Академический Документы

Профессиональный Документы

Культура Документы

Standard Operation Procedure

Загружено:

ved847Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Standard Operation Procedure

Загружено:

ved847Авторское право:

Доступные форматы

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

STANDARD OPERATING PRACTICES

1X 20 MW CAPTIVE POWER PLANT

TRINETRA CEMENTS ,BANSWARA,RAJASTHAN

THERMAX

POWER DIVISION

THERMAX LTD,

PUNE

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

THERMAX LTD.

POWER DIVISION (O& M)

1X 20 MW POWER PLANT

OPERATING PRESSURE: - 88 KG/ Sq. cm.

OPERATING TEMPERATURE: - 5205 Degree C.

STEAM GENERATION: - 95 TPH BFG BOILER

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

THIS SECTION COVERS BOILER ACCESSORIES AND

MOUNTING DETAILS & SOP

WATER TUBE,

SINGLE DRUM, TOP SUPPORTED,

CFBC BOILER

OPERATING PRESSURE: - 43.0 Kg. / SQ.CM.

OPERATING TEMPERATURE: - 4405 0 CEN.

STEAM GENERATION: - 22 TPH BFG FIRED BOILER

SAFETY VALVES

NOS.-03

DESCRIPTION

DRUM 1

DRUM 2

SH

MAKE

TYCO SANMAR LTD.

TYCO SANMAR LTD.

TYCO

LTD.

SET PR.

53 KG/CM2

54 KG/CM2

50.5 KG/CM2

TAG NO.

1-PSV 2196

1-PSV 2197

1-PSV 2193

RELIEVING CAP.

9680 KG/HR

9680 KG/HR

4840 KG/HR

TYPE

SPRING LOADED

SPRING LOADED

SPRING LOADED

SIZE ORIFICE

1.5 H2 3

1.5 H2 3

1.5 H2 3

FLUID

SAT. STEAM

SAT. STEAM

SH STEAM

Prepared by: Thermax Limited, Power Division (O&M)

SANMAR

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

OPERATING TEMP.

270C

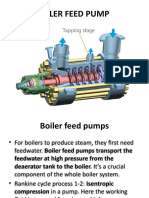

BOILER FEED PUMPS

SOP

270C

NOS.-02

MAKE

KSB PUMPS, PUNE

TYPE

HAD 50/14

SL. NO.

5111016442

CAPACITY

27 M3 /HR.

HEAD

655 MTRS

SPEED

2900 RPM

PUMP POWER

76.9 KW

BEARING OIL

SERVO VG 46

SPECIFIC GRAVITY

0.9429

SHUT OFF HEAD

NPSH

772 M

4.1 M

NOM.EFFICIENCY

60%

SHAFT SEAL TYPE &

SIZE

MOTOR

MECHANICAL

SEAL,ESSIL NFAF

P13

CGL(90KW/2960)

COUPLING

MAKE/TYPE/SIZE

BFP MOTOR BRG.

D.E./ND.E

MAKE RATHI/GEAR

TYPE WITH SPACER

6315 FOR BOTH

ENDS

BURNER

Prepared by: Thermax Limited, Power Division (O&M)

445C

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

MAKE

SOP

THERMAX BABCOCK

AND WILCOX LTD.

FORCED

OPERATING

DRAUGHT TYPE

TYPE OF AIR

CONTROL

ACCOSSORIES

AIR QUANTITY FOR

BURNER

EXCESS AIR

FUEL FLOW AT

MCR(INDICATIVE)

NO.OF FLAME

SCANNER

LEAD LAG

ARRANGEMENT,VALVE

AT FAN SUCTION

CONTROL

24805KG/HR FOR BFG

33% BFG

33117 KG/HR (100%) BFG

2NOS

DM WATER TRANSFER PUMP 02

MAKE

GRUNDFOS

MODEL NO

A96571029P10938

TYPE

CRNCM5-13A-FGJ-G-VHQQV

DISCHARGE

5.8 M3 /HR

HEAD

66.1 MTRS

SPEED

2899 RPM

MOTOR MAKE

CG

MOTOR TYPE

MMG0901-2-24-FT-115-E2

MOTOR

POWER

2.2 KW

BRG.D.E/N.D.E

6305ZZ/6205ZZ

FANS

DUTY

CONDITION

UNIT

MAKE

MODEL

QUANTITY

NO.

FD FAN

ID FAN

SCANNER COOILNG

FAN

FLAKTWOOD(INDIA)

LTD.

HABB-7-063-115-02-6-1

FLAKTWOOD(INDIA)

LTD.

HABB-7-112-183-04-18

1X100%

FLAKTWOOD(INDIA)

LTD.

HD-8-41-C-R3

1X100%

Prepared by: Thermax Limited, Power Division (O&M)

2X100%

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

NATURE OF

MEDIUM

DESIGN MASS

AIRFLOW

AIR TEMP. AT

FAN INLET

ABSORBED

POWER AT

OPERATING

TEMP.WITH

SPEED

CONTROL

FAN SPEED

SOP

CLEAN AIR

CLEAN AIR

CLEAN AIR

KG/SEC

8.3

19.3

0.07M/SEC

DEG.CEN.

55

195

40

KW

35

95

1.3

RPM

1447

980

2900

22218 CK,

HOUSING SNA 518

,SAME FOR BOTH

ENDS

45KW,4 POLE,FRAME

SIZE-ND 250M,MAKE

CG

RESILIENT

TYPE,MAKE-GBM

NO-8MC-108Z-MZ67

22222 EK/C3

HOUSING SNA 522,

SAME FOR BOTH

ENDS

110KW,6

POLE,FRAME SIZEND 315 LX,MAKE CG

RESILIENT

TYPE,MAKE-GBM

NO-11MC111Z-M-308

HOUSING NO. SNA

508-607,BRG.FOR

OUTLET DAMPER

FL204(UC 202)

3.7 KW,2 POLE,

,MAKE MARATHON

FREE/FIXED

BEARING

MOTOR

COUPLING

MODEL

/MAKE

RESILIENT

TYPE,MAKE-GBM

NO-IFC-101ZK-K18/35

LP DOSING SYSTEM

SL

NO.

DESCRIPTION

PARAMETER

HP DOSING SYSTEM

LP DOSING SYSTEM

MAKE

RAVI INDUSTRIES

RAVI INDUSTRIES

I.D.750X750HTX5THK./300LI

T.

0-10LPH. 61 KG/CM

I.D.750X750HTX5THK./300LIT

TANK(SS) SIZE

VOLUME

PUMP

CAPACITY/PRESSURE

PUMP MAKE

METACHEM

METACHEM

TYPE & SPEED

RECIPROCATING

PLUNGER,VARIABLE

STROKE

RECIPROCATING

PLUNGER,VARIABLE

STROKE

NO. OF PUMPS

2 SET

2 SET

0-10LPH. 6KG/CM

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

MOTOR

MOTORIED

AGITATOR / MOTOR

PRESSURE RELIF

VALVE SET

PRESSURE

SOP

0.5HP,0.37KW,1500RPM,450

V,TEFC IP55

0.5HP,0.37KW,1500RPM,450

V,TEFC IP55

75 KG/CM

0.5HP,0.37KW,1500RPM,450V,

TEFC IP55

0.5HP,0.37KW,1500RPM,450V,

TEFC IP55

10KG/CM

MOUNTINGS

DRUM GAUGE GLASS - LHS & RHS

MAKE

PRODUCT S.NO.

CHEMTROLS SAMIL (I)

PVT.LTD.

LG-2579/2578

VISIBILITY

320 MM

TAG No.

1LG-2199/2198

SIZE

1X600 #,C/C500 MM

ATTEMPERATOR

NOS. -01

ACTUATOR

MAKE

FISHER

SIZE

34 INCH

SR. NO.

TA45844

TRAVEL

INCH

VALVE BODY

MAKE

FISHER

SIZE

1 INCH

SR. NO.

TA45844

TYPE

FZ

PORT SIZE

1/4INCH

ATING

600RF

PLUG

316 SST/COCR-A FQL-2

STEM

316 SST

BODY

WCC

SEAT

316SST/COCR-A

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

SOOT BLOWER

MAKE- SITSON INDIA LIMITED

SL

NO.

DESCRIPTION

TYPE OF SOOT BLOWER

ROTARY SB

SB NUMBER

SB 1

SB 2

SB 3& 4

SB 5& 6

QUANTITY

1 EACH

1 EACH

1 EACH

1 EACH

LOCATION

PSH

SSH

ECONOMISER

BLOWING PRESSURE

KG/CM (G)

BLOWING ANGLE

DEGREES

STEAM CONSUMPTION

(KG/NOZZLE/MIN)

NOZZLE

21

21

21

CONVECTION

BANK

21

360

360

SB 3-180

SB-4-360

2

SB- 5 360

SB-6 180

2

20 ODX 20 LG

20 OD X 20 LG

20 OD X 20 LG

20 OD X 20 LG

BLOWING

TIME/BLOWER (MIN)

1&2

1&2

1&2

1&2

5

6

7

8

INDUCED DRAFT FAN (ID FAN).

START UP: For starting Boiler ID Fan proceed as stated below.

Ensure the tightness of all the foundation bolts, & the coupling bolts.

Ensure all interlocks (Motor & Fan) are Healthy.

Ensure Drum level is at NWL.

Ensure suction damper is in CLOSE condition.

Get the Required clearance from Field Engineer.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Start the fan from LPB (LCS) or from PLC.

Open the suction damper as per requirement & observe Furnace Draft.

Check all parameters, Bearing temperatures, vibrations, Motor body

temperatures etc.

STOPPING: To Stop INDUCED DRAFT FAN follow below mentioned Steps.

Close the suction damper.

Give STOP command either from LPB (LCS) or from PLC.

ALLOWING FOR MAINTENANCE:

Local Push Button should be pressed.

Isolate from Electrical side.

FORCED DRAFT FAN (FD FAN).

START UP: For starting Boiler FD Fan proceed as stated below.

Ensure the tightness of all the foundation bolts, & the coupling bolts.

Ensure all interlocks (Motor & Fan) are Healthy.

Ensure ID fan is Running.

Ensure FD fan suction damper is in closed condition.

Ensure Furnace pressure is Normal.

Get the Required clearance from Field Engineer.

Start the fan from LPB (LCS) or from PLC.

Open the suction damper as per requirement & observe the FD air flow.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

10

Check all parameters, Bearing temperatures, vibrations, Motor body

temperatures etc.

STOPPING: To Stop FORCED DRAFT FAN follow below mentioned Steps.

Close the Suction damper.

Give STOP command either from LPB (LCS) or from PLC.

ALLOWING FOR MAINTENANCE:

Local Push Button should be pressed.

Isolate from Electrical side.

SCANNER COOLING AIR FAN

START UP: For starting Scanner cooling air Fan proceed as stated below.

Ensure the tightness of all the foundation bolts, & the coupling bolts.

Get the Required clearance from Field Engineer.

Start the fan from LPB (LCS).

Open the manual suction damper.

Check all parameters, Bearing temperatures, vibrations, Motor body

temperatures etc.

STOPPING: To Stop Scanner cooling air fan follow below mentioned Steps.

Close the Suction damper.

Give STOP command either from LPB (LCS) or from PLC.

ALLOWING FOR MAINTENANCE:

Local Push Button should be pressed.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

11

Isolate from Electrical side.

BOILER FEED WATER PUMP (BFP).

START UP: For starting Boiler Feed Water pump proceed as stated below.

Ensure Deaerator level is Healthy.

Ensure all interlocks (Motor & also Pump) are Healthy and in Service.

Pump and Motor are properly lubricated and Oil cups contain Oil up to

NORMAL LEVEL.

Keep Feed control valve (FCV) & its by-pass valve are in closed position.

Ensure CT sump level is NORMAL, CT Fans are running, ACW pump is

running.

Ensure cooling water I/L & O/L valves for Bearings cooling, Gland cooling &

etc. are opened.

Ensure SUCTION DP is below 0.2 kg/cm2.

Open SUCTION Valve.

Keep DISCHARGE valve closed.

Ensure Min Re-circulation & Balancing Leak off line Valves are opened.

START pump either from LPB (LCS) or PLC.

Gradually open DISCHARGE Valve.

Check all parameters, Bearing temperatures, vibrations, Suction/Discharge

pressures, balance leak off pressure Motor winding temperatures etc.

STOPPING: To Stop BOILER FEED PUMP follow below mentioned Steps.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

12

Isolate the feed water control valve and Discharge valve.

Give STOP command either from LPB (LCS) or from PLC.

IF THE PUMP IS KEPT AS STAND BY:

Dont Isolate:

a).Gland Cooling Water, Bearing Cooling Water Lines.

b).Suction Valve, Balancing Leak-Off Valve, Discharge Valve,

ALLOWING FOR MAINTENANCE:

Isolate the bearing cooling water Line valves.

Isolate Gland Cooling Water.

Isolate the Suction Valve.

Isolate Discharge and min-recirculation valves.

Isolate Balancing Leak-Off Valves.

Isolate from Electrical side.

BOILER GAUGE GLASS OPERATION

This procedure is applicable wherever maintenance activities of gauge glass has been

completed, and cleared for service. Assume that all the isolating valves on steam and

waterside are closed and drains and vents are open. Follow the below steps to take

boiler gauge glass in service.

Close gauge glass vent valve (s).

Open steam side isolation valve partly.

Allow steam to flow through drain to heat up gauge glass at least for

fifteen minutes.

Close drain and see that steam is getting condensed in the gauge glass

to build up level.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

13

When condensate level in gauge glass is found to be more than 50%,

open water side valve gradually.

See that the level is stabilized at 50% of gauge glass.

Open both steam and water side valves full.

Match level of gauge glass with that of control room indication.

TO FLUSH GAUGE GLASS

Follow the steps given below to flush the gauge glass. Flushing of gauge glass should

be carried out at least once in a day.

Close steam side valve.

See that gauge glass is filled with water.

Close waterside valve and drain valve of gauge glass.

Crack open steam side valve.

See that gauge glass gets emptied.

Repeat above said activities at least twice.

Normalize the gauge glass valves and match local level with that of

control room indication

CHARGING OF MAIN STEAM LINE:

Ensure that boiler has achieved at least 60% of its rated pressure.

Ensure that all the drain line valves are open along with steam trap by

pass.

Open MSSV by pass when the steam pressure reaches 10 Kg/cm2, and

ensure heating of line till dry steam is coming out of all the drains.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

14

Increase the pressure by throttling all the drains and heat up for another

10 min.

Once dry steam is observed to come out from all the drains, close the

steam trap by pass and keep all the traps in service.

Increase pressure of the steam line by throttling all the drains in such a

way that pressure before and after MSSV should be near about same

then open the Boiler MSSV.

Increase pressure and temperature as required for turbine start up.

It is to be noted that increase of temperature up to 300 C should be 3-5

C per minute. Above 300 C the increase of main steam line should be

5-7 C per minute.

DEAERATOR CHARGING:

Follow the steps below for charging of deaerator.

Ensure that deaerator is filled with DM water with above

60% level.

Deaerator vent is open.

Open the trap by pass drains in the Auxiliary line and

remains open till no condensate found.

Open the isolation valve of PCV slowly and operate the

PCV and TCV to maintain the 10 kg/cm2 pressure and 250C Temp.

Ensure that steam line is charged and Pegging steam line is

heated up to the Pegging steam PCV.

Open the Pegging steam PCV in such a way to maintain the

Deaerator operating pressure of 1 kg/cm2.

While charging steam to deaerator hammering/ rolling sound

will be observed from deaerator.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

15

If the sound / noise is beyond tolerable limit, reduce the

steam pressure.

See that FW temperature is gradually increasing.

SOP

Once deaerator pressure at 1 kg/cm2 is achieved and

temperature is being maintained at 120 deg C, put PCV & TCV on

auto.

If bleed steam is available for change over, proceed as

follows.

Heat up the bleed line by opening the drain lines.

Ensure that Turbine inlet steam flow is 12 TPH before

charging the bleed line.

Ensure that turbine bleed steam pressure is around 10

kg/cm2, open the QCNRV.

Ensure that the steam has charged up to the Pegging steam

PCV, and then operate the pegging steam PCV in such a way to

maintain the deaerator operating pressure.

SOP FOR CHARGING PROCESS STEAM LINE.

Ensure drain before and after Process PCV is open.

Ensure that T.G Bleed steam pressure is around 10Kg/cm2g.

Communicate with BF control room to open the header drain.

After getting clearance from BF control room open manual isolation

valve fully & maintain the pressure of 6Kg/cm2g & Flow of 1.2 TPH

through PCV & FCV.

Ensure steam flow at BF battery limit.

Close all the Trap By-Pass drain valves once it is ensured no condensate

is entrapped in the system.

Incase bleed is not available maintain the same through Boiler PRDS-1

system.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

16

SOP OF PUMPS

DM TRANSFER PUMP

START UP: For starting DM transfer pump proceed as stated below.

When a PUMP is kept in Remote & Auto MODE Its Suction & Discharge will be kept open, unless specific logic & Protection

is implemented & its minimum recirculation valve is open condition.

START UP CHECKS

Ensure clearance from maintenance and get clearance from Field Operator to

start.

Ensure DM storage tank level is Normal.

All field instruments are in service.

Ensure SUCTION valve is in OPEN condition.

Coupling Guard is in position & fastened firmly.

Ensure DISCHARGE Valve is in CLOSED condition.

Ensure Deaerator Make Up control valve & its by- pass valve are in closed

condition.

Ensure Boiler initial filling line valve is in closed condition.

Ensure its minimum recirculation valve is in open condition.

Ensure that all the protections & interlocks are in service.

Give START command by operating LPB (LCS) or from PLC.

Once Pump achieves normal speed, Open DISCHARGE valve slowly.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

17

Check for any abnormal Sound, Current, Vibration, Bearing Temperatures etc

& Record.

STOPPING: To Stop a DM transfer Pump follow below mentioned Steps.

Give STOP command either from LPB (LCS) or from PLC.

IF THE PUMP IS KEPT AS STAND BY:

Dont Isolate:

A).Suction Valve, Minimum Recirculation Valve, Discharge Valve,

ALLOWING FOR MAINTENANCE:

START UP CHECKS: To Take MCW & ACW in to Service, Proceed as stated

below.

Coupling Guard is in position and fastened firmly.

Ensure all interlocks are Healthy (Motor).

Ensure that Cooling Tower sump level is up to Normal Working level.

Ensure Cooling Water Return line Valves inlet to CT is in OPEN condition.

Charge BFP cooling water, LO cooler, Generator cooler, sample cooler.

Ensure Pump SUCTION is in OPEN condition.

Ensure Pump DISCHARGE is in CLOSED condition.

Prime the Pump by opening Air Release valve on the Pump.

Start MCW & ACW pump and after ensuring pump rotates with full RPM,

gradually open DISCHARGE valve.

Check Motor Amps, Discharge pressure, vibration, bearing temperatures.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

18

Maintain Required FLOW & HEADER PRESSURE by throttling Cooling

Water Return line Valves inlet to CT as per requirement.

Maintain the Sump level is Normal.

NOTE: Before putting MCW/ACW pump in AUTO

Isolate the Suction Valve.

Isolate Discharge valve.

Isolate from Electrical side.

COOLING WATER PUMP (MCW/ACW)

STAND-BY) Mode, Ensure pumps Suction and Discharge valves are open and

Priming of Pump is done.

STOPPING: To Stop MCW/ACW Pump follow below mentioned Steps.

Close DISCHARGE valve.

Give STOP command either from LPB (LCS) or from PLC.

ALLOWING FOR MAINTENANCE:

Close the Suction Valve.

Close Discharge Valve.

Isolate from Electrical side.

CONDENSATE EXTRACTION PUMP (CEP)

START UP CHECKS: To Take CEP in to Service, Proceed as stated below.

Ensure clearance from maintenance and get clearance from Field Operator to

start.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

19

Ensure Hotwell level is Normal.

Ensure Gland cooling & sealing water line valves are OPEN.

Ensure Hotwell level is just above NWL (Around 40%, before Starting CEP).

Vacuum balancing line valve is in OPEN condition.

Ensure Suction & Discharge Valves are in OPEN Condition.

Ensure Hotwell Level Control Valve is in CLOSE condition and Recirculation

control valve is in OPEN condition (Up-stream and Down-stream isolation

valves are in open condition and bypass valve is in CLOSE condition).

Ensure condensate I/L & O/L valve of Ejector condenser is opened.

Check Suction Strainer Differential Pressure (DP - < 0.5 kg/cm).

START pump either from LPB (LCS) or from PLC.

Put the pump in Re-circulation (Hotwell level control valve position 0)

mode, if passing through Hotwell level control valve is observed close

isolation valve before Hotwell level control valve.

After starting CEP adjust Discharge pressure by opening Recirculation

By- pass valve.

STOPPING: To Stop CEP follow below mentioned Steps.

Close DISCHARGE valve.

Give STOP command either from LPB (LCS) or from PLC.

IF THE PUMP IS KEPT AS STAND BY:

Dont Isolate:

a).Gland Cooling Water, Bearing Cooling Water Lines.

b).Suction Valve, Balancing Leak-Off Valve, Discharge Valve,

ALLOWING FOR MAINTENANCE:

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

20

Isolate Gland Cooling Water.

Isolate the Suction Valve.

Isolate Discharge and min-recirculation valves.

Isolate vacuum Balancing line Valve.

Isolate from Electrical side.

SOP FOR FILTER CHANGE OVER AND CLEANING

CHANGE OVER: Follow the below mentioned steps for change over of filter. This

procedure is valid for duplex filter.

Filter DP (0.8) is high enough to change the running filter on to stand by

filter.

Ensure that stand by filter is provided with filter element, which is cleaned

or replaced with a new one.

Open the vent of the filter.

Open the filter equalizer line.

See that air is coming out of filter, close vent as soon as full bore liquid

comes out of it.

Change the position of the lever watching arrow facing to the direction of

stand by filter.

Observe that filter DP has come down to minimum DP position in the

indicator.

Close the equalizer line. Now choked filter is isolated and fresh stand by

filter is in service.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

21

SOP FOR CLEANING OF CHOKED FILTER ELEMENT

Follow below steps to clean or replace filter element.

Open drain and vent of choked filter.

Ensure complete draining of filter body.

Open the filter flange and remove the filter element(s).

Clean the filter body from inside.

Clean the filter element with fresh water and dry it with dry air.

Close the filter flange.

Close the drain of filter

Open the equalizer of filter to prime the filter.

Close filter vent when air is completely removed.

Check for any leakage from the flange. If no leakage persists, close

equalizer.

SOP FOR OIL COOLER CHANGE OVER:

This procedure is valid where duplex type oil cooler is provided. When running cooler

is required to do maintenance due to leakage, non-performing etc., it needs to change

over to standby one. Proceed as per below mentioned steps for cooler change

operation.

Ensure stand-by one ready for operation.

Ensure vents on both tube and shell side of the incoming cooler is

open.

Ensure the cooler drains are closed.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

22

Charge Cooling water in the cooler and close waterside vents after

removing entrapped air.

Open cooler oil equalizer line. It takes some times to fill a cooler.

Close oil vent once entrapped air is completely removed.

Change the position of the lever watching arrow facing to the direction

of stand by cooler.

Check all the parameters of oil and cooling water.

Control oil temperature by operating CW valve.

SOP FOR EJECTOR SYSTEM

TO TAKE HOGGER IN SERVICE

Ensure that all the drains in the auxiliary steam line are in open

condition.

Before going for vaccum pulling seal the glands of Turbine.

Ensure air line valves are closed for service air ejectors.

Vacuum breaker valve is in closed condition.

Ensure that Steam for ejector is available at its design pressure &

temperature.

Open steam valve for hogger ejector and wait for few minutes till it is

ensured no water vapour is coming out fro the exhaust line.

Open the air valve of hogger ejector.

See that vacuum is being built up in the turbine exhaust system.

TO TAKE SERVICE EJECTOR OPERATION

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

23

Ensure that CEP is in operation and Hotwell level is being maintained

on auto.

Ensure minimum quantity of condensate is flowing through ejector

condenser.

Identify the ejector set and Open steam for second stage ejector of

service ejector.

Open air line for second stage ejector.

Open steam for 1st stage ejector.

Open air lines for 1st stage ejectors.

Now hogger ejector and service ejector are in line.

ISOLATION OF HOGGER EJECTOR

Close air valve for hogger ejector.

Close steam for hogger ejector.

See that vacuum is being maintained by service ejector set

TURBINE-GENERATOR SECTION

TURBINE: - MAKE- SIEMENS

ALTERNATOR: - TD POWER SYSTEMS LTD.

GEAR BOX

:- TRIVENI ENGINEERING & INDUSRY LTD.

THIS SECTION GIVES YOU DETAILS OF TURBINE-GENERATOR AND OTHER RELATED

EQUPMENTS

& SOP

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

24

TURBINE

MAKE-

SIEMENS

TYPE

HORIZONTAL,IMPULSE,MULTI STAGE,MULTI VALVE,AXIAL

FLOW,CONDENSING

MODEL NO.- SST200VE25A

POWER RATED : 4700KW

MAX.

: 4700KW

P INLET

41 KG/CM2

T INLET

P EXTR. 1

10 KG/CM2

T EXTR. 1

P EXHAUST

-0.9 KG/CM2

T EXHAUST

435 C

274.2 C

45.5 C

ALTERNATOR

MAKE TOYO DENKI POWER SYSTEMS LTD.

( AC GENERATOR )

OUTPUT

5875KVA

SPEED

1500 RPM

TYPE

TC125

NO. OF POLES

NO. OF PHASE

COOLING SYSTEM

IC81W7

ENCLOUSER SYSTEM

IP54

CURRENT AC

514 A

VOLTAGE AC

6600V

FREQUENCY

50HZ

TURBINE & GENERATOR GEAR BOX

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

25

MAKE TRIVENI ENGINEERING & INDUSTRY LTD.

WORK NO.

2908

OIL VISCOSITY

ISOVG-46

SL. NO.

0600x000006HSGH

RATED SPEED

INPUT/OUTPUT

12056/1500

(RPM)

RATED POWER

5050 KW

RATIO

8.037

CONDENSER

MAKE :- GODAVARI ENGG. LTD.

ORDER NO

9422

NO OF

TUBES

1442

DESIGN

CONDENSER SURFACE

AREA

TUBE SIDE

PRESSURE

5 KG/CM

TEMPERATURE

50C

SHELL SIDE

1 KG/CM

100C

OIL CIRCULATION SYSTEM

MAIN OIL TANK

MAKE- ENPRO IMDUSTRIES PVT.LTD.

RESERVOIR

CAPACITY

445m

7000 LTRS

EMERGENCY OIL PUMP (DC DRIVE)

ROTARY GEAR PUMP

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

MAKE

SOP

26

MODEL

RDRN-200L

SIZE

DELPD PUMPS &

GEARS (P) LTD.

50 NB

PRESSURE

1.5 KG/CM2

SPEED

1500RPM

FLOW

200 LPM

MOTOR

MAKE

CROMPTOM

GREAVES

FREQUENCY

50HZ

POWER

2.2 KW

SPEED

1500 RPM

CURRENT

28AMPS

AUXILIARY OIL PUMP

MAKE

TUSHACO

PUMP MODEL

T3ST 70/54

PUMP CAPACITY

495 LPM

SPEED

1450 rpm

DISCHARG PRESSURE

5 KG/CM

MOTOR

MAKE

CROMPTON

GRAVES

TYPE

1LA0133-AY81

POWER

7.5 KW

SPEED

1450 RPM

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

FREQUENCY

SOP

27

50HZ

OVEF EXHAUST FAN

FAN

MAKE

TCF-NADI

INDUSTRIAL FANS

MODEL

TBR-R13V

VOLUME

700CMH

STATIC PRESSURE

150 MMWC

MOTOR

MAKE

CROMPTOM

GREAVES

TYPE

1LA0090-24A80

POWER

1.5 KW

SPEED

2860 RPM

LUBE OIL FILTER

02 Nos.

MAKE BHAGWATI FILTER LTD

TYPE

BASKET

DESIGN PR.

4 BAR

FLOW

325 LPM

MESH RATING

25 MICRON

CONTROL OIL FILTER

02 Nos.

MESH RATING

10 MICRONS

FLOW

46 LPM

PRESSURE

9.5 BARG

TYPE

BASKET

OIL COOLER

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

28

MAKE - ENPRO INDUSTRIES PVT. LTD.

WORK ORDER :: 8080

MODEL

BEM

HEAT DUTY

170457 KACAL/HR

TEST PR

10.5 BAR

OIL CENTRIFUGE

MAKE- ALFA LEVEL

.

TYPE

MAB-103B-24

PUMP NO

4180365

SL NO

4180365/09

BOWL

524700-88

PRODUCT NO

881145-09-01

MAX.SPEED (BOL)

8571RPM

SPEED(MOTOR

1500RPM

POWER

MAX.DENSITY OF

FEED

1100KG/CU.MTR

MAX.DENSITY OF

SEDIMENT

PROCESS TEMP.

MIN/MAX

0/100 DEG.CENT

CONDENSATE EXTRACTION PUMP

5000KG/CU.MTR

02 NOS

MAKE

KSB

CAPACITY

22 M 3 /HR

TYPE

CPX-EO-40-250

HEAD

70 MT

SL. NO.

5111019641

MOTOR POWER

15KW

SPEED

3000 RPM

MOTOR

MAKE-ABB

MOTOR BEARING

DE-6309ZZC3,NDE6308ZZC 3

TYPE

HX160MLD2

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

MAIN COOLING WATER PUMPS

MAKE

SOP

29

02 NOS

PUMP BRG. NO.

D.E./N.D.E

CAPACITY

6309ZZ

TYPE

FLOW MORE PVTD.

LTD.

FIG 5821 SIZE 30H

HEAD

25MT

SPEED

1460 RPM

MOTOR

POWER

MAKE-ABB

MOTOR BEARING

DE - 6319 C3

NDE-6316C3

132 K.W.

AUXILARY COOLING WATER PUMPS NO

1430 M3/HR

02 NOS

MAKE

FLOW MORE PVTD. LTD.

PUMP BRG. NO.

D.E./N.D.E

6307

TYPE

FIG 5823 125X100 SIZE

CAPACITY

140 M3/HR

HEAD

30 MTRS

SPEED

1460 RPM

MOTOR

BEARING

D.E.-6310ZZC3

N.D.E.-6309ZZC3

MOTOR

POWER

MAKE- ABB

18.5 K.W.

STEAM EJECTOR

MOTIVE STEAM PR.

10 KG/CM2

MOTIVE STEAM TEMP.

350C

MOTIVE STEAM CONSUMPTION

300 KG/HR

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

STEAM CONSUMPTION FOR HOGGER

SOP

30

350 KG/HR

STANDARD OPERATION PRACTICE

FOR

TURBINE ROLLING.

COLD START-UP PROCEDURE.

Put Power, cooling water and air in service.

Check all valves of pressure gauges, pressure switches, level switches if they are

open.

Ensure Oil level in MOT (Main Oil Tank) is Healthy i.e. above 30%.

Start Oil Vapor Extraction Fan and energize Heaters in MOT to raise the Oil

Temp to 40-42C.

Start the Auxiliary oil pump, Control oil pump-1 and put the Emergency oil pump

and another control oil pump-2 in AUTO.

Keep the position of changeover valve of Oil Cooler to be taken into service.

Charge the water side of Oil Cooler after ensuring ACW Pump is in service (open

cooling water I/L valve 100% and open the cooling water side vent. Than open

cooling water O/L valve 100% after ensuring water is coming out from the water

side vent and than vent valve is to be closed.). Ensure water side drain valves are

closed. Ensure all water side drain & vent valves of stand by Oil Cooler are

closed.

Open the shell side vent of Oil Cooler to release the air entrapped inside the shell

and ensure drains of shell side are closed. Ensure shell side all drain & vent valves

of stand by Oil Cooler are closed. After ensuring oil is coming out from shell side

vent of Oil Cooler, vent is to be closed.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

31

Open the Lube Oil Filter vent to release the air entrapped inside the Filter &

ensure drain of Lube Oil Filter is closed. All drain & vent of stand by Lube Oil

Filter are closed. After ensuring oil is coming out from vent of Lube Oil Filter,

vent is to be closed.

Open the Control Oil Filter vent to release the air entrapped inside the Filter &

ensure drain of Control Oil Filter is closed. All drain & vent of stand by Control

Oil Filter are closed. After ensuring oil is coming out from vent of Control Oil

Filter, vent is to be closed.

After Starting AOP Ensure OHOT (Over Head Oil Tank) Level is raised up to the

required Level.

Ensure Lube Oil Header Pressure is above 3.0 kg/cm2.

Ensure Lube Oil Outlet flow through Sight Glasses provided

Put the TG set on Barring gear for the following minimum periods of time:

Shaft Stand Still

Minimum Turning Time

o Less than 1 day

2 Hours

o Up to 7 days

6 Hours

o 7 to 30 days

12 Hours

o More than 30 days

24 Hours

Ensure all the steam drains, warm up vent are in open condition, use trap by- pass

in line during warm up of steam line.

Open Boiler MSSV by-pass at 10 Kg/cm2 and start line heating of PRDS system.

Open the Boiler MSSV at 25 Kg/cm2 and close the By-pass valve.

Close the Trap By-pass and take steam trap in line once it is ensured that all the

condensate is removed from the system.

Charge the gland sealing once the required pressure 10 kg/cm2 and temperature

above 250 C.

Maintain the gland sealing pressure and Temperature as mentioned below.

Front Gland Sealing pressure & Temp. - .08 Kg/cm2 & 400C.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

32

Rear Gland Sealing pressure & Temp. - .08 Kg/cm2 & 250C

o To maintain the Gland sealing temperature in Rear side TCV is

provided.

o Keep both the Gland sealing PCV and TCV in Auto.

Pull the Vaccum once the required Aux. Steam pressure 10 Kg/cm2 and Temp.

above 300C is achieved.

Open slowly Turbine MSSV by-pass valve till the pressure reaches 25- 30

Kg/cm2 (g) to ESV inlet.

Open the manual isolation valve of Turbine steam stop valve, once the all the

parameters achieved as mentioned below:

Turbine Inlet Steam Pressure- 40 Kg/cm2.

Turbine Inlet Steam Temperature-420C.

Vaccum Achieved (-0.9 Kg/cm2g).

From the keyboard of control and Protection (PLC) system give Reset and then

Run command to Turbine.

ESV will open with its pilot and thereafter fully open with the pressure rise in the

control valve block.

Check that LP valve demand is 100% closed and HP opening demand is around

18% to 19%.

Ensure in the field that three LEDs of the Solenoid valve will start glow also the

LP servomotor will close fully.

Live steam flows into the control valve block to warm up the valve casing and

then out to the drain. Temperature increases app.4C/min.

Close manually controlled drain from the control valve block after warming-up is

finished.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

33

The speeding of the turbo set can be started by WOODWARD governor.

Speeding should be carried out according to start-up graphs, respecting the stand

still time (thermal conditions of turbine).

The MOP (main oil pump) feeds the oil system for all duties sufficiently. Cut out

AOP at app. 80-90% normal speed if not switched off automatically. Put AOP on

Auto mode.

Resulting matching of frequency, voltage, phase sequence &rotating field

direction of generator. In Auto synchronization the speed of the turbine,

frequency, voltage will be matched automatically.

After synchronizing increase the load to app. 2% of its rated load in order to avoid

the activation of reverse power relay.

Continue increasing the load according to start-up graphs by pushing the

corresponding keys on the WOODWARD Do not allow exhaust steam

temperature to exceed 105C.For cooling them spray condensate into the exhaust

hood neck.

Once the rated speed of the Turbine is achieved go for synchronizing, which can

be done either manually or Auto.

Manual synchronizing can be done by manually adjusting the speed of the turbine

GOVERNOR.

During loading check all parameters and check also the control stage pressure.

Check the cooling air temperature of generator and open cooling water to the air

cooler if required.

HOT START-UP PROCEDURE

Once the tripping reason is detected and the cause is eliminated, and ready to start

up then follow the steps: Keep the live steam line up to the emergency stop valve pressurized and gland

steam open unless turbine rests far longer than 60 minutes.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

34

Open the Turbine drains trap by pass, it will be remain open until it is ensured that

no condensate is trapped.

The oil unit remains in full operation, maintain the oil temperature between 45C

to 49C.

Keep the Turning gear in permanent operation.

Open the ESV and raise the speed through WOODWARD GOVERNER.

Once the rated speed is achieved do the synchronization either manually or

automatically.

SIEMENS SYSTEM WRITE UP

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

35

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

36

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

37

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

38

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

39

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

40

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

41

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

42

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

43

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

44

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

45

Boiler Start up procedure

Boiler Hot start up

Boiler hot start up is called when boiler started with in 5-10 Hrs after shut down.

PREPARATION

Resume the power supply .

Ensure instrument air pressure 6.0 kg/cm2.

Aux. cooling water pressure & flow is sufficient.

All drains are closed, MSSV also closed.

All sample cooler inlet v/v should be closed.

There should be no pet coke in surge hopper & in DCF.

Start BFP as per requirement.

Start booster pump.

BOILER START UP PROCEDURE

Open the start up vent.

Fill the drum up to NWL through 40% FCV.

Now start the ID fan open suction & discharge damper and maintain furnace draft -1 or -2

mmWC.

Start SA fan and maintain SA pressure 400 mmWc.

Now start PA fan & opened suction damper 100%.

Gradually increased PA air flow.

Continuously watch on bed temp.

Start DCF at minimum rpm.

Once there will be sudden rise in bed temp, so start screw feeder to control bed temp.

Now watch the bed temp. If it is increased rapidly stop DCF.

Now increased PA air flow 40-45TPH.

Now increased DCF speed as per behavior of bed temp.

Start bed material RAV for bed inventory.

When bed temp. Reached 850-900 degree stable boiler on coal

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

46

As the steam temp. & pressure achieved charged the steam line.

Closed the start up vent and main steam drain before, after.

Put furnace draft in Auto.

Set SA pressure as per requirement & put both SA fan in auto.

Watch the drum level and put it in auto.

BOILER OPERATING PROCEDURES

1. START UP OF A COLD BOILER

START UP OF A COLD BOILER

Boiler start up can be termed as cold startup when

1. the boiler has been idle for more than 1 or 2 days

2. there is no pressure in steam drum and temp is less than 70 deg C

PREPARATION

Inspect the boiler prior to startup and check the following

Take Power clearance from electrical side also take clearance from instrumentation side.

All the access doors are closed.

All personnel are cleared.

All material are removed from furnace and other circuits.

Starting equipment interlocks are in position

Boiler is filled with D.M water up to NWL.

WATER AND STEAM CIRCUIT

Check the following valves are in closed condition.

Control valves and their bypass valves.

Blow down valves.

Main steam stop valve.

Drain valves of water level gauges.

All drain valves of water wall headers and economizer headers.

Check the following valves are in open condition

All isolation valves before and after feed control valves

Drum air vents

Main steam line drain

Valves of water level gauges, pressure gauges and level transmitters

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

47

All isolation valves for instruments

AIR AND FLUE GAS CIRCUIT

Ensure the following

I.D. Fan inlet damper is closed.

S.A. Fan inlet damper is closed.

Over fire air damper is closed.

P.A. Fan inlet damper is closed.

Wind box damper is closed.

Manual bed drain gates are closed.

Bed ash cooler drain gates are closed.

ESP and chimney are free from men and materials and doors are closed.

WATER FILL UP IN BOILER

Filling water temp should not be more than 38 deg C of the boiler metal temp and minimum

feed water temp acceptable is 20 deg C.

During filling of a cold boiler, the ambient temp should be used as an indicator of the boiler

metal temp.

Assuming an ambient temp of 40 deg C, the maximum temp of filling water shall be 78 deg C.

Boiler water fill up shall be of following two methods

1.

2.

Normal filling circuit by boiler feed water pump (Top fill up)

Initial startup line through D.M. transfer pump (Bottom fill up) to Eco bottom header.

NORMAL FILLING CIRCUIT (TOP FILL UP)

Ensure Economizer inlet & outlet header vents, steam drum vent, wing wall vents, saturated

steam header vent, and startup vent are all kept full open.

During water fill up, post an attendant at the drum level to monitor the local gauge glass and

to communicate control room when the drum level reached 50 mm below NWL (NWL is 50%

of drum level)

Start boiler feed water pump and open discharge valve gradually to full open condition

Open 40% feed control valve gradually (10 to 15%) and fill the water at a slow rate to ensure

removal of entrapped air from the pressure parts.

Close the air vents one by one after water flows out in the vents in the order of economizer,

steam drum , wing wall , saturated steam header and super heater

Once water comes out of super heater vent, close feed control valve and BFW pump discharge

valve and finally stop BFW pump

Steam drum level has to be brought down to NWL after super heater coils and headers are

filled with water by opening IBD valve

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

48

Before draining ensure vents of wing wall, super heater and drum are opened after BFW pump

is stopped

INITIAL START UP FILLING (BOTTOM FILL UP)

Ensure Economizer inlet & outlet header vents, steam drum vent, wing wall, super heater

vents and startup vent are all kept full open

Ensure the economizer inlet header drain valves are open

Start the transfer pump.

Close the air vents one by one after water flows out in the vents in the order of economizer,

steam drum , wing walls and super heater

Once water comes out of final super heater vent, close the Eco. bottom header initial filling

isolation valve and transfer pump discharge valve and finally transfer pump shall be switched

off

Before draining ensure vents of, super heater and drum, wing walls & saturated steam header

vents are opened after transfer pump is stopped

BED MATERIAL FILLING PROCEDURE

Start I.D. fan

Start S.A. Fan

Start P.A. fan

Maintain the furnace pressure as -2 to -5 mmWc

Start Bed material RAV at full speed.

Slowly increased air flow to avoid any chocking of nozzles.

Continuously watch furnace and co-ordinate with control room.

Bed height should be 700mm from bubble cap.

After getting sufficient bed height give a minimum fluidization.

Not down the wind box pressure for minimum fluidization.

Now decrease the air flow and check the bed that there is uniform fluidization in bed.

BOILER START UP PROCDURES

Start LDO pump at least 3 hours before start up & keep oil in recirculation mode.

Light up the oil burner as per Burner startup procedures and maintain the oil pressure 4.5-5.5

kg/cm2.

Maintain SA air flow for burner 12TPH and furnace pressure -2 to -3 mmWC.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

49

Slowly increased PA air flow proper heat transfer through bed material.

After getting 2 kg/cm2 drum pressure gradually increase oil flow.

When the drum pressure reaches 2 kg/cm2 close the drum vent valve, wing walls vents,

saturated steam header vents & super heater vents.

Main steam startup vent valve should be kept in open condition till the boiler is connected to

load to safeguard the super heater coils from overheating.

Now increased the PA air & keep bed in minimum fluidization state.

Gradually increase oil flow and monitor drum level. If necessary, give blow down and

maintain NWL

Observe the bed temp rise in bed. The expected heat up is around 50-70 deg C per hour till

100 deg C

Watch the bed for uniform fluidization. The bed temp will start rising fast due to the radiation

heat of the oil burner.

Once the bed temp reaches around 400 deg C start introduction of coal to the comp.

INTRODUCTION OF COAL TO BED AND STABILISATION

Once the bed temp is around 450 to 500 deg C in any one of the thermocouples, start the drag

chain feeder and run at minimum speed.

Observe the bed and check coal burning or not.

Without flame in the bed do not continue fuel feeding for prolonged time.

Slowly increase the fuel feeding RPM when the bed temp is around 600 deg C and in rising

trend.

Once the fuel is admitted to the bed there will be a rapid bed temp raise and should be

controlled by adjusting the fuel to the combustor and adjusting air flow to the bed.

Also start screw feeder to avoid sudden temp rise of bed.

Bed temp is to be stabilized around 850 deg C for coal and once the temp is stabilized burner

can be withdrawn when the temp rising rate is so fast.

Once the bed temp reaches 850 deg C bed material additions shall be taken up and bed level

shall be raised from the existing level to 1400-1500 mm.

On the water side watch the drum level maintain drum level to NWL by switching on feed

pump

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

50

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

51

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

52

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

53

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

Prepared by: Thermax Limited, Power Division (O&M)

54

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

55

TURBINE ALARM & TRIP SET POINT LIST

4.7 MW Captive Power Plant

S.NO.

Instr.Tag

No.

Description

Unit

Set Values

Alarm

Trip

DPI-501

Lube Oil Filter

Kg/Cm2

0.8

DIP-401

Control Oil Filter

Kg/Cm2

0.8

DPS201A

/DPS201B

CEP Differential Pressure

(DP)

Kg/Cm2

0.5

PI-101

Main steam pressure Low

Low

Kg/Cm2

26

20

PI-101

Main steam pressure High

High

Kg/Cm2

43

44

TI-101

Main steam temperature

Low Low

Deg C

425

420

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

56

TI-101

Main steam temperature

High High

Deg C

435

449

PSL-401

Control Oil Pressure Low

Low

Kg/Cm2

8.5

7.5

PI-103

Exhaust Pressure High

High

Kg/Cm2

-0.85

-0.81

10

TI-103/TI104

Exhaust Temperature

High High

Deg C

105

120

11

OSP- 901

Over Speed trip from

Governor

RPM

12

LSHH-201

Hotwell level High High

13

PBLT1

/PBLT2

Emergency trip (PB) from

Gauge Panel

14

D86GT

Generator Differential

Relay acted

15

PI-502

Lube oil Pressure Low

Low

16

EMG PLC

Emergency trip command

for DCS

17

YI-801B/YI802B

Turbine front bearing

vibration High High

Microns

63

83

18

YI803B/YI804B

Turbine rear bearing

vibration High High

Microns

63

83

19

YI-805B/YI806B

Gearbox Pinion (DE)

bearing vibration High

High-High Speed

Microns

66

125

20

TI - 809

Gearbox Pinion (NDE)

bearing vibration High

High-High Speed

Microns

66

125

Kg/Cm2

13180

70%

90%

2 out of 2

0 = Trip

D86GT

From relay : = 1

2.55

1.8

DCS Push

Button

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

57

21

ZI-801B

Rotor axial displacement

High High

MM

22

TI - 801

Turbine thrust Non-Active

side temperature High

High

Deg C

95

100

23

TI-803

Turbine thrust Active side

temperature High High

Deg C

95

100

24

TI-805

Turbine front journal

bearing temperature High

High

Deg C

110

120

25

TI-806

Turbine rear journal

bearing temperature High

High

Deg C

110

120

26

TI-810

Gearbox pinion shaft (DE)

bearing temperature High

High

Deg C

100

110

27

TI-809

Gearbox pinion shaft

(NDE) bearing

temperature High High

Deg C

100

110

28

TI-807

Gearbox Gear shaft (DE)

bearing temperature High

High

Deg C

100

110

29

TI-808

Gearbox Gear shaft (NDE)

bearing temperature High

High

Deg C

100

110

30

TI-851

Gearbox Gear shaft Thrust

(NDE) Temperature

Deg C

100

110

31

TI-850

Gearbox Gear shaft Thrust

(DE) Temperature

Deg C

100

110

32

TI-811

Alternator front bearing

Temperature High High

Deg C

85

90

33

TI - 811

Alternator rear bearing

Temperature High High

Deg C

85

90

34

ESD - 901

Emergency shutdown

command from Govenror

Governor

0 to trip

0.4/+0.4

Prepared by: Thermax Limited, Power Division (O&M)

0.6/+0.6

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

58

35

TI 811

Alternator front bearing

temperature

Deg C

85

90

36

TI 812

Alternator rear bearing

temperature

Deg C

85

90

37

TI 813

Alternator winding

temperature - U1 phase

Deg C

140

145

38

TI 814

Alternator winding

temperature - V1 phase

Deg C

140

145

39

TI 815

Alternator winding

temperature - W1 phase

Deg C

140

145

40

TI 816

Alternator winding

temperature - U2 phase

Deg C

140

145

41

TI 817

Alternator winding

temperature - V2 phase

Deg C

140

145

42

TI 815

Alternator winding

temperature - W2 phase

Deg C

140

145

43

TI 823

Alternator core

temperature - 1

Deg C

130

135

44

TI 824

Alternator core

temperature - 1

Deg C

130

135

45

TI 825

Alternator core

temperature - 1

Deg C

130

135

46

TI 819

Alternator inlet air

temperature - 1

Deg C

52

47

TI 820

Alternator outlet air

temperature - 1

Deg C

80

48

TI 821

Alternator inlet air

temperature - 1

Deg C

52

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

49

Alternator inlet air

temperature - 1

TI 822

SOP

Deg C

59

80

BOILER ALARM & TRIP SET POINT LIST

4.7 MW Captive Power Plant

S.NO.

Instr.Tag

No.

Description

Unit

Set Values

Alarm

Trip

LI-101

A/B/C

Drum Level Low Low

25

20

LI-101

A/B/C

Drum Level High High

70

80

PI-112

Main steam pressure Low

Low

Kg/Cm2

43

PI-112

Main steam pressure High

High

Kg/Cm2

46

TI-121

Main steam temperature

Low Low

Deg C

420

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

60

TI-121

Main steam temperature

High High

Deg C

460

PI-114 A/B

Furnace Pressure High High

mmwc

130

140

PI-114 A/B

Furnace Pressure Low Low

mmwc

-130

10

PI-116

BFG Presuure High High

mmwc

350

500

11

PI-116

BFG Pressure Low Low

mmwc

150

50

12

PI-206

Deaerator Pressure High

Kg/Cm2

1.5

13

PI-206

Deaerator Pressure Low

Kg/Cm2

0.5

14

LI-201

Deaerator Level Low Low

20

140

10 BFP will

TRIP

START, STOP PERMISSIVE AND INTERLOCKS

TURBINE RESET PERMISSIVE

1.EOP Should be ready and will be selected in Auto mode.

2.Lube oil tank level should be greater than 30%.

3.Overhead oil tank level switch should be healthy.

4.Emergency Push Button from the TSP panel should be released.Reset Command from PLC

At 10800 RPM AOP manual stop and MOP change over function.

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

61

COASTING DOWN TESTS

Turbine coasting down time = 6 mins 8 sec.

LOGICS AND INTERLOCKS TEST

1. Auxillary Oil Pump

Start Permissive

1.Pump should be in Remote selection.

2.Pump should not tripped in overload.

AOP will start in Auto

1. When Lube oil header Pressure becomes low of 2.5 Kg/cm2.

AOP will Stop in Auto/Protection

1.When Lube oil header pressure becomes greater than 3 Kg/Cm2.

2.When Turbine speed will achieved 90% of rated RPM with 120 Sec of time delay

3.When AOP motor will trip in overload.

2.Emergency oil pump

Start Permissive

1. EOP ready to start signal will display in

PLC

2. EOP should not trip in overload.

Emergency oil pump will start in Auto/Interlock

1.When Lube oil pressure becomes low low of 1.8Kg/Cm2

2.Incase of Turbine speed is greater than 20 RPM and Lube oil

pressure is low low irrespective of mode selection in PLC,EOP will start

automtaically and cannot be stopped untill the pressure becomes

normal or Turbine speed come to stand still.

3.Barring Gear Motor

Start Permissive

1.Barring Gear motor should not trip in overload.

2.Lube oil pressure is greater than 2.55 Kg/cm2.

3.Turbine speed is less than 20 RPM.

Barring Gear will Start in Auto.

1.When turbine speed is less than 20 RPM.

Auto stop command / Protection

1.When Lube oil header pressure is less than 2.55 Kg/Cm2

2.When turbine speed is greater than 315 RPM

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

4.Control Oil Pump

Start Permissive

1.Pump should be in Remote selection.

2.No over load trip activated.

3.MOT tank level not low low i.e. greater than 30%

Stand By COP will start in Auto Mode

1.When Control oil pressure becomes low of 8.5 Kg/Cm2.

2.When running Control oil pump tripped in overload.

COP will stop in Auto/Protection

1. When MOT level goes below 30%.

2. When pump will be overloaded.

5. Oil Vapour Extractor Fan - 1

Start Permissive

1.Fan selection should be in Remote.

2.Fan should not be over load trip.

OVEF will start in Auto Mode.

1. Auxiliary oil pump should be in running condition.

2.Emergency oil pump should be in running condition.

3.Turbine speed should be greater than 90% RPM.

Auto Stop command / Protection

1.Vapour extractor fan overload tripped.

6. CONDENSATE EXTRACTION PUMP - 1

Start Permissive

1.Hotwell level should be normal greater than 50%.

2.CEP pump shoullde be Remote selected.

3.Pump should not be over load trip.

CEP will start in Auto

1.Stand By Pump wil start in Auto if Condensate discharge pressure becomes low

i.e. less than 3.0Kg/Cm2.

2.Stand By Pump wil start in Auto if Hotwell level becomes High of 70%.

3.Runnig Condensate extraction pump Tripped.

CEP will Stop in Auto/Protection

1.Pump will trip in Auto if Hotwell level becomes low low 20%.

2.Running Condensate extraction pump Tripped.

7.VACUUM BREAKER VALE (VBV201)

Prepared by: Thermax Limited, Power Division (O&M)

62

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

63

Vaccun Brekaer valve will open in AUTO.

1.When Turbine Axial Displacement is greater than 0.6 mm

2.When Lube oil pressure becomes low low i.e. less than 1.8Kg/Cm2

3.when Generator tripped due to Differential protection.

4.When Turbine speed is less than 70% of rated speed.

Manual Open Command Block

1. If the turbine speed is greater than 8400 RPM manual open command is blocked.

2. Valve can be manually closed when all the protection is normal.

8. DEAREATOR BLEED VALVE

OPEN PERMISSIVE

1. Main steam flow should be greater than 10 TPH.

2.Pressure difference across the bleed valve should be less then 0.1 Kg/Cmm2

3. Turbine should not be in tripped condition.

Bleed valve Auto close/Protection

1. When Turbine inlet Main steam flow less than 9 TPH.

2. When Turbine Trip.

PLANT TRIP INTERLOCK CHECKING FORMAT

STEAM TURBINE

S.No.

DESCRIPTION

Hand Trip test

by Push button

on Local TSP

panel

Remote Trip

test by Push

button on

Governor panel

UOM

SET

VALUE

ACTUAL

VALUE

METHOD OF TESTING

RESULT

EXPECTED

Trip

Put STG on turning

gear, by pass vacuum

protetction,reset STG

Turbine trip

& ESV

close

Trip

as above

as above

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

Over speed Trip

from Governor.

Over speed Trip

from OSP

system

Exhaust

Pressure High

High

Main steam

temperature

High High

8

9

10

11

Main steam

temperature

Low Low

Exhaust

Temperature

High High

Turbine thrust

Non-Active side

temperature

High High

Turbine thrust

Active side

temperature

RPM

RPM

Kg/cm2

SOP

64

13188

Operate the turbine at

working speed and do

the OS testing through

Woodward it is advised

to test the electrical OS

at operating speed by

resetting OS electrical at

operating speed. After

testing normalize the set

value

Turbine trip

13250

Operate the turbine at

working speed and do

the OS testing through

Woodward. it is advised

to test the electrical OS

beyond mechanical OS

value as back up

protection

Turbine trip

-0.81

Put STG on turning

gear, normalize pass

vacuum protection to

reset STG otherwise,

pull some vacuum

above trip value and

reset the STG Now

reduce vaccum by

controlling ejector steam

pressure to trip value.

Note the trip value

STG will not

get reset, in

the second

case turbine

must trip

Turbine trip

deg C

449

Put STG on turning

gear, by pass vacuum

protetcion,reset

STG,simulate through

DCS

deg C

420

as above

Turbine trip

deg C

120

as above

Turbine trip

deg C

100

as above

Turbine trip

deg C

100

as above

Turbine trip

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

SOP

65

High High

12

13

14

15

16

17

18

19

20

Turbine front

journal bearing

temperature

High High

Turbine rear

journal bearing

temperature

High High

Gearbox pinion

shaft (DE)

bearing

temperature

High High

Gearbox pinion

shaft (NDE)

bearing

temperature

High High

Gearbox Gear

shaft (DE)

bearing

temperature

High High

Gearbox Gear

shaft (NDE)

bearing

temperature

High High

Gearbox Gear

shaft Thrust

(NDE)

Temperature

Gearbox Gear

shaft Thrust

(DE)

Temperature

Alternator front

bearing

Temperature

High High

Alternator rear

bearing

Temperature

High High

deg C

120

as above

Turbine trip

deg C

120

as above

Turbine trip

deg C

110

as above

Turbine trip

deg C

110

as above

Turbine trip

deg C

110

as above

Turbine trip

deg C

110

as above

Turbine trip

deg C

110

as above

Turbine trip

deg C

110

as above

Turbine trip

deg C

90

as above

Turbine trip

deg C

90

as above

Turbine trip

Prepared by: Thermax Limited, Power Division (O&M)

POWER DIVISION

THERMAX LIMITED

Project

Document

Title

Rev.

Page

1 x 20 MW CPP

TRINETRA CEMENTS

BANSWARA,RAJASTHAN

26

Hotwell level

High High

90

28

LUB OIL

PRESSURE LL

Kg/cm2

1.8

SOP

66

Reset turbine and check

the hotwell level by

actually rising the same

Prepared by: Thermax Limited, Power Division (O&M)

Turbine trip

Turbine trip

Вам также может понравиться

- Typ. Slow Firing Alkali BoiloutДокумент3 страницыTyp. Slow Firing Alkali Boiloutsantoshkumarmishra2009100% (2)

- VSLP 1×135MW power plant project turbine operation rulesДокумент148 страницVSLP 1×135MW power plant project turbine operation rulesAmitabh Singh83% (6)

- Indiabulls Power Limited: Sop/Opns/ Operations DepartmentДокумент2 страницыIndiabulls Power Limited: Sop/Opns/ Operations Departmentarvidkumar87060100% (1)

- CFBC Boiler Startup and ShutdownДокумент42 страницыCFBC Boiler Startup and ShutdownAshvani Shukla100% (1)

- CFBC Boiler Start Up ProcedureДокумент4 страницыCFBC Boiler Start Up ProcedurePrasad Aher100% (1)

- Sop of WHRPPДокумент21 страницаSop of WHRPPHaider AliОценок пока нет

- Condenser Flood Test 8 of 11Документ14 страницCondenser Flood Test 8 of 11Sara LopezОценок пока нет

- Cold Startup ProcedureДокумент8 страницCold Startup ProcedureRahul KurmiОценок пока нет

- Standard Operating Instruction: Sop For CT FanДокумент5 страницStandard Operating Instruction: Sop For CT FanSonratОценок пока нет

- Cold Startup Procedure PDFДокумент6 страницCold Startup Procedure PDFSai SwaroopОценок пока нет

- Turbine SopДокумент8 страницTurbine SopDominic Daniel100% (1)

- Commissioning Steps Power Plant Under 40Документ3 страницыCommissioning Steps Power Plant Under 40ssheart_mind100% (1)

- Operation Procedures For MDBFPДокумент7 страницOperation Procedures For MDBFPJackSparrow86100% (1)