Академический Документы

Профессиональный Документы

Культура Документы

Pipe Sizing Criteria Schedule 40 Steel S-40 Steel: 198962529.xls - Ms - Office

Загружено:

angel darioОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pipe Sizing Criteria Schedule 40 Steel S-40 Steel: 198962529.xls - Ms - Office

Загружено:

angel darioАвторское право:

Доступные форматы

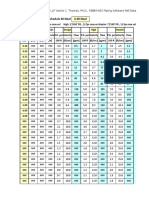

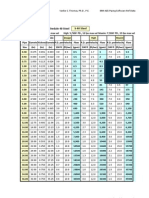

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

S-40 Steel

Pipe Sizing Criteria Schedule 40 Steel

Design: 3'/100' PD , 10 fps max vel

Nominl Outside Wall

Inside

IBM-AES Piping Software Ref-Data

High: 5'/100' PD , 12 fps max vel Maxim: 7'/100' PD , 15 fps max vel

Design

High

Maxim

Pipe Diameter

Thickness

DiameterP.D. perVelocity Flow P.D. perVelocity Flow P.D. perVelocity Flow

Size

(in)

(in)

(in)

100 ft (ft/sec) (gpm) 100 ft (ft/sec) (gpm) 100 ft (ft/sec) (gpm)

0.38

0.675

0.091

0.493

3.0

0.9

0.5

5.0

1.7

7.0

2.5

1.5

0.50

0.840

0.109

0.622

3.0

1.6

1.5

5.0

2.1

7.0

2.6

2.5

0.75

1.050

0.113

0.824

3.0

2.1

3.5

5.0

2.7

4.5

7.0

3.3

5.5

1.00

1.315

0.133

1.049

3.0

2.4

6.5

5.0

3.2

8.5

7.0

3.7

10

1.25

1.660

0.140

1.380

3.0

2.6

12

5.0

3.7

17

7.0

4.5

21

1.50

1.900

0.145

1.610

3.0

3.2

20

5.0

4.3

27

7.0

5.1

32

2.00

2.375

0.154

2.067

3.0

3.8

40

5.0

4.8

50

7.0

5.7

60

2.50

2.875

0.203

2.469

3.0

4.3

65

5.0

5.7

85

7.0

6.5

97

3.00

3.500

0.216

3.068

3.0

4.8

110

5.0

6.3

145

7.0

7.6

175

3.50

4.000

0.226

3.548

3.0

5.3

160

5.0

7.0

200

7.0

8.5

250

4.00

4.500

0.237

4.026

3.0

5.8

230

5.0

7.6

300

7.0

8.8

350

5.00

5.563

0.258

5.047

3.0

6.4

400

5.0

8.3

520

7.0

10.3

640

6.00

6.625

0.280

6.065

3.0

7.7

690

5.0

10.0

900

7.0

12.2

1,100

8.00

8.625

0.322

7.891

3.0

9.0

1,400

5.0

12.0

1,900

7.0

14.1

2,200

10.00

10.75

0.365

10.02

2.7

10.0

2,500

3.8

12.0

3,000

5.8

15.0

3,700

12.00

12.75

0.406

11.94

2.1

10.0

3,500

3.0

12.0

4,200

4.6

15.0

5,200

14.00

14.00

0.437

13.13

1.9

10.0

4,200

2.7

12.0

5,100

4.1

15.0

6,300

16.00

16.00

0.500

15.00

1.7

10.0

5,500

2.3

12.0

6,600

3.6

15.0

8,300

18.00

18.00

0.562

16.88

1.5

10.0

7,000

2.0

12.0

8,400

3.0

15.0

10500

20.00

20.00

0.593

18.81

1.3

10.0

8,900

1.8

12.0

10400 2.6

15.0

13000

22.00

22.00

1.250

20.75

1.1

10.0

10500 1.6

12.0

12600 2.4

15.0

15700

24.00

24.00

1.360

22.64

1.0

10.0

12500 1.4

12.0

15000 2.2

15.0

18700

26.00

26.00

0.750

25.25

0.9

10.0

15500 1.3

12.0

18600 2.1

15.0

23300

28.00

28.00

0.750

27.25

0.8

10.0

18100 1.2

12.0

21700 2.0

15.0

27100

30.00

30.00

0.750

29.25

0.7

10.0

20800 1.1

12.0

25000 1.9

15.0

31300

32.00

32.00

0.750

31.25

0.6

10.0

23800 1.0

12.0

28500 1.8

15.0

35700

34.00

34.00

0.750

33.25

0.5

10.0

26900 0.9

12.0

32300 1.7

15.0

40400

36.00

36.00

0.750

35.25

0.4

10.0

30300 0.8

12.0

36300 1.6

15.0

45400

Schedule 40 Steel

S40-Crit

198962529.xls.ms_office

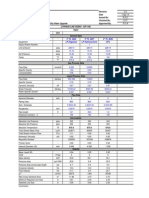

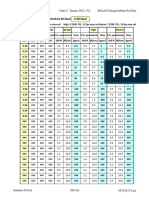

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

CLOSED SYSTEMS

Design Criteria:

3 Frictional Pressure Drop per 100 Pipe Length with a Maximum Velocity of 10 ft/sec

Figure - 1

Friction Loss for CLOSED Piping Systems: Schedule 40 Steel

Schedule 40 Steel

S40-Crit

Source: Carrier Systems Des

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

100 Pipe Length with a Maximum Velocity of 10 ft/sec

Piping Systems: Schedule 40 Steel

Schedule 40 Steel

Source: Carrier Systems Design

S40-Crit

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

OPEN SYSTEMS

Design Criteria:

3 Frictional Pressure Drop per 100 Pipe Length with a Maximum Velocity of 10 ft/sec

Figure - 2

Friction Loss for OPEN Piping Systems: Schedule 40 Steel

Schedule 40 Steel

S40-Crit

Source: Carrier System

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

100 Pipe Length with a Maximum Velocity of 10 ft/sec

ng Systems: Schedule 40 Steel

Schedule 40 Steel

Source: Carrier Systems Design

S40-Crit

198962529.xls.ms_office

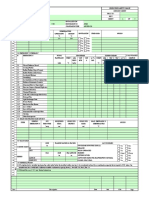

Skidmore, Owings + Merrill, LLP

COPPER

PLASTIC

Copper , Plastic

IBM-AES Piping Software Ref-Data

Physical Dimensions and Sizing Criteria

Nominal Type K Copper

Pipe Size Diameter (ins)

(ins)

Outside Inside

0.25

0.375

0.305

0.38

0.5

0.402

0.50

0.625

0.527

0.75

0.875

0.745

1.00

1.125

0.995

1.25

1.375

1.245

1.50

1.625

1.481

2.00

2.125

1.959

2.50

2.625

2.435

3.00

3.125

2.907

3.50

3.625

3.385

4.00

4.125

3.857

5.00

5.125

4.805

6.00

6.125

5.741

8.00

8.125

7.583

10.00 10.125 9.449

12.00 12.125 11.315

Nominal

Pipe Size

(ins)

0.50

0.75

1.00

1.25

1.50

2.00

2.50

3.00

3.50

4.00

5.00

6.00

8.00

10.00

12.00

Varkie C. Thomas, Ph.D., P.E.

Type L Copper

Diameter (ins)

Outside Inside

0.375

0.315

0.5

0.43

0.625

0.545

0.875

0.785

1.125

1.025

1.375

1.265

1.625

1.505

2.125

1.985

2.625

2.465

3.125

2.945

3.625

3.425

4.125

3.905

5.125

4.875

6.125

5.845

8.125

7.725

10.125 9.625

12.125 11.565

Type M Copper

Diameter (ins)

Outside Inside

0.5

0.625

0.875

1.125

1.375

1.625

2.125

2.625

3.125

3.625

4.125

5.125

6.125

8.125

10.125

12.125

0.45

0.569

0.811

1.055

1.291

1.527

2.009

2.495

2.981

3.459

3.935

4.907

5.881

7.785

9.701

11.617

Physical Dimensions and Sizing Criteria

(ASPE Data Book)

Pipe Sizing Criteria

Velocity Loss in

Flow

Ft/sec PD/100 GPM

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.5

3

3

3

3

3

3

3

3

3

3

2.5

2.5

2.2

1.9

1.5

1

0.5

1

3

7

12

17

35

70

110

160

225

380

575

1105

1835

2800

(ASPE Data Book)

Schedule 40 PVC Schedule 40 CPVCPolyethylene (75 psi)

Pipe Sizing Criteria

Diameter (ins)

Diameter (ins)

Diameter (ins) Velocity Loss in

Flow

Outside Inside Outside Inside Outside Inside Ft/sec PD/100 GPM

0.840

0.622

0.840

0.622

0.782

0.622

1.050

0.824

1.050

0.824

0.824

1.000

1.315

1.049

1.315

1.049

1.300

1.050

1.660

1.380

1.660

1.380

1.710

1.380

1.900

1.610

1.990

1.610

2.000

1.610

2.375

2.067

2.375

2.067

2.567

2.067

2.875

2.469

2.875

2.469

3.500

3.068

3.500

3.068

3.670

3.068

4.500

4.026

4.500

4.026

6.625

8.625

10.750

12.750

6.065

7.981

10.020

11.938

6.625

6.065

Cu-PVC

4.820

4.026

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

Copper Pipe Sizing Chart

Design Criteria:

3 Frictional Pressure Drop per 100 Pipe Length with a Maximum Velocity of 10 ft/sec

Figure - 3

Friction Loss for Copper Piping Systems: Types K, L, & M

Copper , Plastic

Cu-PVC

Source: Carrier Syst

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

per 100 Pipe Length with a Maximum Velocity of 10 ft/sec

er Piping Systems: Types K, L, & M

Copper , Plastic

Source: Carrier Systems Design

Cu-PVC

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Pipe Sizing Criteria:

Varkie C. Thomas, Ph.D., P.E.

Schedule 80 Steel

Schedule 80 Steel

S-80 Steel

Extra Strong Steel

Outside Wall

XS Steel

Outside Wall

Pipe Size Veloc

Diameter Thickness Diameter Flow

Diameter Thickness Diameter Flow

(ins)

(fps)

(ins)

(ins)

(ins)

(gpm)

(ins)

(ins)

(ins)

(gpm)

0.375

1.0

0.675

0.126

0.423

0.5

0.675

0.126

0.423

0.5

0.500

1.5

0.840

0.147

0.546

0.840

0.147

0.546

0.750

2.0

1.050

0.154

0.742

2.5

1.050

0.154

0.742

2.5

1.000

2.5

1.315

0.179

0.957

5.5

1.315

0.179

0.957

5.5

1.250

3.0

1.660

0.191

1.278

12

1.660

0.191

1.278

12

1.500

3.5

1.900

0.200

1.500

20

1.900

0.200

1.500

20

2.000

4.0

2.375

0.218

1.939

35

2.375

0.218

1.939

35

2.500

4.5

2.875

0.276

2.323

60

2.875

0.276

2.323

60

3.000

5.0

3.500

0.300

2.900

100

3.500

0.300

2.900

100

3.500

5.5

4.000

0.318

3.364

150

4.000

0.318

3.364

150

4.000

6.0

4.500

0.337

3.826

215

4.500

0.337

3.826

215

5.000

6.5

5.563

0.375

4.813

365

5.563

0.375

4.813

365

6.000

7.5

6.625

0.432

5.761

600

6.625

0.432

5.761

600

8.000

9.0

8.625

0.500

7.625

1,275

8.625

0.500

7.625

1,275

10.000

10.0

10.750

0.593

9.562

2,230

10.750

1.000

9.750

2,320

12.000

10.0

12.750

0.687

11.374

3,150

12.750

1.000

11.750

3,370

14.000

10.0

14.000

0.750

12.500

3,810

14.000

1.000

13.000

4,120

16.000

10.0

16.000

0.843

14.312

4,995

16.000

1.000

15.000

5,490

18.000

10.0

18.000

0.937

16.124

6,340

18.000

1.000

17.000

7,050

20.000

10.0

20.000

1.031

17.938

7,850

20.000

1.000

19.000

8,800

22.000

10.0

22.000

2.250

19.750

9,510

22.000

1.000

21.000

10,750

24.000

10.0

24.000

2.438

21.562

11,340

24.000

1.000

23.000

12,900

26.000

10.0

26.000

1.000

25.000

15,240

28.000

10.0

28.000

1.000

27.000

17,780

30.000

10.0

30.000

1.000

29.000

20,510

32.000

10.0

32.000

1.000

31.000

23,440

34.000

10.0

34.000

1.000

33.000

26,560

36.000

10.0

36.000

1.000

35.000

29,880

S80-XS

Maxim

S-80 Steel

Nominal Maxim

Sch 80 , XS Steel

Inside

IBM-AES Piping Software Ref-Data

Inside

Maxim

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

CAST IRON

Nominal

Pipe Size

(ins)

3

4

5

6

8

10

12

14

16

18

20

22

24

30

36

42

48

Physical Data

IBM-AES Piping Software Ref-Data

Hydraulic Handbook

Colt Industries

125 PSI Cast Iron

Diameter (ins)

Outside Inside

3.96

3.06

5.00

4.04

175 PSI Cast Iron

Diameter (ins)

Outside Inside

3.96

3.00

5.00

3.96

250 PSI Cast Iron

Diameter (ins)

Outside Inside

Pipe Sizing Criteria

Velocity Loss in

Flow

Ft/sec PD/100 GPM

3.1

4.5

100

2.8

5.1

200

7.10

9.30

11.40

13.50

15.65

17.80

19.92

22.06

6.08

8.18

10.16

12.14

14.17

16.20

18.18

20.22

7.10

9.30

11.40

13.50

15.65

17.80

19.92

22.06

6.00

8.10

10.04

12.00

14.01

16.02

18.00

20.00

7.22

9.42

11.60

13.78

15.98

18.16

20.34

22.54

6.00

8.00

10.00

12.00

14.00

16.00

18.00

20.00

2.9

2.6

2.7

2.5

1.9

1.7

1.9

1.2

6.8

7.7

9.0

9.7

9.4

9.6

10.0

9.2

600

1,200

2,200

3,400

4,500

6,000

8,000

9,000

26.32

32.40

38.70

45.10

51.40

24.22

30.00

35.98

42.02

47.98

26.32

32.74

39.16

45.58

51.98

24.00

30.00

36.00

42.02

48.06

26.90

33.46

40.04

24.00

30.00

36.00

1.2

0.9

0.7

0.5

0.5

10.0

10.0

9.5

9.3

9.8

14,000

22,000

30,000

40,000

55,000

ALUMINUM , BRASS

Nominal

Pipe Size

(ins)

0.38

0.50

0.75

1.00

1.25

1.50

2.00

2.50

3.00

3.50

4.00

5.00

6.00

8.00

10.00

12.00

Varkie C. Thomas, Ph.D., P.E.

Handbook for Mechanical Engineers : Baumeister & Marks

Aluminum Schedule 40

Diameter (ins) Thickness

Outside Inside

(ins)

0.675

0.493

0.091

0.840

0.622

0.109

1.050

0.824

0.133

1.315

1.049

0.133

1.660

1.380

0.140

1.900

1.610

0.145

2.375

2.067

0.154

2.875

2.469

0.203

3.500

3.068

0.216

4.000

3.548

0.226

4.500

4.026

0.237

5.563

5.047

0.258

6.625

6.065

0.280

8.625

7.981

0.322

10.750 10.020 0.365

12.750 12.000 0.375

Iron , Aluminum , Brass

Aluminum Schedule 80

Diameter (ins) Thickness

Outside Inside

(ins)

0.675

0.423

0.126

0.840

0.546

0.147

1.050

0.742

0.154

1.315

0.957

0.179

1.660

1.278

0.191

1.900

1.500

0.200

2.375

1.939

0.218

2.875

2.325

0.276

3.500

2.900

0.300

4.000

3.364

0.318

4.500

3.826

0.337

5.563

4.813

0.375

6.625

5.761

0.432

8.625

7.625

0.500

10.750 9.750

0.500

12.750 11.750 0.500

Fe-Al-Br

Brass (85% Cu, 15% Zn)

Diameter (ins) Thickness

Outside Inside

(ins)

0.675

0.494

0.092

0.840

0.625

0.108

1.050

0.822

0.114

1.315

1.062

0.127

1.660

1.368

0.146

1.900

1.600

0.150

2.375

2.062

0.157

2.875

2.500

0.188

3.500

3.062

0.219

4.000

3.500

0.250

4.500

4.000

0.250

5.563

5.062

0.251

6.625

6.125

0.250

8.625

8.000

0.313

10.750 10.019 0.363

12.750 12.000 0.375

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

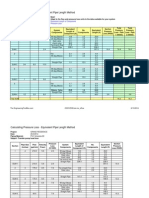

( f = 0.2083 x (100/C)^1.85 x Q^1.85/D^4.8635 )

PIPE DESIGN BASED ON HAZEN WILLIAMS FORMULA

Source: Cameron Hydraulic Data, 1926-62

Values of C

High (smooth, clean)

Average

Design (old)

Pipe Material

Low (old, corroded)

Copper, Brass, Tin, Lead, Glass

155 to 120

140

130

Cast Iron, Wrought Iron, Steel (seamless)

150 to 80

130

100

C= 155 represents new, clean smooth surfaces C = 80 represents old, corroded, rough surfaces

Sizing Criteria: 3 PD per 100 Pipe Length

Pipe Sizing Criteria for Cast Iron and Steel: Cameron Hydraulic Data,

Old 1926-62

Pipes: C =

Cast Iron

Steel : Sch-40 & Sch-80

Pipe

Size

Flow Velocity Loss Flow Velocity Loss

(ins) (gpm) (fps) PD/100' (gpm) (fps) PD/100'

0.50

1

1.1

2.1

0.75

2.5

1.5

2.9

1.00

5

1.9

3.2

1.25

10

2.2

3.1

1.50

14

2.2

2.7

2.00

28

2.7

2.9

2.50

45

3.0

2.9

3.00

75

3.5

2.9

80

3.5

3.0

3.50

110

3.7

2.8

120

4.0

3.1

4.00

160

4.1

2.9

170

4.3

3.2

5.00

280

4.6

2.8

300

4.8

3.0

6.00

450

5.1

2.8

500

5.6

3.2

8.00

1000 6.4

3.0

1000 6.4

3.0

10.00 1800 7.4

3.0

1800 7.3

3.0

12.00 3000 8.5

3.2

3000 8.5

3.2

Steel : XS

Flow Velocity Loss

(gpm) (fps) PD/100'

1

1.4

4.0

2

1.5

3.2

4

1.8

3.3

8

2.0

3.0

12

2.2

2.9

24

2.6

3.0

40

3.0

3.2

70

3.4

3.0

100

3.6

2.9

140

3.9

2.9

260

4.6

2.9

400

4.9

2.7

900

6.3

3.1

1700 7.3

3.0

2800 8.3

3.1

Pipe Sizing Criteria for Cast Iron and Steel: Cameron Hydraulic Data,

Old 1926-62

Pipes: C =

Pipe

Size

(ins)

0.50

0.75

1.00

1.25

1.50

2.00

2.50

3.00

3.50

4.00

5.00

6.00

8.00

Cast Iron

Steel : Sch-40 & Sch-80

Flow Velocity Loss Flow Velocity Loss

(gpm) (fps) PD/100' (gpm) (fps) PD/100'

1

1.5

2.9

1

1.4

2.5

3

2.2

4.1

3

2.0

3.2

6

2.5

3.6

6

2.3

3.1

10

2.6

3.1

10

2.5

2.9

15

2.8

2.7

2.7

2.6

2.6

30

3.2

2.6

30

3.1

2.5

60

4.1

3.3

60

4.0

3.1

90

4.3

3.0

90

4.2

2.8

140

5.0

3.2

140

4.9

2.9

190

5.2

3.0

190

5.1

2.8

350

6.2

3.2

350

6.0

3.0

550

6.8

3.1

550

6.6

2.8

1100 7.8

2.8

1200 8.2

3.0

Hazen-Williams Sizing

Haz-Will

Steel : XS

Flow Velocity Loss

(gpm) (fps) PD/100'

1

1.3

2.0

3

1.9

2.7

6

2.2

2.7

10

2.4

2.6

15

2.6

2.4

35

3.5

3.1

60

3.9

2.9

100

4.6

3.2

140

4.8

2.9

200

5.3

2.9

350

5.9

2.8

600

7.1

3.2

1200 8.1

2.9

100

Steel: XXS

Flow Velocity Loss

(gpm) (fps) PD/100'

2

4

6

12

20

40

60

90

160

280

700

2.3

2.0

2.0

2.2

2.7

3.1

3.3

3.7

4.0

4.8

6.0

11.7

4.7

3.6

2.9

3.3

3.3

3.1

3.2

2.8

3.1

3.2

130

Steel: XXS

Flow Velocity Loss

(gpm) (fps) PD/100'

1.5

1.6

2.7

3

1.8

2.6

6

2.2

2.6

12

2.6

2.7

20

3.2

3.3

35

3.4

2.7

60

3.9

2.9

100

4.4

2.8

150

5.0

3.1

200

5.1

2.7

400

6.4

3.1

650

7.1

3.0

1300 8.3

3.0

198962529.xls.ms_office

Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings + Merrill, LLP

IBM-AES Piping Software Ref-Data

Dynamic Pressure Losses through Fittings

EL = L/D* D (EL = Equivalent Length. L=Pipe Length, D = Pipe Diameter)

Velocity Pressure Factor (K) for Water : K = C*D**E: Pressure Drop (PD) = K*VP

FITTING IDENTIFICATION

ColRo

Description

w

A8

90 deg Elbow: Regular Screwed

L/D Factors

Name

K Factors

Water Glycol Brine Diesel Petrol Steam

Gas

Coeff C

Expon E

EL90-RG-SC

45

53

61

45

36

30

35

1.5

-0.6092

A9

90 deg Elbow: Long Radius Screwed EL90-LR-SC

25

29

34

25

20

15

20

0.75

-0.8787

A10

90 deg Elbow: Regular Flanged

EL90-RG-Fl

45

53

61

45

36

30

35

0.45

-0.253

A11

90 deg Elbow: Long Radius Flanged EL90-LR-FL

25

29

34

25

20

15

20

0.4

-0.463

A12

45 deg Elbow: Regular Screwed

EL45-RG-SC

25

29

34

25

20

20

25

0.35

-0.1365

A13

45 deg Elbow: Regular Flanged

El45-RG-FL

15

18

20

15

12

15

20

0.22

-0.1414

A14

Return U-Bend: Regular Screwed

BEND-RG-SC

90

105

123

90

72

70

75

1.35

-0.5

A15

Return U-Bend: Regular Flanged

BEND-RG-FL

90

105

123

90

72

70

75

0.425

-0.255

A16

Return U-Bend: Long Radius

BEND-LR-SC

50

59

68

50

40

45

45

0.426

-0.5182

A17

Tee: Line Flow Screwed

TEE-LF-SC

20

24

27

20

16

20

25

0.9

A18

Tee: Branch Flow Screwed

TEE-BF-SC

65

76

89

65

52

65

70

1.85

-0.3747

A19

Tee: Line Flow Flanged

TEE-LF-FL

20

24

27

20

16

20

25

0.265

-0.4695

A20

Tee: Branch Flow Flanged

TEE-BF-FL

65

76

89

65

52

65

70

-0.2851

A21

Strainer: Basket

STRAINER

90

105

123

90

72

70

75

2.4

-0.5609

A22

Union / Coupling

UNION

45

53

61

45

36

30

35

0.083

-0.6644

A23

Inlet: Bell-Mouthed

INLET-BM

20

24

27

20

16

20

25

0.05

A24

Inlet: Square-Edged

INLET-SE

45

53

61

45

36

30

35

0.5

A25

Outlet: All Types

OUTLET

65

76

89

65

52

65

70

Pipe Fittings Data

Fittings

198962529.xls.ms_office

Varkie

Skidmore, Owings + Merrill, LLP

C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

Dynamic Pressure Losses through Valves

EL = L/D* D (EL = Equivalent Length. L=Pipe Length, D = Pipe Diameter)

Velocity Pressure Factor (K) for Water : K = C*D**E: Pressure Drop (PD) = K*VP

ColRo

w

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A28

A29

A30

FITTING IDENTIFICATION

Name

Description

Angle : Screwed

Angle : Flanged

Balancing

Ball

Butterfly

Check Swing : Screwed

Check Swing : Flanged

Gate : Screwed

Gate : Flanged

Gate : Electric Motor

Gate : Pneumatic Motor

Globe : Screwed

Globe : Flanged

Globe : Electric Motor

Globe : Pneumatic Motor

Lock Shield

Plug Cock

Pressure Reducing

Quick Open

Pressure Regulator

Relief / Safety

Solenoid

Foot Valve

Valve Fittings Data

Water

ANGLE-SC

175

ANGLE-FL

175

BALANCING 350

BALL

10

BUTTERFLY 50

CHECK-SC

150

CHECK-FL

150

GATE-SC

10

GATE-FL

10

GATE-EM

10

GATE-PM

10

GLOBE-SC

350

GLOBE-FL

350

GLOBE-EM

350

GLOBE-PM

350

LOCK-SHIELD 10

PLUG-COCK 150

PRV

10

QUICKOPEN 350

PR-REG

10

RELIEF

0

SOLENOID

350

FOOT

50

L/D Factors

Glycol

205

205

410

12

59

176

176

12

12

12

12

410

410

410

410

12

176

12

410

12

0

410

59

Valves

Brine

238

238

477

14

68

204

204

14

14

14

14

477

477

477

477

14

204

14

477

14

0

477

68

Diesel

175

175

350

10

50

150

150

10

10

10

10

350

350

350

350

10

150

10

350

10

0

350

50

GasolineSteam

140

150

140

150

280

30

8

10

40

0

120

75

120

75

8

10

8

10

8

10

8

10

280

300

280

300

280

300

280

300

8

10

120

130

8

10

280

300

8

10

0

0

280

300

40

0

Gas

200

200

350

10

0

100

100

10

10

10

10

350

350

350

350

10

150

10

350

10

0

350

0

K Factors

Coeff C Expon E

4.5

4.5

4.25

4.25

12.5

12.5

0.24

0.24

12.5

12.5

3.5

3.5

2

2

0.24

0.24

1

1

0.24

0.24

0.24

0.24

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

0.24

0.24

12.5

12.5

0.24

0.24

12.5

12.5

0.24

0.24

0

0

12.5

12.5

0.8

0.8

198962529.xls.ms_office

Skidmore, Owings Merrill

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

PROPERTIES OF LIQUIDS

Liquid

Water

Glycol

Brine

Diesel

Petrol

Properties

-30

Density (lb/cu ft)

Specific Gravity ( = Density / 62.4 )

Kinematic viscosity (sq ft/sec)

Specific heat (Btu/lb oF)

Density (lb/cu ft)

67.98

Specific Gravity ( = Density / 62.4 )

1.09

Kinematic viscosity (sq ft/sec)

595.00

Specific heat (Btu/lb oF)

0.70

Density (lb/cu ft)

78.59

Specific Gravity ( = Density / 62.4 )

1.26

Kinematic viscosity (sq ft/sec)

171.70

Specific heat (Btu/lb oF)

0.66

Density (lb/cu ft)

59.20

Specific Gravity ( = Density / 62.4 )

0.95

Kinematic viscosity (sq ft/sec)

376.70

Specific heat (Btu/lb oF)

0.47

Density (lb/cu ft)

46.10

Specific Gravity ( = Density / 62.4 )

0.74

Kinematic viscosity (sq ft/sec)

11.00

Specific heat (Btu/lb oF)

0.47

30

67.55

1.08

190.00

0.73

78.21

1.25

77.50

0.67

57.40

0.92

161.50

0.48

45.50

0.73

9.80

0.48

Temperature

60

100

150

210

62.42

62.37

62.00

61.20

59.81

1.00

1.00

0.99

0.98

0.96

0.00

12.17

7.39

4.76

3.20

1.00

1.00

1.00

1.00

1.01

67.11

66.55

65.74

64.68

63.12

1.08

1.07

1.05

1.04

1.01

85.40

48.60

22.60

12.50

6.40

0.76

0.78

0.81

0.85

0.88

77.71

77.21

76.09

1.25

1.24

1.22

34.70

21.80

8.90

0.68

0.69

0.71

56.10

54.90

53.00

51.10

0.90

0.88

0.85

0.82

80.70

48.30

29.10

7.50

0.49

0.50

0.51

0.52

44.90

44.70

44.30

42.40

0.72

0.72

0.71

0.68

8.80

7.00

5.50

3.00

0.49

0.50

0.51

0.52

PROPERTIES OF HIGH TEMPERATURE HOT WATER

Increase in Frictional Pressure Loss due to Pipe Age

Hydraulic Handbook by Colt Industries

Multipliers

Temp

Satur.

Density Specific

Kinem Sp. Heat

deg F

Press

lb/cu ft Gravity = Viscos Btu/lb oF

Pipe Age

Small

Medium

Large

psig

Years

1 - 3 4 to 12 14 - 48

Density/62.4 sq ft/sec

212

0

59.81

3.2

1.0055

0

1

1

1

0.96

220

2.5

59.63

3

1.0068

5

1.4

1.35

1.3

0.96

240

10.3

59.1

2.7

1.0104

10

2.2

1.9

1.6

0.95

260

20.7

58.51

2.5

1.0148

15

3.6

2.7

1.8

0.94

280

34.5

57.94

2.3

1.02

20

5

3.5

2

0.93

300

52.3

57.31

2.1

1.26

25

6.3

4.2

2.1

0.92

350

119.9

55.59

1.9

1.044

30

7.25

4.73

2.2

0.89

400

232.6

53.65

1.7

1.067

35

8.1

5.2

2.3

0.86

0.83

450

407.9

51.55

1.5

1.095

40

8.75

5.58

2.4

45

9.25

5.93

2.6

50

9.6

6.23

2.86

STANDARD MOTOR SIZES

60

10

7

3

1

50

Fluid Properties

2

60

3

75

5

100

7.5

125

10

150

Fluids

15

200

20

250

25

300

30

400

40

500

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

STEAM PRESSURE CLASSIFICATION AND PIPE SIZING DESIGN CRITERIA

Pressure Classifications

Vacuum: Less than 0 psig

Low: 0 to 15 psig

Medium: 15 to 30 psig

High: 30 to 150 psig

High: 150 to 250 psig

Pressure

Initial Steam

Sizing Criteria

Maxim System

Maxim Veloc

Class

Press (psig)

(psi/100ft)

PD (psig)

(ft/min)

Low

Low

Medium

High

High

High

3.5

12

30

50

100

150

0.25

0.5

0.75

1

2

2

1

3.5

7.5

10

20

25

4,000

4,000

6,000

8,000

10,000

10,000

LOW PRESSURE STEAM PIPE SIZING CRITERIA : Flow Rates of Steam (lbs/hr)

Initial Steam Saturation Pressure = 3.5 psig

Initial Steam Saturation Pressure = 12 psig

Sizing Criteria: PD (psi) per 100 feet of Pipe

Sizing Criteria: PD (psi) per 100 feet of Pipe

Pipe

1/16

1/8

1/4

1/2

3/4

1/16

1/8

1/4

1/2

3/4

Size

0.063

0.125

0.25

0.5

0.75

1.0

2.0

0.063

0.125

0.25

0.5

0.75

1.0

2.0

0.75

14

20

29

36

42

60

11

16

24

35

43

50

73

1.0

17

26

37

54

68

81

114

21

31

46

66

82

95

137

1.25

36

53

78

111

140

162

232

45

66

96

138

170

200

280

1.5

56

84

120

174

218

246

360

70

100

147

210

260

304

430

2.0

108

162

234

336

420

480

710

134

194

285

410

510

590

850

2.5

174

258

378

540

680

780

1150

215

310

460

660

820

950

1370

3.0

318

465

660

960

1190

1380

1950

380

550

810

1160

1430

1670

2400

3.5

462

670

990

1410

1740

2000

2950

550

800

1218

1700

2100

2420

3450

4.0

640

950

1410

1980

2450

2880

4200

800

1160

1690

2400

3000

3460

4900

5.0

1200

1680

2440

3570

4380

5100

7500

1430

2100

3000

4250

5250

6100

8600

6.0

1920

2820

3960

5700

7000

8400

11,900

2300

3350

4850

5700

8600

10,000

14,200

8.0

3900

5570

8100

11,400

14,500

16,500

24,000

4800

7000

10,000

14,300

17,700

20,500

29,500

10.0

7200

10,200

15,000

21,000

26,200

30,000

42,700

8800

12,600

18,200

26,000

32,000

37,000

52,000

12.0

11,400

16,500

23,400

33,000

41,000

48,000

67,800

13,700

19,500

28,400

40,000

49,500

57,500

81,000

10

12

Steam and Condensate

Steam-Condns

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

MEDIUM PRESSURE STEAM PIPE SIZING CRITERIA : Flow Rates of Steam (lbs/hr)

Initial Steam Saturation Pressure = 30 psig

Initial Steam Saturation Pressure = 60 psig

Sizing Criteria: PD (psi) per 100 feet of Pipe

Sizing Criteria: PD (psi) per 100 feet of Pipe

Pipe

1/8

1/4

1/2

3/4

Pipe

1/8

1/4

1/2

3/4

Size

0.125

0.25

0.5

0.75

1.0

2.0

Size

0.125

0.25

0.5

0.75

1.0

2.0

0.50

0.75

10

14

17

19

28

12

17

21

25

35

22

32

39

45

64

0.50

0.75

16

20

28

40

49

57

81

1.00

32

45

64

79

91

129

1.00

40

57

81

100

115

163

1.25

70

99

142

174

202

283

1.25

89

127

179

219

253

358

1.50

110

156

220

270

312

440

1.50

139

197

279

342

395

558

2.00

223

316

446

546

630

892

2.00

282

282

565

691

800

1,130

2.50

368

520

735

900

1,040

1,472

2.50

465

660

930

1,140

1,318

1,860

3.00

675

953

1,340

1,652

1,905

2,690

3.00

853

1,205

1,690

2,090

2,410

3,410

3.50

990

1,405

2,010

2,470

2,850

4,020

3.50

1,275

1,800

2,550

3,120

3,605

5,090

4.00

1,420

2,020

2,850

3,490

4,025

5,700

4.00

1,800

2,550

3,610

4,462

5,100

7,220

5.00

2,625

3,720

5,260

6,450

7,450

10,550

5.00

3,320

4,710

6,660

8,150

9,440

13,300

6.00

4,315

6,100

8,650

10,600

12,200

17,300

6.00

5,475

7,725

11

13,420

15,450

21,900

8.00

9,000

12,700

18,000

22,000

25,420

36,000

8.00

11,360

16,100

22,800

27,900

32,200

45,550

10.00

16,400

23,200

33,300

40,250

46,500

65,750

10.00

20,800

29,400

41,500

51,000

58,900

83,250

105,500

12.00

33,300

47,100

66,700

81,750

94,500

133,200

12.00

26,350

37,250

52,500

64,500

74,500

HIGH PRESSURE STEAM PIPE SIZING CRITERIA : Flow Rates of Steam (lbs/hr)

Initial Steam Saturation Pressure = 30 psig

Initial Steam Saturation Pressure = 60 psig

Sizing Criteria: PD (psi) per 100 feet of Pipe

Sizing Criteria: PD (psi) per 100 feet of Pipe

Pipe

1/2

3/4

Pipe

1/2

3/4

Size

0.5

0.75

1.0

2.0

5.0

Size

0.5

0.75

1.0

2.0

5.0

0.50

21

26

30

43

68

0.50

23

29

33

47

75

0.75

50

61

70

99

160

0.75

54

66

77

109

172

1.00

100

120

140

200

320

1.00

109

134

155

220

347

1.25

220

270

310

440

690

1.25

241

296

341

483

764

1.50

340

420

480

680

1,080

1.50

375

460

532

751

1,185

2.00

690

850

980

1,390

2,190

2.00

760

930

1,075

1,520

2,410

2.50

1,140

1,400

1,620

2,280

3,610

2.50

1,250

1,535

1,775

2,550

3,960

3.00

2,090

2,560

2,960

4,180

6,610

3.00

2,280

2,815

3,245

4,590

7,260

3.50

3,120

3,830

4,420

6,250

9,870

3.50

3,430

4,200

4,850

6,850

10,880

4.00

4,420

5,420

6,260

8,840

13,960

4.00

4,840

5,930

6,850

9,700

15,350

5.00

8,170

10,020

11,580

16,350

25,840

5.00

8,950

11,000

12,700

17,950

28,400

6.00

13,420

16,450

19,020

26,840

42,410

6.00

14,710

18,070

20,800

29,500

46,500

8.00

27,930

34,250

39,580

55,870

88,280

8.00

30,650

37,550

43,400

61,400

97,100

10.00

50,970

62,500

72,230

101,900

161,100

10.00

56,000

68,500

79,100

112,000

177,000

12.00

81,810

100,300

115,900

163,600

258,500

12.00

89,900

110,200

127,100

179,600

284,100

Pipe Slope (in. / 10 ft)

Pressure Drop (psi / 100 ft)

Steam and Condensate

Steam-Condns

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

Pressure Drop (psi/100) sizing criteria for open gravity (sloped pipe) condensate return

CONDENSATE FLOW RATE (lbs/hr)

Condensate Return Pressure = 0 psig

Supply Steam at 5 psig

Pipe

Size

Supply Steam at 15 psig

PD (psi per 100 feet)

Pipe

1/16

1/4

0.063

0.25

1.0

Size

Supply Steam at 30 psig

PD (psi per 100 feet)

Pipe

1/16

1/4

0.063

0.25

1.0

Size

PD (psi per 100 feet)

1/16

1/4

0.063

0.25

1.0

0.5

240

520

1100

0.5

95

210

450

0.5

60

130

274

0.75

510

1120

2400

0.75

210

450

950

0.75

130

280

590

1.0

1000

2150

4540

1.0

400

860

1820

1.0

250

530

1120

1.25

2100

4500

9500

1.25

840

1800

3800

1.25

520

1110

2350

1.5

3170

6780

14,200

1.5

1270

2720

5700

1.5

780

1670

3510

2.0

6240

13,300

2.0

2500

5320

2.0

1540

3270

2.5

10,000

21,300

2.5

4030

8520

2.5

2480

5250

3.0

18,000

28,000

3.0

7200

15,200

3.0

4440

9360

4.0

37,200

78,000

4.0

14,900

31,300

4.0

9180

19,200

6.0

110,500

6.0

44,300

6.0

27,300

8.0

228,600

8.0

91,700

8.0

56,400

Supply Steam at 50 psig

Pipe

Size

0.5

Supply Steam at 100 psig

PD (psi per 100 feet)

Pipe

1/16

1/4

0.063

0.25

1.0

Size

42

92

200

0.5

0.75

91

200

420

1.0

180

380

800

1.25

370

800

1.5

560

1200

2.0

1110

2.5

1780

3.0

4.0

Supply Steam at 150 psig

PD (psi per 100 feet)

Pipe

1/16

1/4

0.063

0.25

1.0

Size

28

62

133

0.5

0.75

62

134

290

1.0

120

260

544

1680

1.25

250

540

2520

1.5

380

810

2350

2.0

750

3780

2.5

1200

3190

6730

3.0

6660

13,800

4.0

6.0

19,600

8.0

40,500

Size

0.063

0.25

1.0

0.5

56

120

0.75

120

1.0

240

0.063

0.25

1.0

109

0.75

50

110

230

1.0

100

210

450

1130

1.25

200

440

930

1700

1.5

310

660

1400

1590

2.0

610

1300

2550

2.5

980

2100

2160

4550

3.0

1760

3710

4460

9340

4.0

3640

7630

6.0

13,200

6.0

10,800

8.0

27,400

8.0

22,400

Size

260

0.5

260

560

500

1060

PD (psi per 100 feet)

1/16

1/4

0.063

0.25

1.0

43

93

200

0.75

93

200

420

1.0

180

390

800

1.5

750

1600

3,320

1.5

570

1210

2500

2.0

1470

3,100

6450

2.0

1120

2350

4900

2.5

2,370

5,000

10,300

2.5

1800

3780

7800

3.0

4,230

8,860

3.0

3200

6,710

4.0

8,730

18,200

4.0

6,620

13,800

6.0

25,900

53,600

6.0

19,600

40,600

8.0

3,400

110,300

8.0

40,500

83,600

Steam and Condensate

51

Pipe

1/4

1/4

Supply Steam at 150 psig

PD (psi per 100 feet)

1/16

1/16

23

Supply Steam at 100 psig

Pipe

PD (psi per 100 feet)

Steam-Condns

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

PROPERTIES OF STEAM

Press

Temp

Volume

Enthalpy btu/lb

Press

Temp

Volume

psig

deg F

cuft

Liquid

Latent

psig

deg F

cuft

Liquid

Latent

Steam and Condensate

Enthalpy btu/lb

212

26.8

180.1

970.3

65

311.8

5.49

281.8

901.3

215.5

25.13

183.6

968.1

70

316.4

5.18

286.2

898

218.7

23.72

186.8

966

75

320.1

4.91

290.4

894.8

221.7

22.47

189.8

964.1

80

323.9

4.66

294.4

891.9

224.5

21.35

192.7

962.3

85

327.6

4.44

298.2

899

227.3

20.34

195.5

960.5

90

331.2

4.24

301.9

886.1

229.9

19.42

198.2

958.8

95

334.6

4.06

305.5

883.3

232.4

18.58

200.7

957.2

100

337.9

3.89

308.9

880.7

234.9

17.81

203.2

955.6

105

341.1

3.74

312.3

878.1

237.2

17.11

205.6

954.1

110

344.2

3.59

315.5

875.5

10

239.5

16.46

207.9

952.5

115

347.2

3.46

318.7

873

11

241.7

15.86

210.1

951.1

120

350.1

3.34

321.7

870.7

12

243.8

15.31

212.2

949.7

125

352.9

3.23

324.7

868.3

13

245.9

14.79

214.3

948.3

130

355.6

3.12

327.6

865.9

14

247.9

14.31

216.4

946.9

135

358.3

3.02

330.4

863.7

15

249.8

13.86

218.3

945.6

140

360.9

2.93

333.1

861.5

16

251.7

13.43

220.3

944.3

145

363.4

2.84

335.8

859.3

17

253.6

13.03

222.2

943

150

365.9

2.76

338.4

857.2

18

255.4

12.66

224

941.8

155

368.3

2.68

340.9

855

19

257.1

12.31

225.7

940.6

160

370.6

2.61

343.4

853

20

258.8

11.98

227.5

939.5

165

372.9

2.54

345.9

850.9

21

260.5

11.67

229.2

938.3

170

375.2

2.47

348.3

848.9

22

262.2

11.37

230.9

937.2

175

377.4

2.41

350.7

846.9

23

263.8

11.08

232.5

936.1

180

379.5

2.35

353

845

24

265.4

10.82

234.1

935

185

381.6

2.3

355.2

843.1

25

266.9

10.56

235.6

934

190

383.7

2.24

357.4

841.2

30

274.1

9.45

243

928.9

195

385.8

2.19

359.6

839.2

35

280.7

8.56

249.8

924.2

200

387.8

2.13

361.9

837.4

40

286.8

7.83

256

919.8

210

391.7

2.04

366

833.8

45

292.4

7.2

261.8

915.7

220

395.5

1.95

370.1

830.3

50

297.7

6.68

267.2

911.8

230

399.1

1.88

374.1

826.8

55

302.7

6.23

272.4

908.1

240

402.7

1.81

377.8

823.4

60

307.3

5.83

277.2

904.6

250

406.1

1.74

381.6

820.1

Steam-Condns

198962529.xls.ms_office

Skidmore, Owings Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

Example:

6800 lbs per hour of steam flow in a 2 inch pipe at 100 psig pressure.

What is the pressure (psi) drop per 100 ft length of pipe and the flow velocity

Answer: psi/100 = 11 velocity = 32,000 fpm

Figure - 17

ASHRAE

Steam Flow Rates at Various Pressures and Velocities for Schedule 40 Pipe

Steam Pipe Sizing Charts

Steam-Charts

198962529.xls.ms_office

Sou

Skidmore, Owings Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

ure.

f pipe and the flow velocity?

fpm

dule 40 Pipe

Source:

Steam Pipe Sizing Charts

Steam-Charts

198962529.xls.ms_office

Skidmore, Owings Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

Figure 18

Steam flow at 30 psig

Source: ASHRAE

Design Criteria:

0.75 psi per 100 ft pipe

Max Vel = 6,000 fpm

Figure 19

Steam flow at 50 psig

Source: ASHRAE

Design Criteria:

1.0 psi per 100 ft pipe

Max Vel = 8,000 fpm

Steam Pipe Sizing Charts

Steam-Charts

198962529.xls.ms_office

Skidmore, Owings Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

Figure 20

Steam flow at 100 psig

Source: ASHRAE

Design Criteria:

2.0 psi per 100 ft pipe

Max Vel = 10,000 fpm

Figure 21

Steam flow at 150 psig

Source: ASHRAE

Design Criteria:

2.0 psi per 100 ft pipe

Max Vel = 10,000 fpm

Steam Pipe Sizing Charts

Steam-Charts

198962529.xls.ms_office

Skidmore, Owings Merrill LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

Natural Gas Pipe Sizing Tables and Charts

Steel Pipe - Schedule 40

Downstream

Pressure

DPipe Dimension (in)

Press

(psig)

1/2"

3/4"

1 1/4

1 1/2

2 1/2

9.5

355

745

1,400

2,880

4,310

8,305

515

1,080

2,030

4,160

6,240

12,020 19,150 33,860 69,060 124,940

8.5

350

730

1,370

2,815

4,210

8,120

8.1

475

995

1,875

3,850

5,770

11,100 17,700 31,300 63,840 115,500

7.6

300

630

1,190

2,440

3,650

7,040

7.2

440

910

1,720

3,530

5,290

10,190 16,240 28,710 58,560 105,940

6.6

290

615

1,160

2,380

3,565

6,865

10,940 19,345 39,460 71,390

6.3

395

830

1,560

3,210

4,810

9,260

14,760 26,090 53,210 96,260

5.7

245

515

970

1,990

2,990

5,730

9,140

5.4

355

745

1,400

2,880

4,310

8,310

13,245 23,415 47,760 86,400

4.7

240

500

940

1,935

2,900

5,580

8,895

4.5

315

660

1,240

2,540

3,810

7,340

11,695 20,680 42,170 76,300

13,240 23,400 47,730 86,350

12,940 22,880 46,600 84,420

11,215 19,830 40,440 76,170

inlet upstream pressure is more than 5 psig (35 kPa)

fittings factor 1.2 - equivalent pipe length = pipe length + 20%

16,160 32,950 59,620

15,730 32,080 58,030

For natural gas the nominal BTU/cf varies from about 900 to 1100 BTU/cf. In general it is common to set

1 Cubic Foot (CF) = Approx 1,000 BTUs

1 CFH 1 MBH

1 Btu/h = 0.293 W

LP Natural Gas

Natural-Gas

198962529.xls.ms_office

Skidmore, Owings Merrill LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

Steel Pipe - Schedule 40

Capacity of Pipe (MBH CFH)

Pipe SizeInside

(in)

Nomin

al

dia

Pipe Length (ft)

10

20

40

80

150

300

1/2"

0.622

120

85

60

42

31

22

3/4"

0.824

272

192

136

96

70

50

1.049

547

387

273

193

141

100

1 1/4

1.38

1,200

849

600

424

310

219

1 1/2

1.61

1,860

1,316

930

658

480

340

2.067

3,759

2,658

1,880

1,330

971

686

2 1/2

2.469

6,169

4,362

3,084

2,189

1,593

1,126

3.068

11,225

7,938

5,613

3,969

2,898

2,049

4.026

23,479 16,602 11,740

8,301

6,062

4,287

5.047

42,945 30,367 21,473 15,183 11,088

7,841

6.065

69,671 49,265 34,836 24,632 17,989 12,720

7.981 141,832 100,290 70,916 50,145 36,621 25,895

pressure less than 1 1/2 psig

pressure drop 0.5 inches water column

specific gravity of natural gas 0.6 energy content in natural gas 1000 Btu/lb

1 Cubic Foot (CF) = Approx 1,000 BTUs

common to use fittings factor 1.5 - equivalent pipe length

1 CFH = 1 MBH

in table above = pipe length + 50%

For natural gas the nominal BTU/cf varies from about

900 to 1100 BTU/cf. In general it is common to set

LP Natural Gas

Natural-Gas

198962529.xls.ms_office

Skidmore, Owings Merrill LLP

Varkie C. Thomas, Ph.D., P.E.

Copper Tubing - type K

IBM-AES Piping Software Ref-Data

Copper Tubing - type L

Capacity of Pipe (MBH CFH)

Capacity of Pipe (MBH CFH)

Size (in)Inside

NominPipe

Outsid

al

Dia

Dia

Pipe Length (ft)

PipeOutsid

Size (in)Inside

Nomina

l

Dia

Dia

10

20

40

80

1/4"

3/8"

0.305

15

10

1/4"

3/8"

3/8"

1/2"

0.402

33

24

17

12

3/8"

1/2"

5/8"

0.527

74

52

37

26

5/8"

3/4"

0.652

138

97

69

3/4"

7/8"

0.745

203

143

1 1/8

0.995

469

1 1/4

1 3/8

1.245

894

Pipe Length (ft)

10

20

40

80

0.315

16

11

1/2"

0.43

41

29

20

14

1/2"

5/8"

0.545

81

58

41

29

49

5/8"

3/4"

0.666

146

103

73

52

101

72

3/4"

7/8"

0.785

236

167

118

84

332

235

166

1 1/8

1.025

511

362

256

181

632

447

316

1 1/4

1 3/8

1.265

936

662

468

331

pressure less than 1 1/2 psig

common to use fittings factor 1.5 - equivalent pipe length

in table above = pipe length + 50%

pressure less than 1 1/2 psig

common to use fittings factor 1.5 - equivalent pipe length

in table above = pipe length + 50%

pressure drop 0.5 inches water column

pressure drop 0.5 inches water column

specific gravity of natural gas 0.6

specific gravity of natural gas 0.6

energy content in natural gas 1000 Btu/lb

energy content in natural gas 1000 Btu/lb

One MBH is equivalent to 1000 BTU's per hour

One MBH is equivalent to 1000 BTU's per hour

LP Natural Gas

1 Btu/h = 0.293 W

1 lb = 0.4536 kg

1 ft (foot) = 0.3048 m

1 in water = 248.8 N/m 2 (Pa) = 0.0361 lb/in 2 (psi) = 25.4 kg/m 2 = 0.0739 in mercury

1 psi (lb/in 2 ) = 6,894.8 Pa (N/m 2 )

Natural-Gas

198962529.xls.ms_office

Skidmore, Owings Merrill LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

The capacity of a low pressure natural gas (less than 1 psi) pipe line can be calculated with the Spitzglass formula like

q = 3550 k ( h / l SG) 1/2

(1)

where

q = natural gas flow capacity (cfh)

h = pressure drop (in Water Column)

l = length of pipe (ft)

k = [d 5 /(1 + 3.6/d + 0.03 d)] 1/2

d = inside diameter pipe (in)

SG = specific gravity

For natural gas the nominal BTU/cf varies from about 900 to 1100 BTU/cf . In general it is common to set

1 Cubic Foot (CF) = approx 1,000 BTUs

1 CFH = 1 MBH

The specific gravity of natural gas varies from 0.55 to 1.0 .

The downstream pressure in a houseline after the meter/regulator is in general in the

range of 7 to 11 inches Water Column, or about 1/4 psi.

Example - Natural Gas Pipe Capacity

The capacity of a 100 ft natural gas pipe with a nominal diameter 0.5 inches (actual ID 0.622 in )

and 0.5 inches WC pressure drop can be calculated as

=

k = [(0.622 in )5 /(1 + 3.6 / (0.622 in) + 0.03 (0.622 in))] 1/2

0.117

q = 3550 0.117 ( (0.5 in) / (100 ft) 0.60 ) 1/2 = 37.9 cfh

Specific gravity of natural gas is set to 0.60 .

LP Natural Gas

Natural-Gas

198962529.xls.ms_office

Skidmore, Owings Merrill LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

= 0.0739 in mercury

LP Natural Gas

Natural-Gas

198962529.xls.ms_office

Skidmore, Owings + Merrill

Varkie C. Thomas, Ph.D., P.E

Fixture Data : Domestic Hot and Cold Water

Fixture Type

Supply Minim Fixture

/ Description

Code

PSIG

GPM

Bathroom Group TANK

8

0

Bathroom Group VALVE 8

0

Water Closet

TANK

8

0

Water Closet

VALVE 15

0

Urinal

TANK

8

0

Urinal

VALVE 8

0

Shower Head

TANK

8

3

Bathtub

TANK

8

4

Lavatory

TANK

8

2

Service Sink

TANK

8

3

Kitchen Sink

TANK

8

3

Restaurant Sink

TANK

8

3

Drinking Fountain TANK

8

2

Dish Washer

TANK

8

3

Clothes Washer

TANK

8

4

Private Use : Fixture Units

Cold

Hot

Total

4.5

3

6

6

3

8

3

0

3

6

0

6

3

0

3

4

0

4

2

2

3

7.5

7.5

10

1

1

1.5

2

2

3

2

2

3

3

3

4

1

0

1

2

2

3

2

2

3

Conversion Table : Fixture Units to GPM

Fixture Units

Fixture Units

Flow

Flow

GPM

Tank

Valve

GPM

Tank

Valve

1

0

34

63

18

2

1

35

66

20

3

3

36

69

21

4

4

37

74

23

5

6

38

78

25

6

7

39

83

26

7

8

40

86

28

8

10

41

90

30

9

12

42

95

31

10

13

43

99

33

11

15

44

103

35

12

16

45

107

37

13

18

46

111

39

14

20

47

115

42

15

21

48

119

44

16

23

49

123

46

17

24

50

127

48

18

26

51

130

50

19

28

52

135

52

20

30

53

141

54

21

32

54

146

57

22

34

5

55

151

60

23

36

6

56

155

63

24

39

7

57

160

66

25

42

8

58

165

69

26

44

9

59

170

73

27

46

10

60

175

76

28

49

11

62

185

82

29

51

12

64

195

88

30

54

13

66

205

95

31

56

14

68

215

102

32

58

15

70

225

108

33

60

16

72

236

116

Plumbing Fixture Units

IBM-AES Piping Software Ref-Data

Public Use : Fixture Units

Cold

Hot

Total

4.5

3

6

4.5

3

6

5

0

5

10

0

10

3

0

3

5

0

5

4

4

5

7.5

7.5

10

2

2

3

4

4

5

4

4

5

3

3

4

2

0

2

3

3

4

3

3

4

(from ASPE Data Book)

Fixture Units

Flow

Gpm

Tank

Valve

74

245

124

76

254

132

78

264

140

80

275

148

82

284

158

84

294

168

86

305

176

88

315

186

90

326

195

92

337

205

94

348

214

96

359

223

98

370

234

100

380

245

105

406

270

110

431

295

115

455

329

120

479

365

125

506

396

130

533

430

135

559

460

140

585

490

145

611

521

150

638

559

155

665

596

160

692

631

165

719

666

170

748

700

175

778

739

180

809

775

185

840

811

190

874

850

200

945

931

FixtUnits

Flow

GPM

210

220

230

240

250

260

270

280

290

300

310

320

330

340

350

360

370

380

390

400

410

420

430

440

450

500

550

600

700

800

900

1000

Minim Conn. Size

Cold

Hot

0.50

0.50

1.00

0.50

0.38

0.00

1.00

0.00

0.38

0.00

1.00

0.00

0.50

0.50

0.50

0.50

0.38

0.38

0.50

0.75

0.50

0.50

0.50

0.50

0.38

0.00

0.38

0.38

0.50

0.50

Fixture Units

Tank

Valve

1018

1009

1091

1091

1173

1173

1254

1254

1335

1335

1418

1418

1500

1500

1583

1583

1668

1668

1755

1755

1845

1845

1926

1926

2018

2018

2110

2110

2204

2204

2298

2298

2388

2388

2480

2480

2575

2575

2670

2670

2765

2765

2862

2862

2960

2960

3060

3060

3150

3150

3620

3620

4070

4070

4480

4480

5380

5380

6280

6280

7280

7280

8300

8300

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

Horizontal Fixture Branches and Stacks

Pipe

IBM-AES Piping Software Ref-Data

Building Drains and Sewers

Any Horiz One Stack More than 3 Br Intervals

Diam

Fixture

3 Br Interv Total for Total at One

(ins)

Branch

or Less

Stack

Br. Interval

1.5

2.0

10

24

2.5

12

20

42

3.0

20

48

4.0

160

5.0

Pipe

Max Fixture Units that may be Connected

Diam

Slope per Foot

1/4 inch

1/2 inch

2.0

21

26

2.5

24

31

72

20

3.0

42

50

240

500

90

4.0

180

216

250

360

540

1100

200

5.0

390

480

575

6.0

620

960

1900

350

6.0

700

840

1000

8.0

1400

2200

3600

600

8.0

1400

1600

1920

2300

10.0

2500

3800

5600

1000

10.0

2500

2900

3500

4200

12.0

3900

6000

8400

1500

12.0

2900

4600

5600

6700

15.0

7000

15.0

7000

8300

10000

12000

Plumbing Sanitary Drainage

Sanitary

(ins)

1/16 inch

1/8 inch

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

Horizontal Vent Sizing Table (BOCA National Plumbing Code)

Horizontal Branch

Diam

Slope

Diameter of Vent (inches)

1.25

1.5

10

12

Maximum Developed Length of Vent (feet)

(in/ft)

1.25

2.5

0.125

0.25

0.50

1.5

0.125

0.25

0.50

2.5

10

12

15

0.125

0.25

290

0.50

150

380

0.125

180

450

0.25

96

240

0.50

49

130

0.125

190

0.25

97

420

0.50

50

220

0.125

190

0.25

98

310

0.50

48

160

410

0.125

190

490

0.25

97

250

0.50

46

130

0.125

190

0.25

97

250

0.50

46

130

0.125

190

0.25

91

310

0.50

38

150

410

0.125

190

500

0.25

85

240

0.50

32

110

0.125

180

0.25

79

420

0.50

26

200

0.125

0.25

0.50

Plumbing Sanitary Vents

Vents

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

Vertical Vent Sizing Table

(BOCA National Plumbing Code)

Diameter of Vent (inches)

Stack

Total

Diam

FUs to

(ins)

Stack

1.25

30

1.5

50

150

10

30

100

12

30

75

200

20

26

50

150

IBM-AES Piping Software Ref-Data

1.25

1.5

2.5

10

12

Maximum Developed Length of Vent (feet)

2.5

42

30

100

300

10

42

150

360

1040

21

32

110

270

810

53

27

94

230

680

102

25

86

210

620

43

35

85

250

980

140

27

65

200

750

320

23

55

170

640

540

21

50

150

580

190

28

82

320

990

490

21

63

250

760

940

18

53

210

670

1400

16

49

190

590

500

33

130

400

1000

1100

26

100

310

780

2000

22

84

260

660

2900

20

77

240

600

1800

31

95

240

940

3400

24

73

190

720

5600

20

62

160

610

7600

18

56

140

560

4000

31

78

310

960

7200

24

60

240

740

11000

20

51

200

630

15000

18

46

180

570

7300

31

120

380

940

13000

24

94

300

720

20000

20

79

250

610

26000

18

72

230

500

15000

40

130

310

25000

31

96

240

38000

26

81

200

50000

24

74

180

10

12

15

Plumbing Sanitary Vents

Vents

198962529.xls.ms_office

Skidmore, Owings + Merrill, LLP

Varkie C. Thomas, Ph.D., P.E.

IBM-AES Piping Software Ref-Data

ROOF DRAIN AND LEADER SIZING

Rain

(in./hr.)

1

2

3

4

5

6

7

8

9

10

11

12

2

2880

1440

960

720

575

480

410

360

320

290

260

240

Size of Drain or Leader Diameter (in.)

3

4

5

6

8

8800

18400 34600 54000 ######

4400

9200

17300 27000 58000

2930

6130

11530 17995 38660

2200

4600

8650

13500 29000

1760

3680

6920

10800 23200

1470

3070

5765

9000

19315

1260

2630

4945

7715

16570

1100

2300

4325

6750

14500

980

2045

3845

6000

12890

880

1840

3460

5400

11600

800

1675

3145

4910

10545

730

1530

2880

4500

9660

HORIZONTAL RAINWATER PIPE SIZING

1/8 Slope

Maximum Rainfall (in./hr)

Pipe

Size

2

3

4

5

3

1644

1096

822

657

4

3760

2506

1880

1504

5

6680

4453

3340

2672

6

10700 7133

5350

4280

8

23000 15330 11500 9200

10

41400 27600 20700 16580

12

66600 44400 33300 26650

15

###### 72800 59500 47600

6

548

1253

2227

3566

7600

13800

22200

39650

HORIZONTAL RAINWATER PIPE SIZING

1/2 Slope

Maximum Rainfall (in./hr)

Pipe

Size

2

3

4