Академический Документы

Профессиональный Документы

Культура Документы

245 Full

Загружено:

Balu BhsИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

245 Full

Загружено:

Balu BhsАвторское право:

Доступные форматы

http://sdj.sagepub.

com/

Design

The Journal of Strain Analysis for Engineering

http://sdj.sagepub.com/content/46/4/245

The online version of this article can be found at:

DOI: 10.1177/0309324711401501

2011 46: 245 The Journal of Strain Analysis for Engineering Design

K Ramesh, T Kasimayan and B Neethi Simon

A comprehensive review Digital photoelasticity

Published by:

http://www.sagepublications.com

On behalf of:

Institution of Mechanical Engineers

can be found at: The Journal of Strain Analysis for Engineering Design Additional services and information for

http://sdj.sagepub.com/cgi/alerts Email Alerts:

http://sdj.sagepub.com/subscriptions Subscriptions:

http://www.sagepub.com/journalsReprints.nav Reprints:

http://www.sagepub.com/journalsPermissions.nav Permissions:

http://sdj.sagepub.com/content/46/4/245.refs.html Citations:

What is This?

- Jun 10, 2011 Version of Record >>

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

Digital photoelasticity A comprehensive review

K Ramesh*, T Kasimayan, and B Neethi Simon

Department of Applied Mechanics, Indian Institute of Technology, Madras, India

The manuscript was received on 25 April 2010 and was accepted after revision for publication on 2 February 2011.

DOI: 10.1177/0309324711401501

Abstract: Digital photoelasticity has rapidly progressed in the last few years and has matured

into an industry-friendly technique. This review thematically classifies all the developments

in digital photoelasticity and highlights the relative merits and drawbacks of the various tech-

niques. The overall objective is to provide enough information and guidance to allow an end-

user to make an informed choice on the type of technique to be used in a particular situation.

Keywords: isochromatics, isoclinics, phase-shifting, phase maps, inconsistency, ambiguity,

phase unwrapping, stress separation, digital polariscope, reflection photoelasticity, integrated

photoelasticity.

1 INTRODUCTION

Photoelasticity is a whole-field optical experimental

technique that is based on the principle of stress/

strain-induced birefringence. It directly gives infor-

mation about principal stress/strain difference (iso-

chromatics) and principal stress/strain direction

(isoclinics) in the form of fringe contours. In the

early days of its development, quantitative isochro-

matic data were obtained easily only at the fringe

contours and tedious compensation techniques

were required to evaluate them at other places.

Extensive use of digital computers coupled with

cost-effective image processing systems have signif-

icantly revolutionized photoelastic analysis and

paved the way for a new branch of photoelasticity,

known as digital photoelasticity [1, 2].

Digital photoelasticity is truly a whole-field experi-

mental technique and has now matured to the level

of being able to quantitatively evaluate information

on isochromatics and isoclinics at every pixel over

the model domain [1147]. For visual appreciation

of the whole-field experimental data, these values

are plotted as grey-scale images with intensity values

from zero to 255 and are termed as isoclinic and/or

isochromatic phase maps. In the early 1990s, the use

of digital computers was confined to automating the

conventional data collection techniques with suitable

techniques being developed for fringe thinning,

fringe skeletonization, and fringe multiplication

methodologies [1]. Once the acquisition of intensity

information of the whole image was made possible

at video rates through the development of suitable

digital hardware, photoelasticity saw a paradigm

shift in the data acquisition techniques. Intensity-

based processing methods became more common-

place, and these data acquisition methods can be

broadly classified into spatial and frequency domain

methods. Phase-shifting, polarization-stepping, load-

stepping, and multiple wavelengths are techniques

that belong to the spatial domain method.

The Fourier transform (FT) approach is an exam-

ple of a frequency domain approach; however, its

application proved to be computationally expensive

and it could only provide either isoclinic or isochro-

matic data but not the two together [57]. The

drawbacks of FT methods led to the conclusion that

this approach was not a promising route for future

developments in digital photoelasticity [1], and

recent works on FT methods [810] have reinforced

this statement. Keeping this in mind, the present

review focuses on spatial domain methods in digital

photoelasticity.

The earliest reviews [1113] on digital photoelas-

ticity appeared in the period 19971998 and were

focused on the use of digital computers in photo-

*Corresponding author: Department of Applied Mechanics,

Indian Institute of Technology, Madras, Chennai, India,

e-mail: kramesh@iitm.ac.in

REVIEW 245

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

elasticity and highlighted the potential of intensity-

based approaches for further research. The reviews

of [2] and [14] focused on specific issues and were

also quite brief. The last 5 years have seen rapid

strides in advancing digital photoelasticity, and

solutions for many subtle issues raised by research-

ers have been obtained. Also, considerable success

has been achieved in solving problems in industrial

environments. While initial digital photoelastic

methods required specific optical arrangements

which may not be obtainable in a conventional

commercial polariscope, newer techniques have

resolved this problem. Now there is a range of tech-

niques that can be used to obtain either quick

approximate solutions or detailed studies in cases

where the accuracy of the evaluated parameters is

crucial. From a users point of view, for any specific

problem, one needs to know which technique is the

best one to use. Knowledge of the merits/drawbacks

of the techniques/algorithms will enable a user to

make an informed choice as per the requirement,

and also aid in the development of newer techni-

ques to overcome the drawbacks and enhance the

advancement of digital photoelasticity. Keeping this

in mind, this paper reviews the current status of

digital photoelasticity and also attempts to provide

logical explanations on the development of the field

wherever possible. The various sections are orga-

nized thematically rather than chronologically, to

facilitate easy access of information to the user.

2 EARLY METHODS FOR PHOTOELASTIC

PARAMETER EVALUATION

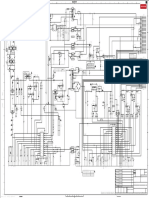

In order to appreciate the various algorithms used

in digital photoelasticity, it is desirable to know the

generic plane, mixed, and circular arrangements in

the polariscope, and the corresponding expressions

for intensity of the transmitted light (Fig. 1). In the

intensity expressions, a and b refer to the orienta-

tion of the polarizer and analyser, j and h refer to

the orientation of the slow axis of the I and II

quarter-wave plates, I

a

accounts for amplitude of

light, and I

b

accounts for the background light

intensity. The model parameters at the point of

interest are the phase retardation, d, and the orien-

tation of the reference axis, u. The phase-shifted

images are obtained by suitably rotating the optical

elements in the polariscope. Ramesh [1] used the

example of Tardys method of compensation to

highlight that the rotation of an optical element is

akin to providing a phase-shift. By recording a few

phase-shifted images as intensity distributions, and

subsequently processing them, one can obtain the

photoelastic parameter distributions over the model

domain. Although there are many reports in the lit-

erature on techniques that use this principle, the

credit for calling these methodologies as phase-

shifting techniques (PSTs) goes to Asundi [15]. The

concept of phase-shifting in photoelasticity was

first introduced by Hecker and Morche [16] in 1986.

They recorded five phase-shifted images and dem-

onstrated the possibilities for the determination of

isochromatic data over the whole domain using

a circular polariscope arrangement.

Later, Kihara [17] reported an eight-step method

using a mixed polariscope arrangement for data

acquisition and analysed the exit light using a

quarter-wave plate and an analyser combination.

Patterson and Wang [18] extended the work of

Hecker and Morche [16] and proposed a six-step

PST for the determination of both isoclinic and iso-

chromatic data which gave a new impetus to digital

photoelasticity. They were the first to obtain both

isoclinic and isochromatic data over the model

domain. Table 1 lists the optical arrangements for

the six-step PST proposed by Patterson and Wang

[18] which uses left circularly polarized light as the

incident light in all six steps.

Using the equations listed in Table 1, the isoclinic

and isochromatic parameters are obtained as [18]

u

c

=

1

2

tan

1

I

5

I

3

I

4

I

6

_ _

=

1

2

tan

1

I

a

sind sin2u

I

a

sind cos 2u

_ _

for sind 6 0

(1)

d

c

= tan

1

I

4

I

6

I

1

I

2

cos 2u

c

_ _

=tan

1

I

a

cos 2u

c

sind

I

a

cos 2u

c

cos d

_ _

for cos 2u

c

6 0

(2)

d

c

= tan

1

I

5

I

3

I

1

I

2

sin2u

c

_ _

=tan

1

I

a

sin2u

c

sind

I

a

sin2u

c

cos d

_ _

for sin2u

c

6 0

(3)

where, the subscript c refers to the principal value

of the inverse trigonometric function.

Since only fringe order N and principal stress

direction u need to be determined, Sarma et al. [19]

focused on obtaining the smallest number of optical

arrangements to evaluate these parameters and

proposed a three-step method using a plane polari-

scope. Although conceptually appealing, true

whole-field determination of the parameters was

not possible [20]. Asundi [15] extended Tardys

method of compensation using four phase-shifted

246 K Ramesh, T Kasimayan, and B Neethi Simon

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

images for the evaluation of isochromatic para-

meters lying on a particular isoclinic contour.

Dupre et al. [21] attempted a five-step method

with different optical arrangements. Ramesh and

Ganapathy [20] performed a Jones calculus analysis

of the six-step phase-shifting method of Patterson

and Wang [18] and simplified the evaluation of the

expression for the intensity of transmitted light.

This approach opened up the possibility of conve-

niently exploring new optical arrangements.

The challenges in the initial development of digi-

tal photoelasticity were the identification of the

right combination of optical arrangements and the

efficient processing of the recorded intensity data.

One of the issues that affected the evaluation of iso-

chromatic parameters was that, depending on the

choice of the basic equation (equation (2) or (3))

the denominator can go to zero for particular

values of u; thereby the parameter estimation

over the domain is not uniform. This issue was

ably addressed by Quiroga and Gonza`lez-Cano [22]

Table 1 Optical arrangements for six-step PST when

the angle u refers to the slow axis of the

model

j h b Intensity equation

3p/4 0 p/4 I

1

=I

b

+

Ia

2

(1 + cos d)

3p/4 0 3p/4 I

2

=I

b

+

Ia

2

(1 cos d)

3p/4 0 0 I

3

=I

b

+

Ia

2

(1 sin2u sind)

3p/4 p/4 p/4 I

4

=I

b

+

Ia

2

(1 + cos 2u sind)

3p/4 p/2 p/2 I

5

=I

b

+

Ia

2

(1 + sin2u sind)

3p/4 3p/4 3p/4 I

6

=I

b

+

Ia

2

(1 cos 2u sind)

Fig. 1 Generic arrangement of: (a) plane polariscope; (b) circular polariscope; and (c) mixed

polariscope

Digital photoelasticity A comprehensive review 247

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

who suggested the following form of intensity

processing

d

c

=tan

1

(I

5

I

3

) sin2u

c

+(I

4

I

6

) cos 2u

c

(I

1

I

2

)

_ _

=tan

1

I

a

sind

I

a

cos d

_ _ (4)

which whilst being deceptively simple is a significant

development as noted by Ramesh [1] in 2000; how-

ever, it took some time for researchers to see its

advantages.

Once the basic methodology was established for

whole-field parameter determination, the research

focus changed to refining the existing methodologies

for better accuracy. Mangal and Ramesh [23] using

a charge-coupled device (CCD) camera, experimen-

tally recorded the characteristic intensity variations

in high-stress gradient zones created by the poor

monochromation of the light source. To enhance the

accuracy of data reduction in stress concentration

zones, Ramesh and Sreedhar [24] reported the use of

optically enhanced tiling and Xue-Feng et al. [25]

extended this approach to phase unwrapping.

In 1998, Ajovalasit et al. [26] proposed a subtle

modification of the basic six-step phase-shifting

algorithm that has both left and right circularly

polarized light incident on the model. They showed

that such a modification can reduce the influence of

mismatches of the quarter-wave plates on the accu-

racy of the results. Sai Prasad and Ramesh [27] per-

formed a systematic study on the role of background

intensity on the performance of various PSTs for

both plane and circular polariscope arrangements.

This study highlighted the importance of explicitly

accounting for the background light intensity in

designing an algorithm in order for it to satisfactorily

process experimentally recorded images. This study

also suggested a simple way to assess any new PST.

Although several different phase-shifting algo-

rithms have been proposed [1], the expressions

used for the intensity of the transmitted light tend

to be similar. Ramesh [1] reported that there are

multiple possible optical arrangements and pre-

sented these arrangements for the popular six-step

PST (appendix 1). Prashant and Ramesh [28]

observed that the choice of optical arrangement

influences the processing of the experimentally

recorded images since the role of the quarter-wave

plate error is highly dependant on the choice of the

optical arrangement. Although the multiple optical

arrangements for the dark and bright fields yield

different intensity equations in the presence of

quarter-wave plate error e (appendix 1), the

multiple optical arrangements yield the same inten-

sity equation for I

3

, I

4

, I

5

, and I

6

. However, when the

input handedness is changed, the term sin e gets

negated as 2 sin e in the intensity equations. This

offers the possibility of judiciously combining left

and right circularly polarized lights to minimize the

quarter-wave plate error, which is the principle pos-

sibly used by Ajovalasit et al. [26]. Prashant and

Ramesh [28] and Prashant [29] showed that six sets

of such arrangements are possible (Table 2).

In 1997, Ramesh and Deshmukh [30] introduced

PST for colour images. They suggested that the

green image plane (l 546 nm) in the colour

domain can act as an optical filter. Ji and Patterson

[31] performed a study on the simulation of error in

automated photoelasticity for the six-step PST pro-

posed in [18]. They considered the effect of quarter-

wave plate mismatch on photoelastic parameters

for a white light source and suggested that median

band filters, with a centre wavelength of 550 nm,

reduced quarter-wave plate mismatch error.

Tamrakar and Ramesh [32] reported a more com-

prehensive simulation of quarter-wave plate mis-

match error and optical misalignment in digital

photoelasticity for few PSTs using a Jones calculus

approach. Ajovalasit et al. [33] reviewed the

quarter-wave plate mismatch error in the evaluation

of photoelastic parameters for a few data acquisi-

tion techniques in automated photoelasticity.

Initial research in digital photoelasticity was con-

fined to evaluating only the isochromatic fringe

order. Although the six-step method proposed by

Patterson and Wang [18] allows the estimation of

both isochromatic and isoclinic parameter values,

the method is highly sensitive to any mismatch

of the quarter-wave plates. The contribution by

Ajovalasit et al. [33] to minimize the influence of

quarter-wave plate error by making pertinent

changes in the optical arrangement is a significant

step, but if one also wants the isoclinic parameter

values, these methods fail miserably [34].

Table 2 Combinations of intensity equations that

give the least error in the presence of

quarter-wave plate

Set 1 Set 2 Set 3 Set 4 Set 5 Set 6

I#

1

I#

1

I#

1

I#

1

I#

1

I#

1

I#

2

I#

2

I#

2

I#

2

I#

2

I#

2

I#

3L

I#

5L

I#

3L

I#

5L

I#

3L

I#

3R

I#

3R

I#

5R

I#

3R

I#

5R

I#

4L

I#

4R

I#

4L

I#

6L

I#

6L

I#

4L

I#

5R

I#

5L

I#

4R

I#

6R

I#

6R

I#

6R

I#

6R

I#

6L

Prime denotes intensity equation in the presence of quarter-wave

plate error, while L and R denotes optical arrangement with left

and right circularly polarized light, respectively.

248 K Ramesh, T Kasimayan, and B Neethi Simon

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

3 METHODS TO EVALUATE ISOCLINIC

PARAMETERS

One of the earliest methods for isoclinic parameter

evaluation by processing intensity data was proposed

by Brown and Sullivan in 1990 [35]. They recorded

four isoclinics, i.e. 0, 22.5, 45, and 67.5 using

a monochromatic light source for whole-field isoclinic

evaluation, which they termed as a polarization-

stepping method. Since an isoclinic parameter cannot

be defined on an isochromatic skeleton they sug-

gested that, while recording polarization stepped

images, the load must be minimized such that only

fringe orders less than or equal to 0.5 are present.

Chen and Lin [36] proposed a polarization-stepping

method in which both the polarizer and the analyser

are kept parallel. In 1999, Mangal and Ramesh [37]

proposed a load-stepping method combined with

a PST to obtain the continuous isoclinic parameter

for the whole-field. The isoclinic parameters obtained

from two different loads are logically added to reduce

the isochromatic interaction in the isoclinics. Petrucci

[38] utilized the optical arrangement of Brown

and Sullivan [35] and replaced the monochromatic

light source with a white light source. In doing so, the

noise due to isochromaticisoclinic interactions was

significantly reduced even at moderate fringe orders.

Nurse [39] utilized a monochrome CCD camera

with three different filters to get three different wave-

lengths using a white light source. He adopted an

over-deterministic least squares approach to reduce

the noise in the evaluation of the isoclinic para-

meters. Kihara [40, 41] used three different wave-

lengths of linearly polarized light and proposed an

unwrapping technique using an arctangent function

to reduce the error due to quarter-wave plates.

Zhenkun et al. [42] proposed a five-step PST and per-

formed a comparative study between the use

of monochromatic light and white light. They con-

cluded that the isoclinic parameters obtained using

white light gave better results, except for the zones

where the fringe order was zero. Ajovalasit et al. [43]

studied the influence of spectral content of the light

source, spectral response of the camera, and quarter-

wave plate error on selected PSTs using white light.

The various PSTs for isochromatic parameter eval-

uation have resulted in isoclinic parameters with

variable accuracies. Ramji et al. [34] performed

a comparative study on various spatial domain algo-

rithms for the evaluation of isoclinic parameters.

They examined isoclinic values obtained using

plane, circular, and mixed polariscope arrangements,

and suggested that plane- polariscope-based algo-

rithms are better for isoclinic parameter evaluation.

4 SPECIAL ZONES IN PHASE MAPS AND PHASE

UNWRAPPING METHODOLOGIES

Wang and Patterson [44] noticed that whole-field

evaluation of the isochromatic parameter was errone-

ous in regions where u is beyond 6p/4, and proposed

the use of fuzzy sets to handle this problem. It is clear

that the evaluation of isochromatic parameters is

influenced by the isoclinics. As the initial focus in dig-

ital photoelasticity was to evaluate only isochromatic

data, researchers focussed on obtaining isochromatics

without considering the influence of u.

In 1996, Buckberry and Towers [45] proposed

a three wavelength approach to obtain isochromatic

parameters that were independent of isoclinic para-

meters and thereby free of ambiguous zones. This

approach was extended by Nurse [39] to obtain

both isochromatic and isoclinic parameters. In

1998, Ekman and Nurse [46] proposed a load-

stepping approach combined with a PST, which

was akin to the multiple wavelength approach, and

made an attempt to determine the isoclinic para-

meters using unwrapped isochromatic parameters.

However, the results were noisy and furthermore

the information obtained in the low-stressed

regions was of poor quality. Ramesh and Tamrakar

[47] proposed a new approach to the processing of

data recorded in the load-stepping approach [46]

and reduced the noise significantly in the evalua-

tion of the isochromatic phase map. Later, Asundi

et al. [48] and Liu et al. [49] proposed a two-step

load-stepping method. The main disadvantages of

load-stepping approaches are that they require

a large number of images (compared to a normal

PST) and are applicable only to live-loaded models.

There have been attempts to develop a suitable

expression for fractional retardation evaluation,

which does not use u and Ramesh and Mangal [50]

proposed one such method using a normal six step

PST. However, its use who proposed the use of

a normal six-step PST, unfortunately, its use intro-

duced an ambiguity in the sign of the fractional

retardation. This could be addressed by invoking

the fringe gradient direction and they called their

methodology to resolve this ambiguity an interac-

tive approach.

In conventional photoelasticity, the slow and fast

axes have no role to play in data interpretation.

However, Vinayak et al. [51] highlighted the role of

the fast and slow axes in digital photoelasticity by

incorporating them in the final intensity equations.

Their study reinforced the earlier observations on

the influence of the isoclinic value on the evalua-

tion of the isochromatic parameter. The arctangent

Digital photoelasticity A comprehensive review 249

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

function used in most of the algorithms returns

a principal isoclinic value in the range -p/4 \u \

p/4, whereas physically the isoclinic value is in the

range -p/2 \u \p/2. In view of this, the evaluated

u corresponds to different principal stress directions

in different zones which can be seen in the isoclinic

phase map (Fig. 2(a)); the zones corresponding to

one of the principal stresses are labelled as incon-

sistent zones. Ramesh [3, 4] noted that the inconsis-

tent zones in the isoclinic phase map lead to the

formation of ambiguous zones (Fig. 2(b) in the iso-

chromatic phase map, in which the direction of

fractional fringe order gradient is reversed. Such an

understanding was missing in the early develop-

ments of digital photoelasticity. It is surprising that

although the consistency aspect of isoclinics has

influenced the evaluation of isochromatic data, the

noise present in the isoclinics did not affect it [1].

Regularized phase tracking (RPT) to demodulate

a single noisy interferogram [52] was extended to

digital photoelasticity by Quiroga and Gonza`lez-

Cano [53]. They used five images to estimate the iso-

clinic and isochromatic parameters and a quality

map to determine the path of the RPT. Since the iso-

clinic parameters were not used in the estimation of

the isochromatic parameters, they are free of ambi-

guity and also unwrapped directly. RPT is a sequen-

tial phase and frequency estimation strategy which

uses the information contained in previously demo-

dulated pixels to demodulate the subsequent pixels

in a fringe pattern. It works by minimizing a cost

function which has at least two terms: one to

account for the fidelity between the estimated func-

tion and the observed fringe field, and the other

(called the regularization term) to ensure smooth-

ness of the estimated function. The main drawback

of RPT methods is that a large processing time

is required to make a good estimation of the para-

meters. Moreover, the estimation is poor in areas of

high fringe density and the technique has been

shown to work only for simple fringe fields.

The isochromatic phase map needs to be free of

ambiguous zones for phase unwrapping to be mean-

ingful. Figure 3(a) shows the phase map of a disk

under diametral compression (from experimentally

recorded images) in which near the load application

points one observes a black streak, and after that

there is a reversal in the fractional fringe order gradi-

ent indicating an ambiguous zone. Even though the

ambiguous zone boundaries are not well defined,

the interactive approach [50] which operates on all

six phase-shifted images takes care of this and the

isochromatic phase map after the removal of ambig-

uous zones is shown in Fig. 3(e). To simplify data

processing, efforts have also been aimed at develop-

ing methodologies to work directly on the phase

map. Prasad et al. [54] developed an image proces-

sing methodology which works directly on the phase

map to remove the ambiguous zones; its limitation

is that the ambiguous zone boundary should be dis-

tinct and sharp. Figure 3(b) shows the problem of

a ring under diametral compression in which the

ambiguous zone boundaries are seen distinctly and

Fig. 3(f) shows the corrected phase map using the

image processing methodology. Prashant et al. [55]

introduced a theta checking approach to identify

subtle ambiguous boundaries by monitoring the iso-

clinic values, which was demonstrated for the prob-

lem of a beam under three-point bending (a small

portion near the central region is shown in Fig. 3(c)),

and the corrected phase map is shown in Fig. 3(g).

Figures 3(d) and 3(h) show the variation of isoclinics

over the depth of the beam. In 2006, Ashokan and

Ramesh [56] proposed two novel approaches: the

simulated dark field approach and the negation

Fig. 2 Theoretically simulated phase maps for disc

under diametral compression (one-quarter is

shown) (a) isoclinic phase map with inconsis-

tent zone and (b) isochromatic phase map with

ambiguous zone. The isochromatic skeleton

seen in (a) is where the isoclinic is not defined

Fig. 3 Ambiguous zone: (a) boundary not seen dis-

tinctly: (b) boundary seen distinctly; (c)

boundary is subtle; (d) isoclinics variation

along the depth of the phase map shown in

(c). Ambiguous zones are corrected by: (e)

interactive approach; (f) image processing

approach; (g) monitoring the isoclinic value;

(h) isoclinics variation along the depth of the

phase map shown in (g)

250 K Ramesh, T Kasimayan, and B Neethi Simon

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

approach. The simulated dark field approach pro-

vides a simple way of identifying the ambiguous

zones in the isochromatic phase map.

In the case of isoclinic phase maps, unwrapping

refers to the process of obtaining the direction of

either of the principal stresses s

1

or s

2

consistently

over the domain, whereas in the case of isochro-

matic phase maps, unwrapping refers to suitable

addition of the integral value to the fractional retar-

dation values to get continuous fringe order data

[57]. Phase unwrapping in an isochromatic phase

map received initial attention in digital photoelasti-

city. For effective phase unwrapping, the phase map

has to be free of ambiguous zones [56]. The two key

issues are: how to avoid propagation of errors and

how to handle complex geometries with cut outs.

The simplest phase unwrapping scheme is to use

a raster scanning approach. Early algorithms adopted

this strategy and Madhu and Ramesh [58] proposed

an approach to unwrap complex geometries contain-

ing cut outs. The multiply connected models are

unwrapped by dividing them into an assembly of

simply connected domains; this concept is known as

domain delimiting. The boundary coordinate infor-

mation required for delimiting is obtained using

boundary extraction techniques [59]. Domain mask-

ing is used to mask out the zone outside the simply

connected domain which is currently being

unwrapped. Raster scanning in principle can propa-

gate noise and this topic has been extensively investi-

gated in the literature. Quiroga et al. [60] augmented

Bones technique [61] and used the second difference

of the phase of the neighbourhood pixels as a selec-

tion criterion for phase unwrapping of subsequent

pixels. Asundi and Wensen [62] adopted grey-scale

masking and the flood-fill approach to phase unwrap-

ping. This is a fast phase unwrapping algorithm in

which areas with higher reliability are unwrapped

before those with a lower reliability. Following the

practice on the use of quality maps in other interfer-

ometry techniques, Siegmann et al. [63] introduced

the use of quality-guided unwrapping algorithms in

photoelasticity and suggested the use of phase deriva-

tive variance for evaluating the quality map. Ramji

et al. [64] performed a comparative study of autono-

mous phase unwrapping algorithms in digital photoe-

lasticity and recommended the use of the phase

derivative variance and maximum phase gradient

approach to evaluate a quality map.

5 FOUR-STEP METHODS

In time-varying problems, recording multiple

images can be cumbersome. In order to extend

digital photoelasticity to such situations, attention

has been focussed on developing PSTs that use the

minimum number of images. Sarma et al. [19] were

the first to proceed in this direction in 1992; their

three-step method was found to be insufficient, as

experimentally, four variables need to be deter-

mined [1, 13, 18, 27], namely, N, u, I

a

, and I

b.

Thus,

development of four-step methods was a logical

step towards this goal.

The first four-step PST was proposed by Barone

et al. [65] in 1997. They utilized the first four optical

arrangements of Patterson and Wangs six-step

arrangement for the evaluation of whole-field photoe-

lastic parameters [18]. Later in 1998, Patterson and

Wang [66] reduced their six-step method to a four-

step method by removing the second and last optical

arrangements and recorded four phase-shifted images

simultaneously using four cameras. Plouzennec et al.

[67] used a four-step PST with plane polariscope

arrangements for the evaluation of photoelastic para-

meters. The expression for evaluating the isochromatic

parameters contained a cosine function, which posed

problems in unwrapping. Asundi et al. [68] proposed

a four-step method that could be set in a conventional

commercial polariscope, which used the first, second,

and fourth optical arrangements of Ajovalasit et al.

[26] and their fifth optical arrangement was suitably

modified. In 2002, Ajovalasit et al. [33] proposed an

optimum four-step method. They essentially used the

first four optical arrangements of their six-step

method [26] with a modification of the first two opti-

cal arrangements to use crossed quarter-wave plates

as in conventional photoelasticity, which improved

the overall accuracy of the evaluated photoelastic

parameters.

In 2005, Prashant and Ramesh [28] performed

a systematic study on the role of the quarter-wave

plate error on the performance of the various four-

step PSTs. They found that the error [(d# 2 d) / 2p]

varied as a function of u and is the least in an over-

all sense for the algorithm proposed by Ajovalasit

et al. [33].

6 TOTAL FRINGE ORDER EVALUATION

USING A SINGLE IMAGE

There have been several attempts to evaluate the

total fringe order using a single isochromatic image

with monochrome, tricolour, or white light as source

of illumination. Servin and Quiroga [69] used a single

monochrome bright field image to obtain unwrapped

isochromatics, by applying a RPT with a three-level

quality map. Yoneyama et al. [70] developed a trico-

lour photoelastic system for the evaluation of

Digital photoelasticity A comprehensive review 251

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

isoclinic and isochromatic parameters using a single

tricolour image; however, they reported that the

methodology lacked repeatability. Quiroga et al. [71]

adapted a RPT to obtain isochromatic parameters

from a single tricolour image; however, this approach

was computationally intensive.

In RGB photoelasticity (RGBP) [72, 73] or three-

fringe photoelasticity (TFP) [74], a single isochromatic

image under white light is used to estimate the total

fringe order by comparing the red (R), green (G), and

blue (B) values of the unknown photoelastic fringe pat-

tern with a calibration table. For any test data point,

an error term e is defined as

e =

(R

e

R

c

)

2

+(G

e

G

c

)

2

+ (B

e

B

c

)

2

_

(5)

where the subscripts e and c refer to the experi-

mentally measured values and the values in the cal-

ibration table, respectively. The calibration table is

searched until the error e is a minimum to get the

total fringe order. Although the approach is straight-

forward, noise is present in the evaluated fringe

order. Ramesh and Deshmukh [74] attempted to

reduce the noise and found that the use of the dif-

ference in RGB values between dark and bright field

images gave less noise, but required the recording

of two images at a time.

There are several reports in the literature that sug-

gest that the noise present in the results obtained by

TFP could be removed by imposing fringe order con-

tinuity [73, 7578]. Ajovalasit et al. [73] proposed

a method to reduce the noise by identifying two

minima and selecting the one which had a fringe

order closer to the neighbouring pixel. Quiroga et al.

[75] proposed the use of an additional regularization

term to account for the smoothness of the estimated

fringe order and demonstrated it for a simple prob-

lem. Ashokan and Ramesh [77] proposed quality-

assisted TFP to identify and iteratively remove noise

in the total fringe order evaluated using conventional

TFP. Dubey and Grewal [78] found that by applying

a median filter on the recorded dark field isochro-

matic image, one could obtain continuous fringe

order variation if the filtering process was repeated

a sufficient number of times.

Madhu and Ramesh [76] highlighted that noise

in TFP is due to the repetition of colour and incor-

porated fringe order continuity by adding a new

term in the error definition as

e =

(R

e

R

c

)

2

+(G

e

G

c

)

2

+(B

e

B

c

)

2

+(N

p

N)

2

3 K

2

_

(6)

where N

p

is the fringe order obtained for the neigh-

bourhood pixel to the point under consideration in

the specimen, N is the fringe order at the current

checking point of the calibration table, and K is a

problem-dependant factor that is specified by the

user. This approach was christened refined TFP

(RTFP) and its single-shot data acquisition capabil-

ity has been demonstrated effectively for a transient

thermal stress problem [79].

Ideally, the same test specimen and lighting con-

ditions are used in both the calibration and applica-

tion experiments, which is often not possible in an

industrial scenario, and simple ways of modifying

the calibration table have been investigated. Madhu

et al. [80] introduced a colour adaptation technique

in TFP in which the no-load bright field images of

the calibration and application specimens are used

to tune the calibration table developed for a standard

material to suit the specimen under test. Recently,

Neethi Simon and Ramesh [81] proposed another

colour adaptation scheme using a single image; thus

it is applicable to analysing stress-frozen slices as

well. Though the focus was to accommodate only

a small tint variation, in view of the two-point

scheme adopted, the method was found to also work

for large variations [82]. Stress-frozen slices of a fuse-

lage square lug were chosen to illustrate the use of

colour adaptation in TFP ((Fig. 4(a)). Figure 4(b)

shows the total fringe order obtained by conven-

tional TFP and the noise present therein is reduced

using the colour adaptation technique (Fig. 4(c)).

The streaks in Fig. 4(c) are removed by RTFP (Fig.

4(d) and further improved by smoothing (Fig. 4(e)).

TFP was originally used to estimate total fringe

orders up to a value of three as beyond this point

the colours tend to merge [74]; however, there have

been attempts to push this limit. Ajovalasit and

Petrucci [83] combined the RGB values and a PST

to evaluate the continuous fringe order up to

a value of four. This hybrid technique removes the

unwrapping step in the isochromatic parameter

estimation but requires more than one image. Jones

and Wang [84] proposed fringe combination match-

ing to extend the isochromatic parameter estima-

tion up to a fringe order value of 5.5. It has been

shown [75, 85] that by implementing a selective

search within the calibration table, the total fringe

order up to a value of 12 could be estimated.

Ajovalasit et al. [85] suggested the use of a filament

lamp with a continuous spectrum to measure up to

four fringe orders, and a fluorescent lamp with a dis-

crete spectrum to measure up to 12 fringe orders.

They also proposed the use of a search window in

the calibration table such that one could directly

identify the local minima which are of interest,

rather than the global minima, using the standard

equation itself.

252 K Ramesh, T Kasimayan, and B Neethi Simon

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

7 DIGITAL TECHNIQUES FOR OTHER

VARIANTS OF PHOTOELASTICITY

7.1 Reflection photoelasticity

Ramesh and Mangal [86] extended digital photo-

elastic analysis to reflection photoelasticity by

designing a new reflection polariscope in which

the individual elements could be rotated indepen-

dently, and they performed a six-step PST to evalu-

ate both isoclinic and isochromatic parameters.

Later, Chen and Chen [87] performed polarization

stepping in reflection photoelasticity. Patterson

and Wang [66] and Lesniak et al. [88] extended the

use of four-step PST for reflection photoelasticity.

In 2008, Chang et al. [89] applied a modified ver-

sion of RGBP to a reflection arrangement. In this,

they generated a calibration table only for discrete

fringe orders and interpolated the values between

them.

Adopting a conventional commercial reflection

polariscope for digital reflection photoelasticity was

made possible by Kasimayan and Ramesh [90], who

proposed a simple five-step approach to obtain

accurate whole-field isoclinic and isochromatic

parameters. The first four steps record four isocli-

nics that are used for whole-field isoclinic determi-

nation and the last step records a dark field

isochromatic image which is processed using RTFP

to obtain the total fringe order for the whole

domain. The effectiveness of the five-step method

was demonstrated for the problem of assembly

stresses in a flange coupling (Fig. 5).

7.2 Integrated photoelasticity

In integrated photoelasticity, one has to experimen-

tally measure three parameters to define the opti-

cally equivalent model [91] for every point in the

specimen: the axis of the retarder (u); the retarda-

tion introduced by the retarder (2D); and the rota-

tory power of the rotator (g). Mangal and Ramesh

[92] were the first to use digital photoelastic techni-

ques for integrated photoelasticity. They proposed

a ten-step PST to determine the three characteristic

parameters. Aben [93] proposed a method for the

interpretation of the integrated fringe patterns for

FlamantBoussinesq problems under a concentrated

load. Later, Tomlinson and Patterson [94] proposed

a six-step PST for the evaluation of whole-field

characteristic parameters. They reported that

although the wrapped phase maps of characteristic

parameters are satisfactory, the unwrapped phase

maps need to be improved. In 2007, Hecker [95]

presented a review of PSTs applied to integrated

photoelasticity. He investigated the effect of white

light and a monochromatic light source with plane

and circular polariscope arrangements for the eval-

uation of characteristic parameters, and concluded

that the white light plane polariscope with two

polarizers lead to enhanced characteristic direc-

tions, whereas the monochromatic light circular

and mixed polariscopes gave better characteristic

retardation.

7.3 Dynamic photoelasticity

For impact studies, the speed of the stress waves

determines the exposure time. To-date, the demon-

stration of digital photoelastic approach for such

ultra-fast events has been shown only by Asundi

et al. [96] who performed dynamic photoelastic anal-

ysis using a time delay and integration (TDI) camera.

Fig. 4 Stress-frozen slice of fuselage square lug (a)

colour dark field isochromatics. The grey scale

image representation of fringe order variation

obtained by (b) TFP without colour adapta-

tion; (c) TFP with colour adaptation; (d) RTFP

applied for (c); (e) smoothed isochromatics in

colour plot (colour images appear in black and

white in the print version)

Digital photoelasticity A comprehensive review 253

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

Asundi and Sajan [97] recommended the use of light-

emitting diodes in conjunction with the TDI camera

instead of the laser diode they initially used [98].

Dynamic phase-shifting was achieved by splitting the

beam into four using a multispectral imager [96].

8 DIGITAL POLARISCOPES

To record phase-shifted images, one needs to rotate

the individual optical elements to the desired opti-

cal arrangement, one at a time. As this is prone to

optical misalignment and is also cumbersome,

efforts have been aimed at developing automated

polariscopes. The first generation of these replaced

manual rotation of the optical elements by stepper

motors controlled by a personal computer [99,

100]. Lesniak et al. [101] and Zickel et al. [102]

developed a grey field polariscope which had a sta-

tionary input polarizer and quarter-wave plate. The

output analyser was rotated at a constant speed and

eight images were recorded in one half-cycle for

photoelastic parameter evaluation. Aben et al. [103]

developed a second-generation automated polari-

scope, specifically for the evaluation of residual

stress in glass components. In this set-up, instead

of rotating the optical elements, the polarization of

the input light is modified based on the principle of

reversibility of optical systems; thereby, only one

stepper motor is needed for automation.

Third-generation digital polariscopes aim at

simultaneously recording as many phase-shifted

images as possible, and they paved the way for

dynamic and real-time photoelastic analysis.

Hardware limitations forced researchers to use only

four-step PSTs (minimum number of images) for

developing automated polariscopes. The first model

proposed by Patterson and Wang [66] required four

separate CCD cameras. It used prismatic beam

splitters, making data interpretation difficult, as it is

difficult to account for their polarization behaviour.

A compact unit which uses only one CCD camera

Fig. 5 Assembly stresses in a flange coupling (a) Photograph showing the assembly; experimen-

tally obtained (Right quarter portion is shown) (b) dark field isochromatics; (c) unwrapped

isoclinics in grey scale; (d) unsmoothed isoclinics in binary; (e) smoothed isoclinics in

binary; (f) total fringe order by TFP; (g) total fringe order by RTFP; (h) smoothed isochro-

matics colour plot (but appearing in black and white in the print version)

254 K Ramesh, T Kasimayan, and B Neethi Simon

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

has been developed by Asundi et al. [96] who modi-

fied a multi-spectral imager for PST; however, it is

bulky and shares the problem of prismatic beam

splitters. Prashant et al. [104] performed prelimi-

nary studies on a multiple polar imager and

explored its use in digital photoelastic studies.

Lesniak et al. [88] combined the features of a polari-

scope and a kaleidoscope to develop a piece of

equipment, which they christened as poleidoscope.

In this set-up, a suitable lens is developed by sec-

tioning a conventional lens into four quadrants, and

separating the quadrants by a small amount,

thereby giving four identical images. Thus, they

overcame the problem of prismatic beam splitters

and were able to perform both reflection and trans-

mission photoelastic studies.

Yoneyama et al. [105] performed real-time PST at

video rates by rotating an analyser at a constant

speed and the output quarter-wave plate at twice the

speed of the analyser. Images were continuously

recorded using a CCD camera, to get the phase dis-

tributions of isochromatic and isoclinic parameters.

However, the isoclinic parameter obtained for

a time-varying load was not found to be as accurate

as the isochromatic parameter. Later, Lei et al. [106]

adopted the technique proposed by Yoneyama et al.

[105] and described 14 algorithms by changing the

orientation of the analyser and second quarter-wave

plate. Among the 14 algorithms, five of them were

found to be good in determining the whole-field iso-

chromatic parameters with a slow time-varying load.

9 COMPOSITE METHODS FOR PHOTOELASTIC

PARAMETER ESTIMATION

In 2002, Barone et al. [107] proposed a composite

six-step PST that is theoretically free of quarter-

wave plate errors in isoclinic studies, and the errors

are moderate in isochromatic studies. Around this

time it was realized by the research community that

though isoclinic evaluation is simple in conven-

tional photoelasticity, it is quite involved in digital

photoelasticity. Thus, attention was focused on

improving the evaluation of isoclinics by PST. Ramji

and Ramesh [108] reported another composite six-

step PST to minimize the errors. However, both of

the methods reported in [107] and [108] use very

complex equations for the evaluation of photoelas-

tic parameters and later studies [109, 110] showed

that these methods are very sensitive to optical

misalignment errors. Yoneyama and Kikuta [111]

attempted to reduce the influence of quarter-wave

plate error by proposing a seven-step PST. Though

the accuracy of isoclinics seemed comparable to

that of Barone et al. [107], the isochromatic para-

meters were poor in comparison to the values

obtained in Barone et al. [107] and Patterson and

Wang [18]. DAcquisto et al. [112] showed that the

quarter-wave plate mismatch error, which is usually

considered to be a constant, is in fact non-

uniformly distributed over the quarter-wave plate.

Recently, Ramji et al. [110] performed an error anal-

ysis that incorporated both the non-uniform quar-

ter-wave plate error and the misalignment of the

optical elements.

In order to improve the accuracy of evaluating

photoelastic parameters in complex problems,

Ramji and Ramesh proposed a ten-step PST [113].

The proposed methodology combine the four-step

approach of Brown and Sullivan [35] for isoclinic

data evaluation and a six-step circular -polariscope-

based method for isochromatic data evaluation

(Table 3). The optical arrangements were carefully

selected to minimize the influence of quarter-wave

plate mismatch error. As inconsistent zones in iso-

clinic phase maps cause the formation of ambigu-

ous zones in an isochromatic phase map, (Fig.6(a))

initially the isoclinics need to be unwrapped.

Unwrapping of the isoclinic phase map is com-

plicated by the presence of isotropic points and

p-jumps. At an isotropic point all isoclinics merge,

while a p-jump is a sudden jump of 180 in the isocli-

nic values which starts from an isotropic point [4]. To

take care of isotropic points while unwrapping, Pinit

and Umezaki [114,115] proposed a four-step colour

PST and a simple phase unwrapping algorithm, and

Table 3 Optical arrangements and the equations

for parameter estimation by the ten-step

method

a j h b Intensity equation

p/2 0 I

1

=I

b

+I

a

sin

2 d

2

sin

2

2u

5p/8 p/8 I

2

=I

b

+

Ia

2

sin

2

d

2

1 sin4u

3p/4 p/4 I

3

=I

b

+I

a

sin

2

d

2

cos

2

2u

7p/8 3p/8 I

4

=I

b

+

Ia

2

sin

2

d

2

1 + sin4u

p/2 3p/4 p/4 p/2 I

5

=I

b

+

Ia

2

(1 + cos d)

p/2 3p/4 p/4 0 I

6

=I

b

+

Ia

2

(1 cos d)

p/2 3p/4 0 0 I

7

=I

b

+

Ia

2

(1 sin2u sind)

p/2 3p/4 p/4 p/4 I

8

=I

b

+

Ia

2

(1 + cos 2u sind)

p/2 p/4 0 0 I

9

=I

b

+

Ia

2

(1 + sin2u sind)

p/2 p/4 3p/4 p/4 I

10

=I

b

+

Ia

2

(1 cos 2u sind)

Parameter estimation:

u

c

=

1

4

tan

1

I

3

I

2

I

4

I

1

_ _

d

c

=tan

1

(I

9

I

7

) sin2u +(I

8

I

10

) cos 2u

(I

5

I

6

)

_ _

u used in the evaluation of d

c

is the unwrapped isoclinic value.

Digital photoelasticity A comprehensive review 255

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

Villa et al. [116] proposed a RPT unwrapping algo-

rithm. Zhang et al. [117] proposed a 12-step PST to

obtain isochromatic and isoclinic parameters that are

free of inconsistencies, but the accuracy obtainable is

limited. In 2008, Ramji and Ramesh [57] proposed an

adaptive quality-guided phase unwrapping algorithm

for unwrapping isoclinics which is able to accom-

modate the presence of isotropic points as well as

p-jumps. It uses phase derivative variance to gener-

ate the quality map (Fig 6(b)) which provides the

information of good and bad quality pixels and suit-

ably selects the path of unwrapping to get the contin-

uous isoclinics (Fig 6(c)).

The semblance of an isochromatic skeleton on

isoclinic phase map (Fig. 6(c)) is actually noise due

to isochromaticisoclinic interaction and smoothing

of isoclinic data is mandatory for their use in stress

separation studies. This noise is clearly evident when

one looks at the binary representation of isoclinics

(Fig. 6(e)). Ramji and Ramesh [57] proposed an out-

lier smoothing algorithm to reduce the noise due to

isochromaticisoclinic interaction (Fig. 6(f)) which

was found to be robust [118]. However, this required

domain delimiting at isotropic points and p-jumps;

Kasimayan and Ramesh [119] improved the outlier

smoothing algorithm to automatically take care of

Fig. 6 Ring under diametral compression. Experimentally obtained: (a) wrapped isoclinic phase

map (with inconsistent zones marked); (b) quality map to identify the good quality and

bad quality zones in isoclinic phase map. Unwrapped isoclinic phase map: (c) before

smoothing (faint isochromatic skeletons are actually noise); (d) after smoothing. Binary

plot of isoclinics: (e) before smoothing; and (f) after smoothing; (g) isochromatic phase

map free of ambiguous zones obtained by the ten-step method; (h) quality map to iden-

tify the good quality and bad quality zones in isochromatic phase map; (i) colour repre-

sentation of unwrapped isochromatics (but appearing in black and white in the print

version)

256 K Ramesh, T Kasimayan, and B Neethi Simon

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

this problem. The unwrapped and smoothed isocli-

nic values (Fig. 6(d)) are then used to obtain isochro-

matics, which are completely free of ambiguous

zones (Fig. 6(g)) and subsequently unwrapped to get

the continuous fringe order (Fig. 6(i)).

10 STRESS SEPARATION

In certain class of problems, it is necessary to find

individual stress components over the domain.

Although review papers exist on general stress sepa-

ration methodologies [120, 121], here only those

techniques which use digital photoelastic methods

are reviewed.

In 1998, Quiroga and Gonza`lez-Cano [122] pre-

sented a procedure for stress separation using prin-

cipal stress difference with the digital photoelastic

techniques available at that time, and the sum of

principal stresses using the multi-grid numerical

technique for plane stress problems. However, the

sum of principal stresses data for the problem of

a disk under diametral compression obtained by

them is distorted and lacked symmetry. Later,

Mangal et al. [123] used finite element modelling

(FEM) to get the sum of the principal stresses and

a six-step PST to get the principal stress difference.

Ramesh and Mangal [124] proposed a methodology

for stress separation using only isochromatics data

with multiple oblique incidences. However, the

technique required data with a very high accuracy.

Yoneyama et al. [125] combined a MachZehnder

interferometer with a circular polariscope to sepa-

rate the stresses. A load-stepping approach [47] was

used to obtain (s

x

- s

y

) and a five-step phase step-

ping technique was used to obtain (s

x

+ s

y

). In

1997, Zhenkun et al. [126] proposed a similar

method in which they adopted load-stepping to rec-

tify inconsistency and ambiguous zones in isoclinic

and isochromatic phase maps. These methods

require either two experimental methods or the use

of FEM. Petrucci and Restivo [127] proposed a pro-

cedure for the stress separation along stress trajec-

tories, starting from free boundaries, based on the

integration of LameMaxwell equations. This

requires precise trajectory calculation for which

they also proposed an algorithm.

The parameters obtained by the ten-step

method of Ramji and Ramesh [113] are accurate

and can be used to perform stress separation by

the shear difference technique [118, 128]. For digi-

tal implementation, a suitable boundary identifica-

tion technique [58] as well as a careful scanning

and book-keeping of the values [59] are needed.

Figures 7(a) to (c) show the smoothed pseudo

stress-fringe contours of s

x

, s

y

, and t

xy

for the

problem of a ring under diametral compression

(one quarter of the model). The quantitative com-

parison of the individual stress components with

the analytically obtained values (Fig. 7(d)) is quite

good. In this problem, the presence of free bound-

aries simplified the implementation of the meth-

odology. As the presence of a free boundary is not

always possible, Ashokan and Ramesh [129] pro-

posed an adaptive scanning approach, in which it

is sufficient to know the stress components for just

one point in the model domain.

11 FUSION OF RAPID PROTOTYPING, FEM,

AND DIGITAL PHOTOELASTICITY

The potential of combining rapid prototyping for

model making, digital photoelasticity for experi-

mental analysis, and FEM for numerical analysis

for a design scenario was reported by Ramesh

et al. [130]. Issues related to the identification of

a suitable stereolithography resin [131] and build

styles [132] were also addressed. The stereolithogra-

phy process introduces a characteristic noise and

a method to handle this effectively in digital photo-

elastic analysis has been recently proposed [133].

Fig. 7 Variation of individual stresses (smoothed) for

the problem of a ring under diametral com-

pression determined by shear difference algo-

rithm. Pseudo stress-fringe contours: (a) s

x

;

(b) s

y

; (c) t

xy

; (d) quantitative comparison of

individual stress components obtained using

shear difference with analytically obtained

stress components

Digital photoelasticity A comprehensive review 257

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

Comparison of FEM results with that of photo-

elasticity could be made simpler if suitable

post-processing of FEM results is done to plot

photoelastic fringes. Ramesh et al. [134] were the

first to present a realistic way of plotting fringe con-

tours from FEM results by invoking a scanning

scheme. Thickness variation of the fringes is mim-

icked by plotting the variable with an error term e.

The method was later extended to plot fringe con-

tours both in grey and colour, for photoelastic coat-

ings [135]. The use of a plotting scheme to identify

errors in FEM [136] and also general guidelines to

model discontinuities better in FEM discretization

[137] have also been reported. Umezaki and

Terauchi [138] have extracted isotropic points from

an isoclinic phase map using the simulated con-

tours obtained from FEM. Ragulskis and Ragulskis

[139] plotted isoclinics by post-processing FEM

results and used a smoothing procedure to generate

results suitable for hybrid experimentalnumerical

analysis.

A novel use of fringe plotting for three-

dimensional (3D) analysis has been reported by

Karthick Babu and Ramesh [140]. This facilitates

selection of a suitable load, slicing plan, and view-

ing direction for stress-frozen models [141] and is

important as mechanical slicing destroys the model.

For an arbitrary slice, the post-processing of a 3D

FEM model is illustrated for the problem of

a sphere under diametral compression (diameter =

61 mm, load = 378 N, F

s

= 0.35 N/mm/fringe). The

sphere is modelled using a commercial FEM pack-

age using tetrahedral elements (Fig. 8(a)). For

a slice whose location is shown in Fig. 8(b), the

experimental dark field isochromatics (Fig. 8(c))

closely match the dark field isochromatics plotted

from FEM results (Fig. 8(d)).

The success of post-processing FEM results for

plotting fringe contours also opened up new possi-

bilities. Identification of inconsistent zones in an

isoclinic phase map and the ambiguous zones in an

isochromatic phase map are tedious and complex

problems. To resolve these issues, Ashokan and

Fig. 8 (a) Sphere subjected to compression discretised

using ten-noded elements; (b) location of slice;

(c) experimental dark field image; and (d) dark

field isochromatics plotted from FEM results

Fig. 9 Circular disk under three radial loads: (a) FEM

mesh with boundary conditions; (b) numeri-

cally obtained wrapped isoclinic phase map;

(c) numerically obtained unwrapped isoclinic

phase map; (d) experimental wrapped isoclinic

phase map; (e) experimental unwrapped isocli-

nic phase map; (f) numerically obtained iso-

chromatic phase map with ambiguous zones;

(g) numerically obtained isochromatic phase

map without ambiguous zones; (h) experimen-

tal isochromatic phase map with ambiguous

zones; and (i) experimental isochromatic phase

map without ambiguous zones

258 K Ramesh, T Kasimayan, and B Neethi Simon

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

Ramesh [142] proposed an eigenvalue approach

for plotting the phase maps with and without

ambiguous/inconsistent zones, by post-processing

the FEM results. For a disc under three radial loads

(Fig. 9(a), the simulated phase maps plotted from

FEM results (Figs 9(b), (c), (f), and (g)) compare

well with the experimental phase maps (Figs 9(d),

(e), (h), and (i)). Recently, the identification of

inconsistent zones by plotting an inconsistency

map from FEM results has been proposed [143].

The plotting of fringes and phase maps can be fur-

ther simplified by judiciously using the post-

processing features of the FEM packages [144].

12 CONCLUSIONS

Digital photoelasticity provides scope for evaluating

photoelastic parameters over the entire model

domain, and the range of benchmark problems and

application problems that have been solved using

this technique is summarized in Appendix 2.

Among the various digital photoelastic techniques

in the spatial domain, PSTs play a vital role in the

evaluation of photoelastic parameters. This survey

has highlighted that for isochromatic parameter

determination, a circular polariscope arrangement

is essential; the influence of quarter-wave plate

error can be minimized by using the conventional

wisdom of keeping them in the crossed position as

far as possible, and also by intelligently combining

the use of right and left circularly polarized incident

light. For isoclinic determination, use of a plane

polariscope is advantageous and a simple polariza-

tion-stepping approach [35] gives better results. If

a monochromatic light source is used, then the iso-

clinic parameters are not defined at isochromatic

skeletons; thereby, smoothing of the isoclinic phase

map is essential and an outlier smoothing algorithm

is found to perform better than other smoothing

strategies. Data extraction in these zones is better

when white light is used; nevertheless, further

smoothing is desirable.

Although the role of inconsistent and ambiguous

zones in isoclinic and isochromatic phase maps was

only partly understood in the early developments of

digital photoelasticity, now effective methods have

been developed to handle these zones. The use of

adaptive quality-guided phase unwrapping [57] has

effectively removed the inconsistent zones in the

isoclinic phase map and the use of unwrapped iso-

clinics in the evaluation of isochromatic parameters

has totally eliminated the appearance of ambiguous

zones in isochromatic phase maps. Identification of

inconsistent zones is difficult for complex problems

and in such situations it can be done numerically

[142, 143] as suitable post-processing methodolo-

gies of FEM results have been developed.

Though in principle, a four-step method is suffi-

cient for evaluating all the requisite parameters, if

accuracy is equally important, then among the vari-

ous techniques, the use of the ten-step method of

Ramji and Ramesh [57] is recommended since it is

robust even in the presence of the usual optical mis-

alignments and mismatch of quarter-wave plates. It

is worthwhile to note that in other interferometer-

based techniques, even though only one phase infor-

mation needs to be evaluated, the use of a large

number of steps is shown to improve accuracy [145].

Several problems of practical interest such as

evaluation of stress concentration factor, stress

intensity factors, and contact stress parameters

require only isochromatic data. If the focus is only

on isochromatic data, then single-shot data acquisi-

tion is possible through RGBP, which also facilitates

transient analysis. The recent advances of extending

the range of RGB methods beyond three fringe

orders makes it suitable for handling generic situa-

tions; however, the development of a calibration

table is quite involved. If the fringe order is less than

three (which is so for many problems such as bima-

terial interface crack problems, thin stress-frozen

slices or fringes in a photoelastic coating test), TFP

with its recent advances of RTFP [76] combined

with colour adaptation [80, 81] is recommended.

The generation of the calibration table is simple and

quite attractive for an industrial scenario.

In dynamic applications, if the focus is to get

both isoclinic and isochromatic data, then use of

automated polariscopes employing four-step meth-

ods is necessary. However, if the focus is only on

isochromatics, then RTFP is ideally suited for

dynamic applications as well. With suitable ultra-

high-speed cameras it can be applied to problems

of varied complexity.

Conventional commercial polariscopes can be

effectively used as digital polariscopes to evaluate

both isochromatic and isoclinic parameters with

the development of the five-step method [146]. The

five-step method in reflection photoelasticity [91]

promises exploration of a new range of industrial

problems, as both isoclinic and isochromatic para-

meters are determined for the entire field. If the

fringe order is beyond three, then the use of new

approaches of extending RGBP is recommended for

isochromatic parameter evaluation.

For evaluation of individual stress components in

two-dimensional problems, use of adaptive shear dif-

ference stress separation technique [129] in conjunc-

tion with data acquisition by the ten-step method

Digital photoelasticity A comprehensive review 259

J. Strain Analysis Vol. 46

at AMRITA SCHOOL OF BUSINESS on June 3, 2013 sdj.sagepub.com Downloaded from

[118] is recommended. Further research in digital

photoelasticity needs to focus on development of

efficient RPT methodologies, enhancement of data

acquisition and processing at stress concentration

zones, and evaluation of individual stress compo-

nents from a 3D model using only photoelastic data.

Authors 2011

REFERENCES

1 Ramesh, K. Digital photoelasticity: advanced tech-

niques and applications, 2000 (Springer-Verlag,

Berlin, Germany).

2 Patterson, E. A. Digital photoelasticity princi-

ples, practice and potential. Strain, 2002, 38(1),

2739.

3 Ramesh, K. Photoelasticity. In Springer handbook

of experimental solid mechanics (Ed. W. N. Sharpe),

2008, pp. 701742 (Springer, New York, New York).

4 Ramesh, K. E-book on experimental stress analy-

sis, 2009, available from http://apm.iitm.ac.in/

smlab/kramesh/book_5.htm (access date 21st

March 2011).

5 Quan, C., Bryanston-Cross, P. J., and Judge, T. R.

Photoelasticity stress analysis using carrier fringe

and FFT techniques. Opt. Lasers Engng, 1993,

18(2), 79108.

6 Morimoto, Y., Morimoto Jr, Y., and Hayashi, T.

Separation of isochromatics and isoclinics using

Fourier transform. Exp. Tech., 1994, 18(5), 1317.

7 Ng, T. W. Photoelastic stress analysis using an

object step loading method. Exp. Mech., 1997, 37,

137141.

8 Ajovalasit, A. and Zuccarello, B. Limitation of

Fourier transform photoelasticity: influence of

isoclinics. Exp. Mech., 2000, 40, 384392.

9 Zuccarello, B. and Tripoli, G. Photoelastic stress

pattern analysis using Fourier transform with car-

rier fringes: influence of quarterwave plate error.

Opt. Lasers Engng, 2002, 37, 401416.

10 Ajovalasit, A., Pitarresi, G., and Zuccarello, B.

Limitation of carrier fringe methods in digital

photoelasticity. Opt. Lasers Engng, 2007, 45,

631636.

11 Patterson, E. A., Ji, W., and Wang, Z. F. On image

analysis for birefringence measurement in photoe-

lasticity. Opt. Lasers Engng, 1997, 28(1), 1736.

12 Ramesh, K. and Mangal, S. K. Data acquisition

techniques in digital photoelasticity: a review.

Opt. Lasers Engng, 1998, 30(1), 5375; errata, ibid,

1999, 31, 85.

13 Ajovalasit, A., Barone, S., and Petrucci, G. A

review of automated methods for the collection

and analysis of photoelastic data. J. Strain Anal.

Engng Des., 1998, 33(2), 7591.

14 Ramesh, K. Digital photoelasticity current trends

and future possibilities. In Proceedings of the

International Conference on Computers & experi-

mental engineering and sciences, Chennai India,

2005, pp. 21592164 (Tech Science Press, Forsyth,

USA). 16 December, 2005

15 Asundi, A. Phase-shifting in photoelasticity. Exp.

Tech., 1993, 17(1), 1923.

16 Hecker, F. W. and Morche, B. Computer-aided

measurement of relative retardations in plane

photoelasticity. In Experimental stress analysis

(Ed. H. Wieringa), 1986, pp. 535542 (Martinus

Nijhoff, Dordrecht, The Netherlands).

17 Kihara, T. Automatic whole-field measurement of

photoelasticity using linear polarised incident

light. In Proceedings of the Ninth International

Conference on Experimental mechanics, Copenha-

gen, Denmark, 1990, vol. 2, pp. 821827. 2024

August 1990

18 Patterson, E. A. and Wang, Z. F. Towards full

field automated photoelastic analysis of complex

components. Strain, 1991, 27(2), 4956.

19 Sarma, V. S. S .S. R., Pillai, S. A., Subramanian, G.,

and Varadan, T. K. Computerized image proces-

sing for whole-field determination of isoclinics

and isochromatics. Exp. Mech., 1992, 32(1), 2429.

20 Ramesh, K. and Ganapathy, V. Phase-shifting

methodologies in photoelastic analysis the

application of Jones calculus. J. Strain Anal.

Engng Des., 1996, 31(6), 423432.

21 Dupre, J. C., Bremand, F., and Lagarde, A.

Photoelastic data processing through digital image

processing: isostatics and isochromatics recon-

struction. International Conference on Photo-

elasticity: New Instrumentation, Materials and

Data Processing Techniques, London, UK, 1993.

22 Quiroga, J. A. and Gonzalez-Cano, A. Phase mea-

suring algorithm for extraction of isochromatics

of photoelastic fringe patterns. Appl. Opt., 1997,

36(32), 83978402.

23 Mangal, S. K. and Ramesh, K. Factors affecting

the intensity distribution in high stress gradient

zones in digital photoelasticity. Strain, 1998,

34(4), 133134.

24 Ramesh, K. and Sreedhar, D. Optically enhanced

tiling (OET) in digital fringe pattern analysis.

Strain, 1998, 34(4), 127131.

25 Xue-Feng, Y., Long-Hui, J., Wei, X., Guan-

Chang, J., and Hsien-Yang, Y. Digital shifting