Академический Документы

Профессиональный Документы

Культура Документы

Slivers

Загружено:

Varun MishraИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Slivers

Загружено:

Varun MishraАвторское право:

Доступные форматы

The Scientific Bulletin of VALAHIA University MATERIALS and MECHANICS Nr.

7 (year 10) 2012

SLIVER DEFECTS ON LOW CARBON STEELS, COLD ROLLED STRIPS

Dumitrescu A.T., Catangiu A. University Valahia of Trgovite E-mail: acatangiu@yahoo.co.uk Abstract. One definition of slivers could be: defects in the nature of irregularly shaped pieces of steel clinging loosely to finished steel. Slivers may result from defective composition (over-oxidized, high sulfur); defective teeming of molten steel; defective heating (burning); tearing of corners in early stages of rolling; etc. So, from the definition is obvious that the origin of slivers could be in different stages of steel flow route but, the main source of slivers is related to nonmetallic inclusions formed and entrapped on the subsurface of continuous cast slabs, as are FeO and Al2O3. These inclusions are generated by mould slag entrapment on solidifying shell, re-oxidation during continuous casting by air, refractory materials, ladle slag, etc.The present paper contains metallographic analysis of areas connected to slivers from 5 cold rolled coils of strips with thickness varying between 1.8mm to 4.1mm and the carbon content from 0.04% to 0.188% and in all analyzed areas have been observed only FeO inclusions related to slivers defects, inclusions formed during continuous slab casting process.

Keywords: sliver, low carbon steels, cold rolled strips

1. INTRODUCTION The quality of finished steel products is often impaired by the presence of surface defects such as slivers, cracks, laps, etc. and/or internal defects like cracks, porosity, segregation, etc. Defects in finished steel products may arise from poor steel quality (high nonmetallic inclusion content) at steel making stages or may be caused during subsequent downstream operations such as casting, reheating, hot/cold rolling or drawing. Such defects may remain undetected in intermediate processing stages and ultimately show up in the finished product during final inspection. Line defects appear on the surface of finished strip product, with several tens of micrometers to millimeter in width and 0. 1 - 1. 0 m in length slivers are irregular, flatly formed laminations of varying size and shape that occur in longitudinal direction of the strip and are distributed irregularly over the strip width (OKOF, 1996) This surface defect is believed to result from nonmetallic inclusions caught near the surface of the slab (<15 mm from the surface), coupled with elongated bubbles The inclusions can be oxide particles,casting powder, alumina clusters, refractory, etc. When the sliver defects are examined, it is found that there are different causes for an identical macroscopic form. Electron probe microanalysis (EPMA), confirmed for some cases, these inclusions to be Al2O3 that formed during steel making and surfaced during hot rolling [1] There are other slivers, which have Fe-oxide (scale) present along the lamination with an alloy enriched internal oxidation (IO) in the substrate. These solidstate re-oxidation products typically are about 1micron Table 1. Chemical composition of the coils Coil. C Mn P S A B C D E 0,04 0,034 0,04 0,188 0,106 0,24 0,28 0,26 0,56 0,35 0,019 0,015 0,013 0,018 0,01 0,007 0,007 0,007 0,0096 0,0101 Si 0,016 0,029 0,016 0,015 0,01 in diameter and are formed as a result of oxygen diffusion ahead of a scale front where they precipitate from solid solution at elevated temperatures. In carbon steels, they often are accompanied by localized decarburization[2]. While IO has been observed to occur from damage as late as the first roughing stand, since the internal oxides form at elevated temperatures they are generally believed to be an evidence of the defect present in the slab before reheating. Consequently, slivers with IO are commonly presumed to be the result open or coarse cracks on the cast slab, indicating a problem with the casting operation. A considerable share of sliver defects also has scale present along the lamination, yet, because of the absence or only weak presence of internal oxidation in the sliver region, the hot rolling stage is attributed to be the cause. However, FeO-type sliver defects can occur with or without dispersed oxides often referred to as internal oxidation[3]. Some slivers were found from mold slag entrainment, Mold fluxes not melting homogenously tend to have several phases with areas of high melting and low viscosity oxides, which are available for entrapment, Mold fluxes during strand startup do not immediately supply the necessary liquid layer essential for lubrication, and consist of a combination of dry powder, semi-molten and molten [4] Although several experiments have been conducted to establish how the defects form/evolve from slab to strip, many questions remain.

Cu 0,02 0,03 0,03 0,01 0,01

Cr 0,02 0,02 0,03 0,02 0,02

Ni 0,04 0,03 0,03 0,02 0,02

Mo 0,006 0,004 0,007 0,007 0,002

V 0,004 0,005 0,004 0,003 0,002

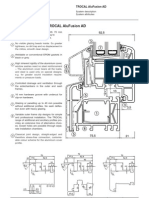

14

The Scientific Bulletin of VALAHIA University MATERIALS and MECHANICS Nr. 7 (year 10) 2012 manganese content between 0.26% and 0.56%. In the case of another chemical elements from strips composition the variation range is quite small. In Fig.1A-D are presented the defects on the surfaces of coils and the position for metallographic specimens cutting. So, for example for A coil, the specimens 1 and 2 have been cut transversal and 3 longitudinal with respect to the rolling direction.

2. Defects on the surface of cold rolled coil

In the present paper have been analyzed the sliver defects observed on the surface of 5 cold rolled coils of strips with thickness varying between 1.8mm to 4.1mm and width being from 1092mm to 1219mm. In the Table 1 is shown the strips chemical composition. From Table 1 it can be observed the carbon content of analyzed strips varies between 0.04% and 0.188%, a quite large variation, and the

Figure 1. Metallographic specimens cut out from tested coils The position of defects, with respect to the strip width, is different from one strip to another, consequently seems not to be related to rolls or another equipment damage, even the defects appearance is quite similar, width of 815mm and length from 70 to 100mm. After un-etched metallographic examination of specimens cut longitudinally with respect to the rolling direction it can be observed for A coil (Fig. 2),the defect consists on sub-surface iron oxides which have variable thickness (max. 26m) and are found along the surface at the depth varying in the interval: 16-23m. Figure 3. Metallographic specimens (A coil; x100) examination of etched

In Fig.4 is shown the defect zone at x500 magnification and can be seen the decarburization in the zone of defect.

Figure 2. Metallographic examination of un-etched specimens (A coil) The same defect has been observed for specimen no.2, the maximum depth being 26m. In Fig.3 the etched image of specimen no.1 shows that the defect belongs to a region without decarburization and the average grain size increases from the surface, where is 9, to 5-6 at 400m depth.

Figure 4. Metallographic specimens (A coil; x500)

examination

of

etched

In order to verify if the decarburization is related to the defect or not has been analized at the same magnification, another zone of the specimen, being observed the decarburized zone as in the Fig.4. In Fig.1B is presented the defect on the surface of B coil and the position for metallographic specimens cutting. So, the specimens 1 and 2 have been cut transversal to the rolling direction. Even the defect aspect looks like to

15

The Scientific Bulletin of VALAHIA University MATERIALS and MECHANICS Nr. 7 (year 10) 2012 the defect from Fig.1A on the metallographic analysis didn`t been observed oxydized zones inside the strip but only surface iregullarities. Consequently, we believe the defect has been removed by pickling. In Fig.1C is presented the C coils surface defect and the position of metallographic specimens cutting. The un-etched image of superficial defect shows iron oxides disposed under the strip surface at the depths which vary between 10m and 20m and defect thickness varies between 10 and 15m. The same results has been shown in Fig.5 for the specimen no.2, which is at 3cm distance from the specimen no.1.

Figure 7. Metallographic specimens (C coil; x500)

examination

of

etched

In these figure (Fig.7) can be observed a light decarburization, but only along of a one grain size depth. In Fig.1D is shown the defect on the surface of D coil and the position for cutting of metallographic specimen. From Fig.8 can be observed that the defect is similar to the previous presented and consisting of rows of iron oxides along the strip surface and at a depth of 30-40m.

Figure 5. Metallographic examination of un-etched specimens (C coil) In Fig.6 is shown the specimen no.1 from C coil in etched condition. It can be observed that the defect is discontinuous and some regions of it are connected to the surface.

Figure 8. Metallographic examination of un-etched specimens (D coil) The defect thickness varies between 20 and 36m.

Figure 6. Metallographic specimens (C coil; x100)

examination

of

etched

In Fig.7 the same defect area as in Fig.6 are presented at higher magnification. Figure 9. Metallographic examination of etched specimens (D coil; x100) In Fig.9 is shown the etched image of the specimen and can be observed the grain size variation across

16

The Scientific Bulletin of VALAHIA University MATERIALS and MECHANICS Nr. 7 (year 10) 2012 the thickness and the absence of decarburization along the iron oxides from the surface. In Fig.10 is shown the defect zone at x500 magnification and can be observed the decarburized zone over the defect.

Figure 10. Metallographic examination of etched specimens (D coil; x500) Metallographic examination at the same magnification performed over another zone of the specimen far away from the defect is shown a decarburized zone with the same depth as in Fig.10. In Fig.1E is shown the E coil surface defect. From the sample presented in this figure has been cut a metallographic specimen, cross to the defect, at 5cm from the defect tip. In Fig. 11 is presented the un-etched image of the strip cross section in the defect zone and can be observed that under the strip surface there are rows of iron oxides which thickness varies between 10 to 17m and they are at 16-27m under the strip surface.

Figure 12. Metallographic examination of etched specimens (E coil; x100) In Fig.13 the same zone as from the Fig.12 is observed at higher magnification (x500).

Figure 13. Metallographic examination of etched specimens (D coil; x500) At this magnification can be observed that the iron oxides are connected to the surface by very fine cracks, which cross the grains, parallel to the specimen surface. Over this crack is observed a light decarburization.

3. CONCLUSIONS: Figure 11. Metallographic examination of un-etched specimens (E coil) In Fig.12 is shown the etched image of the cross section through the strip in the defect zone and can be observed the fine granulation of this strip, 10-11. The metallographic analysis of 5 samples from 5 different coils showed clear deffect evidences into 4 samples. The sample from the coil B has no defect, no matter the surface aspect incriminated its presence. Surface roughness variation may explain the surface aspect. Probably, the defect has been removed by pickling. In all 4 samples with defects, rows consisting of iron oxides, deformed in the rolling direction, (whose depth beneath the surface varies between 10 and 40m) have been found. The average oxides depth, for each analyzed strip, was 20m . The oxides thickness varies between 10 to 40m.

17

The Scientific Bulletin of VALAHIA University MATERIALS and MECHANICS Nr. 7 (year 10) 2012 The presence of iron oxide clearly indicates that no other inclusions of any kind are defect connected. Even the macroscopic aspect of the defects on one coil to another is quite different, the source of iron oxide should be connected with slab preexisting defect subjected to furnace atmosphere during slab reheating and less probable to a defect induced into slab surface during rolling and oxidation occurring in the same process, because the defect position across the width is different for one coil to another. The decarburization is not connected to the defect presence, being observed also in another surface zones, far from the defect and the presence of decarburized areas on the strip surface, even in the slivers zones, is a suplementary argument for the prexistence of defects during the rolling process.

4. REFERENCES:

[1].P. Zahumensky, M. Merwin, Evolution of artificial defects from slab to rolled products, Journal of materials processing technology 1 9 6 (2 0 0 8 ) 266278. [2].Weihua Sun, A.K. Tieu, Zhengyi Jiang, Cheng Lu, High temperature oxide scale characteristics of low carbon steel in hot rolling, Journal of Materials Processing Technology 155 156 (2004) 13071312. [3]. Zhang Li-feng, Inclusion and Bubble in Steel- A Review, Journal, of Iron and Steel Research, International,. 3 ( 3 ) (2006), 01-08. [4].Hiroshi Utsunomiya, Shoichi Doi, Ken-ichiro Hara, Tetsuo Sakai, Shusuke Yanagi, Deformation of oxide scale on steel surface during hot rolling, CIRP Annals - Manufacturing Technology 58 (2009) 271274

18

Вам также может понравиться

- Brittle Fracture in Steel StructuresОт EverandBrittle Fracture in Steel StructuresG.M. BoydОценок пока нет

- SMS Casting BreakoutsДокумент20 страницSMS Casting BreakoutsShubham KaushikОценок пока нет

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceОт EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceОценок пока нет

- Selection Process Overview: - at Concept (Preliminary) LevelДокумент23 страницыSelection Process Overview: - at Concept (Preliminary) LevelSudheer Kumar PetetiОценок пока нет

- Corrosion of SS in Nitric Acid ServiceДокумент23 страницыCorrosion of SS in Nitric Acid ServiceAdriaan de Witt100% (1)

- Welding Metallurgy and Weldability of Nickel-Base AlloysОт EverandWelding Metallurgy and Weldability of Nickel-Base AlloysРейтинг: 5 из 5 звезд5/5 (1)

- The Iron Puddler My life in the rolling mills and what came of itОт EverandThe Iron Puddler My life in the rolling mills and what came of itОценок пока нет

- 04-200-R1 Silicon Iron AnodesДокумент2 страницы04-200-R1 Silicon Iron Anodessams1101Оценок пока нет

- Chapter 7 - Dislocations and Strengethening MechanismsДокумент50 страницChapter 7 - Dislocations and Strengethening MechanismsmikeengineeringОценок пока нет

- MicrostructuresДокумент10 страницMicrostructuresErin BarryОценок пока нет

- ERW Pipe Issues and DefectsДокумент2 страницыERW Pipe Issues and Defectskaveh-bahiraee100% (1)

- The Forms of Corrosion-Part2Документ71 страницаThe Forms of Corrosion-Part2quiron2010100% (1)

- Properzi Up-Date The CCR Continuous Casting Rolling Technology With New Rolling Stands - 2008Документ9 страницProperzi Up-Date The CCR Continuous Casting Rolling Technology With New Rolling Stands - 2008Failed100% (1)

- Basics of Metallographic Specimen PreparationДокумент13 страницBasics of Metallographic Specimen PreparationFlop ShowОценок пока нет

- Corrosion Swimming)Документ6 страницCorrosion Swimming)skenny1Оценок пока нет

- Physical MetallurgyДокумент101 страницаPhysical MetallurgySheikh Sabbir SarforazОценок пока нет

- White Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsДокумент7 страницWhite Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsdanemsalОценок пока нет

- Friction Stir Welding ENHANCEMENT SEMINAR Friction Stir WeldingДокумент66 страницFriction Stir Welding ENHANCEMENT SEMINAR Friction Stir Weldingrobertalha100% (1)

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsОт EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsОценок пока нет

- Deformation Behavior of The Surface Defects of Low Carbon Steel in Wire Rod RollingДокумент6 страницDeformation Behavior of The Surface Defects of Low Carbon Steel in Wire Rod RollingAvinash KumarОценок пока нет

- Convexity Aws PDFДокумент4 страницыConvexity Aws PDFHJ SJОценок пока нет

- Adiabatic Shear Localization: Frontiers and AdvancesОт EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddОценок пока нет

- Shielding Vs Non-Shielding CoatingsДокумент62 страницыShielding Vs Non-Shielding CoatingsAce AceОценок пока нет

- Chromate Conversion Coatings and Their Current AppДокумент5 страницChromate Conversion Coatings and Their Current AppDeni HermawanОценок пока нет

- Module OrderДокумент2 страницыModule OrderhreerОценок пока нет

- Metalography and Microstructures of Stainless Steels and Maraging SteelsДокумент32 страницыMetalography and Microstructures of Stainless Steels and Maraging SteelsChaguy VergaraОценок пока нет

- Chapter11 Mechanical BehaviorДокумент31 страницаChapter11 Mechanical BehaviorDheivendranRamiah100% (1)

- 885F Embrittlement of Duplex Stainless SteelДокумент4 страницы885F Embrittlement of Duplex Stainless Steeljaymin444Оценок пока нет

- MSE 101 - Lecture 12 - Plastic DeformationДокумент33 страницыMSE 101 - Lecture 12 - Plastic DeformationKate Lynn PabelicoОценок пока нет

- Analysis On The Cause of Longitudinal Crack On The Hot-Rolled Ribbed Bar SurfaceДокумент5 страницAnalysis On The Cause of Longitudinal Crack On The Hot-Rolled Ribbed Bar SurfaceTanjidul IslamОценок пока нет

- Corrosion Quiz - IngДокумент5 страницCorrosion Quiz - IngErik Alfiandy100% (1)

- Module 4c - Corrosion Resistant Alloys (CRA's)Документ11 страницModule 4c - Corrosion Resistant Alloys (CRA's)Anonymous 7yN43wjlОценок пока нет

- 2.1) Technical Data Sheet - SS-COAT 909-Silver Zinc CoatДокумент3 страницы2.1) Technical Data Sheet - SS-COAT 909-Silver Zinc CoathaharameshОценок пока нет

- Durability Durability of of Steel Steel Structures StructuresДокумент21 страницаDurability Durability of of Steel Steel Structures StructuresKris d100% (1)

- On Types of Corrosion, Reasons and Prescribed Repairs 29.07.2015 Ver 01Документ57 страницOn Types of Corrosion, Reasons and Prescribed Repairs 29.07.2015 Ver 01Ankur SinhaОценок пока нет

- Welding International Volume 25 Heat Tint Colours On Stainless Steel and Welded JointsДокумент5 страницWelding International Volume 25 Heat Tint Colours On Stainless Steel and Welded JointsAPIОценок пока нет

- Annealing (Metallurgy)Документ5 страницAnnealing (Metallurgy)Vijay Vikram SinghОценок пока нет

- Advances in Research on the Strength and Fracture of Materials: An OverviewОт EverandAdvances in Research on the Strength and Fracture of Materials: An OverviewD M R TaplinОценок пока нет

- Application Note Stainless SteelДокумент6 страницApplication Note Stainless SteelVictoria TechiОценок пока нет

- Steel Heat Treatment Handbook Chapter 12Документ46 страницSteel Heat Treatment Handbook Chapter 12Syed Shoaib Raza100% (1)

- 25 Macro Micro ExaminationДокумент14 страниц25 Macro Micro ExaminationAdhanom G.100% (1)

- Sheet Metal WorkДокумент29 страницSheet Metal WorkSolcastic SoulОценок пока нет

- Friction Stir WeldingДокумент20 страницFriction Stir WeldingjoshibecОценок пока нет

- "Hot Topics": Effect of Carbon in Ductile IronДокумент4 страницы"Hot Topics": Effect of Carbon in Ductile IronAdeel BhattiОценок пока нет

- IIW Document XIII-2235-08Документ11 страницIIW Document XIII-2235-08Amanda SmithОценок пока нет

- Endless Casting and Rolling of Long Products: The Competitive Substitute of Conventional Mini-MillsДокумент8 страницEndless Casting and Rolling of Long Products: The Competitive Substitute of Conventional Mini-MillsJJОценок пока нет

- CLSCC LiteratureДокумент62 страницыCLSCC LiteratureNakarin PotidokmaiОценок пока нет

- Effect of Elements in SteelДокумент3 страницыEffect of Elements in SteelJayakrishnan Radhakrishnan100% (1)

- Automated Coil Trimming System For Wire Rod Mills in The Digital EraДокумент10 страницAutomated Coil Trimming System For Wire Rod Mills in The Digital EraJJОценок пока нет

- Cast IronДокумент15 страницCast IronJohnОценок пока нет

- ARTICLE - Destructive Testing Basics (2012)Документ4 страницыARTICLE - Destructive Testing Basics (2012)Sangameswaran RamarajОценок пока нет

- Defects Hydrogen Cracks IdentificationДокумент5 страницDefects Hydrogen Cracks Identificationarif maulanafОценок пока нет

- Terminating Resistor: RS-422 Communication Instruction ManualДокумент1 страницаTerminating Resistor: RS-422 Communication Instruction ManualasdОценок пока нет

- QAV - 1.1. Report (Sup1)Документ2 страницыQAV - 1.1. Report (Sup1)Rohit SoniОценок пока нет

- Oil Checks On Linde Reach Stacker Heavy TrucksДокумент2 страницыOil Checks On Linde Reach Stacker Heavy TrucksmliugongОценок пока нет

- Hydraulic Eaton Vickers VQ Vane Pump: Intra-Vane Mechanism FeaturesДокумент7 страницHydraulic Eaton Vickers VQ Vane Pump: Intra-Vane Mechanism FeaturesMiguel VlntìnОценок пока нет

- Windchill Business Administrator's GuideДокумент395 страницWindchill Business Administrator's GuidevundavilliravindraОценок пока нет

- Total PDFДокумент35 страницTotal PDFMauricio ThanatosОценок пока нет

- Sec 1038Документ4 страницыSec 1038Lauren BowenОценок пока нет

- Fab - Y-Strainers - 2nd EditionДокумент15 страницFab - Y-Strainers - 2nd EditionRichard V. Quispe CastillonОценок пока нет

- Heatsink Calculation and Examples: Application NoteДокумент3 страницыHeatsink Calculation and Examples: Application NoteAmador Garcia IIIОценок пока нет

- Rahul Soni BiodataДокумент2 страницыRahul Soni BiodataRahul SoniОценок пока нет

- Ropecon Conveyor SystemДокумент4 страницыRopecon Conveyor Systemjayaraman3Оценок пока нет

- WWW - Manaresults.Co - In: Set No. 1Документ1 страницаWWW - Manaresults.Co - In: Set No. 1My Technical videosОценок пока нет

- Electromagnetic Shielding of Impulse Magnetic Fields Using Thin-Walled ShellsДокумент4 страницыElectromagnetic Shielding of Impulse Magnetic Fields Using Thin-Walled ShellsGuru VelmathiОценок пока нет

- RME ReviewerДокумент354 страницыRME ReviewerRene100% (1)

- ME (PE) II Sem SyllabusДокумент71 страницаME (PE) II Sem Syllabusm elangoОценок пока нет

- 03-Instruction Set ArchitectureДокумент40 страниц03-Instruction Set ArchitectureccoccoheadОценок пока нет

- Solar Street LightДокумент8 страницSolar Street LightAlizaIbrahim0% (2)

- FFSA BriefДокумент4 страницыFFSA Briefcontactnandu7415Оценок пока нет

- Aspen Plus Model For Moving Bed Coal GasifierДокумент30 страницAspen Plus Model For Moving Bed Coal GasifierAzharuddin_kfupm100% (2)

- Urea ProjectДокумент17 страницUrea ProjectAbdo Shaaban100% (2)

- Exercises 1 FinalДокумент2 страницыExercises 1 FinalRemalyn Quinay CasemОценок пока нет

- Cve 240-Assignment 5 - Chapter 4Документ3 страницыCve 240-Assignment 5 - Chapter 4Ehab Wilson0% (1)

- Ram 100Документ2 страницыRam 100MAT-LIONОценок пока нет

- How To Find MAC Address On A Mobile PhoneДокумент11 страницHow To Find MAC Address On A Mobile PhoneEyiwin WongОценок пока нет

- IA-NT-PWR-2.4-Reference GuideДокумент110 страницIA-NT-PWR-2.4-Reference GuideSamuel LeiteОценок пока нет

- EL3020 Data PDFДокумент24 страницыEL3020 Data PDFichrakОценок пока нет

- 2D Position Measurement With Optical Laser Mouse SensorДокумент4 страницы2D Position Measurement With Optical Laser Mouse SensorDhrupad GuptaОценок пока нет

- Alufusion Eng TrocalДокумент226 страницAlufusion Eng TrocalSid SilviuОценок пока нет

- Ivd Symbols FinalДокумент14 страницIvd Symbols FinalDennis ChenОценок пока нет