Академический Документы

Профессиональный Документы

Культура Документы

PCB Layout Guidelines

Загружено:

Chindris IoanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PCB Layout Guidelines

Загружено:

Chindris IoanАвторское право:

Доступные форматы

PCB LAYOUT GUIDELINES As in any switching regulator, the layout of the printed circuit board is very important.

Rapidly switching currents associated with wiring inductance, stray capacitance and parasitic inductance of the printed circuit board traces can generate voltage transients which can generate electromagnetic interferences (EMI) and affect the desired operation. As indicated in the igure !", to minimi#e inductance and ground loops, the length of the leads indicated by heavy lines should be $ept as short as possible. or best results, single%point grounding (as indicated) or ground plane construction should be used. &n the other hand, the '() area connected to the 'in * (emitter of the internal switch) of the +M*,-, should be $ept to a minimum in order to minimi#e coupling to sensitive circuitry. Another sensitive part of the circuit is the feedbac$. It is important to $eep the sensitive feedbac$ wiring short. .o assure this, physically locate the programming resistors near to the regulator, when using the ad/ustable version of the +M*,-, regulator.

Input Capacitor (Cin) .he Input (apacitor 0hould 1ave a +ow E0R . or stable operation of the switch mode converter a low E0R (E2uivalent 0eries Resistance) aluminium or solid tantalum bypass capacitor is needed between the input pin and the ground pin to prevent large voltage transients from appearing at the input. It must be located near the regulator and use short leads. 3ith most electrolytic capacitors, the capacitance value decreases and the E0R increases with lower temperatures. or reliable operation in temperatures below %*,4( larger values of the input capacitor may be needed. Also paralleling a ceramic or solid tantalum capacitor will increase the regulator stability at cold temperatures. RM0 (urrent Rating of (in .he important parameter of the input capacitor is the RM0 current rating. (apacitors that are physically large and have large surface area will typically have higher RM0 current ratings. or a given capacitor value, a higher voltage electrolytic capacitor will be physically larger than a lower voltage capacitor, and thus be able to dissipate more heat to the surrounding air, and therefore will have a higher RM0 current rating. .he conse2uence of operating an electrolytic capacitor above the RM0 current rating is a shortened operating life. In order to assure ma5imum capacitor operating lifetime, the capacitor6s RM0 ripple current rating should be7

I rms >!.* d I Load where d is the duty cycle, for a buc$ regulator

d=

ton Vout = T Vin

t V

out on = and d = T for a buc$boost regulator. Vout +Vin Output Capacitor (Cout) or low output ripple voltage and good stability, low E0R output capacitors are recommended. An output capacitor has two main functions7 it filters the output and provides regulator loop stability. .he E0R of the output capacitor and the pea$%to%pea$ value of the inductor ripple current are the main factors contributing to the output ripple voltage value. 0tandard aluminium electrolytics could be ade2uate for some applications but for 2uality design low E0R types are recommended. An aluminium electrolytic capacitor6s E0R value is related to many factors such as the capacitance value, the voltage rating, the physical si#e and the type of construction. In most cases, the higher voltage electrolytic capacitors have lower E0R value. &ften capacitors with much higher voltage ratings may be needed to provide low E0R values that are re2uired for low output ripple voltage. The Output Capacitor Require an ESR !a"ue That #a an Upper an$ Lo%er Li&it As mentioned above, a low E0R value is needed for low output ripple voltage, typically !8 to *8 of the output voltage. )ut if the selected capacitor6s E0R is e5tremely low (below 9.9, ), there is a possibility of an unstable feedbac$ loop, resulting in oscillation at the output. .his situation can occur when a tantalum capacitor, that can have a very low E0R, is used as the only output capacitor. At Lo% Te&perature ' Put in Para""e" A"u&iniu& E"ectro"(tic Capacitor %ith Tanta"u& Capacitor Electrolytic capacitors are not recommended for temperatures below %*,4(. .he E0R rises dramatically at cold temperatures and typically rises : times at %*,4( and as much as !9 times at %"94(. 0olid tantalum capacitors have much better E0R spec at cold temperatures and are recommended for temperatures below %*,4(. .hey can be also used in parallel with aluminium electrolytics. .he value of the tantalum capacitor should be about !98 or *98 of the total capacitance. .he output capacitor should have at least ,98 higher RM0 ripple current rating at ,* $1# than the pea$%to%pea$ inductor ripple current. Catch Dio$e Locate the Catch Dio$e C"o e to the L)*+,+ .he +M*,-, is a step%down buc$ converter; it re2uires a fast diode to provide a return path for the inductor current when the switch turns off. .his diode must be located close to the +M*,-, using short leads and short printed circuit traces to avoid EMI problems. U e a Schott-( or a So.t S%itchin/

U"tra01a t Reco2er( Dio$e 0ince the rectifier diodes are very significant source of losses within switching power supplies, choosing the rectifier that best fits into the converter design is an important process. 0chott$y diodes provide the best performance because of their fast switching speed and low forward voltage drop. .hey provide the best efficiency especially in low output voltage applications (,.9 < and lower). Another choice could be ast%Recovery, or =ltra% ast Recovery diodes. It has to be noted, that some types of these diodes with an abrupt turnoff characteristic may cause instability or EMI troubles. A fast%recovery diode with soft recovery characteristics can better fulfill a 2uality, low noise design re2uirements. .able " provides a list of suitable diodes for the +M*,-, regulator. 0tandard ,9>?9 1# rectifier diodes such as the !@"99! series or !@,"99 series are @&. suitable. In$uctor .he magnetic components are the cornerstone of all switching power supply designs. .he style of the core and the winding techni2ue used in the magnetic component6s design has a great influence on the reliability of the overall power supply. =sing an improper or poorly designed inductor can cause high voltage spi$es generated by the rate of transitions in current within the switching power supply, and the possibility of core saturation can arise during an abnormal operational mode. <oltage spi$es can cause the semiconductors to enter avalanche brea$down and the part can instantly fail if enough energy is applied. It can also cause significant R I (Radio re2uency Interference) and EMI (Electro%Magnetic Interference) problems.

Вам также может понравиться

- 12 Steps Design SMPS TransformersДокумент11 страниц12 Steps Design SMPS TransformersRnDES1 CMLОценок пока нет

- Detuned, Series Filter Reactor For Power Factor Corection CapacitorДокумент5 страницDetuned, Series Filter Reactor For Power Factor Corection CapacitorNghia NguyenОценок пока нет

- Capacitor Circuits: Reactance, Filters, Discharge TimesДокумент33 страницыCapacitor Circuits: Reactance, Filters, Discharge TimesJan BooysenОценок пока нет

- Reference Design Low Cost CompassДокумент4 страницыReference Design Low Cost CompassHany MaximousОценок пока нет

- Flyback Converter Design ThesisДокумент8 страницFlyback Converter Design Thesisleanneuhlsterlingheights100% (2)

- Snoa842 PDFДокумент13 страницSnoa842 PDFBiswajit SinghОценок пока нет

- Buck Converter Design DemystifiedДокумент6 страницBuck Converter Design DemystifiedEric MorissetОценок пока нет

- Edc Lab ManualДокумент84 страницыEdc Lab Manualprojectboy0% (1)

- Laird Macomber Cde Solid-Polymerium-Alu-CapacitorДокумент8 страницLaird Macomber Cde Solid-Polymerium-Alu-CapacitorKrzyszto FPОценок пока нет

- TransformerLess Low Cost Power SupplyДокумент6 страницTransformerLess Low Cost Power Supplyknk761987Оценок пока нет

- ESR Meter Circuit Operation GuideДокумент5 страницESR Meter Circuit Operation GuideOscar PachecoОценок пока нет

- Decoupling TechniquesДокумент14 страницDecoupling TechniquesTrọng ToànОценок пока нет

- Capacitor Choice Is Key in Buck Converter DesignДокумент2 страницыCapacitor Choice Is Key in Buck Converter DesignbmmostefaОценок пока нет

- Lic QB With AnswerДокумент29 страницLic QB With AnswerNoddy SenОценок пока нет

- HighfreqДокумент6 страницHighfreqnickslam007Оценок пока нет

- A New Concept of Power Quality Monitoring: AbstractДокумент6 страницA New Concept of Power Quality Monitoring: AbstractlokvisОценок пока нет

- ARRL Homebrew 50-Watt AmpДокумент52 страницыARRL Homebrew 50-Watt AmpdodicОценок пока нет

- EB-104 Get 600 Watts RF From Four Power FETsДокумент9 страницEB-104 Get 600 Watts RF From Four Power FETsEdward YanezОценок пока нет

- Pe 26 Ee17Документ23 страницыPe 26 Ee17Syed AfzalОценок пока нет

- EMC Filter Design With RB Common Mode ChokesДокумент22 страницыEMC Filter Design With RB Common Mode Chokeskaem1189Оценок пока нет

- Linear IC ApplicationsДокумент8 страницLinear IC ApplicationsSwarna SugandhОценок пока нет

- Transistor Ratings and Packages: Bipolar Junction Transistors (Incomplete)Документ2 страницыTransistor Ratings and Packages: Bipolar Junction Transistors (Incomplete)contrasterОценок пока нет

- Antenna Analyzer vk5jst Version 1 Instructions PDFДокумент10 страницAntenna Analyzer vk5jst Version 1 Instructions PDFPisu Miau Pisu MiauОценок пока нет

- 3-Phase PFC KolarДокумент7 страниц3-Phase PFC KolarJayant SalianОценок пока нет

- Power Transformer DesignДокумент13 страницPower Transformer Designswiss22100% (1)

- UntitledДокумент7 страницUntitledAnonymous iQMKqMqqWОценок пока нет

- E 987002Документ2 страницыE 987002dugamdugonjaОценок пока нет

- Power Failure AlarmДокумент17 страницPower Failure AlarmPurva Patil33% (3)

- Development of A High Frequency and High-Voltage Pulse Transformer For A TWT HvpsДокумент4 страницыDevelopment of A High Frequency and High-Voltage Pulse Transformer For A TWT HvpsShyam SuryaОценок пока нет

- Ee6303 - Linear Integrated Circuits and ApplicationsДокумент19 страницEe6303 - Linear Integrated Circuits and ApplicationsBALAKRISHNANОценок пока нет

- Capacitor Selection Guidelines An 1099Документ4 страницыCapacitor Selection Guidelines An 1099indeshmukhОценок пока нет

- Engineers Note - Capacitors Are Key To Voltage Regulator Design - EE TimesДокумент12 страницEngineers Note - Capacitors Are Key To Voltage Regulator Design - EE TimeskamranishfaqОценок пока нет

- CapacitorsДокумент4 страницыCapacitorsJohn David YermoОценок пока нет

- POWER DIODES: KEY TYPES AND CHARACTERISTICSДокумент61 страницаPOWER DIODES: KEY TYPES AND CHARACTERISTICSSaiBhavaniCОценок пока нет

- A Constant-Current Source GuideДокумент5 страницA Constant-Current Source GuideAnonymous TPVfFif6TOОценок пока нет

- Ee6303 - Linear Integrated Circuits and Applications Unit-I Circuit Configuration For Linear IcsДокумент18 страницEe6303 - Linear Integrated Circuits and Applications Unit-I Circuit Configuration For Linear IcsNarasimha KumarОценок пока нет

- CURRENT TRANSFORMERS - GoodДокумент4 страницыCURRENT TRANSFORMERS - GoodNguyễn QuyềnОценок пока нет

- Power Transformer DesignДокумент13 страницPower Transformer DesignMohammad AliОценок пока нет

- Thermal Overload ProtectorДокумент69 страницThermal Overload ProtectorSai Printers100% (1)

- Aerosemi: Features ApplicationsДокумент9 страницAerosemi: Features Applicationsttnaing100% (1)

- RF Controlled ApplianceДокумент14 страницRF Controlled ApplianceNEX456Оценок пока нет

- Choosing The Inductor For A Buck ConverterДокумент8 страницChoosing The Inductor For A Buck ConverterjboronatsОценок пока нет

- Inductors: Application NotesДокумент4 страницыInductors: Application Notesm.muthu lakshmiОценок пока нет

- EL Transf 12VДокумент4 страницыEL Transf 12VmarjanchoОценок пока нет

- Transformador Electrnico para La Lmpara Del Halgeno 12cv 214Документ5 страницTransformador Electrnico para La Lmpara Del Halgeno 12cv 214billy_lxОценок пока нет

- Components FullДокумент15 страницComponents FullFlux PrimeОценок пока нет

- Guide to Choosing Power Electronics CapacitorsДокумент38 страницGuide to Choosing Power Electronics CapacitorsSunil GeorgeОценок пока нет

- Another Interesting Circuit From Burt Design PadДокумент13 страницAnother Interesting Circuit From Burt Design PadmoisesHolaОценок пока нет

- Single Phasing EffectsДокумент41 страницаSingle Phasing EffectsdiljithОценок пока нет

- Transformer Part 3 of 3Документ25 страницTransformer Part 3 of 3Rajan BhandariОценок пока нет

- Reactive Power Management Solutions GuideДокумент72 страницыReactive Power Management Solutions GuideSatyendra Kumar100% (2)

- GBPPR 'Zine - Issue #38Документ70 страницGBPPR 'Zine - Issue #38GBPPRОценок пока нет

- Alternador ReguladorДокумент32 страницыAlternador ReguladorcaldasferreirasoutoОценок пока нет

- Tuen Voltage AmplifirДокумент8 страницTuen Voltage Amplifirkaran007_mОценок пока нет

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsОт EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsРейтинг: 3 из 5 звезд3/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Рейтинг: 2.5 из 5 звезд2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesОт EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesОценок пока нет

- STEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10От EverandSTEM: Science, Technology, Engineering and Maths Principles Teachers Pack V10Оценок пока нет

- Ioan Chindris ResumeДокумент2 страницыIoan Chindris ResumeChindris IoanОценок пока нет

- DWDMДокумент57 страницDWDMmajorhone100% (1)

- DWDMДокумент57 страницDWDMmajorhone100% (1)

- Sysengin Samp WДокумент27 страницSysengin Samp WChindris IoanОценок пока нет

- Self Assessment Grid For LanguagesДокумент1 страницаSelf Assessment Grid For LanguagesediekittenОценок пока нет

- DWDMДокумент57 страницDWDMmajorhone100% (1)

- New Text DocumentДокумент1 страницаNew Text DocumentChindris IoanОценок пока нет

- Clicker Hero SaveДокумент6 страницClicker Hero SaveChindris IoanОценок пока нет

- TL 6 Reference ManualДокумент321 страницаTL 6 Reference ManualChindris IoanОценок пока нет

- Process SimulateДокумент3 страницыProcess SimulateChindris Ioan100% (1)

- JP 72Документ9 страницJP 72Chindris IoanОценок пока нет

- Wind of ChangeДокумент1 страницаWind of ChangeChindris IoanОценок пока нет

- Ejercicios Solidworks PDFДокумент50 страницEjercicios Solidworks PDFRic Frs80% (5)

- S7-Plcsim V5.4Документ72 страницыS7-Plcsim V5.4mohammad abdОценок пока нет

- LM 2575Документ0 страницLM 2575Chindris IoanОценок пока нет

- Pad Eye, Solidwork - TutorialДокумент28 страницPad Eye, Solidwork - TutorialJogi Oscar SinagaОценок пока нет

- BS EN 62305-3:2011 Part 3: Physical Damage and Life HazardДокумент47 страницBS EN 62305-3:2011 Part 3: Physical Damage and Life HazardOmar fethiОценок пока нет

- 14 Sensor Vibration Switch Sw-18010pДокумент2 страницы14 Sensor Vibration Switch Sw-18010pgreg rezaОценок пока нет

- Isolation Fault TroubleshootingДокумент6 страницIsolation Fault Troubleshootingraymknd gerard macarineОценок пока нет

- ABB Price Book 737Документ1 страницаABB Price Book 737EliasОценок пока нет

- NS and NSX - Zs ValuesДокумент5 страницNS and NSX - Zs ValuesmostafabasionyОценок пока нет

- Bus Bar SystemДокумент21 страницаBus Bar SystemBhavika DabhiОценок пока нет

- LC1D1801 Telemecanique LC1-D18-01 Contactor ReplacementДокумент1 страницаLC1D1801 Telemecanique LC1-D18-01 Contactor Replacementjamal debakОценок пока нет

- Electrical SOR Jan2010Документ73 страницыElectrical SOR Jan2010kokuei100% (1)

- EXB19027 - Brochure - Galion Low ResДокумент24 страницыEXB19027 - Brochure - Galion Low ResHwei Hwa LimОценок пока нет

- Inel Catalogue - Apr'22Документ32 страницыInel Catalogue - Apr'22Vennila Valley0% (1)

- JBL - Ctrl14C - T v1 PDFДокумент2 страницыJBL - Ctrl14C - T v1 PDFashielanieОценок пока нет

- Sony Active Subwoofer Service ManualДокумент14 страницSony Active Subwoofer Service ManualStefanøs GeForceОценок пока нет

- Samsung Service ManualДокумент53 страницыSamsung Service Manualcdcdaniel75% (4)

- 3.3 Energy Efficient Lighting Systems Ppt-Ak - KhanraДокумент25 страниц3.3 Energy Efficient Lighting Systems Ppt-Ak - KhanraumisygОценок пока нет

- BT120032 DatamodulДокумент1 страницаBT120032 DatamodulAirton SousaОценок пока нет

- APC Smart-UPS XL 2200VA 230V Tower/Rack Convertible: Part Number: SUA2200XLIДокумент5 страницAPC Smart-UPS XL 2200VA 230V Tower/Rack Convertible: Part Number: SUA2200XLIemailabenkОценок пока нет

- Irf9410 PDFДокумент7 страницIrf9410 PDFgiapy0000Оценок пока нет

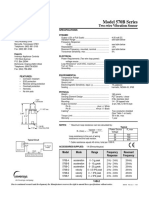

- Model 570B Series vibration sensor specificationsДокумент2 страницыModel 570B Series vibration sensor specificationsrafaelnoleto842339Оценок пока нет

- SM Si12-710 2mxs50fv1bДокумент182 страницыSM Si12-710 2mxs50fv1bDoan Tien DoОценок пока нет

- H 1041 - SEHS7807 - Uso Del Multitach 6V-2100 - 6V3121Документ26 страницH 1041 - SEHS7807 - Uso Del Multitach 6V-2100 - 6V3121nopainmadafakaОценок пока нет

- Revere 1100 Wide Beam Mercury Floodlight Bulletin 1966Документ2 страницыRevere 1100 Wide Beam Mercury Floodlight Bulletin 1966Alan MastersОценок пока нет

- VE MPPT Calc 2 - 4Документ18 страницVE MPPT Calc 2 - 4MemoPalacioОценок пока нет

- Transformer FundamentalsДокумент4 страницыTransformer FundamentalsChewLee TanОценок пока нет

- R.M.K. College of Engineering and TechnologyДокумент7 страницR.M.K. College of Engineering and TechnologyvlkumashankardeekshithОценок пока нет

- DET40073 - Topic 2cДокумент26 страницDET40073 - Topic 2cHAAVINESHОценок пока нет

- On PD-SOIДокумент27 страницOn PD-SOIpramodagarwal_nitrklОценок пока нет

- CMOS INVERTER-WPS OfficeДокумент15 страницCMOS INVERTER-WPS OfficekusumaОценок пока нет

- Technical Details: Complementary Metal-Oxide-Semiconductor (CMOS)Документ4 страницыTechnical Details: Complementary Metal-Oxide-Semiconductor (CMOS)Testing toolsОценок пока нет

- A Panel LVMDP MCCB 400A: NO Uraian QT Y SAT Harga Satuan (RP) Jumlah Harga (RP)Документ2 страницыA Panel LVMDP MCCB 400A: NO Uraian QT Y SAT Harga Satuan (RP) Jumlah Harga (RP)MulyadiThesantoz CiwalkОценок пока нет

- (For NTSC) : (Without Price)Документ15 страниц(For NTSC) : (Without Price)Paulo chagas paulo ratoОценок пока нет