Академический Документы

Профессиональный Документы

Культура Документы

Motors

Загружено:

rimi7alИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Motors

Загружено:

rimi7alАвторское право:

Доступные форматы

TM

SQUIRREL CAGE INDUCTION MOTORS Water Conditioning GRD2000 TECHNICAL SPECIFICATIONS

Technical Bulletin 6.10, Rev. 0 December 1998

Squirrel Cage Induction Motors

29 Royal Road, Guelph, Ontario, Canada N1H 1G2

Telephone:(519) 836-0500, Fax:(519) 837-3067, Website www.glegg.com

TM

SQUIRREL CAGE INDUCTION MOTORS Water Conditioning GRD2000 TECHNICAL SPECIFICATIONS

Technical Bulletin 6.10, Rev. 0 December 1998

Table of Contents

Section 1.0 2.0 3.0 Scope References Design

3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 General Service Conditions Enclosure Speed Electrical Service Insulation Class Noise Level Bearings Space Heaters

Page

2 2 3 3 4 4 4 5 6 6 6 6 7 8 8 8 9

4.0 5.0 6.0 7.0

Materials of Construction Nameplate Documentation Inspection, Examination and Testing

Attachment A Induction Motor Data Sheet

29 Royal Road, Guelph, Ontario, Canada N1H 1G2

Telephone:(519) 836-0500, Fax:(519) 837-3067, Website www.glegg.com

1 of 9

TM

SQUIRREL CAGE INDUCTION MOTORS Water Conditioning GRD2000 TECHNICAL SPECIFICATIONS

Technical Bulletin 6.10, Rev. 0 December 1998 1.0 Scope

This specification establishes the minimum requirements for the design, materials, testing, inspection and performance of small squirrel cage induction motors and submersible motors less than 250 horsepower in size.

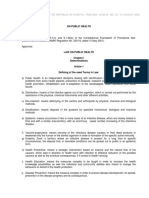

ROTOR FAN BALL BEARING STATOR

EYE BOLT CAST IRON FRAME

BALL BEARING BRACKETPULLEY END

FAN GUARD LEADS CONDUIT BOX

KEYED SHAFT

Figure 1-1: Three Phase Totally Enclosed Motor

2.0 References

The latest edition or revision of the following references are part of this specification: National Electrical Manufacturers Association (NEMA) MG1 Motors and Generators MG2 Safety Standard for Construction and Guide for Selection, Installation and Use of Electric Motors Canadian Standards Association (CSA) C390-93 Energy Efficiency Test Methods for Three Phase Induction Motors (Performance of electrical products) C22.2 #100 Motors and Generators Institute of Electrical and Electronics Engineers (IEEE) 112 Standard Test Procedure for Polyphase Induction Motors and Generators 85 Airborne Sound Measurements on Rotating Electric Machinery (test procedure for)

29 Royal Road, Guelph, Ontario, Canada N1H 1G2

Telephone:(519) 836-0500, Fax:(519) 837-3067, Website www.glegg.com

Table of Contents

2 of 9

TM

SQUIRREL CAGE INDUCTION MOTORS Water Conditioning GRD2000 TECHNICAL SPECIFICATIONS

Technical Bulletin 6.10, Rev. 0 December 1998 3.0 Design

3.1 General 3.1.1 Motors shall be two bearing, squirrel cage induction type with single shaft extensions suitable for drive applications. The selection of the motor shall be coordinated with the manufacturer of the driven equipment to ensure optimum compatibility. All motors shall be UL listed, or CSA approved if being installed in Canada. All non-submersible motors with a frame size larger than or equal to 182 or weighing >70 lbs. shall be complete with a lifting eye bolt. In accordance with MG-2-1.3, a single eye bolt shall be designed to lift the motor at any angle between 0 and 30o, and when multiple eye bolts are used any angle between 0 and 45o, with a minimum safety factor of five (5). The service factor for all motors shall not be less than 1.0 in accordance with MG-1-12.47.2. Motors with a service factor of 1.15 are preferred, provided that the maximum BHP does not exceed the motor rating at 1.0 service factor. All three phase motors shall comply with NEMA design B, see MG-11.16.1.2. Motors shall be designed to withstand full voltage starting, developing locked rotor, breakdown and pull-up torques as specified in MG1-12.38, 12.39 and 12.40 respectively, The locked rotor current shall not exceed the values shown in MG-1 -1 2.35 for 60 Hz and 12.36 for 50 Hz. The slip at rated load shall not exceed 5%. All single phase motors shall comply with NEMA design L, M, N, or 0, see MG-1-1.17.1 and 1.17.2. Motors shall be designed to withstand full voltage starting, developing locked rotor and breakdown torques as specified in MG-1-12.32.2 and 12.32.1 respectively. The locked rotor current shall not exceed the values shown in MG-1 -1 2.33. Motors shall operate successfully under running conditions at the rated load when there are fluctuations in the rated voltage of +/- 10%, fluctuations in the rated frequency of +/- 5% or a combined fluctuation of +/- 10% (with the frequency component not to exceed +/- 5%). Motors shall be rated for continuous full-load operation. 3.1.7 Motors shall be dynamically balanced. The use of solder or weld deposition for balancing is not acceptable. The maximum allowable peak-to-peak amplitude vibration shall be in compliance with MG-1-12.06.

3.1.2

3.1.3

3.1.4

3.1.5

3.1.6

29 Royal Road, Guelph, Ontario, Canada N1H 1G2

Telephone:(519) 836-0500, Fax:(519) 837-3067, Website www.glegg.com

Table of Contents

3 of 9

TM

SQUIRREL CAGE INDUCTION MOTORS Water Conditioning GRD2000 TECHNICAL SPECIFICATIONS

Technical Bulletin 6.10, Rev. 0 December 1998

3.2 Service Conditions All non-submersible motors shall be designed for the following service conditions: An ambient temperature of -40 to 40o C. An altitude less than 3300 feet. Rigidly mounted to fixed surface. Sufficient movement of free air to allow proper ventilation. Industrial environments that will have airborne particles. Industrial or coastal environments that will have high levels of humidity or salt-laden air.

All submersible motors shall be designed for the following service: Maximum ambient water temperature of 30o C with water flow past the motor of 0.5 ft/sec.

3.3

Enclosure (Non-Submersible) All motors shall be totally enclosed to alleviate the need for an additional enclosure, structure or shield for protection from environmental conditions. Motors that are smaller than or equal to 1/4 HP shall be totally enclosed nonventilated (TENV). Motors larger than 1/4 HP shall be totally enclosed fan cooled (TEFC). TEFC motors shall be complete with one or more fans that are an integral part of the unit but are mounted external to the enclosing parts. All enclosures shall be suitably painted or plated to prevent corrosion when installed in an industrial or coastal environment. No external part of any motor shall exceed 170 degrees C under any operating condition.

3.4

Speed All motors shall be of the constant speed type. The synchronous speeds shall be 3600 rpm and 1800 rpm for 60 Hz units and 3000 rpm and 1500 rpm for 50 Hz units.

29 Royal Road, Guelph, Ontario, Canada N1H 1G2

Telephone:(519) 836-0500, Fax:(519) 837-3067, Website www.glegg.com

Table of Contents

4 of 9

TM

SQUIRREL CAGE INDUCTION MOTORS Water Conditioning GRD2000 TECHNICAL SPECIFICATIONS

Technical Bulletin 6.10, Rev. 0 December 1998

3.5 Electrical Service 3.5.1 All motors smaller than and equal to 1/4 HP shall be 120/l/60 VAC or 220/1/ 50 VAC as required by the site conditions. All motors larger than 1/4 HP shall be 460/3/60 VAC, 575/3/60 VAC or 380/3/50 VAC, as required by the site conditions. Dual voltage motors are acceptable. All motors smaller than or equal to 1/4 HP shall have wiring terminals, wiring leads or a power cord assembly. The power cord assembly shall have a minimum current carrying capacity of 125 percent of the rated current of the machine. They shall be complete with grounding conductors, strain relief to prevent transmitting cord pull to the windings, and a suitable well rounded bushing where the cord passes through the enclosure. Motors larger than 1/4 HP shall be complete with wiring terminals or wiring leads. The wiring terminals shall be the wire binding screw or threaded terminal stud type. The wiring terminals shall be securely fastened and shall be plated or of a suitable material to prevent corrosion. The wiring leads shall be of suitable ampacity and shall not be smaller than 18 AWG. Lead insulation shall be capable of withstanding the high-potential test voltage. All leads shall be properly identified. Provision shall be made to prevent the leads from coming into contact with the internal rotating parts, being abraded or interfering with the operation of the internal devices. The wiring terminals and leads shall be installed in a terminal housing. The housing may be a separate terminal box mounted on the outside of the motor or they may be partially or completely a part of the motor enclosure. Terminal boxes shall be complete with a ground terminal and a cable lug or grounding screw for the ground wire inside the box and a conduit opening. The ground termination shall be in accordance with MG-2, table 1-4. The terminal boxes on all foot-mounted motors shall be capable of withstanding without failure a vertical load of 240 pounds and bending moments on the conduit openings as defined in MG-2-1.5.2. All terminals shall be permanently marked in accordance with MG-1, section 2. The markings shall be on or directly adjacent to terminals to which connections must be made from outside circuits or from auxiliary devices. On motors where no terminal strip is used, permanent markings must be provided on the leads. A connection diagram complete with the terminal or wiring lead markings shall be permanently attached to the motor.

3.5.2

3.5.3

3.5.4

29 Royal Road, Guelph, Ontario, Canada N1H 1G2

Telephone:(519) 836-0500, Fax:(519) 837-3067, Website www.glegg.com

Table of Contents

5 of 9

TM

SQUIRREL CAGE INDUCTION MOTORS Water Conditioning GRD2000 TECHNICAL SPECIFICATIONS

Technical Bulletin 6.10, Rev. 0 December 1998

3.6 Insulation Class Non-submersible motors shall be NEMA class F insulation with a maximum NEMA class B temperature rise. The insulation shall be moisture resistant and resistant to moderate abrasives. Submersible motors will have NEMA class F insulation and operate within NEMA class A temperature rise. 3.7 Noise Level The noise levels of all motors shall not exceed the values given in MG-1-12.49.3 and will be tested in accordance with IEEE 85. 3.8 Bearings Motors shall be complete with anti-friction or sleeve-type bearings. Bearings shall be in accordance with AFBMA standard 9 and shall be selected to provide a minimum L10 service life of 100,000 hours. Bearings shall be regreasable and shall be complete with plugs or alemite grease fittings or bearings can be sealed-for-life type for smaller than and equal to 215T frame motors. Regreasable bearings shall be designed with double shields to prevent the ingress of any foreign substance. 3.9 Space Heaters When space heaters are provided (non-submersible motors) they shall be capable of maintaining the interior of the motor enclosure above the dew point when the motor is not in operation. The space heater shall be rated for 240 volts and operate at 120/l/60 VAC or 220/l/50 VAC as required and wired to a separate terminal box. The maximum sheath temperature will not exceed 150o C.

29 Royal Road, Guelph, Ontario, Canada N1H 1G2

Telephone:(519) 836-0500, Fax:(519) 837-3067, Website www.glegg.com

Table of Contents

6 of 9

TM

SQUIRREL CAGE INDUCTION MOTORS Water Conditioning GRD2000 TECHNICAL SPECIFICATIONS

Technical Bulletin 6.10, Rev. 0 December 1998 4.0 Materials of Construction

All material shall be new and of high quality. The motor frames and end shields shall be of cast iron or steel construction, designed to adequately house, support and secure all motor components. Windings shall be copper, suitable for all conditions of service and shall be random or form wound and securely braced to resist failure through electrical stresses and vibration. Motor shafts shall be fabricated from high grade machined or forged steel of adequate size to withstand the loads normally encountered with the ratings employed. Fans shall be of non sparking corrosion resistant material. All submersible motors must be of corrosion resistant exterior construction for the intended service. A typical material specification for water service is shown below:

Component Castings Stator Shell Stator Ends Shaft Extension Fasteners Seal Cover Seal Diaphragm Diaphragm Plate Diaphragm Spring Sl i ng er Lead Wire Lead Potting Pipe Plug

Ni-Resist Ni-Resist Type 1B 316SS 316SS 17-4SS 316SS 316SS * Nitrile Rubber 316SS 17-4SS Type 100 Hydrin Hypaion Epoxy 316SS

316SS 316SS 316SS 316SS 17-4SS 316SS 316SS * Nitrile Rubber 316SS 17-4SS Type 100 Hydrin Hypaion Epoxy 316SS

* Carbon, Ceramic Face Seal, Optional silicon carbide seal also available

29 Royal Road, Guelph, Ontario, Canada N1H 1G2

Telephone:(519) 836-0500, Fax:(519) 837-3067, Website www.glegg.com

Table of Contents

7 of 9

TM

SQUIRREL CAGE INDUCTION MOTORS Water Conditioning GRD2000 TECHNICAL SPECIFICATIONS

Technical Bulletin 6.10, Rev. 0 December 1998 5.0 Nameplate

All motors shall be complete with a corrosion resistant metal nameplate permanently attached to the motor enclosure. Nameplate markings shall be in compliance with MG-1 -1 0.39.1, 10.40, NRCan and EPACT for small single phase and medium single phase and polyphase motors respectively. The nameplate should include the nominal and minimum guaranteed efficiency values.

6.0 Documentation

The motor manufacturer shall supply a completed motor data sheet for each motor as illustrated in Attachment A.

7.0 Inspection, Examination and Testing

All motors shall successfully pass the tests required by MG-1 , section 12. Highpotential tests shall be conducted only by trained personnel and as a minimum, the safety precautions described in MG-2, 1.10.1 through 1.10.4 should be followed. Testing of motors shall be performed in accordance with IEEE 112 or CSA C390. (Motor manufacturer to state method of testing used.)

29 Royal Road, Guelph, Ontario, Canada N1H 1G2

Telephone:(519) 836-0500, Fax:(519) 837-3067, Website www.glegg.com

Table of Contents

8 of 9

TM

SQUIRREL CAGE INDUCTION MOTORS Water Conditioning GRD2000 TECHNICAL SPECIFICATIONS

Technical Bulletin 6.10, Rev. 0 December 1998 Attachment A Induction Motor Data Sheet

Motor Equipment Number Manufacturer Model Number Enclosure Frame Horsepower Service Factor Electrical Service-Voltage/Phase/Frequency Synchronous Speed (rpm) Full-Load Speed (rpm) NEMA Design Letter Insulation Class Temperature Rise (oC) Current: Full-Load (amps) Locked Rotor (amps) Efficiency: 100% Load 75% Load 50% Load Power Factor: 100% Load 75% Load 50% Load Torque Percent: Locked Rotor Breakdown Torque @ Full-Load (ft-lb) Moment of Inertia (lb-ft2) Acceleration Time (seconds) Typical Noise Level (dbA @ 3 ft) Rotation (viewed from end opposite drive) Bearing Type Mounting Weight Space Heater Voltage/Phase/Frequency Watts / / Minimum Nominal

29 Royal Road, Guelph, Ontario, Canada N1H 1G2

Telephone:(519) 836-0500, Fax:(519) 837-3067, Website www.glegg.com

Table of Contents

9 of 9

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Law No.03 L-233 of Nature Protection (Incl. Biologjical Minimum)Документ62 страницыLaw No.03 L-233 of Nature Protection (Incl. Biologjical Minimum)rimi7alОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Separat Kanalizacine I Atmosferske Mreže (19 Trasa) Za Grad BrusДокумент36 страницSeparat Kanalizacine I Atmosferske Mreže (19 Trasa) Za Grad Brusrimi7alОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Law No.03 L-233 of Nature Protection (Incl. Biologjical Minimum)Документ62 страницыLaw No.03 L-233 of Nature Protection (Incl. Biologjical Minimum)rimi7alОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Waters of KosovoДокумент40 страницWaters of Kosovorimi7alОценок пока нет

- Law No. 02 L-78 On Public HealthДокумент11 страницLaw No. 02 L-78 On Public Healthrimi7alОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Fire ProtectionДокумент15 страницFire Protectionrimi7alОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Kosovo - Terms of Reference LandfillsДокумент28 страницKosovo - Terms of Reference Landfillsrimi7alОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- ZAF CH 019 InkongweniRiver Eng Rev03Документ2 страницыZAF CH 019 InkongweniRiver Eng Rev03rimi7alОценок пока нет

- Riprap For Streambank ProtectionДокумент4 страницыRiprap For Streambank Protectionrimi7alОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Administrative Instruction (Mesp) No. 23 2013 On The Manner and Conditions of Performing The Ranger Tasks For Nature ProtectionДокумент5 страницAdministrative Instruction (Mesp) No. 23 2013 On The Manner and Conditions of Performing The Ranger Tasks For Nature Protectionrimi7alОценок пока нет

- Water QualityДокумент33 страницыWater Qualityrimi7alОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Transitions8 Kosovo KLAДокумент46 страницTransitions8 Kosovo KLArimi7al100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Fire Hydrants and Water Mains PDFДокумент20 страницFire Hydrants and Water Mains PDFrimi7alОценок пока нет

- Low Volume Irrigation, Drip Irrigation, Design and Installaton GuideДокумент24 страницыLow Volume Irrigation, Drip Irrigation, Design and Installaton GuideFriends of Catalyst MagazineОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Swimming Pool TestingДокумент38 страницSwimming Pool Testingrimi7alОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Sub PumpДокумент3 страницыSub Pumprimi7alОценок пока нет

- Reed Beds4Документ7 страницReed Beds4rimi7alОценок пока нет

- CDCS KosovoДокумент61 страницаCDCS Kosovorimi7alОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Topographic SurveyingДокумент111 страницTopographic SurveyingAhmet DerdiyokОценок пока нет

- Kosovo & UsДокумент15 страницKosovo & Usrimi7alОценок пока нет

- Kosovo ChronologyДокумент13 страницKosovo Chronologyrimi7alОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- English Ahtisaari Plan S 2007 168 ADD.1Документ61 страницаEnglish Ahtisaari Plan S 2007 168 ADD.1branislav_skrobonjaОценок пока нет

- Criminal CodeДокумент230 страницCriminal Coderimi7alОценок пока нет

- NIS2011 enДокумент388 страницNIS2011 enrimi7alОценок пока нет

- FrameworkPocket ENG Dec2002Документ17 страницFrameworkPocket ENG Dec2002rimi7alОценок пока нет

- Kosovo Declaration of IndependenceДокумент4 страницыKosovo Declaration of Independencerimi7alОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- b8d Annexigc enДокумент27 страницb8d Annexigc enrimi7alОценок пока нет

- 0107Документ30 страниц0107Prakash ThangavelОценок пока нет

- Case Study 8 Copper Mine Brook, Burlington, Connecticut: Lined WaterwayДокумент20 страницCase Study 8 Copper Mine Brook, Burlington, Connecticut: Lined Waterwayrimi7alОценок пока нет

- Efo 34344Документ77 страницEfo 34344John KupchaОценок пока нет

- Centrifugal Compressor Surge and Speed ControlДокумент13 страницCentrifugal Compressor Surge and Speed ControlDaniel Puello RodeloОценок пока нет

- Us8801359 PDFДокумент49 страницUs8801359 PDFfermeskopОценок пока нет

- Building Utilities Mock Test QuestionnairesДокумент22 страницыBuilding Utilities Mock Test QuestionnairesJames AsasОценок пока нет

- The lEE Regulations, BS 7671 and This Guide PDFДокумент259 страницThe lEE Regulations, BS 7671 and This Guide PDFatramanathanОценок пока нет

- CapacitorДокумент96 страницCapacitorHipolito MBОценок пока нет

- A Pulse TransformerДокумент12 страницA Pulse TransformerPooja Uchagaonkar100% (2)

- Best Tech KoreanДокумент8 страницBest Tech KoreanUkay Dedi SukardiОценок пока нет

- Management Skill: RIG Manager Training DiagramДокумент1 страницаManagement Skill: RIG Manager Training DiagramLong Do100% (1)

- Lbs 405 - 5e Lesson Plan 3Документ11 страницLbs 405 - 5e Lesson Plan 3api-406656032Оценок пока нет

- Crankcase BreathingДокумент5 страницCrankcase BreathingabjithОценок пока нет

- Instrument Transformer.: Y. K. PandharipandeДокумент19 страницInstrument Transformer.: Y. K. Pandharipandeupt vadodaraОценок пока нет

- Introduction and Classification of Defects According To DimensionalityДокумент4 страницыIntroduction and Classification of Defects According To DimensionalitySalem GarrabОценок пока нет

- Kiln Emergency Conditions OkДокумент30 страницKiln Emergency Conditions OkmustafОценок пока нет

- TPG4175 Petrophysics: Course OverviewДокумент8 страницTPG4175 Petrophysics: Course OverviewAngela rismaОценок пока нет

- FPD 21 e PDFДокумент8 страницFPD 21 e PDFrasheedillikkal100% (1)

- Assignments Eco PDFДокумент7 страницAssignments Eco PDFKaman LuitelОценок пока нет

- Powertech ™ 4045Tfm75 Diesel Engine: Marine Propulsion Engine SpecificationsДокумент2 страницыPowertech ™ 4045Tfm75 Diesel Engine: Marine Propulsion Engine SpecificationsDAVIDОценок пока нет

- DHL 2ndДокумент7 страницDHL 2ndSafi UllahОценок пока нет

- 06 FEED Development - Onshore and OffshoreДокумент2 страницы06 FEED Development - Onshore and Offshorezdq02Оценок пока нет

- Newfound Landing NewspaperДокумент22 страницыNewfound Landing NewspaperAudra ToopОценок пока нет

- RFCC Process Technology Manual PDFДокумент779 страницRFCC Process Technology Manual PDFSagar Srinivas100% (8)

- Monthly Equ. Report (21-05-11 To 20-06-11) 1Документ103 страницыMonthly Equ. Report (21-05-11 To 20-06-11) 1sivathegrateОценок пока нет

- Rotary EnginesДокумент27 страницRotary EnginesMuhammad AsifОценок пока нет

- Lecture 4 Water Pipe Sizing PDFДокумент26 страницLecture 4 Water Pipe Sizing PDFAlchea Aldeguer100% (1)

- Screw-Down Crown: To Set Your Basic Analog ModelДокумент3 страницыScrew-Down Crown: To Set Your Basic Analog ModelMatthew GordonОценок пока нет

- SEG mrm10 - Le ManualДокумент20 страницSEG mrm10 - Le ManualPaulo Vitor Coelho ResendeОценок пока нет

- Energy PracticeДокумент2 страницыEnergy PracticelianamrОценок пока нет

- SuperTuff R Tuff R SellSheetДокумент2 страницыSuperTuff R Tuff R SellSheetZainuddinОценок пока нет

- Cuna Ge PandaДокумент62 страницыCuna Ge PandaEmilio A Secas100% (1)

- Dangerous Goods Panel (DGP) : Working PaperДокумент50 страницDangerous Goods Panel (DGP) : Working PaperexpairtiseОценок пока нет