Академический Документы

Профессиональный Документы

Культура Документы

Tolerancia Laminas

Загружено:

pablitochoaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tolerancia Laminas

Загружено:

pablitochoaАвторское право:

Доступные форматы

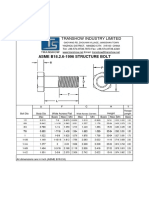

A6/A6M 11

ANNEXES

(Mandatory Information)

A1. PERMITTED VARIATIONS IN DIMENSIONS AND MASS IN SI UNITS

A1.1 Tables A1.1-A1.31 inclusive contain permitted variations in dimensions and mass stated in SI Units.

TABLE A1.1 Permitted Variations in Thickness for Rectangular Carbon, High-Strength Low Alloy, and Alloy Steel Plates, 300 mm and

Under in Thickness When Ordered to Thickness

Tolerancia por debajo de

NOTE 1Permitted variation under specified thickness, 0.3 mm.

cualquier espesor: 0,3mm

NOTE 2Thickness to be measured at 10 to 20 mm from the longitudinal edge.

NOTE 3For specified thicknesses not listed in this table, the permitted variations in thickness shall be as given for the next higher value of specified

thickness that is listed in this table.

NOTE 4For thickness measured at any location other than that specified in Note 2, the permitted variations over specified thickness shall be 134 times

the amounts in this table, rounded to the nearest 0.1 mm.

NOTE 5Where ... appears in this table, there is no requirement.

Permitted Variations Over Specified Thickness for Widths Given in Millimetres, mm

Specified

Thickness,

mm

5.0

5.5

6.0

7.0

8.0

9.0

10.0

11.0

12.0

14.0

16.0

18.0

20.0

22.0

25.0

28.0

30.0

32.0

35.0

38.0

40.0

45.0

50.0

55.0

60.0

70.0

80.0

90.0

100.0

110.0

120.0

130.0

140.0

150.0

160.0

180.0

200.0

250.0

300.0

1200

and Under

Over 1200

to 1500,

excl

1500 to

1800,

excl

1800 to

2100,

excl

2100 to

2400,

excl

2400 to

2700,

excl

2700 to

3000,

excl

3000 to

3300,

excl

3300 to

3600,

excl

3600 to

4200,

excl

4200

and

Over

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.9

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.8

2.0

2.3

2.5

2.8

3.0

3.3

3.5

3.8

4.0

4.3

4.5

4.8

5.4

5.8

7.5

7.5

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.9

0.9

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.8

2.0

2.3

2.5

2.8

3.0

3.3

3.5

3.8

4.0

4.3

4.5

4.8

5.4

5.8

7.5

7.5

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.9

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2.0

2.3

2.5

2.8

3.0

3.3

3.5

3.8

4.0

4.3

4.5

4.8

5.4

6.0

7.5

9.0

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.9

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

3.3

3.5

3.8

4.0

4.3

4.5

4.8

5.4

6.0

7.5

9.0

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.9

0.9

0.9

0.9

1.0

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

3.5

3.5

3.8

4.0

4.3

4.5

4.8

5.4

6.0

7.5

9.0

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.8

0.9

0.9

0.9

1.0

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2.0

2.3

2.5

2.8

3.0

3.3

3.5

3.8

3.8

3.8

4.0

4.3

4.5

4.8

5.4

6.0

7.5

9.0

0.8

0.8

0.9

0.9

0.9

1.0

1.0

1.0

1.0

1.0

1.0

1.1

1.2

1.3

1.3

1.4

1.5

1.6

1.7

1.8

2.0

2.3

2.5

2.8

3.0

3.3

3.5

3.5

3.8

3.8

3.8

4.0

4.3

4.5

4.8

5.4

6.0

7.5

9.0

0.9

0.9

1.0

1.0

1.0

1.0

1.0

1.0

1.0

1.1

1.1

1.2

1.2

1.3

1.5

1.8

1.8

2.0

2.3

2.3

2.5

2.8

3.0

3.3

3.4

3.5

3.5

3.5

3.8

3.8

3.8

4.0

4.3

4.5

4.8

5.4

6.0

7.5

9.0

1.0

1.0

1.1

1.2

1.2

1.3

1.3

1.3

1.3

1.3

1.3

1.4

1.4

1.5

1.5

1.8

1.8

2.0

2.3

2.3

2.5

2.8

3.0

3.3

3.4

3.6

3.6

3.6

3.8

3.8

3.8

4.0

4.3

4.5

4.8

5.4

6.0

7.5

9.0

...

...

...

1.4

1.4

1.5

1.5

1.5

1.5

1.5

1.5

1.6

1.6

1.8

1.8

2.0

2.1

2.3

2.5

2.7

2.8

3.0

3.3

3.5

3.8

4.0

4.0

4.0

4.4

4.4

4.8

5.2

5.6

5.6

5.6

6.3

7.0

7.5

9.0

...

...

...

...

...

...

1.7

1.7

1.8

1.8

1.8

2.0

2.0

2.0

2.2

2.2

2.4

2.6

2.8

3.0

3.3

3.5

3.8

3.8

4.0

4.0

4.0

4.4

4.4

4.4

4.8

5.2

5.6

5.6

5.6

6.3

7.0

8.8

9.0

Copyright by ASTM Int'l (all rights reserved); Fri Mar 30 11:03:13 EDT 2012

31

Downloaded/printed by

Universidad De Antioquia pursuant to License Agreement. No further reproductions authorized.

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- B 18 2 6Документ1 страницаB 18 2 6pablitochoaОценок пока нет

- ASTM A588 PaintingДокумент2 страницыASTM A588 PaintingpablitochoaОценок пока нет

- SONY - Esupport - How To... Rom Outside of WindowsДокумент6 страницSONY - Esupport - How To... Rom Outside of WindowspablitochoaОценок пока нет

- Aws D15.2Документ49 страницAws D15.2pablitochoa100% (4)

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Документ3 страницыSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)pablitochoaОценок пока нет

- Pages From AISC - Specification - 2005-Third - Print PDFДокумент1 страницаPages From AISC - Specification - 2005-Third - Print PDFpablitochoaОценок пока нет

- KWP Non-Clogging Centrifugal Pump: Automation Products AvailableДокумент16 страницKWP Non-Clogging Centrifugal Pump: Automation Products Availablefedeparamos5030100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- GST Retail InvoiceДокумент1 страницаGST Retail Invoicesachin sharmaОценок пока нет

- Ferrous Processing & Trading Co. Company OverviewДокумент5 страницFerrous Processing & Trading Co. Company OverviewfptscrapОценок пока нет

- Plant Layout and Design Quiz - 1 AnswersДокумент4 страницыPlant Layout and Design Quiz - 1 AnswersMuthuMuthu86% (14)

- List SA1 99e Agreed ApproveddocxДокумент3 страницыList SA1 99e Agreed ApproveddocxabhishekinfoОценок пока нет

- FORM - HSE - Daily Project HSE ReportДокумент44 страницыFORM - HSE - Daily Project HSE ReportWerman SeptianОценок пока нет

- LesДокумент4 страницыLesAli ShanОценок пока нет

- Automated Project Managemen..Документ4 страницыAutomated Project Managemen..reach2sharadОценок пока нет

- Architets in DelhiДокумент74 страницыArchitets in DelhiUmang Khurana100% (1)

- Building A Joint Venture in An Emerging Market: - A Burmah Castrol Case StudyДокумент16 страницBuilding A Joint Venture in An Emerging Market: - A Burmah Castrol Case StudyNikhil SachdevaОценок пока нет

- Advanced Control and Information Systems Handbook - 2003 (2003) (338s) PDFДокумент338 страницAdvanced Control and Information Systems Handbook - 2003 (2003) (338s) PDFMatthew Irwin100% (1)

- Weldedmesh Adets B500a b500bДокумент4 страницыWeldedmesh Adets B500a b500bFiraz Kaot'zОценок пока нет

- System Analysis and DesignДокумент24 страницыSystem Analysis and DesignKundan KumarОценок пока нет

- Catalogo GuardianДокумент24 страницыCatalogo GuardianTANIA0% (1)

- Chapter 3 Qualitative Process AnalysisДокумент27 страницChapter 3 Qualitative Process AnalysisJesica RafananОценок пока нет

- Car RentalДокумент30 страницCar RentalKarthik Arumugham100% (5)

- OrgДокумент2 страницыOrgCariza Caballero100% (1)

- Excel IFERROR Function With Formula ExamplesДокумент5 страницExcel IFERROR Function With Formula ExamplesP Singh KarkiОценок пока нет

- GEA Hilge FB HYGIA Brochure A4 EN V012015 PDFДокумент4 страницыGEA Hilge FB HYGIA Brochure A4 EN V012015 PDFShawn AngОценок пока нет

- Chapter 1Документ24 страницыChapter 1vovox1Оценок пока нет

- Question Paper Code: X71451: K. Ramakrishnan College of Technology (Autonomous)Документ2 страницыQuestion Paper Code: X71451: K. Ramakrishnan College of Technology (Autonomous)Madhankumar .JОценок пока нет

- Applications Engineer Semiconductor Chemicals in Albuquerque NM Resume Theodore Andrew AhrДокумент2 страницыApplications Engineer Semiconductor Chemicals in Albuquerque NM Resume Theodore Andrew AhrTheodoreAndrewAhrОценок пока нет

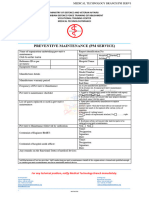

- Preventive Maintenance (PM Service)Документ2 страницыPreventive Maintenance (PM Service)jim tauОценок пока нет

- World Audio Level Reference PDFДокумент1 страницаWorld Audio Level Reference PDFHector Herrera ChavezОценок пока нет

- Introduction To Production and Operations ManagementДокумент17 страницIntroduction To Production and Operations ManagementSyed M. Fakharullah KazmiОценок пока нет

- Sap Landscape TransformationДокумент24 страницыSap Landscape TransformationbhangaramОценок пока нет

- Charles BovillДокумент2 страницыCharles BovillGallg BaronОценок пока нет

- Hydraulic Breaker TOR Series: Break Anything... Except The BankДокумент6 страницHydraulic Breaker TOR Series: Break Anything... Except The BankYeison RamirezОценок пока нет

- Ryobi 1801 Router Operator's ManualДокумент20 страницRyobi 1801 Router Operator's ManualJeremy BaverОценок пока нет

- Tecaran ® Abs: General InfoДокумент6 страницTecaran ® Abs: General InfoPaolo VisentinОценок пока нет

- FLYFokker Leaflet GatewayДокумент2 страницыFLYFokker Leaflet GatewayFredyBrizuelaОценок пока нет