condition

Summary

* One number of Hilti HIT-RE 500 injection adhesive with rebar application is able to

achieve tensile capacity of 34.4 kN at embement depth of 500 mm with edge distance

of 40 mm and bar to bar spacing of 50 mm

Loading table based on difference embedment depth

30 N/mm

6.79 N/mm (ETA 04/0027)

10 mm

460 N/mm

40 mm (min. edge distance 2.5)

50 mm (min. spacing 5)

0 ( assume no transerve

reinforcement influence)

min (S/2, c)

3.91 N/mm (Accordance to ACI 318,

Concrete Splitting critieria)

= 280.4 mm

sp,d

=

sp,d

=

100 [mm] 12.3

120 [mm] 14.7

140 [mm] 17.2

160 [mm] 19.6

180 [mm] 22.1

200 [mm] 24.5

220 [mm] 27.0

250 [mm] 30.7

300 [mm] 34.4

350 [mm] 34.4

400 [mm] 34.4

450 [mm] 34.4

D0

10

12-14

bar size

Drill bit size

d

e

f

o

r

m

e

d

h

i

g

h

b

o

n

d

r

e

i

n

f

o

r

c

i

n

g

b

a

r

s

l

o

a

d

s

i

n

[

k

N

/

b

a

r

]

f

o

r

r

u

l

i

n

g

v

a

l

u

e

s

s

t

e

e

l

,

b

o

n

d

a

n

d

c

o

n

c

r

e

t

e

p

r

e

-

d

r

i

l

l

e

d

h

o

l

e

t

o

b

e

c

l

e

a

n

a

t

t

i

m

e

o

f

i

n

s

t

a

l

l

a

t

i

o

n

E

m

b

e

d

m

e

n

t

d

e

p

t

h

/

a

n

c

h

o

r

a

g

e

:

l

i

n

s

t

5.5 Design example for HIT-RE 500

Design Resistance for Hilti HIT-RE 500 injection adhesive with rebar diameter

10mm based on BS8110 with ACI318, Concrete Spliting Criteria

for Standard application/simply supported elements

Note:

Data and results must be checked for agreement with the actual existing conditions and for plausibility

The calculation shown are proposals only and should be finally checked and approved by architect or

engineer responsible for the project

16

Hilti HIT-HY 200 Hilti HIT Injection System

for Rebar Applications

European

Technical

Approval

ETA-08/0105

EOTA TR 023

Bodycote-

Warrington

Report No. 166402

SGK Report no: 02 015a

WRAS

NSF

MA3557/B

ANSI standard 61

3

rd

party test lab Certificate available

Criteria to check: Approval Ref. No: Approval

Body

The post-install rebar should be

Work like cast-in or better.

Pre-qualification to design according

to building code such as EC2

Catalogue published loading data must

base on approval data.

Fire resistance tested for 4 hours

Non-Corrosive to Rebar

Safe for drinking water approval

(WRAS, NSFj

vOC Content Test Certificate

(Product contains: 4 g/L of vOC j

5.6 Hilti specification guideline for HIT-RE 500

HIT-RE 500

HDM 500

17

Hilti HIT-HY 200 Hilti HIT Injection System

for Rebar Applications

Concrete

Small edge

distance

and spacing

Variable

embedment

depth

CE

conformity

Fire

resistance

European

Technical

Approval

Approved

automatic

cleaning

while drilling

Corossion

tested

Benefits

- Suitable for cracked and noncracked concrete C 20/25 to C 50/60.

- Approved automatic cleaning with the use of the hollow drill-bit

- High loading capacity, excellent handling

- HY 200-R version with extended curing time for rebar applications

- Small edge distance and anchor spacing possible

- Large diameter applications

- In service temperature range up to 120C short term/72C long term

- Manual cleaning for anchor size 8 to 16 and embedment depth h

ef

non-cracked concrete

- Embedment depth range: from 60 ... 160 mm for 8 to 128 ... 640 mm for 32

Hilti HIT-HY 200-R

500 ml foil pack

(also available in 330 ml)

Static mixer

Rebar

Approvals / certificates

Description Authority / Laboratory No. / date of issue

European technical approval

a)

DIBt, Berlin ETA-12/0083 / 2012-08-08

( HIT-HY 200-R )

Fire test report

a) All data given in this section according ETA-12/0083, issued 2012-08-08 and

ETA-11/0492, issued 2012-08-08.

CSTB, Paris 26033756

Setting details

Anchor size 8 10 12 14 16 20 25 28 32

12 14 16 18 20 25 32 35 40

(10)

a)

(12)

a)

(14)

a)

Nominal diameter of

drill bit d

o

[mm]

Data according ETA-11/0493 and

ETA-12/0084, issue 2012-02-06

Setting details

Installation equipment

Anchor size 8 10 12 14 16 20 25 28 32

Rotary hammer

Other tools

TE 2 - TE 30

Compressed air gun or blow out pump, set of cleaning brushes,

dispenser

TE 40 - TE 70

6. HIT-HY 200

6.1 Product information

18

Hilti HIT-HY 200 Hilti HIT Injection System

for Rebar Applications

Working time and curing time for general condition

Hilti HIT-HY 200-R

Temperature of the

base material

-10 C to -5 C

-4 C to 0 C

1 C to 5 C

6 C to 10 C

11 C to 20 C

21 C to 30 C

31 C to 40 C

3 hour 20 hour

2 hour 7 hour

1 hour 3 hour

40 min 2 hour

15 min 1 hour

9 min 1 hour

6 min 1 hour

Working time in which

anchor can be inserted

and adjusted twork

Curing time before anchor

can be loaded tcure

Bore hole drilling

Drill hole to the required embedment depth with an appropriately sized Hilti

TE-CD or TE-YD hollow drill bit with Hilti vacuum attachment. This drilling

method properly cleans the borehole and removes dust while drilling.

After drilling is complete, proceed to the injection preparation step in the

instructions for use.

The Hilti manual pump may be used for blowing out bore holes up to

diameters do = 20mm and embedment depths up to hef = 10d.

Blow out at least 4 times from the back of the bore hole until return air

stream is free of noticeable dust

Brush 4 times with the specified brush size by inserting the steel brush Hilti

HIT-RB to the back of the hole (if needed with extension) in a twisting

motion and removing it.

The brush must produce natural resistance as it enters the bore hole -- if

not the brush is too small and must be replaced with the proper brush

diameter.

Blow out again with manual pump at least 4 times until return air stream is

free of noticeable dust.

Bore hole cleaning

Just before setting an anchor, the bore hole must be free of dust and debris.

Drill Hole to the required embedment depth with a hammer drill set in

rotation-hammer mode using an appropriately sized carbide drill bit.

a) Manual Cleaning (MC) non-cracked concrete only

for bore hole diameters d

o

= 20mm and bore hole depth h

o

= 10d

6.2 Setting instruction

19

Hilti HIT-HY 200 Hilti HIT Injection System

for Rebar Applications

Compressed air cleaning (CAC)

for all bore hole diameters d

0

and all bore hole depth h

0

Injection preparation

Inject adhesive from the back of the borehole without forming air voids

Drill hole to the required embedment depth with an appropriately sized Hilti

Blow 2 times from the back of the hole (if needed with nozzle extension)

over the hole length with oil-free compressed air (min. 6 bar at 6 m/h) until

return air stream is free of noticeable dust. Bore hole diameter = 32 mm

the compressor must supply a minimum air flow of 140 m/hour.

Brush 2 times with the specified brush size by inserting the steel brush Hilti

HIT-RB to the back of the hole (if needed with extension) in a twisting

motion and removing it.

The brush must produce natural resistance as it enters the bore hole -- if

not the brush is too small and must be replaced with the proper brush

diameter.

Blow again with compressed air 2 times until return air stream is free of

noticeable dust.

Tightly attach new Hilti mixing nozzle HIT-RE-M to foil pack manifold (snug

fit). Do not modify the mixing nozzle. Observe the instruction for use of the

dispenser. Check foil pack holder for proper function. Do not use damaged

foil packs / holders. Swing foil pack holder with foil pack into HIT -

dispenser.

Discard initial adhesive. The foil pack opens automatically as dispensing is

initiated. Depending on the size of the foil pack an initial amount of

adhesive has to be discarded.

Discard quantities are

Inject the adhesive starting at the back of the hole, slowly withdrawing the

mixer with each trigger pull. Fill holes approximately 2/3 full, or as required

to ensure that the annular gap between the anchor and the concrete is

completely filled with adhesive along the embedment length.

Overhead installation and installation with embedment depth hef > 250mm.

For overhead installation the injection is only possible with the aid of

extensions and piston plugs. Assemble HIT-RE-M mixer, extension(s) and

appropriately sized piston plug. Insert piston plug to back of the hole and

inject adhesive. During injection the piston plug will be naturally extruded

out of the bore hole by the adhesive pressure.

After injection is completed, depressurize the dispenser by pressing the

release trigger. This will prevent further adhesive discharge from the mixer.

2 strokes for 330 ml foil pack,

3 strokes for 500 ml foil pack,

4 strokes for 500 ml foil pack = 5C.

20

Hilti HIT-HY 200 Hilti HIT Injection System

for Rebar Applications

bar size

drill bit size

edge distance

bar to bar spacing

length to develop yield

d

e

f

o

r

m

e

d

h

i

g

h

b

o

n

d

r

e

i

n

f

o

r

c

i

n

g

b

a

r

s

l

o

a

d

s

i

n

[

k

N

/

b

a

r

]

f

o

r

r

u

l

i

n

g

v

a

l

u

e

s

s

t

e

e

l

,

b

o

n

d

a

n

d

c

o

n

c

r

e

t

e

p

r

e

-

d

r

i

l

l

e

d

h

o

l

e

t

o

b

e

c

l

e

a

n

a

t

t

i

m

e

o

f

i

n

s

t

a

l

l

a

t

i

o

n

a

n

c

h

o

r

a

g

e

:

l

i

n

s

t

D

0

C

s1

s

l

b

10

12-14

40

50

280.4

25

30-32

62.5

125

876.2

32

39-42

80

160

1121.5

20

25-28

50

100

602.4

16

20-22

40

80

448.6

12

16-18

40

60

336.5

[mm]

[mm]

[mm]

[mm]

[mm]

80

100

120

140

160

180

200

220

250

300

320

Embedment depth Design loads in [kN/bar]

12.3

14.7 17.7

17.2 20.6

19.6 23.6 31.4

22.1 26.5 35.3

24.5 29.5 39.3 45.7

27.0 32.4 43.2 50.3

30.7 36.8 49.1 57.1 61.4

34.4 44.2 58.9 68.5 73.6

34.4 47.1 62.8 73.1 78.5 100.5

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

6.3 Precalculated value based on concrete splitting

Hilti HIT-HY 200-R injection adhesive with Rebar application

Precalculated values based on BS8110 with ACI 318: Concrete Splitting Criteria

for Standard application/simply supported elements

Design Resistance for concrete grade (Fcu) =

Steel yield strength =

Installation condition =

Temperature =

30 N/mm

460 N/mm

dry concrete

Range II (-40C to +80C)

Note:

Data and results must be checked for agreement with the actual existing conditions and for plausibility

The calculation shown are proposals only and should be finally checked and approved by architect or

engineer responsible for the project

21

Hilti HIT-HY 200 Hilti HIT Injection System

for Rebar Applications

bar size

drill bit size

edge distance

bar to bar spacing

length to develop yield

d

e

f

o

r

m

e

d

h

i

g

h

b

o

n

d

r

e

i

n

f

o

r

c

i

n

g

b

a

r

s

l

o

a

d

s

i

n

[

k

N

/

b

a

r

]

f

o

r

r

u

l

i

n

g

v

a

l

u

e

s

s

t

e

e

l

,

b

o

n

d

a

n

d

c

o

n

c

r

e

t

e

p

r

e

-

d

r

i

l

l

e

d

h

o

l

e

t

o

b

e

c

l

e

a

n

a

t

t

i

m

e

o

f

i

n

s

t

a

l

l

a

t

i

o

n

a

n

c

h

o

r

a

g

e

:

l

i

n

s

t

D

0

C

s1

s

l

b

10

12-14

40

50

260.3

25

30-32

62.5

125

813.5

32

39-42

80

160

1041.3

20

25-28

50

100

559.3

16

20-22

40

80

416.5

12

16-18

40

60

312.4

[mm]

[mm]

[mm]

[mm]

[mm]

80

100

120

140

160

180

200

220

250

300

320

Embedment depth Design loads in [kN/bar]

13.2

15.9 19.0

18.5 22.2

21.1 25.4 33.8

23.8 28.5 38.1

26.4 31.7 42.3 49.2

29.1 34.9 46.5 54.1

33.0 39.7 52.9 61.5 66.1

34.4 47.6 63.4 73.8 79.3

34.4 49.5 67.7 78.7 84.6 108.3

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

Hilti HIT-HY 200-R injection adhesive with Rebar application

Precalculated values based on BS8110 with ACI 318: Concrete Splitting Criteria

for Standard application/simply supported elements

Design Resistance for concrete grade (Fcu) =

Steel yield strength =

Installation condition =

Temperature =

35 N/mm

460 N/mm

dry concrete

Range II (-40C to +80C)

Note:

Data and results must be checked for agreement with the actual existing conditions and for plausibility

The calculation shown are proposals only and should be finally checked and approved by architect or

engineer responsible for the project

22

Hilti HIT-HY 200 Hilti HIT Injection System

for Rebar Applications

bar size

drill bit size

chemical bond based on

ETA approval

length to develop yield

d

e

f

o

r

m

e

d

h

i

g

h

b

o

n

d

r

e

i

n

f

o

r

c

i

n

g

b

a

r

s

l

o

a

d

s

i

n

[

k

N

/

b

a

r

]

f

o

r

r

u

l

i

n

g

v

a

l

u

e

s

s

t

e

e

l

,

b

o

n

d

a

n

d

c

o

n

c

r

e

t

e

p

r

e

-

d

r

i

l

l

e

d

h

o

l

e

t

o

b

e

c

l

e

a

n

a

t

t

i

m

e

o

f

i

n

s

t

a

l

l

a

t

i

o

n

a

n

c

h

o

r

a

g

e

:

l

i

n

s

t

D

0

F

bd,po

l

b

10

12-14

6.7

164.3

25

30-32

6.7

410.7

32

39-42

6.7

525.7

20

25-28

6.7

328.6

16

20-22

6.7

262.9

12

16-18

6.7

197.1

80

100

120

140

160

180

200

220

250

300

320

Embedment depth Design loads in [kN/bar]

20.9

25.1 30.2

29.3 35.2

33.5 40.2 53.6

34.4 45.2 60.3

34.4 49.5 67.0 83.8

34.4 49.5 73.7 92.2

34.4 49.5 83.8 104.7 130.9

34.4 49.5 88.1 125.7 157.1

34.4 49.5 88.1 134.0 167.6 214.5

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

6.4 Precalculated value based on chemical bond

Hilti HIT-HY 200-R injection adhesive with Rebar application

Precalculated values based on Chemical Bond Strength

for Standard application/simply supported elements

Design Resistance for concrete grade (Fcu) =

Steel yield strength =

Installation condition =

Temperature =

30 N/mm

460 N/mm

dry concrete

Range II (-40C to +80C)

Note:

Data and results must be checked for agreement with the actual existing conditions and for plausibility

The calculation shown are proposals only and should be finally checked and approved by architect or

engineer responsible for the project

23

Hilti HIT-HY 200 Hilti HIT Injection System

for Rebar Applications

bar size

drill bit size

chemical bond based on

ETA approval

length to develop yield

d

e

f

o

r

m

e

d

h

i

g

h

b

o

n

d

r

e

i

n

f

o

r

c

i

n

g

b

a

r

s

l

o

a

d

s

i

n

[

k

N

/

b

a

r

]

f

o

r

r

u

l

i

n

g

v

a

l

u

e

s

s

t

e

e

l

,

b

o

n

d

a

n

d

c

o

n

c

r

e

t

e

p

r

e

-

d

r

i

l

l

e

d

h

o

l

e

t

o

b

e

c

l

e

a

n

a

t

t

i

m

e

o

f

i

n

s

t

a

l

l

a

t

i

o

n

a

n

c

h

o

r

a

g

e

:

l

i

n

s

t

D

0

F

bd,po

l

b

10

12-14

6.7

164.3

25

30-32

6.7

410.7

32

39-42

6.7

525.7

20

25-28

6.7

328.6

16

20-22

6.7

262.9

12

16-18

6.7

197.1

80

100

120

140

160

180

200

220

250

300

320

Embedment depth Design loads in [kN/bar]

20.9

25.1 30.2

29.3 35.2

33.5 40.2 53.6

34.4 45.2 60.3

34.4 49.5 67.0 83.8

34.4 49.5 73.7 92.2

34.4 49.5 83.8 104.7 130.9

34.4 49.5 88.1 125.7 157.1

34.4 49.5 88.1 134.0 167.6 214.5

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

Hilti HIT-HY 200-R injection adhesive with Rebar application

Precalculated values based on Chemical Bond Strength

for Standard application/simply supported elements

Design Resistance for concrete grade (Fcu) =

Steel yield strength =

Installation condition =

Temperature =

35 N/mm

460 N/mm

dry concrete

Range II (-40C to +80C)

Note:

Data and results must be checked for agreement with the actual existing conditions and for plausibility

The calculation shown are proposals only and should be finally checked and approved by architect or

engineer responsible for the project

24

Hilti HIT-HY 200 Hilti HIT Injection System

for Rebar Applications

Concrete grade, fcu

=

Chemical Bond strength, d ,b =

Bar diameter, =

Steel yield strength, f yd =

edge distance, c =

bar to bar spacing, s =

Transverse reinforcement, K

tr

=

C =

Splitting bond, sp,d =

if, (C+ Ktr

) / < 2.5 :

if, (C+ K

tr

) / > 2.5 :

Parameters

Installation condition =

Temperature =

Length to achieve yield =

dry concrete

Range II (-40C to +80C)

f yd

A

s

min ( d ,sp ; d ,b )

d

s

Application condition

Summary

* One number of Hilti HIT-HY 200 injection adhesive with rebar application is able to

achieve tensile capacity of 34.4 kN at embement depth of 300 mm with edge distance

of 40 mm and bar to bar spacing of 50 mm

30 N/mm

6.67 N/mm (ETA 12/0084)

10 mm

460 N/mm

40 mm (min. edge distance 2.5)

50 mm (min. spacing 5)

0 ( assume no transerve

reinforcement influence)

min (S/2, c)

3.91 N/mm (Accordance to ACI 318,

Concrete Splitting critieria)

= 280.4 mm

sp,d

=

sp,d

=

80 [mm]

100 [mm] 12.3

120 [mm] 14.7

140 [mm] 17.2

160 [mm] 19.6

180 [mm] 22.1

200 [mm] 24.5

220 [mm] 27.0

250 [mm] 30.7

300 [mm] 34.4

320 [mm] 34.4

D0

10

12-14

bar size

Drill bit size

Loading table based on difference embedment depth

d

e

f

o

r

m

e

d

h

i

g

h

b

o

n

d

r

e

i

n

f

o

r

c

i

n

g

b

a

r

s

l

o

a

d

s

i

n

[

k

N

/

b

a

r

]

f

o

r

r

u

l

i

n

g

v

a

l

u

e

s

s

t

e

e

l

,

b

o

n

d

a

n

d

c

o

n

c

r

e

t

e

p

r

e

-

d

r

i

l

l

e

d

h

o

l

e

t

o

b

e

c

l

e

a

n

a

t

t

i

m

e

o

f

i

n

s

t

a

l

l

a

t

i

o

n

E

m

b

e

d

m

e

n

t

d

e

p

t

h

/

a

n

c

h

o

r

a

g

e

:

l

i

n

s

t

6.5 Design example for HIT-HY 200

Design Resistance for Hilti HIT-HY 200-R injection adhesive with rebar diameter

10mm based on BS8110 with ACI318, Concrete Spliting Criteria

for Standard application/simply supported elements

Note:

Data and results must be checked for agreement with the actual existing conditions and for plausibility

The calculation shown are proposals only and should be finally checked and approved by architect or

engineer responsible for the project

Hilti HIT injection system

for rebar applications

25

Hilti HIT Injection System

for Rebar Applications

Hilti HIT Injection System

for Rebar Applications

Criteria to check: Approval Ref. No: Approval

Body

The post-install rebar should be

"Work like cast-in" or better.

European

Technical

Approval

ETA-12/0083

EOTA TR 023

Pre-qualification to design according

to building code such as EC2

Catalogue published loading data must

base on approval data.

Fire resistance tested for 4 hours

CSTB Report No. 26033756

Non-Corrosive to Rebar

SGK Report no: 10132-2

3

rd

party test lab Certificate available

vOC Content Test Certificate

(Product contains: 13 g/L of vOC j

6.6 Hilti specification guideline for HIT-HY 200

HIT-HY 200

HDM 500

26

Basic of post-installed

rebar connections

Hilti HIT Injection System

for Rebar Applications

The outperforming HIT The extra-reliable HIT

Hilti HIT-RE 500 Hilti HIT-HY 200

Bond strength

Permissible rebar diameter

range

8 40 mm 8 32 mm

Working time in Malaysia 12 min 6 min

Curing time in Malaysia 8 h 1 h

Suitable for water-filled holes

and underwater use

Drilling method: hammer drilling

Drilling method: diamond drilling

(Coring)

European Technical Approval

(ETA)

ETA-08/0105 ETA-12/0083

Fire resistance tested and

approved

Yes

No

Legend:

7. Differences of HIT-RE 500

and HIT-HY 200

27

Basic of post-installed

rebar connections

Hilti HIT injection system

for rebar applications

Hilti HIT Injection System

for Rebar Applications

The Hilti PROFIS Ferroscan software

shows the position coverage and size of

transverse and longitudinal reinforcement

clearly.

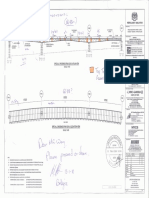

8. Hilti service for engineers

Technical advice

Hiltis qualified engineers and technicians provide consulting, support and advice free of

charge. Theyll be pleased to answer any question on the subject of post-installed rebar

connections on the phone, at your office or on site as per your convenience.

Anchor Fastening Technology Manual

This technical manual provides a wealth of information and practical examples of post-

installed rebar connections as well as all the technical data for the Hilti HIT system for your

easy reference.

User training

By providing special training, Hilti ensures that rebar installation personnel know how to

use the HIT system in accordance with the proper procedures so that post-installed rebar

connections can be made correctly.

Pull-out tests

Hilti offers the possibility of carrying out on-site rebar pull-out tests to validate expected

loads.

Rebar analysis

The Hilti PS 200 Ferroscan System provides information about existing reinforcement by

determining its position, diameter and depth of coverage without the need for destructive

procedures such as removal of concrete. Hilti PROFIS Ferroscan software simplifies the job

of analyzing the data obtained.

28

Basic of post-installed

rebar connections

Hilti HIT Injection System

for Rebar Applications

9. Hilti solutions for post-installed

rebar connections

Design

Our dedicated and professional engineers provide you comprehensive, technical

and engineering advice, design proposals, technical seminars, on-site testing and

installation guidance in your ofce or at your jobsite.

Detection

For the rapid detection, localization and documentation of reinforcement for the

purpose of avoiding cutting through statically-relevant rebars. Also allows verification of

reinforcement where plans no longer exist. (Ferroscan PS 200)

Drilling

Drill faster and more safely with Hilti combihammers and extra-rugged Hilti hammer drill

bits or with Hilti high-performance diamond coring systems. (TE70, DD200)

Cleaning

Hilti HIT Profis Rebar sets keep all the required cleaning accessories conveniently at

hand.

Cutting

Hilti angle grinders featuring Smart Power and fitted with Hilti AC-D cutting discs are

ideal for cutting rebars to length. Alternatively, Hilti cordless reciprocating saws provide

total mobility.

Setting

Make a quick, easy, professional job of post-installed rebar connections with Hilti HIT

injectable mortars and efficient Hilti dispensers.

29

Basic of post-installed

rebar connections

Hilti HIT injection system

for rebar applications

Hilti HIT Injection System

for Rebar Applications

10. Frequently asked questions

a.) Why is it important not only to specify mortar but the overall application?

Post-installed rebar connections typically have signicant embedment lengths. The

equipment used must therefore allow drilling to be carried out accurately, avoiding crossing

with neighboring holes. If dust remains on the walls of the holes drilled, bond strength as

specied cannot be achieved. The holes must therefore be properly cleaned along their

entire length using a steel brush tted to an electric drill.

Injection without creation of air pockets and bubbles is possible only when its done from the

bottom of the hole and when mixer extensions and piston plugs are used. Air bubbles may

cause pressure to build up when the rebar is inserted into the adhesive. This pressure can

become so high that the adhesive is squirted out of the hole towards the worker, causing a

hazard. Air can also inhibit proper curing of the adhesive and, last but not least, the presence

of air impedes bonding, reducing the effective bonding length.

b) What does a European Technical Rebar Approval attest to an adhesive?

The product has passed a number of acceptance tests proving that the behavior of post-

installed rebar connections is at least comparable to that of cast-in-place rebar connections

(comparable load transfer with a comparable load-displacement behavior) under various

conditions.

c.) Which conditions are assessed for a European Technical Rebar Approval? Bond

strength in different grades of concrete, substandard hole cleaning, wet concrete, sustained

load and temperature inuence, freeze-thaw conditions, different installation directions,

maximum embedment depth, avoidance of air bubbles during injection, durability (corrosion,

chemical attack).

d.) The acceptance tests dont include re or fatigue loads. Can loads of this kind be

taken up by post-installed reinforcement?

Its true that the adhesive forms a layer between the concrete and rebar, which may

result in cast-in-place and post-installed rebar connections having signicantly different

characteristics under such conditions. Hilti has performed specic research on these loading

conditions and can provide corresponding design recommendations.

e.) Whats the main difference between cast-in-place and post-installed reinforcement?

While detailing of cast-in-place reinforcement often requires bends or hooks or welded-on

transverse reinforcement, post-installed reinforcement is limited to straight bar ends because

only straight holes can be drilled.

f.) Whats the advantage of the Hilti HIT Rebar Design Method for post-installed

anchorage where depth is limited, e.g. when connecting a slab to a wall?

With cast-in reinforcement, anchorage length can be reduced by using hooks or welded

transverse reinforcement, which is not possible with post-installed reinforcement. Hilti

adhesives, however, usually provide higher bond strength than that specied in building

codes for cast-in-place reinforcement. Since such applications have a large concrete cover,

the designer can take advantage of the high bond strength of the adhesive by reducing the

anchorage length signicantly.

g.) How can moment-resisting connections be designed for post-installed

reinforcement?

Such connections normally require bends in the connecting reinforcement. The Hilti HIT

Rebar Design Method includes a strut-and-tie model for the design of moment-resisting

connections with post-installed straight bars anchored using Hilti adhesives. Laboratory

tests have proven this model to be correct and it has been assessed by independent experts.

30

Basic of post-installed

rebar connections

Hilti HIT Injection System

for Rebar Applications

h.) How can concrete members under tension be connected using post-installed

rebars?

Reinforcement in such members is usually hooked back by bending it around the

perpendicular reinforcement in the base member which, again, isnt possible with post-

installed reinforcement. As a highly experienced specialist in the eld of anchoring to

concrete, Hilti is well qualied to provide recommendations on how these principles should

be used to connect such members. It should be noted that due to the possibility of concrete

cone breakout failure, the design of connections of this kind must take brittle failure mode

into account as it is done in Hilti PROFIS Rebar 2.0

i.) Can the post-installation technology also be used for shear reinforcement?

Although this topic is still under research, Hilti already offers well-proven solutions for post-

installed shear interface reinforcement and for post-installed punching shear reinforcement.

Please ask Hilti Technical Service for details.

Our qualified and experienced account managers, design engineers and customer

service representatives are at your service. Anytime.

For more information, please call us.

31

Basic of post-installed

rebar connections

Hilti HIT injection system

for rebar applications

Hilti HIT Injection System

for Rebar Applications

Baby G-Hotel, Penang

Bakun Dam, Sarawak

B. Braun Medical Industries, Penang

Berjaya Central Park, Kuala Lumpur

Capital Square, Kuala Lumpur

CIMB Tower (KL Sentral, Lot A), Kuala Lumpur

Custom & Immigration Quarantine Complex, Johor

Da:Men, Petaling Jaya

DNP Plaza, Kuala Lumpur

Electried Double Track Project

First Solar Malaysia, Kulim

Four Seasons Hotel, Kuala Lumpur

G-Hotel, Penang

Government Headquarter, Putrajaya

IB Tower, Kuala Lumpur

Icon City, Petaling Jaya

Icon Residence, Mont Kiara

Infenion, Kulim

Jaya One Building, Petaling Jaya

JKR Headquarter (KKR2), Johor

KLCC Convention Center, Kuala Lumpur

KL Monorail Project

KL Gateway, Kuala Lumpur

Kompleks Tabung Haji, Putrajaya

Kuala Lumpur International Airport (KLIA)

Kuala Lumpur International Airport 2 (KLIA2)

Kuantan Port Consortium Extension

KWSP Building, Alor Setar

Legoland Nusajaya, Johor

Light Rail Transit Extension

Manjung Power Plant

M City, Kuala Lumpur

Metro Rapid Transit Project

Mid Valley II

Nu Sentral (KL Sentral, Lot G), Kuala Lumpur

Pavillion, Kuala Lumpur

Penang Bridge 2nd Link (P2x)

Penang Bridge Extension

Pinewoods Iskandar Malaysia Studio, Johor

Prai Power Station

Public Mutual Tower, Kuala Lumpur

Queensbay Mall, Penang

Sepangga Bay, Sabah

SMART Tunnel, Kuala Lumpur

St. Regis (KL Sentral, Lot C), Kuala Lumpur

Sunway Pyramid Hotel, Petaling Jaya

Sunway Pyramid 2, Petaling Jaya

Sunway Velocity, Kuala Lumpur

Taiping Water Head Refurbishment, Perak

Tapah Prison, Perak

Teluk Gong Power Plant

The Troika, Kuala Lumpur

Times Square, Kota Kinabalu

Tropicana City, Petaling Jaya

Universiti Malaysia Sarawak, Sarawak

Uptown Residence, Petaling Jaya

Vales Iron Ore Distribution Hub, Perak

Vision City (Quill Mall), Kuala Lumpur

W Hotel, Kuala Lumpur

KL Convention Centre,

KL

Nu Sentral,

KL

Queensbay Mall,

Penang

Mid Valley - The Gardens,

KL

Government Headquaters,

Putrajaya

KL Pavilion, KL

11. Project reference in Malaysia

32

Basic of post-installed

rebar connections

Hilti HIT Injection System

for Rebar Applications

Milti. Outperform. Outleet.

Toll Free:

1-OOO-OO-OOOG

H||t| [Ma|ays|a) Sdn. Bhd. (157721-A}

Head Office

Level 5-A, Block F, Oasis Square Ara Damansara,

47301 Petaling Jaya, Selangor, Malaysia.

E myhiltihilti.com l www.hilti.com.my

S

m

a

r

t

H

ig

h

w

a

y

HELP College of

Arts & Technology

One-Stop Serviced

Residence & Office

Snior

Sdn Bhd

The Curiousity

Shop

Priton Edar

Jabatan

Perkhimatan

Pos

City Campus

Lodge

J

a

la

n

M

e

tro

P

u

d

u

2

J

a

la

n

S

u

n

g

a

i B

e

s

i

J

a

la

n

L

o

k

e

Y

e

w

J

a

la

n

L

o

k

e

Y

e

w

J

a

la

n

M

e

tro

P

u

d

u

J

a

la

n

S

u

n

g

a

i B

e

s

i

Jalan PJS 11/8

Jalan PJS 11/2

Jalan PJS 11/2

Lebuhraya Pantai Baru

Jalan PJS 11/14

Rock

Cafe

Sunway

University College

Apartment Hostel

Petron

Sunway Pyram|d

Monash University

Sunway Campus

J

a

la

n

P

J

S

1

1

/

6

J

a

la

n

P

J

S

1

1

/

7

J

a

la

n

P

J

S

J

a

la

n

P

J

S

1

1

/

1

Jalan PJS 11/10

Jalan PJS 11/12

Jalan PJS 11/7

Jalan PJS 11/16

Jalan PJS 11/18

Jalan PJS 11/20

J

a

la

n

P

J